Miljø- og Fødevareudvalget 2023-24

MOF Alm.del

Offentligt

Life Cycle Assessment of Packaging

Materials in relation to Extended

Producer Responsibility

Report for the Danish Environmental Protection Agency

Gloria Moscateli

Manon Liscieki

Concetta Lodato

Thomas Fruergaard Astrup

February 2023

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

Life Cycle Assessment of Packaging Materials in relation to Extended Producer

Responsibility

Report to the Danish Environmental Protection Agency

February 2023

By

Gloria Moscateli

Manon Liscieki

Concetta Lodato

Thomas Fruergaard Astrup

Copyright:

Published by:

Reproduction of this publication in whole or in part must include the customary bibliographic

citation, including author attribution, report title, etc.

DTU, Department of Environmental and Resource Engineering, Bygningstorvet, Building

115, 2800 Kgs. Lyngby Denmark

www.sustain.dtu.dk

2

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

Contents

1.

2.

2.1

2.2

3.

3.1

3.2

4.

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

5.

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

6.

6.1

6.2

6.3

7.

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.1

7.2

7.3

3

Abstract

Introduction

Background

Objectives

Packaging overview

Materials

Packaging type

LCA goal and scope

Functional unit

Reference flow

Consequential modelling

Geographical and temporal scope

Data collection

Circular Footprint Formula (CFF) formula

Modelling tool - EASETECH

Impact categories

Model set-up

Production Scenario

Use stage

End-of-life Scenarios

Reuse Scenario

Recycling Scenario

Incineration Scenario

Current end-of-life practices

Life Cycle Inventory

Data sources, inventory data and uncertainties

Number of cycles

Weight of packaging products

Interpretation of the results

PET

PE

PP

PS

PLA

Cartonboard

Corrugated board

Aluminium

Paper

Steel

Glass

5

6

6

7

8

8

9

11

11

12

12

12

13

13

13

14

15

16

17

17

17

18

18

19

21

21

21

22

24

24

25

26

27

28

29

29

30

31

31

32

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

8.

9.

10.

10.1

10.2

11.

11.1

11.2

11.2.1

11.2.2

11.2.3

11.2.4

11.2.5

11.2.6

11.2.7

11.2.8

11.2.9

11.2.10

11.2.11

Conclusion

References

Appendix I

LCI – Electricity modelling update

LCI – Process modelling update

Appendix II

Overview of the climate change potential results

Characterised results for all impact cathegories

PET

PE

PP

PS

PLA

Paper

Cartonboard

Corrugated board

Aluminium

Steel

Glass

34

35

38

38

39

40

41

42

43

44

46

48

50

52

53

54

55

57

58

4

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

1.

Abstract

Packaging products play a crucial role in protecting, preserving, and promoting products. However, the rapid growth

in packaging material consumption and single-use packaging designs contribute significantly to waste generation.

To address this issue, the European Union has established targets and directives for reducing packaging waste

and increasing reusable packaging in the market through a set of measures to promote a circular economy through

targets on waste reduction, reuse, and minimum recycled content; an example is the Revision of Directive 94/62/EC

on Packaging and Packaging Waste . Denmark also aims for faster implementation of circularity and reusability by

introducing Extended Producer Responsibility (EPR) programs. Implementing EPR policies requires systematic

assessments of a product's environmental impact. Life Cycle Assessment (LCA) is a tool that evaluates a product's

impact throughout its entire life cycle. Conducting an LCA for a product is essential for identifying the most impactful

alternatives, encouraging sustainable design, recycling and reuse, and tracking progress in reducing overall

environmental impacts. This study provides an LCA of selected packaging materials considering three end-of-life

scenarios: i) multiple-loop reuse, ii) multiple-loop recycling and iii) incineration as a reference. The aim is to support

the Danish EPA in implementing EPR policies.

The study found that reuse is the most favourable option for all selected materials and packaging types. Recycling

was the second-best option, with the highest benefits observed for energy-intensive materials like metals and glass.

The incineration scenario was found to be the least desirable option, presenting the highest emissions on the

environment for all materials and scenarios. The report provides comparable impact calculations for the three

scenario types across the selected materials.

Keywords: Life Cycle Assessment, packaging, reuse, recycling, Circular Footprint Formula, Extended Producer

responsibility

5

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

2.

Introduction

2.1 Background

Packaging products, such as boxes, bottles, and bags, are essential in everyday life. The term "packaging" refers

to the material used to contain a product or item (EC, 2021; EEA, 2018); some examples are bottles, boxes and

bags. The main functionalities of packaging include protecting the product from damage, tampering, and

contamination, e.g. during transportation, distribution and storage (Williams et al., 2020). Even if packaging often

eases our daily challenges, the rapid and continuous growth in material consumption, such as plastics, paper, and

metals, and material complexity significantly contribute to waste generation (EMF, 2021). In addition, most of the

packaging today is designed for single-use, or in other words, to be disposed of after a single use-phase.

According to data from the Danish Environmental Protection Agency (EPA, 2019), in 2019, households in Denmark

generated approximately 474,000 tonnes of packaging waste (EPA, 2020). This accounted for about 31% of the

total household waste generated in Denmark that year. With a recycling rate of packaging waste of 69% in 2019,

Denmark performed slightly better than the European average recycling rate, estimated at around 64% (Eurostat,

2019).

Packaging waste has been addressed in Europe through international, national and local directives and legislation

(EEA, 2022). The recent revision of the European Union's Packaging and Packaging Waste Directive encourages

the reduction of packaging waste and the share increase of reusable packaging in the market (EC, 2022). The

directive also includes recycling rate targets for packaging waste which all Member States should attain: by 2025,

a minimum of 65% by weight of all packaging waste must be recycled, and a minimum of 70% by 2030 (EU, 2018;

EC, 2022).

Denmark, among other countries, advocates for fast implementation of reusability and circularity in packaging.

Currently, the focus is on implementing Extended Producer Responsibility (EPR) programs, which require

manufacturers and retailers to take responsibility for the end-of-life management, such as recycling or incineration,

of their packaging products (Andreasi Bassi et al., 2020). For a practical application of the EPR policy, systematic

assessments for quantification of environmental impacts are needed from production to end-of-life to avoid rebound

effects, e.g. implementing measures that only shift the impact to another product chain.

An LCA is a standardized methodology for quantifying the environmental impacts of products, systems and services

within the system boundaries, for example, from raw material extraction to end-of-life management, providing a

comprehensive understanding of its associated impacts and opportunities for reduction (ISO, 2006a, 2006b). In

this context, one life cycle or single loop refers to the material being extracted, the product manufactured, used by

the customer after purchase at the point of being discarded, and entering the end-of-life stage. The concept of

multiple loops or cycles considers all stages of a product's existence and the potential for materials to be reused

or recycled in subsequent cycles. The number of cycles or loops in the reuse scenario indicates the number of

times a product can be used before it breaks and becomes unusable. Similarly, in the recycling scenario, the

number of cycles reflects the number of times a material can be processed into a new product before it becomes

too degraded to be recycled again. Recycling and reuse are crucial end-of-life scenarios as they promote the

recirculation of materials and products. By minimizing waste and environmental damage, such as CO

2

emissions

and resource depletion, these scenarios aim to extend the life of materials as much as possible. This circular

approach recognizes that the available materials are finite, and their continued use is essential for sustainable

development.

In the context of EPR programs, conducting an LCA that assesses the multiple cycles of a product is essential for

several reasons: 1) Identifying the hotspots, as a consequence, where the most significant improvements can be

6

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

made; 2) encouraging sustainable design, such as including durability, reparability, and recyclability; 3) tracking

progress and evaluate the effectiveness of the programs in reducing the environmental impact of a product.

2.2 Objectives

The overall goal of this study is to provide the Danish EPA with the potential life cycle environmental impacts

associated with the production, use and disposal of selected packaging products made from various materials.

Three end-of-life scenarios are considered, i.e., multiple-loop reuse, multiple-loop recycling and incineration. The

results are intended for internal decision support at the Danish EPA as part of a broader range of assessments to

define EPR recommendations.

In particular, this study aims to:

•

Collect and review life cycle inventory data for selected packaging products type purchased, used and discarded

in a Danish context;

•

Estimate the number of times the selected packaging products can be reused and recycled;

•

Model the life cycle scenarios for each packaging product in the LCA modelling software EASETECH adopting

a multiple-loop approach;

•

Analyse the potential environmental impacts of each packaging product's end-of-life scenarios.

The study is based on a life cycle assessment (LCA) modelling framework for packaging materials provided in a

previous EPA project from 2021, "Environmental profiles of packaging materials".

7

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

3.

Packaging overview

3.1 Materials

In this report, the selected packaging is from the post-consumer stage after the use phase. Two types of post-

consumer packaging are studied: 1) primary packaging representing packaging in direct contact with the product,

and 2) secondary packaging representing additional packaging used to protect and contain individual units during

storage, transport, and distribution (Miljø- Og Fødevareministeriet, 2015).

Packaging comprises various materials, from cellulose fibres to plastic or other alloys. The project includes the

most frequently used packaging materials in Danish households and alternative packaging materials as

biomaterials.

More specifically:

•

Fossil plastic (PET, PE, PP, PS);

•

Bio-based plastic (PLA);

•

Metals (aluminium, steel);

•

Fibre-based materials (paper, cartonboard, corrugated board);

•

Glass

The included materials associated with each packaging group are shown in Table 1.

Table 1 - Overview of packaging groups and included materials assessed in this study.

Packaging

group

Fossil-

based

plastic

Material

PET

Full name

Polyethylene

terephthalate

Description

PET plastic is a durable, lightweight material

commonly used in primary packaging products

such as bottles, food containers (Andreasi Bassi et

al., 2021).

PE plastics are included in the polyolefin polymer,

a broad family of polymers with moisture barrier and

toughness properties (Bauer et al., 2021). Low-

Density Polyolefin (LDPE) is used in flexible

applications, e.g. in food bags, whereas High-

Density Polyolefin (HDPE) is a stiff material often

used in applications where rigidity is required, e.g.

boxes (Bauer et al., 2021; Cecon et al., 2021).

PP plastic is included in the polyolefin polymers. It

is often used in primary packaging for flexible and

rigid applications (Chappell et al., 2022; Horodytska

et al., 2018)

PS can be rigid or expended as foam. This study

assesses the rigid PS used for packagings, such as

food trays or cups (Ingrao et al., 2015).

Bio-based plastic is made from a feedstock derived

from a renewable resource (Ali et al., 2023). It is a

niche market representing an emerging alternative

to fossil-based plastics (Rosenboom et al., 2022).

Aluminium packaging comprises>90% aluminium

alloys with other metals, such as copper, zinc, and

PE

Polyethylene

PP

Polypropylene

PS

Polystyrene

Bio-based

plastic

PLA

Polylactide Acid

Metals

Aluminium

-

8

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

manganese (Zink et al., 2018). Cans and trays

made of aluminium are commonly found in

household packaging.

Steel

-

Steel cans are produced from tin-coated steel,

tinplate, or electrolytic chromium-coated steel (Zink

et al., 2018). Steel packaging is resistant material

mainly used for canned goods (Van Caneghem et

al., 2019).

Paper packaging consists of cellulosic fibres

forming the structure of the material. Various

additives are used during production for

customizing the technical properties, e.g., fillers,

coatings, biocides, and synthetic binders (Hage,

2007; Ma et al., 2023; Zambrano et al., 2021).

Paper is a flexible material often used for dry foods,

e.g. pastries.

Paper and board consist of cellulosic fibres forming

the structure of the material. Various additives are

used during production and for customizing the

technical properties of paper and board, e.g., fillers,

coatings, biocides, and synthetic binders. (Hage,

2007; Ma et al., 2023; Zambrano et al., 2021)

Cartonboard is often used as secondary packaging,

e.g. cartonboard boxes containing a plastic bag.

Creating a corrugated board involves combining

multiple sheets of paper, which are corrugated

before being adhered to a sturdy board and

trimmed into the desired shape (FEFCO, 2019). A

corrugated board is broadly applied as secondary

packaging, for example, for product storage,

transport, and delivery.

Glass consists of a random structure of silicon

dioxide and metal oxides (Zero Waste Europe,

2022). It is commonly used in packaging, e.g., jars,

bottles, and containers.

Fibre-

based

materials

Paper

-

Cartonboard

-

Corrugated

board

-

Glass

-

-

3.2 Packaging type

This study assesses post-consumer primary and secondary packaging, with no specified usage or application,

which can be found in the form of rigid or flexible packaging:

•

Rigid packaging: solid, firm and not easily distorted or deformed. It is typically made from glass, metal,

cartonboard, plastic, or paperboard. Examples include cans, bottles, jars, and boxes – see Table 2.

•

Flexible packaging: soft and pliable packaging can be easily bent, folded and twisted. It is typically made from

plastic, paper, or foil. Often a layer of plastic film or coating is included, but this product-specific option is not

considered in this study. Examples include bags and films

– see

Table 2.

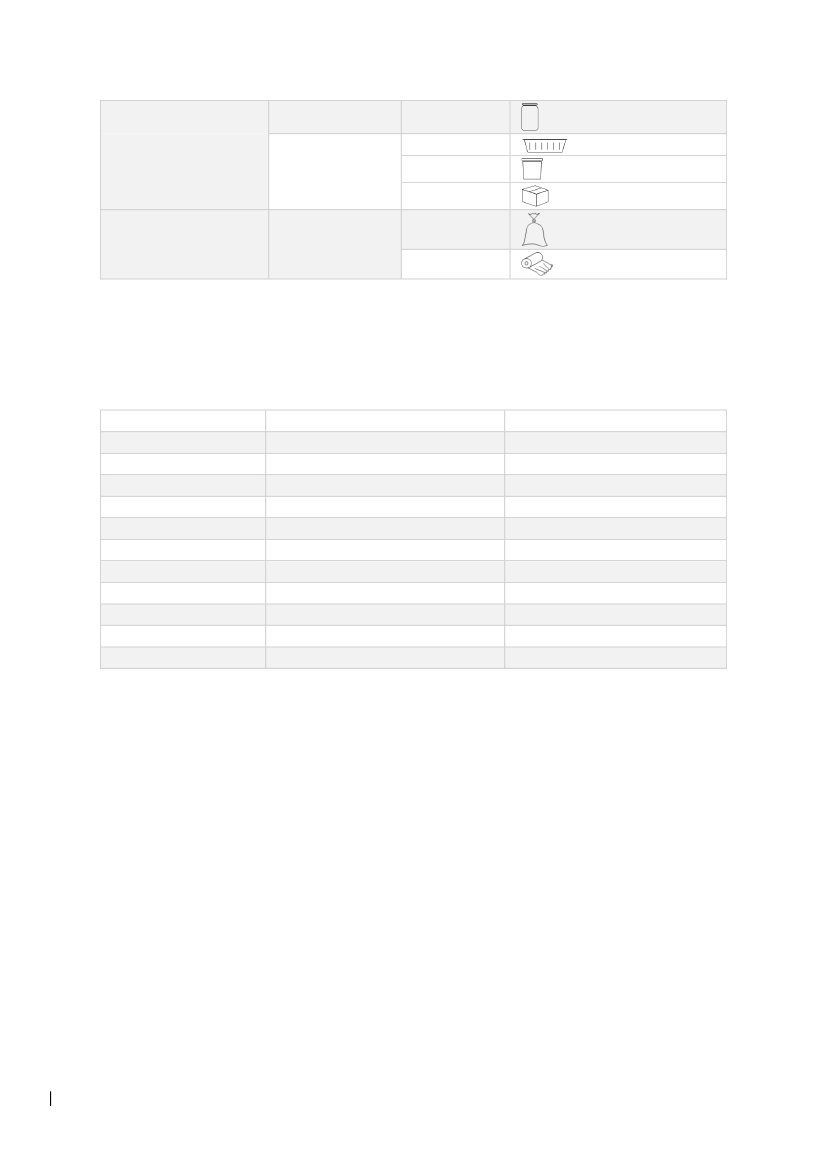

Table 2 - Illustrative example of rigid and flexible packaging.

