Transportudvalget 2013-14

TRU Alm.del

Offentligt

Surveillance ReportPackage / Item:

Bascule span to the Railway bridge “Jernbanebroen over Limfjorden”MT Højgaard

Supplier:

Purpose of visit:Location /Address:

Production & Quality Surveillance – Steel structureVisit No. 3TarconTarnobrzegPoland2012-09-05 to 2012-09-06SISJIDID2012-09-10SISJ/IDRambøll

Date of Visit / Review:Inspector:Checked:Approved:Date issued:Distribution:

Copy to:

Torben Ulrik JallerBent JensenKenneth SørensenKnud V ChristensenFinn Juel HansenPer GehlertJesper LawaetzSøren SommerMogens Højen OlsenSimon Sterndorff JessenSøren DuusInge Damsgaard

BanedanmarkBanedanmarkBanedanmarkBanedanmarkMT HøjgaardMT HøjgaardMT HøjgaardMT HøjgaardRambøllRambøllRambøllRambøll

IntroductionThis report is the result from the third visit of the client’s supervision and control (performed by Rambøll) at Tarcon inPoland the 5 of august to the 6 of august 2012. The purpose of the visit was to follow up on the issues from the first andsecond visit, the quality documentation and the quality plan for steel structure that is required in connection with executionof the new bascule span to the Railway Bridge “Jernbanebroen over Limfjorden”. For further details concerning thesubject and content please refer to the document LF00011-1-ID dated 2012-06-21 concerning QA-STEELMANUFACTURING and Surveillance Report No_ 02_B-Ram-S018 - 12518016G-LF00013-1-ID dated 2012-07-23concerning the first visit at Tarcon and Surveillance Report No. 02 - 12518016G-MB00017-2-ID.pdf concerning thesecond visit.

12518016G\MB00017-2-ID

Page 1 of 7

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

SummaryOverall impression is still that the execution of the steel work is at a high quality. Though, a concern is that severalimportant parts of the procedures and the quality control are still missing or are not yet completed even thought it havebeen commented several times.Generally, the majorities of the comments from Rambøll haven't been answered with a fulfilling answer, and after visitingthe production it is clearly that the comments haven't been successfully implemented. This concerns especially commentsto the welding plans, WPS`s and WPQR`s, NDT, time schedule and drawings.At this inspection at Tarcon Rambøll found that Tarcon had started on welding without a welding plan, furthermoreRambøll had some additionally comments to the WPS`s and WPQR`s. The WPS`s in the production was not coherentwith the WPS`s received from MT Højgaard, It is urgent that MT Højgaard is aware of which WPS`s that are used..Concerning NDT and laminations test Tarcon informed that the plates aren't tested according to the control leveldemanded. These issues are not acceptable and shall be corrected immediately.Rambøll had also a few major comments to the drawings. Based upon a trial test the revision in the production wasn’t thenewest. Rambøll have also asked for the drawings that shows the connections between the elements, but have neverreceived these.To meet the tight time schedule Tarkon are working on 3 shifts, this makes it even more important that MT Højgaard actson the comments immediately,Even though Tarkon works with a quick pace, Rambøll estimate that production is about 2-3 weeks delayed compared totime schedule from MT Højgaard version 7.Total time for the inspection was approximately 8 hours at the shop.

ReportParticipants from Tarcon

Romuald PaweletKarol VdjcickiGregour PanekChief of project engineeringProject managerWelding engineer

MT HøjgaardSvend Schneider Eliasen QHSE ManagerSøren SommerForman / inspektorBanedanmarkBent Jensen

Construction manager

General comments concerning the first surveillance report from 23/07-2012

Generally, the documents that Rambøll ask for at the first and second visit have not been answered with a fulfillinganswer, so the majority of comments from the first and the second are still relevant and have not been corrected andimplemented. This is concerning because a lot of the comment have influence at the quality. MT Højgaard informedRambøll that some of the documents are still in progress of being finished and will be forwarded soon.Rambøll commented again that all documents and information that is required shall be sent/forwarded by email..\\Dkramaalfil01\sagarkiv\2012\12518016G\dok\MB00018-1-SISJ.docx