Packaging design type

Category

Bottle/jar/

can/brick

Product type

examples

Bottle

Jar

Illustration

Rigid

9

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

Can

Tray

Container

(tray/tub/box)

Tub

Box

Bag

Flexible

Bag/film

Film

Note that not all materials are considered to be used to produce both rigid and flexible products. The combination

of packaging design type-material, as considered in this study, is presented in Table 3.

Table 3 - Materials included in the study for flexible and rigid packaging types.

Rigid

PET

PE

PP

PS

PLA

Aluminium

Steel

Paper

Cartonboard

Corrugated board

Glass

R

R

R

R

R

R

R

T

R

R

R

Flexible

T

R

R

R

R

R

T

R

T

T

T

Both rigid and flexible packaging has the potential to be used multiple times or recycled multiple times. Examples

of reusable packaging are refillable water bottles or reusable shopping bags, which can undergo many uses,

whereas examples of single-use packaging are disposable coffee cups designed to be used once and then

disposed of. Typically, reusable packaging is heavier than the corresponding single-use option made of the same

material, as it is designed to be durable and withstand multiple uses; therefore, more material is needed to make

the same packaging product (Greenwood et al., 2021).

10

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

4.

LCA goal and scope

This study aims to provide the potential impacts on the environment associated with the production, use and waste

management of selected design options for packaging. As mentioned above, the considered materials are fossil-

based plastic (PET, PE, PP, PS), bio-based plastic (PLA), fibre-based materials (paper, cartonboard, corrugated

board), metals (aluminium, steel), and glass. Only the primary material constituting the packaging is considered,

while other packaging components, such as labels, ink and glue, are not included in the assessment.

The target audience of the study is the Danish EPA. The study aims to be used for internal decision support at the

Danish EPA as part of the background material for implementing Extended Producer Responsibility of packaging

materials. Note that the results presented in the report provide an overview of the environmental performance of

selected packaging materials; they are intended as "baseline results" to support decision-making.

The scope of this LCA includes all stages of the packaging life cycle, from raw material extraction to end-of-life

management. More specifically, the considered life cycle phases are:

•

Raw material extraction: includes all the extraction activities of any raw material constituting the packaging

product, like metal ore mining and oil drilling;

•

Manufacturing: includes all processes required to convert the raw materials into packaging, such as

assembling;

•

Use: includes the usage of packaging by the end-user, in this case, consumers. No process or activity is

included in this stage, as the packaging does not require any resource or energy consumption during the

use stage.

•

End-of-life: includes three end-of-life scenarios, i.e. reuse, recycling, and incineration.

While raw material extraction, manufacturing and use are the same for each product within the material and the

packaging type selected, the end-of-life considers one option at a time, making three different LCA comparable

pathways.

4.1 Functional unit

In LCA, the Functional Unit (FU) represents the object of the assessment and provides the basis for a fair and

quantitative comparison of alternative ways of providing a function or service (ISO, 2006a, 2006b). This unit defines

the function's qualitative and quantitative aspects, like temporal and geographical scope.

This study considers a wide range of materials which can provide different functionalities in terms of the number of

cycles (see Section 6.2), preservation of mechanical properties after recycling, etc. Moreover, packaging of the

same volume has different weights according to their material (see Section 6.3). Reusable packaging is usually

heavier than the corresponding single-use one made of the same material, as it has been designed to be durable

and to withstand multiple uses; hence, more material is required to satisfy the same functionality. Single-use

products are sent to recycling or incineration.

This assessment intends to compare the potential environmental impacts of different packaging materials and

types. The functional unit is defined as:

The amount of rigid and flexible packaging material, expressed in kilograms (kg), needed to contain 1 liter (L) of

volume of an available product used in Denmark between 2020 and 2030.

11

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

The above-described functional unit allows for a functionally equivalent comparison across packaging materials,

e.g., a 700 g aluminium can serve the same functionality as a 500 g plastic bottle; thus, the results of the LCA can

be compared and aggregated.

4.2 Reference flow

The reference flow represents the amount of material required to fulfil the defined functional unit. The reference

flow varies depending on the material (e.g. steel, PET), the type of packaging design (rigid or flexible), and whether

the packaging is intended for reuse. The reference flows defined in this study are presented in Section 6.3 as the

amount of packaging material required to contain 1 liter of a product used in Denmark between 2020 and 2030.

4.3 Consequential modelling

This LCA follows a consequential modelling approach for evaluating the environmental consequences of changing

the management of the selected materials from the reference scenario representing the current system to several

alternative scenarios (Brandão et al., 2022). It allows for identifying opportunities to reduce those impacts through

product design or selecting more sustainable materials and production processes. Multi-functionality in the model

is handled by system expansion when co-products are used in specific markets and for specific applications (Ekvall

and Weidema, 2004; Weidema, 2003) under the assumption of unconstrain and fully elastic markets (Wernet et

al., 2016).

4.4 Geographical and temporal scope

The production of both primary and secondary raw materials and the manufacturing of packaging products depend

on the market situation of a country. This depends on market factors such as the demand for the materials, pricing,

the accessibility of resources, and the level of technological advancements. In this study, raw material production

is assumed to happen in Europe. In line with the project scope, processes related to converting virgin raw materials

into packaging products, sorting before recycling, reuse and incineration are assumed to happen in Denmark.

Reprocessing in the recycling pathway is handled in Europe except for glass packaging, which is assumed to occur

in Denmark.

An overview of the specific geographical scope for each modelled scenario option for all packaging materials is

presented in Table 5.

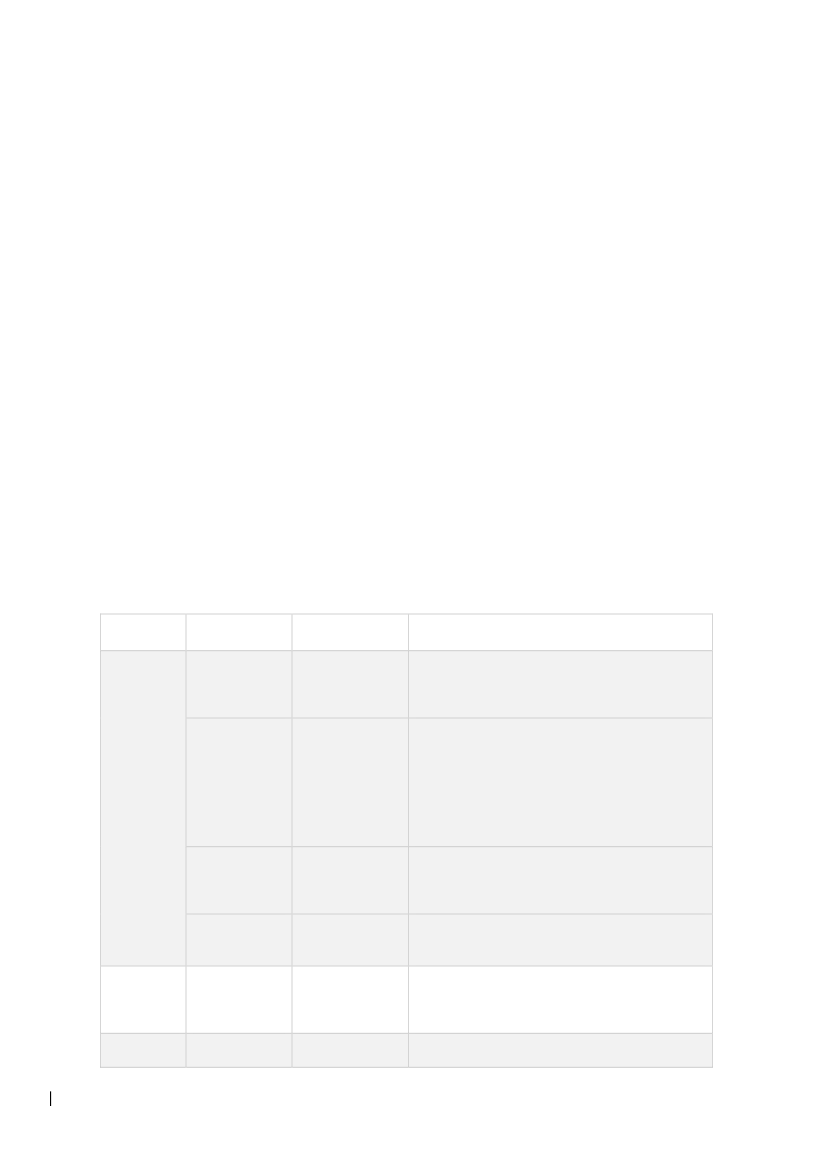

Table 4 - Geographical scope of production and end-of-life scenarios for the selected packaging materials.

Raw

material

production

Europe

Europe

Europe

Europe

Europe

Europe

Europe

Europe

Europe

Conversion

into packaging

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Recycling-

reprocessing

Europe

Europe

Europe

Europe

Europe

Europe

Europe

Europe

Europe

Material

PET

PE

PP

PS

PLA

Paper

Cartonboard

Corrugated

board

Aluminium

12

Reuse

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Sorting

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Incineration

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

Steel

Glass

Europe

Europe

Denmark

Denmark

Denmark

Denmark

Denmark

Denmark

Europe

Denmark

Denmark

Denmark

The temporal scope of the study has been set to cover the period from 2020 to 2030. To ensure that the LCA

accurately reflects this time frame, the current and future technology data has been specifically adapted for this

period.

4.5 Data collection

The modelling and input data are based on the life cycle assessment modelling framework for packaging materials

included in the EPA project "Environmental profiles of packaging materials" (EPA, 2022), including a thorough data

quality assessment of the input data. Most external processes are imported from the Ecoinvent database, version

3.6, and updated to version 3.8 for use in this study. Data for material composition and the incineration process

are obtained from the library of the LCA software EASETECH (Section 4.7).

Several assumptions are made due to insufficient data availability in literature, mainly about multiple-loop

information on recycling and reuse (see Chapter 6 about Life Cycle Inventory).

4.6 Circular Footprint Formula (CFF) formula

When modelling multiple product cycles, the distribution of the environmental impacts among the individual cycles

may be relevant (Rigamonti et al., 2020). Although the modelling in this study assesses the packaging product life

cycle in its entity, the Circular Footprint Formula (CFF) developed by the European Commission is applied to

distribute impacts between individual parts of the product life cycle and to avoid double-counting (EC, 2018). The

circular footprint formula involves a range of parameters, including the “A” factor distributing the environmental

impacts between the upstream production and the downstream end-of-life phases. Thus the impacts are modelled

in two parts (upstream part, i.e. production scenario, and downstream parts, i.e. end-of-life scenario) according to

the A factor (following the recommendations from European Commission for its values):

-

0.2

is used when there is a greater demand for high-quality secondary material than what is being

produced. This study uses this value for metals, fibre-based packaging and glass.

0.5

is used when there is an equilibrium between offer and demand. This study uses this value for plastic

(fossil and bio-based).

0.8

is used when less high-quality secondary material is demanded than produced.

-

-

For more information regarding applying the CFF formula in this project, refer to Section 3.3 in the EPA project

"Environmental profiles of packaging materials – LCA model documentation".

4.7 Modelling tool - EASETECH

This study uses the software EASETECH (Environmental Assessment System for Environmental Technologies)

for the LCA modelling (Clavreul et al., 2014). EASETECH is a process-oriented tool developed at the Technical

University of Denmark to support LCA studies in waste management. When modelling environmental technologies,

the material flows can consist of a very heterogeneous mix of materials; it is crucial to maintain this information

throughout the modelling process. EASETECH is a material flow-based tool where the material flow is defined as

different fractions having physical, chemical, biochemical and nutritional properties associated and tracked in the

model across the entire system, considering material transformation and transition from one process to another

13

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

within the system boundaries (Lodato et al., 2021). Recently, more features have been implemented into

EASETECH, expanding the application of LCA on more complex systems within waste management (Lodato et

al., 2021).

4.8 Impact categories

The potential environmental results are generated in EASETECH using the Environmental Footprint (EF) 3.0

methodology without Long Term impacts, thereby focusing only on the impacts that occur during the life cycle of

the products, i.e. short-term impacts.

The final results of the LCA are presented as characterized impacts, i.e., direct and indirect emissions associated

with the modelled scenarios are converted into standard units and aggregated within each impact category. The

short name and characterized unit for each impact category are listed in Table 5.

A non-zero characterisation factor is applied for biogenic CO

2

-emissions to reflect the temporal effects from an

instant release of CO2 in the case of waste incineration of biogenic materials such as wood relative to the much

slower uptake of CO

2

from regrowing of the corresponding biomass (e.g. through forestry). For details, please refer

to Faraca et al., 2019.

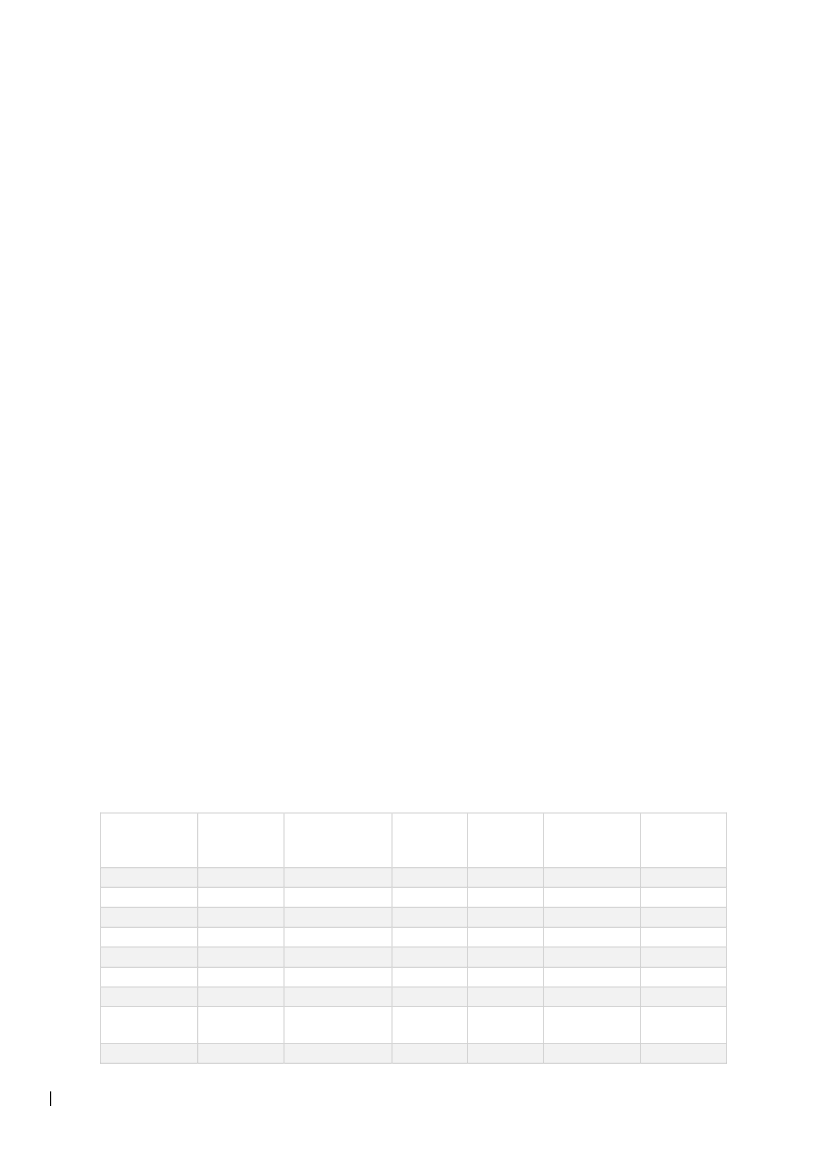

Table 5 - Overview of selected impact categories included in the EF 3.0 methodology.

Impact category

Climate change

Ozone depletion

Human toxicity, cancer effects

Human toxicity, non-cancer effects

Particulate matter/respiratory inorganics

Ionizing radiation, human health

Photochemical ozone formation, human health

Acidification

Eutrophication terrestrial

Eutrophication freshwater

Eutrophication marine

Ecotoxicity freshwater

Land use

Resource use, minerals and metals

Resource use, energy carrier

Short name

CC

OD

HT-C

HT-nC

PM

IR

POF

TA

ET

EF

EM

EcoF

LU

RUMM

RUEC

Characterized unit (CU)

kg CO

2 eq

kg CFC

-11 eq

CTUh

CTUh

Disease incidences

kBq U

235 eq

(to air)

mol H

+ eq

mol N

eq

kg N

eq

kg P

eq

kg N

eq

CTU

e

-

kg SB

eq

MJ

14

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

5.

Model set-up

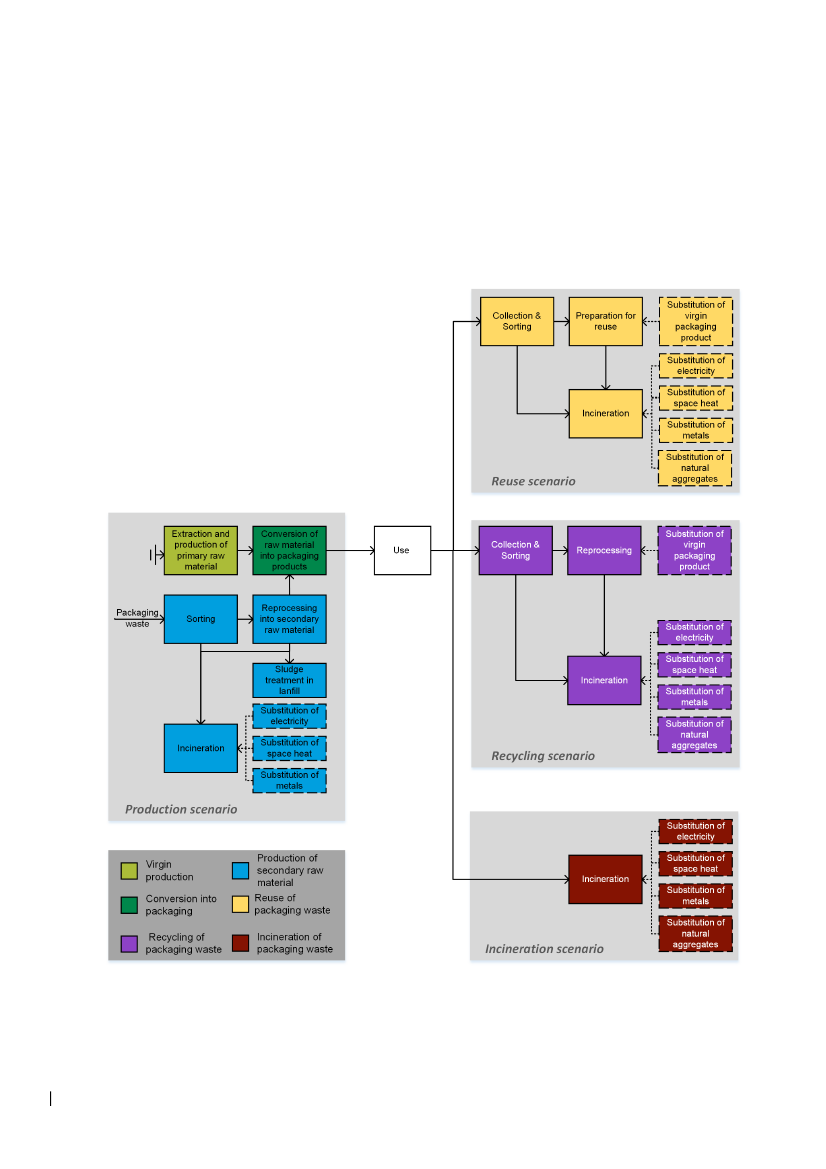

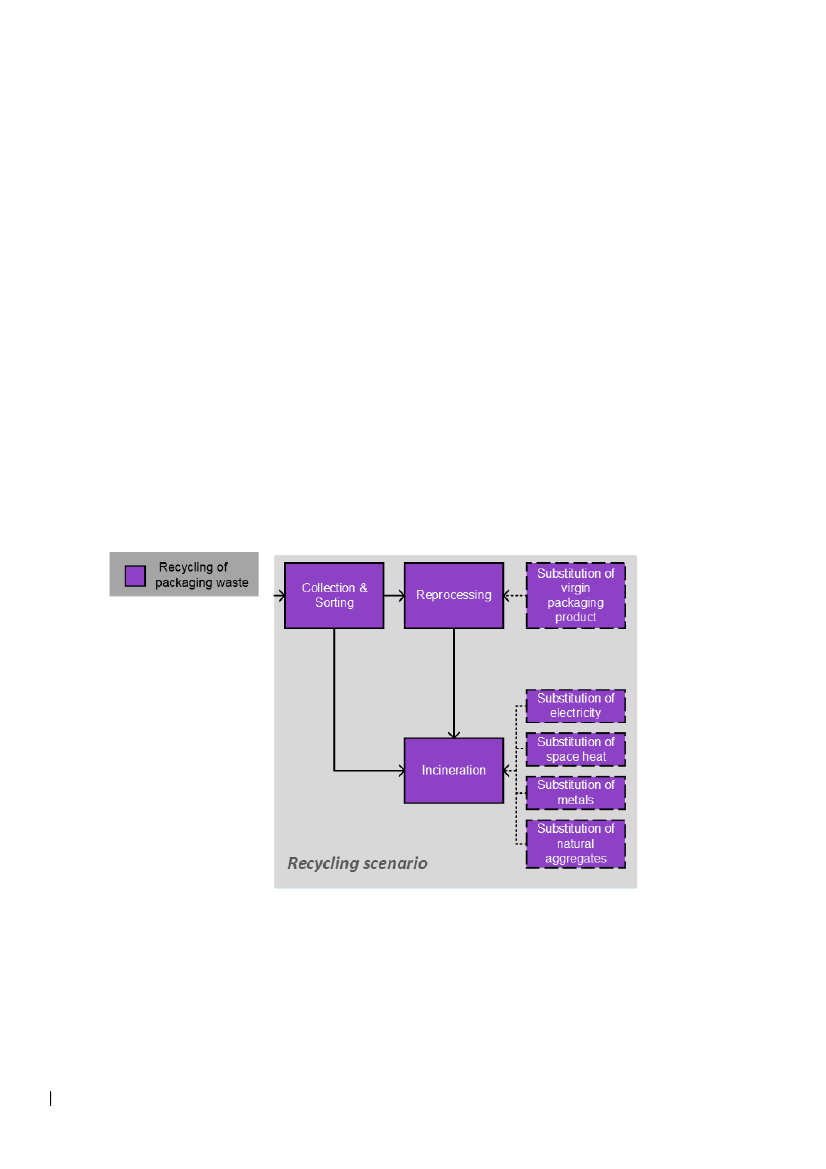

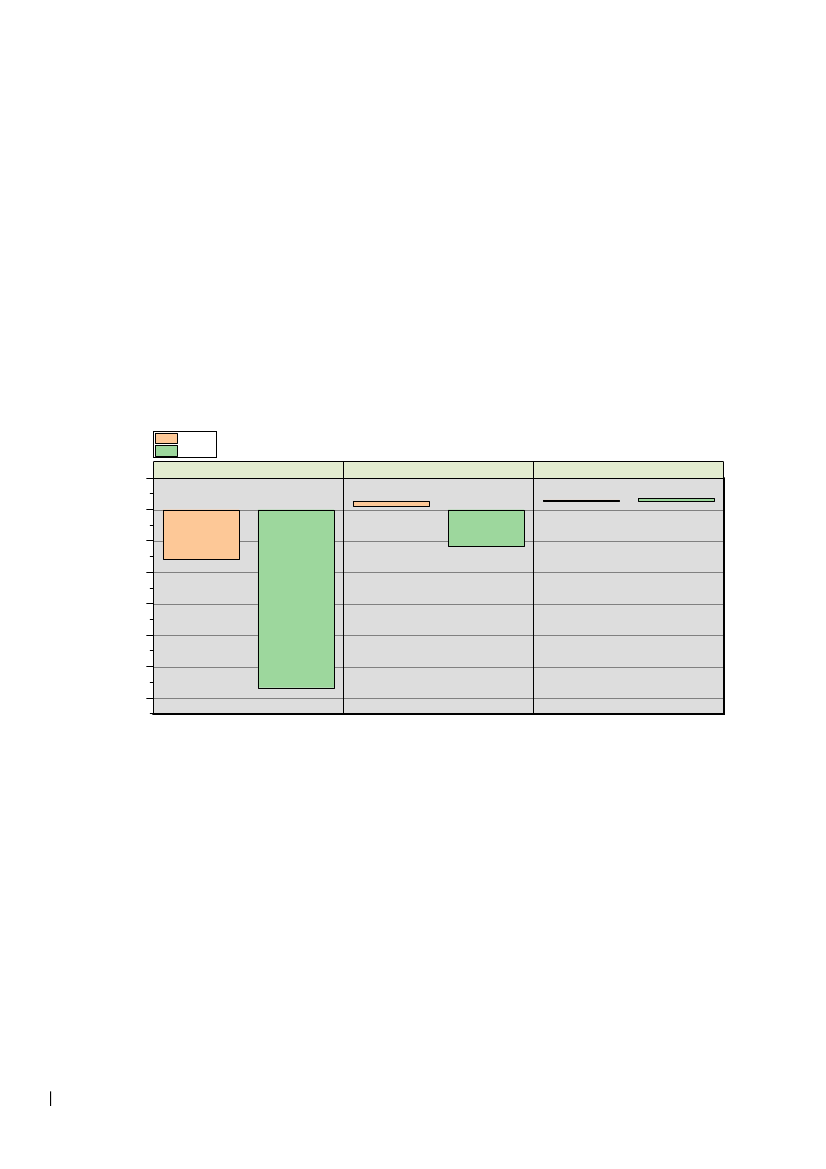

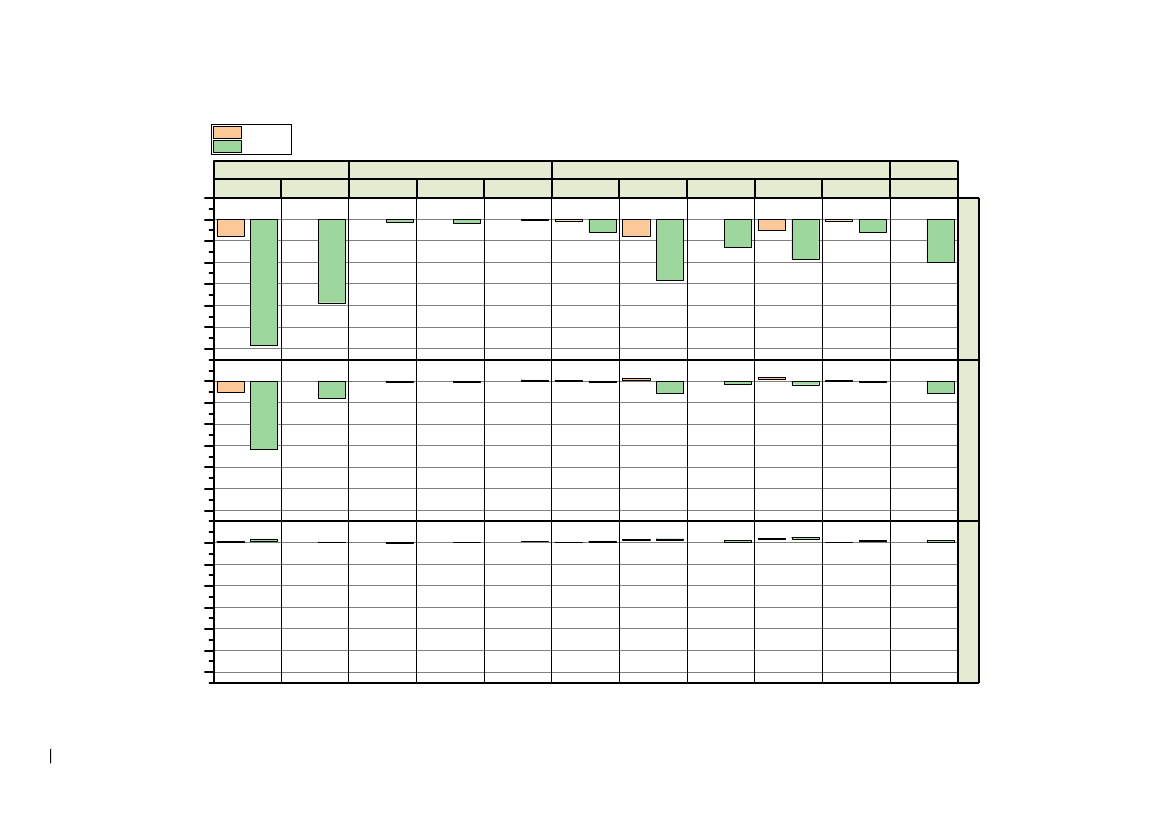

An overview of the process flow diagram for the selected packaging products is illustrated in Figure 1 and described

in more detail in the sections hereafter. Primary raw material extraction and production (light green) and secondary

raw material production (blue) are followed by the conversion into packaging step (dark green). After the use stage,

the model considers three end-of-life scenarios: the reuse scenario (yellow), the recycling scenario (violet) and the

incineration scenario (red). Note that the transportation of the products is not included in this assessment.

Figure 1 - Process flow diagram for selected packaging products: production scenario, use stage, and end-

of-life scenarios. Dotted lines refer to material and energy substitution.