Page 2 of 7

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”Information of the subcontractor Tarcon

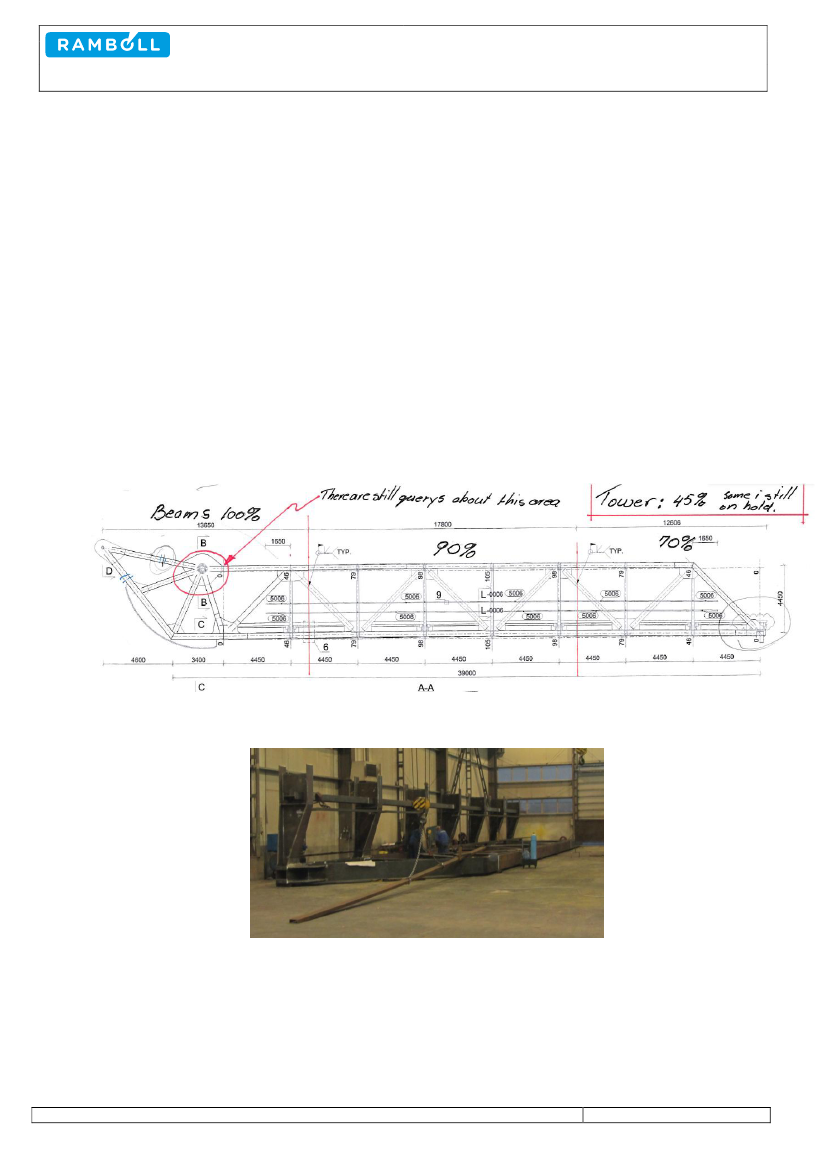

Time schedule for productionTime schedule for:MT Højgaard showed Rambøll a drawing with stage of progress. Rambøll estimate that production is about 2-3 weeksdelayed compared to the time schedule version 7. It is important that MT Højgaard makes a new time schedule that isupdated, because the schedule is used to coordinate with other projects on the site location. Svend Elias from MTHøjgaard promised that a new time schedule will be forwarded to Rambøll the 06-09-2012.Tarcon estimated the following milestones:First bridge elements leaving Tarcon, week nr. 38-39Last bridge element leaving Tarcon, week nr. 42The tower is send sometime between week nr. 39-42, but before the last bridge element. (Some parts are still onhold, this can affect the time schedule)In addition to the week number stated above the transport time from Tarkon to Alborg is estimated to 5 days.To make it possible for Rambøll to follow the stage of progress, Rambøll has required that MT Højgaard sends somepictures showing stages of progress approximately every second day.Stage of progress at the visit

None of the elements have got any surface treatment yet. Rambøll was informed that it takes approximately 7 days tosandblast and paint an element.