15

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

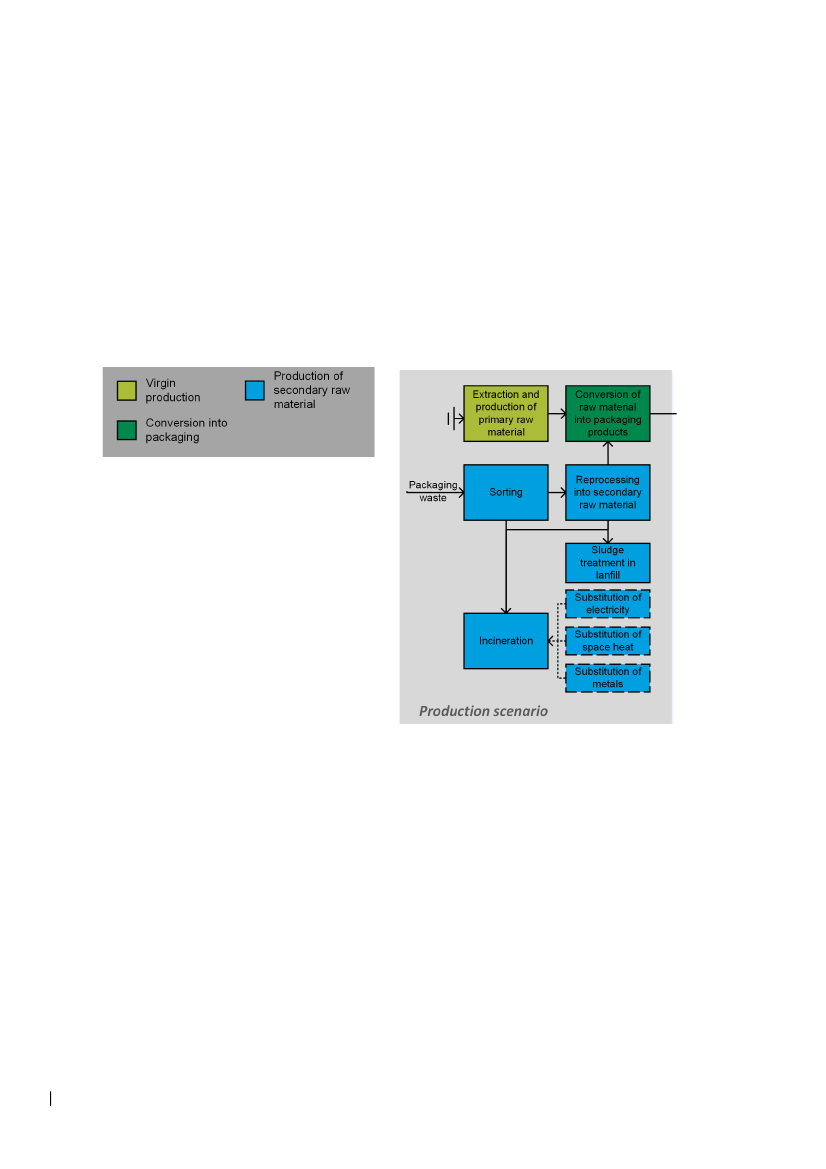

5.1 Production Scenario

The processes modelled in the production scenario are presented in Figure 2Error!

Reference source not found..

The model includes the following production scenario alternatives:

•

Primary raw material production (light green in Figure 2Error!

Reference source not found.):

refers to the

extraction and production of plastic from virgin resources;

•

Secondary raw material production (light blue in Figure 2Error!

Reference source not found.):

refers to the

recovery process of materials from existing products, i.e. in this study, packaging products, through mechanical

recycling. For example, when a plastic bottle reaches its end of life can be processed into plastic pellets. More

information related to the recycling process can be found in Section 4.3.2.

Primary and secondary raw materials are then converted into finished packaging products (dark green in Figure

2).

Figure 2 - Overview of processes modelled in the production scenario. Dotted lines refer to material and

energy substitution.

The recycled content (RC) at the “conversion of raw material into packaging products” in Figure, when the virgin

production flow merges with the secondary material production flow, varies between 0% and 100%, with RC=0%

indicating a product made only of virgin materials, and RC=100% indicating a product entirely made of recycled

materials. In this study, in order to display an intermediate situation, the final results are presented for a recycled

content of 50%, i.e. half from virgin and half from recycled materials (EU, 2018). In reality, the share of recycled

content in a packaging product varies depending on the material type and its end-of-use, e.g. for safety and hygiene

reasons, packaging for certain products, such as medical supplies or food, may require higher levels of recycled

content to be excluded to ensure the safety of the end user (Franz and Welle, 2022). On the other hand, products

with less stringent requirements may use a higher percentage of recycled content without compromising product

quality or safety (BRF, 2020). Therefore, the share of recycled content in a packaging product may vary depending

on the specific end use of the product.

16

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

5.2 Use stage

The use stage is assumed to be burden free. No processes are associated with this stage.

5.3 End-of-life Scenarios

The model includes the following end-of-life scenarios:

•

Reuse

•

Recycling

•

Incineration

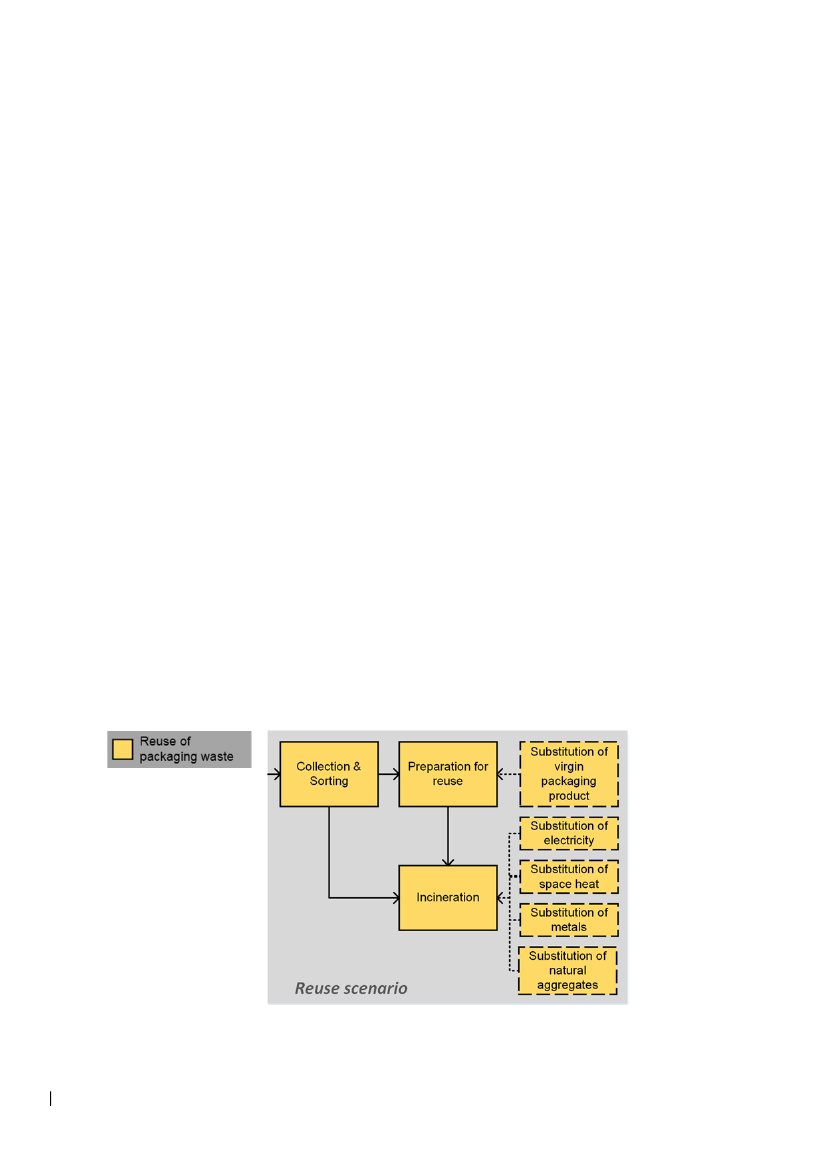

5.3.1

Reuse Scenario

After being used, the packaging waste undergoes a sorting activity at Material Recycling Facilities (MRFs), where

the broken or deformed packaging is discarded and sent to incineration (see Section 0). The remaining waste can

be prepared for being used again through cleaning and sanitizing processes. This process can slightly differ from

one material to another. For instance, the washing activity is performed for most products while not included in

paper and cartonboard. Moreover, differences may occur in the kind of detergent and solvent used to clean and

sanitize the types of packaging. However, for simplicity, such variations are not considered in this study.

The reuse scenario has the main advantage of reducing waste and conserving resources by avoiding production

of the virgin raw materials and the activities involved in the conversion into packaging, which in this study are

assumed to be substituted at every cycle.

The packaging product could be sent for recycling when packaging reuse is impossible. This option is not

considered, as the three end-of-life scenarios are compared directly in this study. Consequently, the residues from

the sorting and preparation for reuse stages are sent to incineration.

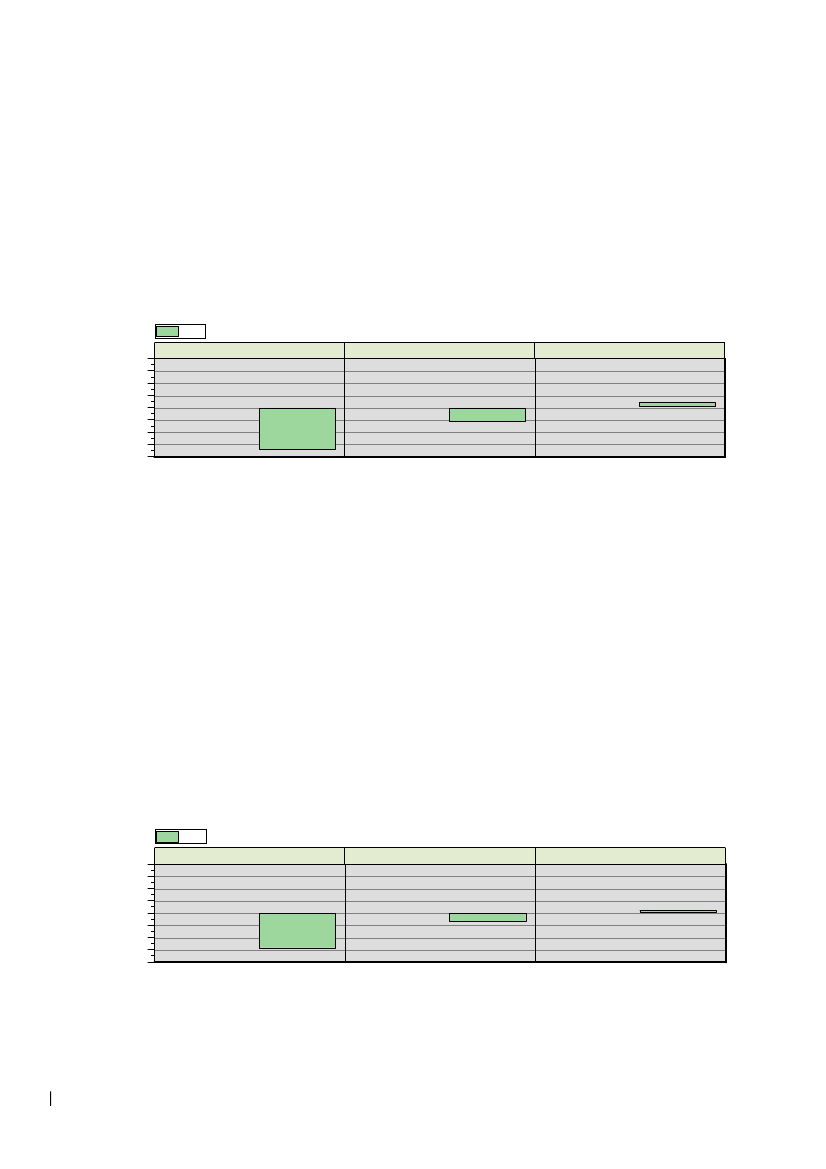

The above-described processes, represented in Figure 3Figure 3 - Overview of processes modelled in the

reuse scenario. Dotted lines refer to material and energy substitution.

, are referred to in this report as the "Reuse" scenario.

Figure 3 - Overview of processes modelled in the reuse scenario. Dotted lines refer to material and energy

substitution.

17

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

5.3.2

Recycling Scenario

Packaging recycling refers to handling packaging waste and converting it into raw materials. The recycling process

can change depending on the type and material being treated; however, it generally includes the following steps:

collection and sorting, reprocessing and treatment of the residues.

After being used for its primary function, the packaging is collected from households, businesses, and other sources

and brought to MRFs, where material types separate the waste, such as metals, paperboard and plastics, either

manually or through sorting machines. The sorted materials are then reprocessed and, in this study, assumed to

substitute virgin raw material to produce single-use packaging. This work considers mechanical recycling as a

reference for reprocessing the selected packaging materials; therefore, activities like grinding and shredding are

the main modelled processes.

The residues from the sorting and reprocessing activities are treated through incineration. Section 0 provides more

information.

The processed materials are then used to manufacture new products, such as other packaging, distributed to

consumers and businesses. These two last steps are out of the scope of this study and thus not included in the

model set-up.

The above-described processes, graphically represented in Figure 4, are referred to in this report as the "Recycling"

scenario.

Figure 4 - Overview of steps modelled in the recycling scenario. Dotted lines refer to material and energy

substitution.

5.3.3

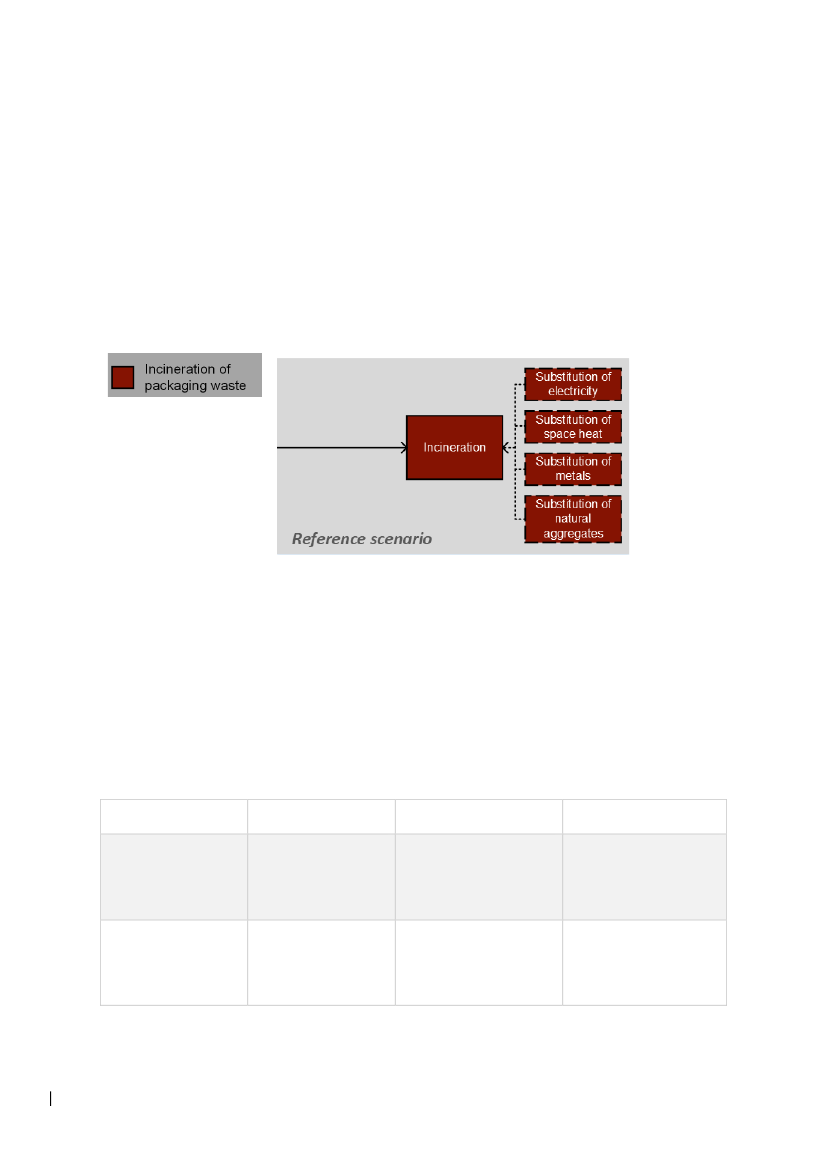

Incineration Scenario

Packaging products and their residues from other processes can be disposed of through incineration. The

incineration process involves combusting waste materials at high temperatures in incineration plants, typically

within the temperature range of 850 to 1100°C (EC, 2020). This converts the heat produced into electricity and

18

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

heat (Ekvall et al., 2021). Once the waste is combusted, it is possible to recover metals from the ashes through

manual sorting, magnetic separation, and eddy current separation (Christensen, 2010). Furthermore, incinerator

ash can be recovered as natural aggregates, substituting for filler materials used in road construction or aggregates

in building materials (Christensen, 2010).

Incineration with energy recovery is a well-established waste treatment in Denmark with Amager Bakke in

Copenhagen as a recent example. The plant has high energy recovery efficiencies and uses advanced air pollution

control technology to minimize emissions of pollutants such as nitrogen oxides, sulfur dioxide, and dioxins (ARC,

2020).

The above-described processes, graphically represented in Figure 5, are referred to in this report as the

"Incineration" scenario.

Figure 5 - Overview of processes modelled in the incineration scenario. Dotted lines refer to material and

energy substitution.

5.3.4

Current end-of-life practices

An outline of the present state of technology development for all packaging materials' three end-of-life options is

provided in the following table.

Table 6 - An overview of the current practices for managing the end-of-life of the chosen packaging

materials - adapted from the EPA project "Environmental profiles of packaging materials"

Material

Fossil plastic types

(PET, PE, PP, PS)

(Abbasi et al., 2022;

EPA, 2019)

Biobased

plastic

types (PLA)

(Razza et al., 2020;

Rosenboom et al.,

2022)

Reuse

Packaging made from

fossil plastic is not

currently reused

Recycling

Source separation is still

maturing in Denmark.

Recycling in Europe with

established technologies

PLA:

Neither

source

separation nor recycling is

well-established

Incineration

Incineration is the default

treatment, if not directed

to

recycling

through

source-separation

Incineration is the default

treatment, if not directed

to

recycling

through

source-separation

Biobased

plastic

packaging

is

not

currently reused

19

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

Fibre-based

materials

(Paper, cartonboard,

corrugated board)

(EPA,

2007)

2019;

Hage,

Fibre-based

packaging

is

currently reused

not

Well-established source

separation

and

technologies for recycling

fibre-based materials

Incineration is the default

treatment, if not directed

to

recycling

through

source-separation

Metals

(aluminium, steel)

(Van

Caneghem et al.,

2019)

Glass

(Agnusdei et al., 2022)

Metal packaging is not

currently reused

Well-established

technologies for recycling

metals. Source separation

is still growing in Denmark

Well-established source

separation

and

technologies for recycling

glass

Incineration is the default

treatment, if not directed

to

recycling

through

source-separation

Incineration is the default

treatment, if not directed

to

recycling

through

source-separation

From unbroken glass

packaging collected at

glass cubes

20

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

6.

Life Cycle Inventory

6.1 Data sources, inventory data and uncertainties

Data and processes are modelled predominantly based on primary data, when available, or data from literature.

While extensive data collection has not been part of this study, the inventory data are primarily based on a previous

EPA report "Environmental profiles of packaging materials - LCA model documentation” (EPA, 2022), including

appendices with relevant data for the selected packaging materials in context of the three end-of-life scenarios.

Production and conversion of raw materials into packaging were modelled mainly based on processes from the

Ecoinvent database, amended with data from other sources, such as literature and primary data, if data were not

available in Ecoinvent.

End-of-life options were modelled as distinct processes, relying on data from literature or primary sources. As

outlined in the documentation, these flow values were either added as individual values or data ranges based on

the available data (EPA, 2022). The values presented as ranges allow for the inclusion of potential variations in

flow values, e.g., sorting and reprocessing efficiency for the packaging products and different process/technology

uses. Data on material composition and incineration processes were obtained from the library of the LCA model

EASETECH.

In this study, additional focus was placed on estimating the number of cycles for the reuse and recycling scenario

(see Section 6.2) as well as the packaging product weight (see Section 6.3). Additionally, the Ecoinvent data were

updated to version 3.8 relative to version 3.6 in the previous EPA report (EPA, 2022). Changes were applied

primarily to marginal electricity in Europe and a few other processes, as outlined in Appendix I.

The EASETECH modelling software uses parameters with defined data intervals assigned a uniform probability

distribution for equal probability within the data range. For the uncertainty analysis, 1000 Monte Carlo simulations

were included: at every simulation, the model extracts a value for each parameter within the defined data interval

following the assigned probability distribution. The results are presented with a 95% confidence interval.

6.2 Number of cycles

The number of cycles or loops is identified for the reuse and the recycling end-of-life scenarios. In the reuse

scenario, the number of cycles indicates the number of times a product can be used before it breaks and becomes

unusable. Similarly, in the recycling scenario, the number of cycles reflects the number of times a material can be

processed into a new product before it becomes too degraded to be recycled again. These two values refer to

different life cycle stages of a product.

In both cases, the number of cycles varies depending on factors related to the product or the involved processes

(Geueke et al., 2018). Generally, packaging made of metals or specific types of plastic has a lower integrity loss

than packaging made of other materials, such as paper (Rigamonti et al., 2020). This is highly affected by the

product's intended use and how this is used and maintained. For instance, paper and cartonboard are relatively

durable materials but easily weakened by moisture, while UV rays can cause the plastic to degrade over time

(Albrecht et al., 2022). Another critical parameter to consider is the thickness of the packaging. Overall, heavier

packaging is more durable than lightweight products of the same type and material as they can withstand repeated

uses with more limited damage (Schroeer et al., 2020). The quality and efficiency of the reuse system and the

recycling plants also play an essential role in the lifespan. For example, if poorly maintained or handled, reusable

products may experience fewer loops than better-preserved products. Thus, variations in the number of cycles

depend on a wide range of factors affecting the product’s life (Lu et al., 2022). Recycling often involves “breaking

down” the product through shredding, washing and extruding it into flakes and reprocessing its materials to make

21

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

new packaging (Berg et al., 2016; Spinacé and De Paoli, 2001). On the contrary, reusing a product often involves

extensive washing, drying and decontamination processes which have fewer degradation effects at the material

level (Coelho et al., 2020).

Very few studies in literature, based on experimental data, have defined the potential number of cycles that a

packaging product could undergo both in the reuse and recycling scenario; however, in most of the cases, the main

focus has been on plastic packaging and often not all the combinations of parameters affecting the condition of the

product are considered (Bø et al., 2013; Simon et al., 2016). Due to substantial uncertainties and variability, the

number of cycles for the reuse and recycling option is included as ranges in this study (Bradley and Corsini, 2023).

The model considers "default" ranges for rigid and flexible packaging products are defined. However, these might

vary slightly depending on the material (Zink et al., 2018). For assessment of specific packaging products the

number of cycles needs to be addressed in detail for the case-study in question.

For this study, a uniform distribution is applied in the model with the ranges representing the minimum and

maximum number of cycles for every packaging material reported in Table 8.

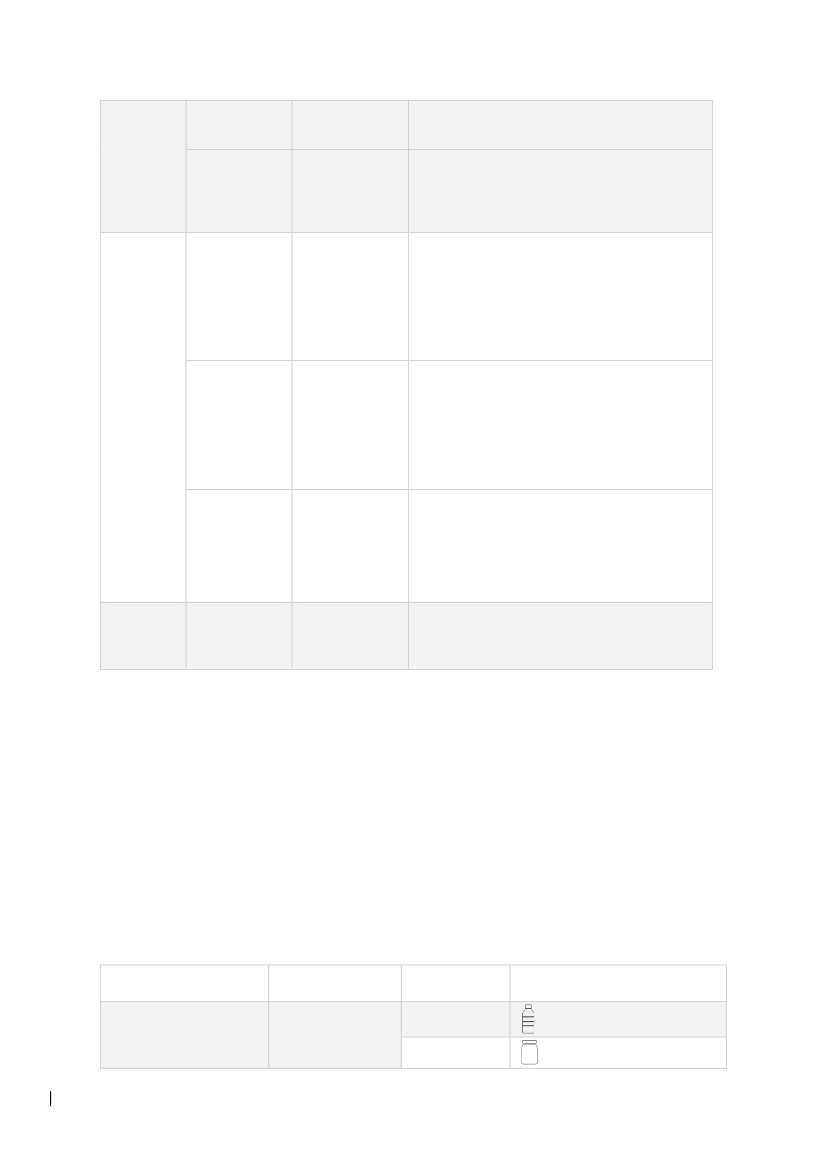

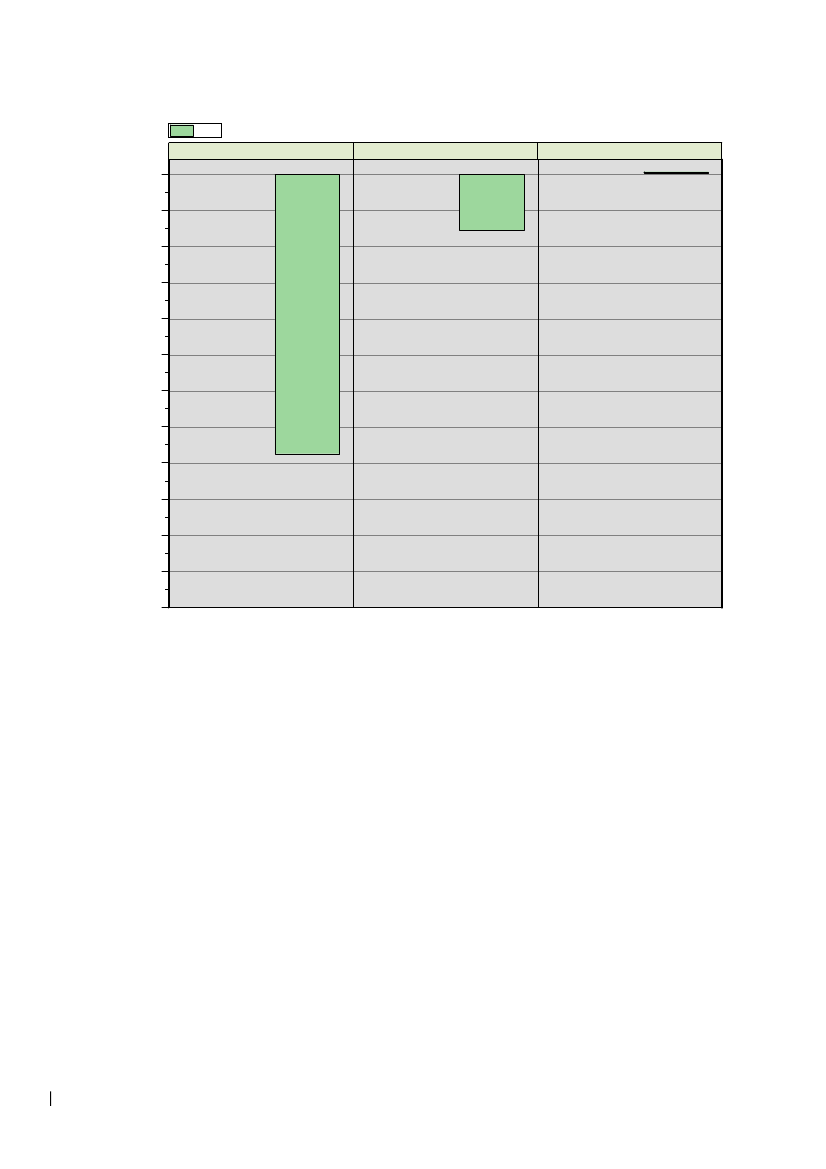

Table 7 – The potential number of cycles a packaging product assumed for reuse and recycling as

represented by a minimum and maximum limit for the selected packaging type and materials. The minimum

of two cycles represents a first cycle followed by a single reuse/recycling phase.