Trial assembleNumber of metal workers, welders and painter on the job:The number of welders has gone from approximately 13 to 24 welders that are working on the project. A new welders listwas received at the visit.

\\Dkramaalfil01\sagarkiv\2012\12518016G\dok\MB00018-1-SISJ.docx

Page 3 of 7

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”Shop drawings and constructionShop drawings:Rambøll was informed that MT Højgaard has implemented a new system for revision control, and that Niras now controlsall drawings from MT Højgaard Vietnam. Some documentation showing the control system will be forwarded.Based on a trial test Rambøll found that some of the drawings in the production weren't the newest revision. This is notacceptable and shall be corrected.

Drawing note from one of the drawings at the shop, the newest revision for this drawing was the 2012.08.31.Rambøll showed concern about the execution of some of the connections with K butt welds, for example detail 1 and 2 ondrawing nr. Bro-21214-2012-015. Tarkon agreed that there are some problems about some of the connections that haveto be solved, and that they have contacted MT Højgaard for a solution to some of these problems. Rambøll find it urgentthat a solution is found and that NIRAS has to be involved.As required at second visit drawings showing the connections between the 8 bridges parts shall be forwarded.Erection, installation transportWay of transport:By truck from Tarcon to Aalborg, the bridge will be divided in 8 parts with maximums lengths of 4.5x3x17m, it has beendecided that the tall part is to be divided in total 4 parts. Brackets are still under consideration. Tarcon is working with atransport company that is specialized in special transport, and has started the progress of getting a transport permit thatgoverns from Tarkon to Aalborg Harbor.JointsField welded joints:After the first visit Rambøll asked for a verified WPS`s for site welds, including necessary weather protection suitable forthe decided weld process and a description of an appropriate treatment of the field weld zone. Rambøll hasn't receivedthis and find it important what it is ready and approved before the work on site starts.QA and execution in shopSuitability of equipment for thermal cutting:Rambøll was informed that only gas cutting with propane gas was used. Based on a trial test in the shop Rambøll has nocomments.Traceability – principle of marking of items:Based on a trial test in the shop, Rambøll found that only pen markers were used, and a logbook with notes about whichwelds each welders had produced were shown. Based on a trial test Rambøll has no comments.Rambøll was informed that scrapped elements has removed from production and placed separate in the production. Andno further elements have been scrapped since the second visit.Sharp edges to be rounded to radius 2 mm:Based on trial test on some of the elements Rambøll has no comments.

\\Dkramaalfil01\sagarkiv\2012\12518016G\dok\MB00018-1-SISJ.docx

Page 4 of 7

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”Pressure test:Some box and pipes profiles had been closed before the visit, but pressure test hadn’t been made yet. A report shall beforwarded to Rambøll as soon as Tarkon starts performing pressure tests.Procedure for flame straightening:Rambøll was informed that flame straightening had been used. An inspection report, according to EN1090-2 section6.5.3, shall be forwarded to Rambøll.NDT:At the shop Rambøll found traces after MPI testing on both stump and fillets welds. Tarcon showed Rambøll logbooksand drawings showing which element that was tested together with an inspection report. Rambøll emphasized theimportance of testing on mixed lots. Based on a trial test Rambøll has no further comments.After last visit Rambøll commented on the extent of NDT, and that it is determent by the welds coefficient of utilization,Niras has afterwards informed at all welds has a coefficient of utilization over 50 %, and that all butts welds will be testedby MPI. Rambøll has no further comments.Rambøll have received a NDT plan where the quality level is stated as B and not B+ as required. At the visit Rambøll wasinformed that it was only a typing mistake and Tarkon showed some NDT reports that stated quality level B+. Rambøllcomment that the NDT plan shall be corrected, so further confusion is avoided.Tension force perpendicular to surface:At the first visit Rambøll commented that UL-examination shall be according to EN 10160, class S2, and all places thathas to be tested shall be shown on the constructions/workshop drawings. Rambøll was informed that Niras has stated onthe drawings where lamination testing is required Based on a trial test of the drawings Rambøll has no comments. Tarconinformed Rambøll that all plates over 20 mm that is delivered UT tested don't fulfill the demanded quality level S2, butonly S1. This is not acceptable.Rambøll asked if the need for materials with improved though thickness properties had been examined, according to EN1993-1-10. Rambøll was informed that MT Højgaard would investigate if this issue has been solved.