Reuse

Packaging material

Packaging type

Cycles

(min – max)

2 - 50

2 - 25

2-5

2 - 25

2 - 50

2 - 25

2 - 50

Recycling

Cycles

(min – max)

2 – 25

2–5

2–5

2 – 15

2 – 50

2 – 25

2 – 50

Plastic

(conventional, bio-based)

Fibre-based materials

(paper, cartonboard,

board)

Rigid

Flexible

Flexible

corrugated

Rigid

Rigid

Metal (steel, aluminium)

Glass

Flexible

Rigid

Every reuse and recycling phase is assumed to be associated with a mass loss, e.g. from discarding broken

packaging in the reuse scenario and processing losses in the recycling scenario. Thus the mass loss rate refers to

the rate at which a product losses mass over its life, in this case, quantified through the number of cycles. The loss

rate value is expressed in percentage and is assumed constant for every cycle. Moreover, being a function of the

number of cycles, it is included in the model as a variable parameter. Therefore, the mass loss rate at the individual

cycles is determined as follows:

Mass loss rate =

$%&'() +, -.-/(0

!""%

6.3 Weight of packaging products

In this study, data on the packaging weight was obtained from the literature and supplemented with sample

measurements of packaging products from Danish retail. To determine the weights of the selected packaging

22

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

products, a regular kitchen scale was used, and only the weight of the main material was considered while

excluding other packaging components such as lids and labels. The weights were then scaled linearly to

correspond with a standard volume of 1 litre following the defined FU. The scaling for packaging containing liquids

was done based on a linear correlation between material weight and volume. If the volume was not expressed in

litres, the packaging dimensions were measured to determine its capacity, which was then scaled to 1 liter. This

method ensured accurate and comparable estimates of the weight of the selected packaging products. Five

packaging products, e.g., bottle, jar, bag, per packaging type, were weighed per packaging material. The weight of

a product can vary due to its material and the manufacturing process. Therefore, the weight data are provided in

ranges.

In general, reusable packaging tends to be heavier than single-use packaging as it is designed to withstand multiple

uses and thus requires manufacturing with more material. Moreover, the estimated mass for single-use packaging

is an input for the recycling and incineration scenario, whereas the estimated mass for the multi-use packaging is

considered for the reuse scenario.

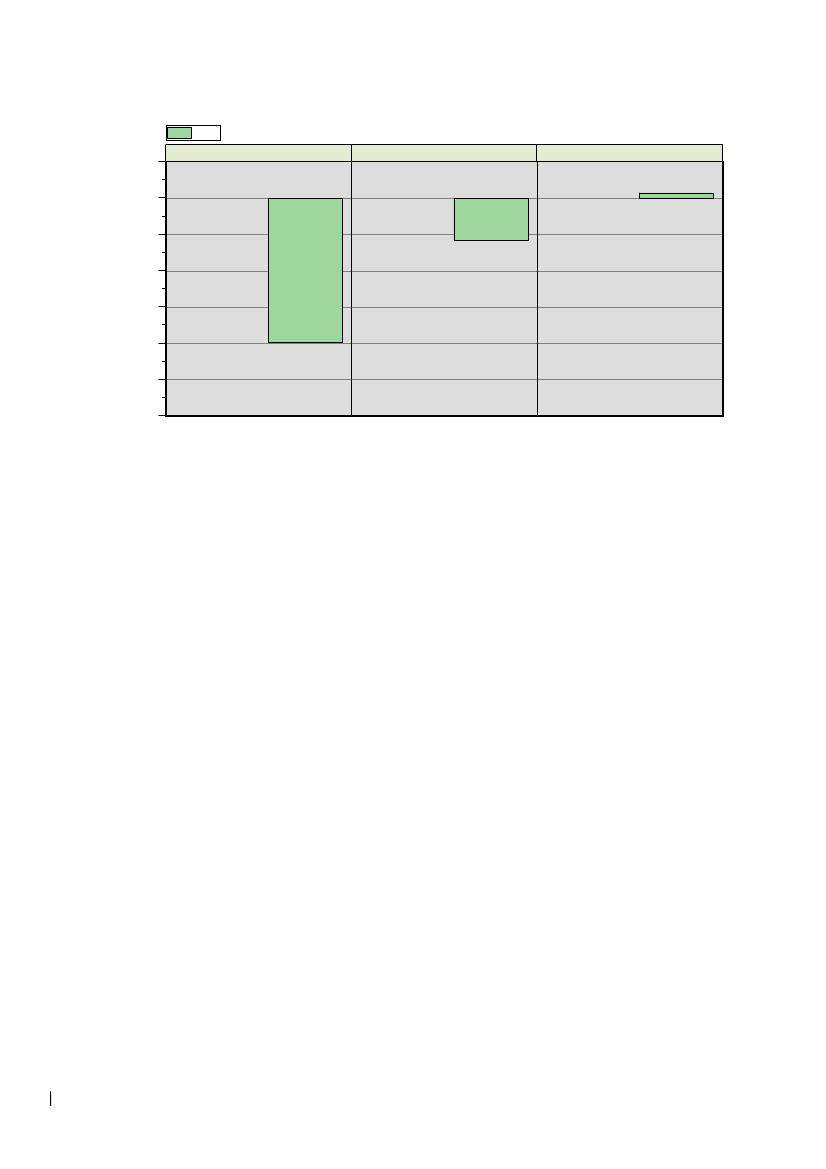

Table 8 outlines the weight data for packaging in line with the functional unit defined in this assessment, as

referenced in Chapter 4.1. The weight is expressed in kilograms per liter of contained packaging product.

Table 8 - Overview of packaging weight expressed in kg/L of contained packaging product.

Flexible

Recycling

and

Incineration

kg/L

(min-max)

0.01 – 0.08

0.01 – 0.05

-

-

0.01 – 0.08

-

-

Reuse

kg/L

(min-max)

0.01 – 0.1

0.01 – 0.08

-

-

0.01 – 0.1

-

-

Rigid

Recycling

Incineration

kg/L

(min-max)

0.02 – 0.2

-

0.02 – 0.08

0.02 – 0.1

0.1 – 0.3

0.1 – 0.3

0.4 – 1.7

and

Reuse

kg/L

(min-max)

0.02 – 0.4

-

0.02 – 0.1

0.02 – 0.2

0.1 – 0.4

0.1 – 0.4

0.4 – 2

Packaging Material

Plastic

Paper

Cartonboard

Corrugated board

Aluminium

Steel

Glass

23

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

7.

Interpretation of the results

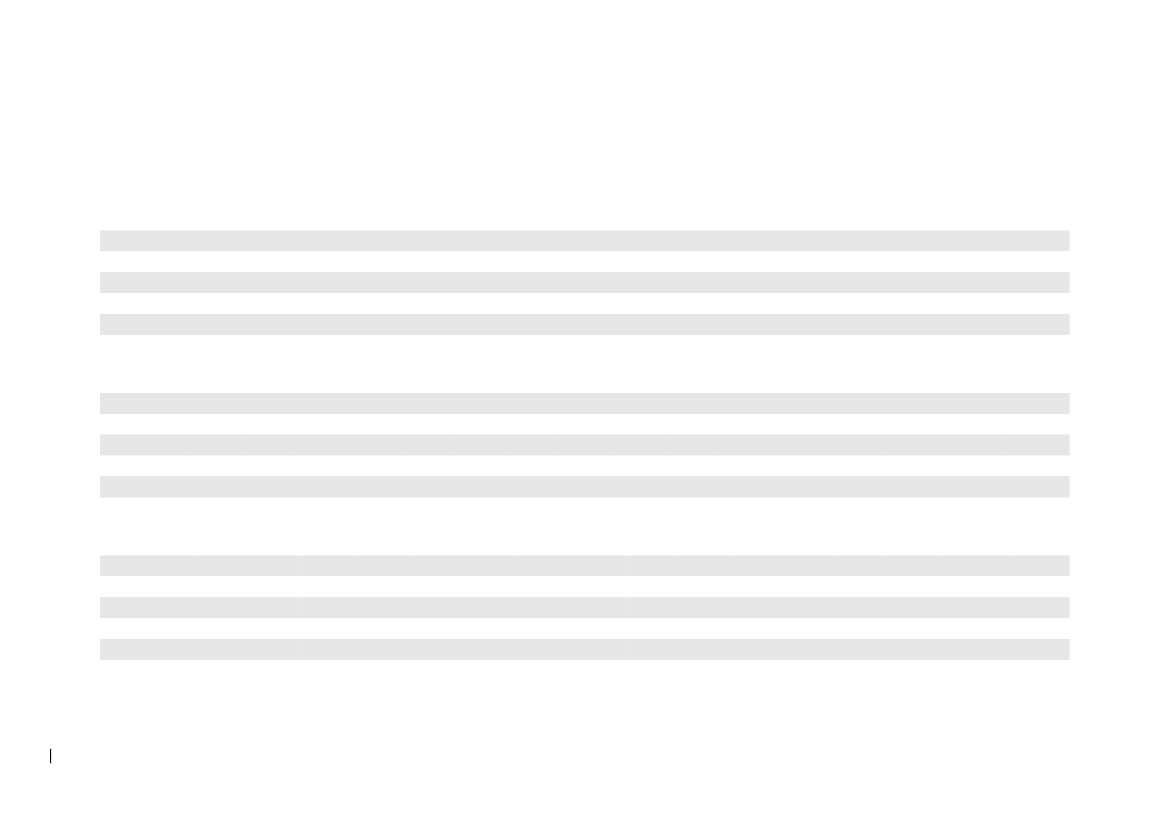

This chapter presents the potential environmental impacts, focusing on climate change impacts expressed as

kg CO

2_eq

/ FU by individual materials. The potential impacts for the other impact cathegories are presented in

tables in Appendix II, using characterized units.

In this chapter, the results are presented as intervals, one for each of the three end-of-life scenarios. These results

intervals represent 95% confidence intervals based on Monte Carlo simulations of the model with the included

parameter data and probability distributions. As such, the “bars” representing results for reuse and recycling in the

following figures are reflecting the ranges in potential number of cycles, i.e. if only a few reuse cycles take place

then the corresponding climate change impact will be in the higher end of the “bar” (see Table 7 for the included

ranges in number of cycles). No additional cycles (or loops) are included in the incineration scenario.

For each packaging material, the results are presented, comparing reuse, recycling, and incineration, with a

recycled content of 50%. This means that 50% of the plastic in the packaging is assumed from primary material,

while the other 50% is from recycled material. The green and orange bars represent rigid and flexible packaging

types, respectively. Moreover, note that numerically negative values in the LCA results indicate environmental

benefits or avoided environmental impacts, while positive values indicate environmental loads.

While evaluating the results in the following sections, it is important to note that potential savings or impacts related

to energy in all scenarios are limited due to the renewable energy sources applied in the modelled energy mix, in

alignment with the electricity and heat targets and forecasts for the temporal scope of 2020-2030 in the study.

7.1 PET

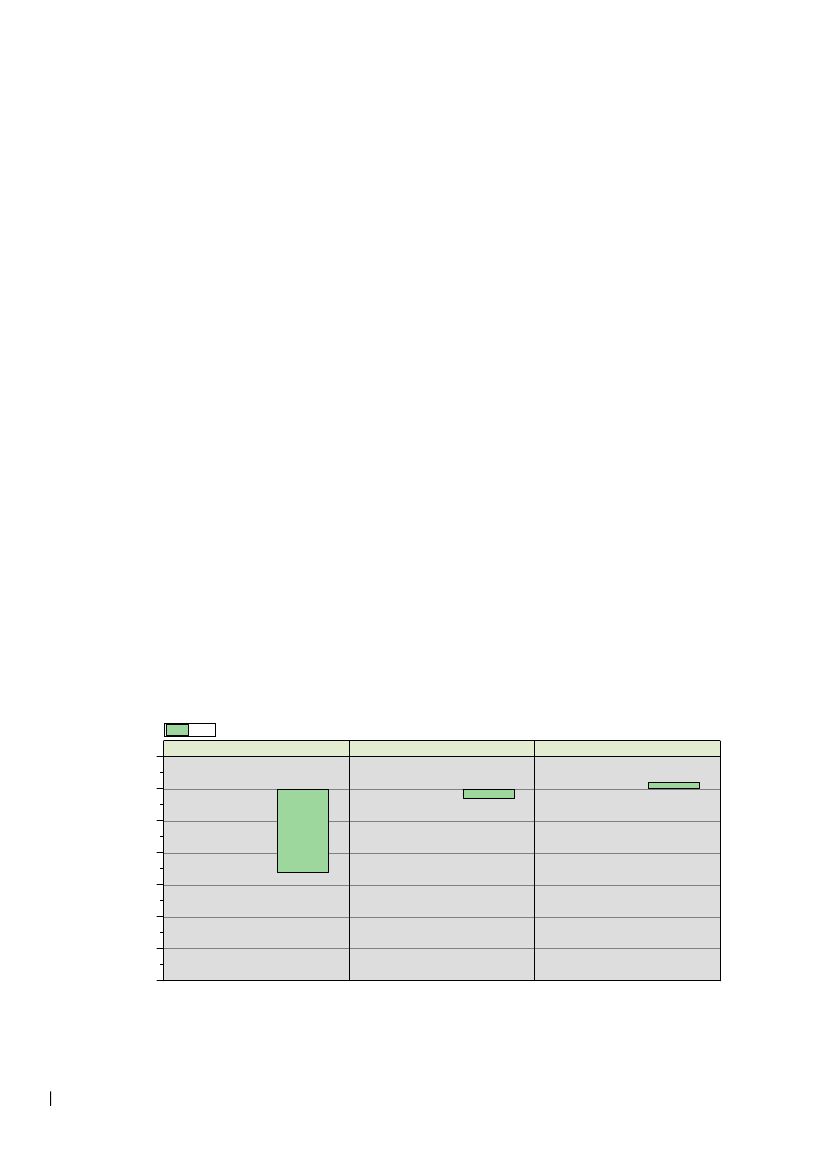

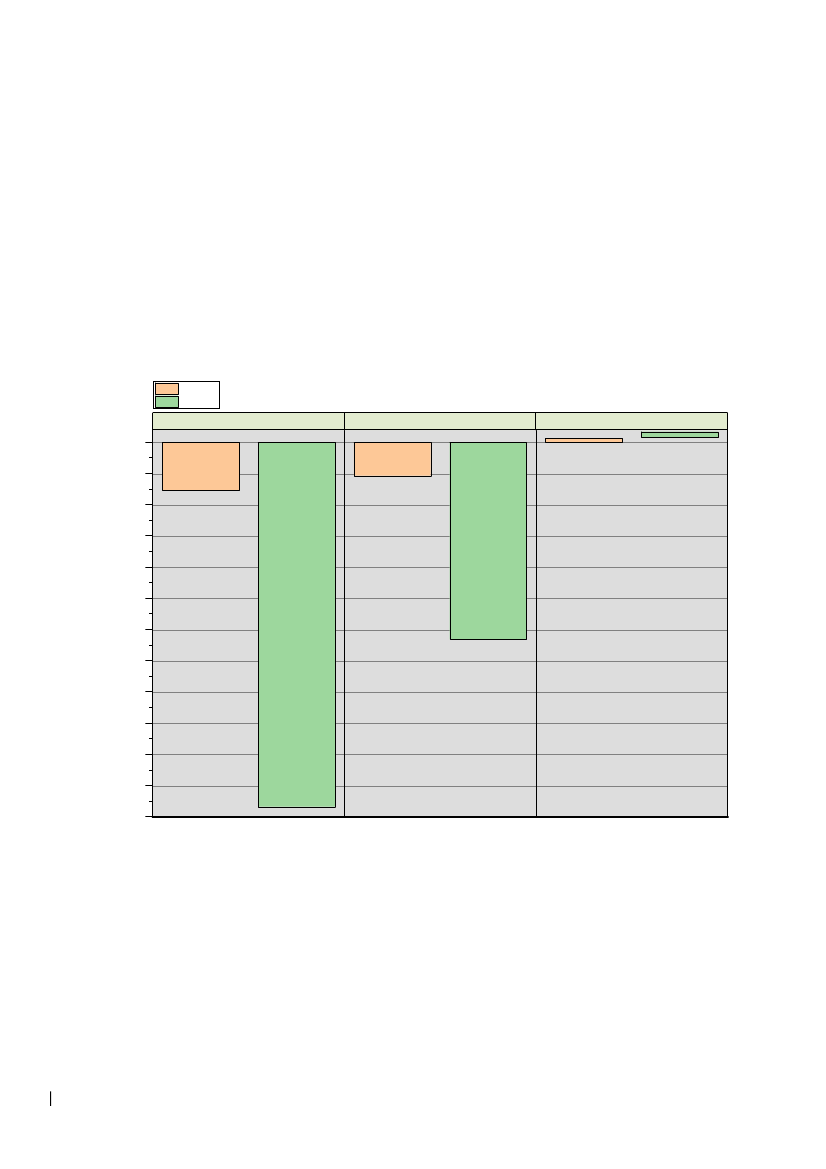

The impact of climate change caused by the full life cycle of rigid packaging products made of PET plastic is

depicted in Figure 6. The result intervals of the life cycle assessment indicate that both reuse and recycling result

in environmental benefits, while incineration represents an environmental load.

Rigid

5

0

-5

kg CO

2

-eq/FU

Reuse

Recycling

Incineration

-10

-15

-20

-25

-30

Figure 6 - Potential environmental impacts within climate change related to the production and end-of-life

management of rigid packaging products made of PET. The result intervals represent a 95% confidence

interval and are presented characterized as kg CO

2

equivalent per functional unit (FU).

24

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

Reusing rigid PET plastic packaging leads to the highest climate change impact savings, as this scenario reduces

the need for resource extraction and production of virgin PET packaging within every cycle. The high savings

observed in this reuse scenario can be attributed to the efficient recovery rate, which ranges between 89% to 93%.

Moreover, the preparation activities for reuse have a limited contribution to climate change.

Recycling rigid PET plastic packaging also results in climate change savings by avoiding the production of virgin

PET plastic due to the net benefits from recycling of secondary raw materials relative to the sorting and

reprocessing activities. Reprocessing requires more energy and resources than those involved in the reuse

scenario, resulting in lower overall environmental benefits. This difference in the results can be also attributed to

the fact that PET packaging has potential for more reuse cycles (2 to 50) than recycling cycles (2 to 25); the lowest

end of the result intervals illustrate the impact savings associated with the highest number of cycles in the two

scenarios.

Incineration of PET plastic packaging is the least favourable option causing net climate change loads to the

environment, mainly due to the relatively high concentration of fossil carbon converted into CO

2

during incineration.

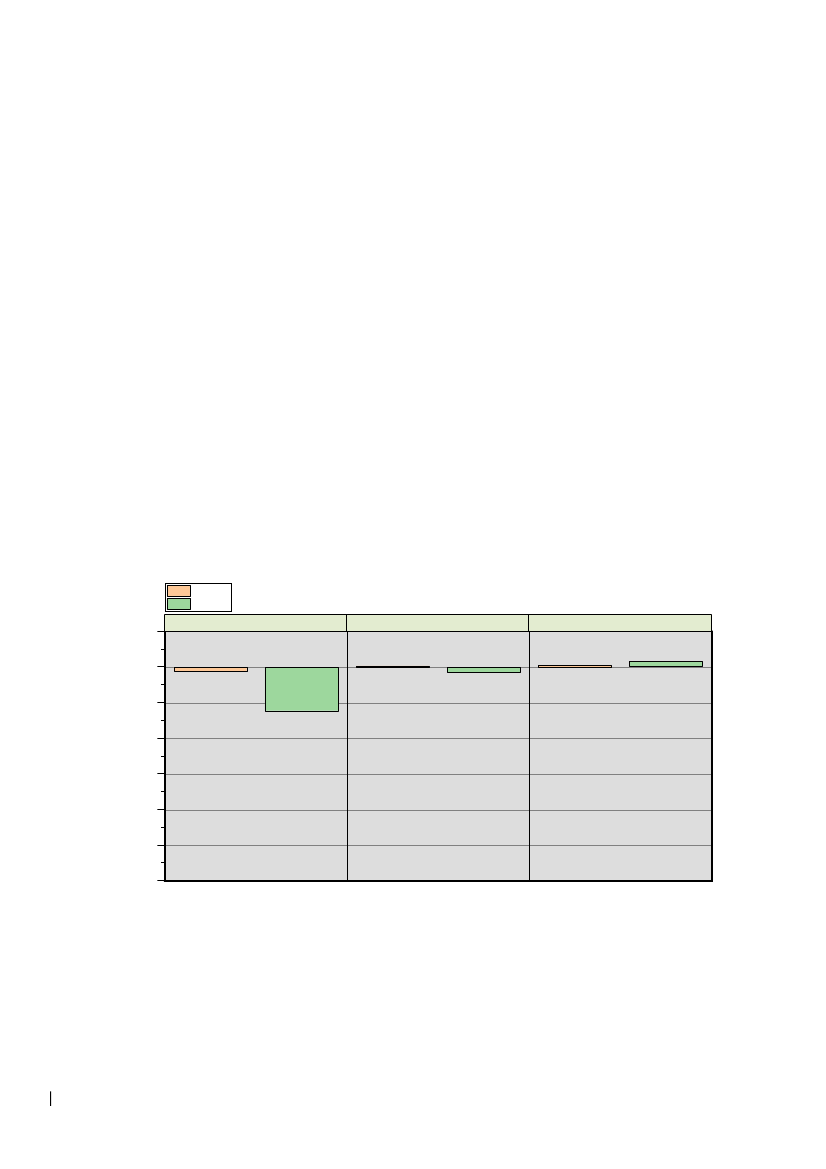

7.2 PE

The environmental impact on climate change of the full life cycle of both rigid and flexible packaging products made

of PE plastic is presented in Figure 7. Overall, the results indicate that reusing the packaging benefits the

environment the most, for both flexible and rigid plastic packaging. Recycling flexible packaging results in net-

positive impacts on the climate change potential score, and net-negative impacts for rigid packaging. The

incineration scenario has a harmful effect on climate change potential for both packaging types.

Flexible

Rigid

5

0

-5

kg CO

2

-eq/FU

Reuse

Recycling

Incineration

-10

-15

-20

-25

-30

Figure 7 - Potential environmental impacts within climate change related to the production and end-of-life

management of rigid and flexible packaging products made of PE. The result intervals represent a 95%

confidence interval and are presented as kg CO

2

equivalent per functional unit (FU).

Reusing PE packaging has a preferable climate change performance than recycling, both for rigid and flexible due

to: 1) reusing PE packaging is assumed to replace the production of new packaging from virgin materials at every

rotation, while recycling only avoids producing raw materials. In recycling, secondary materials are combined with

primary materials to produce new products, avoiding using only primary materials, promoting material circulation,

and partially lowering environmental emissions; 2) reuse has a higher recovery rate than recycling, ranging

25

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

between 89% and 93% for reuse versus 36% to 81% for recycling. With this regard, note that PE has a high fossil

carbon content, meaning that significant amounts of CO

2

are potentially released during the incineration of recycling

residues, reducing even more the benefits of recycling; 3) the CO

2

emissions released during the washing and

preparation processes are less than those for PE recycling. Recycling flexible packaging results in impacts on the

climate change score, while it is beneficial for rigid packaging. Although the production of flexible packaging has

an overall lower environmental impact compared to rigid packaging, rigid PE packaging is associated with the

lowest climate change potential due to its higher assumed number of cycles both in reuse (2 to 50 cycles) and

recycling (2 to 25 cycles) scenarios, compared to flexible packaging (2 to 25 cycles are assumed for the reuse

scenario and 2 to 5 cycles for the recycling scenario).

A significant distinction between the impacts caused by flexible and rigid PE packaging in every scenario also lies

in the amount of material required to fulfil the functional unit of this study. Specifically, less material is required for

flexible PE products resulting, depending on the scenario, in reduced climate change impacts or savings at every

rotation.

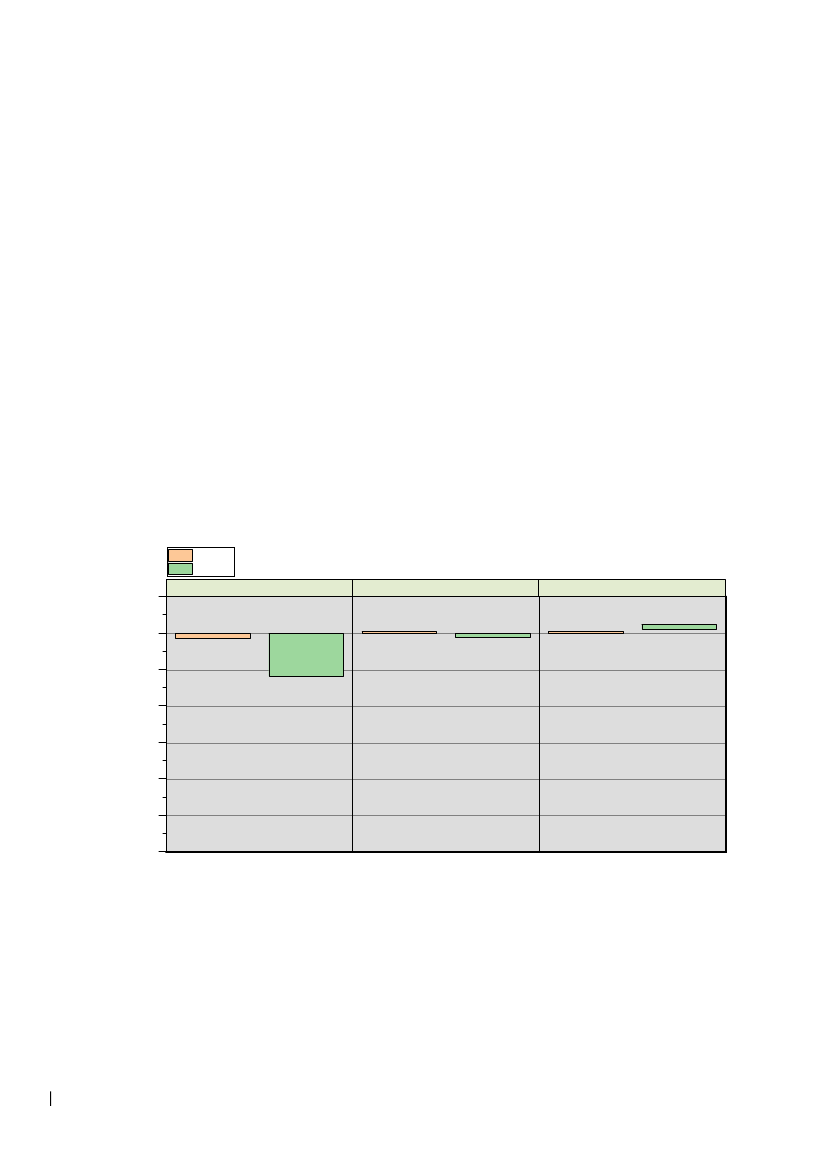

7.3 PP

The impact of climate change caused by the full life cycle of both rigid and flexible packaging products made of PP

plastic is depicted in Figure 8. The results show that the reuse of PP packaging offers the largest contribution to

avoiding climate change impacts for both rigid and flexible plastic packaging. While recycling contributes with net

climate change impacts for flexible PP packaging, rigid PP packaging represents net benefits. The incineration

scenario results in climate change loads for both types of packaging.

Flexible

Rigid

5

0

-5

kg CO

2

-eq/FU

Reuse

Recycling

Incineration

-10

-15

-20

-25

-30

Figure 8 - Potential environmental impacts within climate change related to the production and end-of-life

management of rigid and flexible packaging products made of PP. The result intervals represent a 95%

confidence interval and are presented characterized expressed as kg CO

2

equivalent per functional unit

(FU).

Reusing PP packaging has the highest climate change savings among the three scenarios due to the high

estimated recovery rate of 89% to 93%, versus 48% to 86% for recycling, and the low climate change potential

associated with washing and preparation activities. Recycling PP packaging results in savings in the case of rigid

products and in net positive impacts in case of flexible products, due to the different number of cycles. Both in the

reuse and recycling scenarios, PP rigid packaging has the lowest potential score for climate change due to its

higher estimated number of cycles, i.e. 2 to 50 for reuse and 2 to 25 for recycling of rigid PP packaging, compared

26

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

to 2 to 25 for reuse and 2 to 5 for recycling of flexible PP packaging. In addition, PP also has a high fossil carbon

content, meaning that significant amounts of CO

2

are potentially released during the incineration of recycling

residues, reducing the benefits of recycling. Reusing packaging avoids the need for producing new packaging while

recycling only reduces the demand for virgin raw materials. In the incineration scenario, PP rigid packaging is found

to result in a greater climate change potential emissions..

A significant distinction between the impacts caused by flexible and rigid PP packaging in every scenario also lies

in the amount of material required to fulfil the functional unit of this study. Specifically, less material is required for

flexible PP products resulting, depending on the scenario, in reduced climate change impacts or savings at every

rotation.

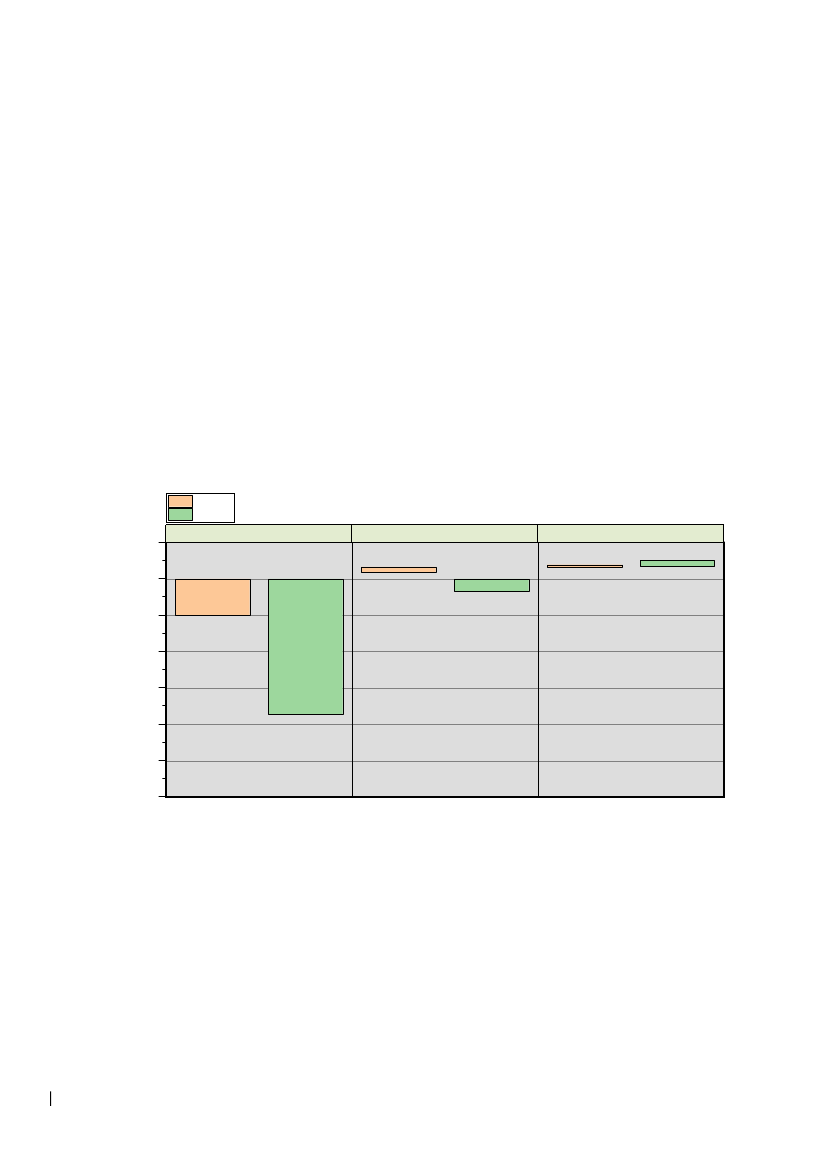

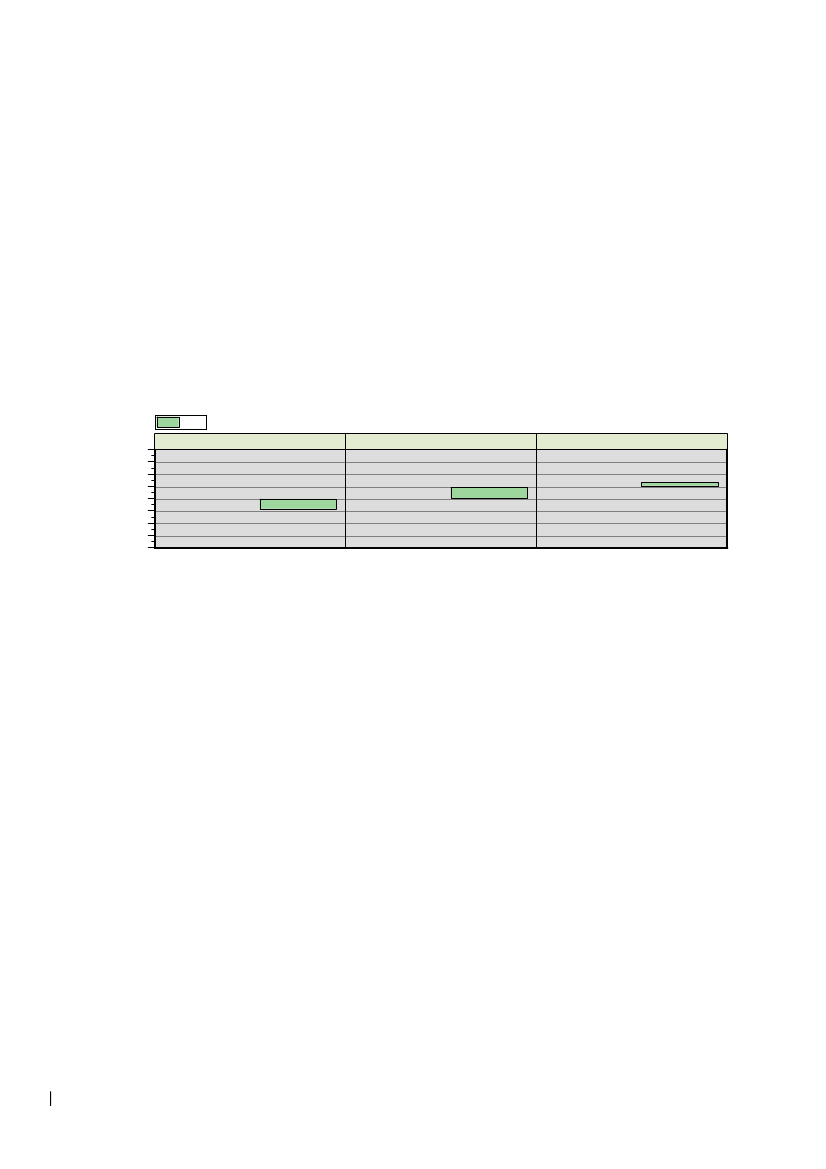

7.4 PS

The environmental impact on climate change of the full life cycle of both rigid and flexible packaging products made

of PS plastic is presented in Figure 9. Overall, the results indicate that the reuse of packaging has the most

significant savings on the climate change score, both for flexible and rigid plastic packaging. Recycling has net

positive emissions for flexible packaging, and net-negative emissions for rigid packaging regarding climate change.

The incineration of PS packaging has a damaging effect on the climate change potential for both types of

packaging.

Flexible

Rigid

5

0

-5

kg CO

2

-eq/FU

Reuse

Recycling

Incineration

-10

-15

-20

-25

-30

Figure 9 - Potential environmental impacts within climate change related to the production and end-of-life

management of rigid and flexible packaging products made of PS. The result intervals represent a 95%

confidence interval and are presented characterized expressed as kg CO

2

equivalent per functional unit

(FU).

Reusing both rigid and flexible PS packaging has the highest climate change savings compared to the other two

scenarios, due to the high estimated recovery rate, ranging from 89% to 93%, %, versus 34% to 64% for recycling,

and the limited climate change impacts associated with washing and preparation activities. Recycling PS packaging

results in net- negative impacts in the case of rigid products and in net positive impacts in the case of flexible

products. Both in the reuse and recycling scenarios, PP rigid packaging has the lowest potential score for climate

change due to its higher number of cycles, estimated to range between 2 and 50 for reuse and between 2 and 25

for recycling of rigid PS packaging, compared to 2 and 25 for reuse and 2 and 5 for recycling of flexible PS

packaging. In addition, PS has a high fossil carbon content, so a significant amount of CO

2

is released during the

27

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

incineration of the recycling residues, significantly reducing the benefits of recycling. Reusing also replaces the

need for producing new packaging, while recycling only reduces the demand for virgin raw materials. In the

incineration option, PS rigid packaging is observed to cause larger climate change impacts than flexible PS

packaging.

A significant distinction between the impacts caused by flexible and rigid PS packaging in every scenario also lies

in the amount of material required to fulfil the functional unit of this study. Specifically, less material is required for

flexible PS products resulting, depending on the scenario, in reduced climate impacts or savings at every rotation.

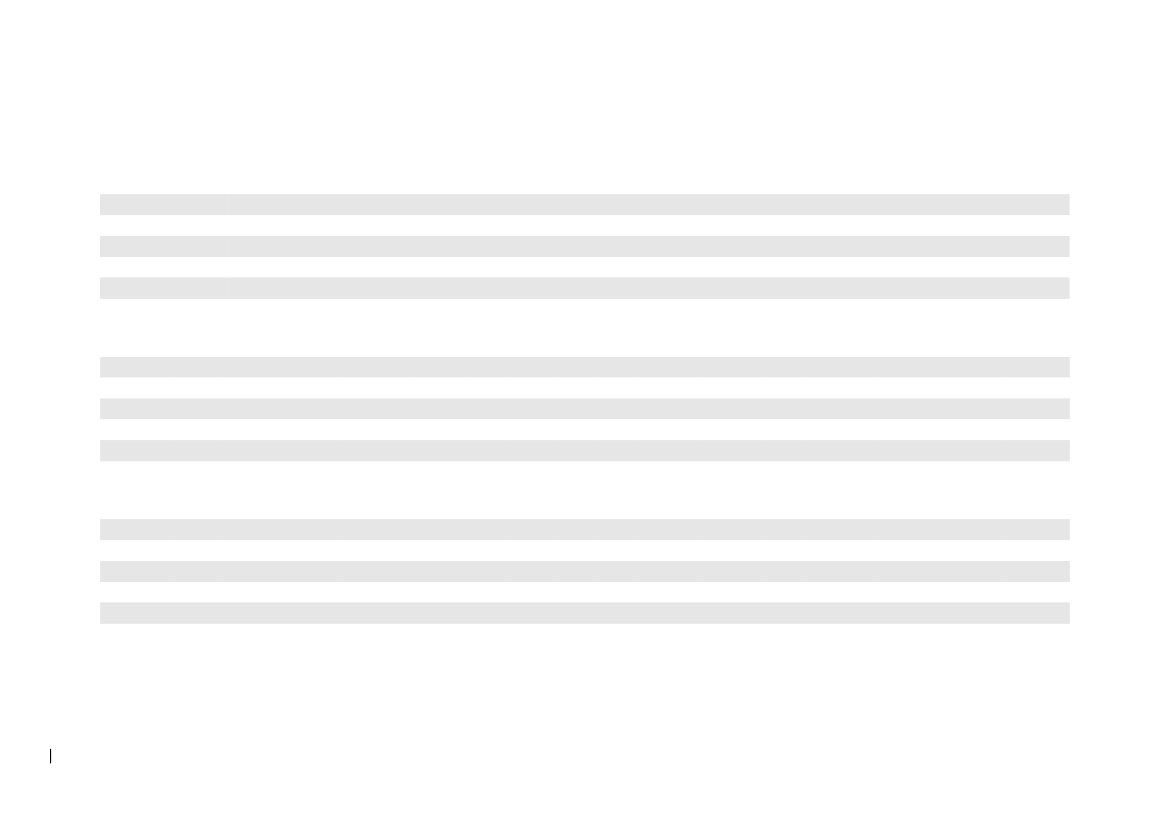

7.5 PLA

The environmental impact on climate change of the full life cycle of both rigid and flexible packaging products made

of PLA plastic is presented in Figure 10. Overall, the results indicate that reusing bio-based PLA packaging

represents climate change savings for both flexible and rigid types, while recycling of flexible packaging results in

net impacts on climate change, and savings for recycling of rigid packaging. Incineration of PLA packaging causes

burdens on the environment, albeit limited.

Flexible

Rigid

5

0

-5

kg CO

2

-eq/FU

Reuse

Recycling

Incineration

-10

-15

-20

-25

-30

Figure 10 - Potential environmental impacts within climate change related to the production and end-of-life

management of rigid and flexible packaging products made of PLA. The result intervals represent a 95%

confidence interval and are presented characterized as kg CO

2

equivalent per functional unit (FU).

Reusing PLA plastic packaging, both rigid and flexible, leads to the highest savings in the climate change, as it

reduces the need for resource extraction and production of PLA packaging at every cycle. Moreover, the

preparation activities for reuse have a limited impact on climate change.

Compared to flexible PLA packaging, PLA rigid packaging has the highest net-negative potential for climate

change. One of the reasons is its higher assumed number of cycles in both reuse and recycling scenarios (2 to 50

and 2 to 25, respectively) compared to flexible packaging (2 to 25 for the reuse scenario and 2 to 5 for the recycling

scenario).

PLA packaging is assumed to contain only biogenic carbon; no fossil CO

2

is released during incineration. Thus, the

benefits are associated with substituting marginal electricity and heat generated during incineration. However, the

net climate change impacts of the incineration scenario are still positive due to the impacts from producing the PLA

packaging.

28

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

A significant difference between the impacts of flexible and rigid PLA packaging in each scenario is related to the

quantity of material necessary to meet the functional unit criteria of this study. In particular, flexible PLA packaging

needs less material, which can lead to a cumulative decrease in climate change effects or savings at every rotation.

7.6 Cartonboard

The environmental impact on climate change of the full life cycle of rigid packaging products made of cartonboard

is presented in Figure 11. Overall, the life cycle analysis findings indicate that reusing and recycling cartonboard

packaging provide net-negative climate change potential emissions while the incineration of cartonboard packaging

causes burdens on the climate change score, albeit limited.

Rigid

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

Reuse

Recycling

Incineration

Figure 11 - Potential environmental impacts of climate change related to the production and end-of-life

management of rigid packaging products made of cartonboard. The result intervals represent a 95%

confidence interval and are presented characterized as kg CO

2

equivalent per functional unit (FU).

The repeated use of cartonboard packaging significantly reduces climate change, as it prevents consequtive

emissions from the production activities of virgin cartonboard packaging, such as deforestation and virgin pulp,

production and conversion into packaging processes. Recycling cartonboards has environmental benefits, as the

CO

2

emissions from the recycling processes are lower than producing new cartonboard packaging. Note that the

results between these two waste management options can vary due to the fact that corrugated packaging can be

reused more frequently (2 to 25 times) than it can be recycled (2 to 15 times).

kg CO

2

-eq/FU

7.7 Corrugated board

The impact of the full life cycle of rigid packaging products made of the corrugated board on climate change is

Carton board

illustrated in Figure 12. The analysis shows that reusing and recycling corrugated board packaging results in climate

change savings, while incineration of corrugated packaging has a relatively small impact on climate change.

Rigid

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

Reuse

Recycling

Incineration

Figure 12 - Potential environmental impacts within climate change related to the production and end-of-life

management of rigid packaging products made of corrugated board. The result intervals represent a 95%

confidence interval and are presented characterized as kg CO

2

equivalent per functional unit (FU).

29

kg CO

2

-eq/FU

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

The repeated use of corrugated packaging significantly reduces climate change, as it avoids multiple times

production of new corrugated packaging, more specifically, the emissions from the production activities of virgin

cartonboard packaging, such as deforestation and virgin pulp, production and conversion into packaging

processes. Recycling corrugated packaging is also environmentally beneficial as the CO

2

emissions from recycling

machinery and equipment are lower than producing virgin materials for corrugated packaging. It is noteworthy that

the results between these two waste management options can vary because corrugated packaging can be reused

more frequently (2 to 25 times) than it can be recycled (2 to 15 times).

7.8 Aluminium

The climate change potential for aluminium packaging products is presented in Figure 13. The life cycle

assessment results indicate that reusing and recycling rigid and flexible aluminium packaging has environmental

benefits, whereas incineration causes net climate change impacts.

Flexible

Rigid

Reuse

0

-5

-10

-15

-20

Recycling

Incineration

kg CO

2

-eq/FU

-25

-30

-35

-40

-45

-50

-55

-60

Figure 13 - Potential environmental impacts of climate change related to the production and waste

management of flexible and rigid aluminium packaging products made of aluminium. The result intervals

represent a 95% confidence interval and are presented characterized as kg CO

2

equivalent per functional

unit (FU).

Reusing rigid and flexible aluminium packaging leads to the highest savings in climate change potential due to its

high recovery rate ranging between 89% and 93% versus 60% and 99% for recycling and the limited environmental

impact associated with washing and preparation activities. Reusing both types of aluminium packaging replaces

the need for new virgin packaging, which typically involves energy-intensive processes.

From Figure 13, it can also be observed that rigid packaging has a higher net-negative potential for climate change

than flexible packaging due to its higher assumed number of cycles in both the reuse and recycling scenarios. The

30

MOF, Alm.del - 2023-24 - Endeligt svar på spørgsmål 393: MFU spm. om oversendelse af de i MOF alm. del - svar på spm. 277 omtalte livscyklusanalyser fra DTU, branchen og EU-Kommissionen

number of potential cycles for the reuse and recycling scenario ranges between 2 and 50 for rigid packaging and

between 2 and 25 for flexible packaging.