Notes from the NDT inspectorWelding procedures, welding planWeld plan:Rambøll found that Tarcon has started welding on the tail section and the tower without a welding plan. This is notacceptable and shall be corrected immediately. MT Højgaard has informed Rambøll that they check that the right WPS`sare used, but how is this possible when there is no welding plan, telling which WPS`s and which welding sequence thatshall be used?A welding plan for the northern end section was shown but it was in polish so this needs to be translated to English.Svend Eliasen promised that the welding plan for the onsite welds will be forwarded before the work starts in Aalborg. Inthe tender material it states that the welding plan shall be forwarded to Rambøll before they start welding.After the first and second inspection Rambøll wrote that the welding plan shall fulfill the requirement in EN 1090-2 section7.2.2 and EN ISO 3834-2 section 10.1 and include; Preheat of tack welds, removal of tack welds when performing finalwelds, minimizing of distortions, sequence of welding, intermediate NDT checking, turning of components during welding,welding positions, avoid of lamellar tearing, acceptance criteria level B+ for welds (highest level)\\Dkramaalfil01\sagarkiv\2012\12518016G\dok\MB00018-1-SISJ.docxPage 5 of 7

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”Rambøll had the following comments to the welding plans received from Tarcon.The need for run off and on plates shall be stated (Rambøll found that Tarkon uses run off and on plates)The need for geometric control measurement shall be statedA description of the controls that the welding engineer has to make.NDT testing shall be made intermediate and not only after the entire section is finished.WPS:At the inspection in the production Rambøll found several WPS`s that wasn’t coherent with the WPS`s found on MTHøjgaard`s FTP server. Rambøll find it concerning that the impression is that MT Højgaard doesn't know which WPS`sthere is used and valid for this project. Rambøll has several times asked for a list showing which WPS`s and coherentWPQR`s that are used on this project. Svend Elias from MT Højgaard couldn’t show Rambøll this list but informedRambøll that this list is 95 % finished, so it should be possible to forward this list to Rambøll soon. Rambøll havecommented that the WPS list shall include which WPS`s there have been deviated from, and which new WPS`s andcoherent WPQR`s that will prove that the deviation is acceptable.Rambøll find it urgent that MT Højgaard immediately makes sure that it is the right WPS`s that is used and placed inproduction.At the second inspection at Tarcon Rambøll found that Tarcon deviated from some of the WPS`s with a high preheat.After the second visit at Tarcon Rambøll required that MT Højgaard investigated where Tarcon had made deviations fromthe WPS`s. Rambøll has several times commented on that several of the WPS`s placed on the FTP server still has a highpreheat, and some of the additional WPS`s found in production have also a high preheat. Rambøll was informed that MTHøjgaard is still working on a report; this shall be forwarded to Rambøll as soon as possible.After the second visit at Tarcon Rambøll had the following question to the deviation rapport; is it correct that the HV differsa lot from EN 15614 table 2? This question still needs to be answered.The welding engineers check:At the second inspection in the shop Rambøll asked for some documentation from the welding engineer showing thatthey control arc voltages, travel speed, preheat and welding sequence etc. The only documentation that was shown wasa log with the elements numbers and coherent WPS and the engineer's signature. This documentation is not fulfilling, itshould include the results from the required control in3834-2 section 14.3.At this inspection Rambøll found that the welding engineer still doesn't document that they make the required control. It isurgent that this I corrected immediately, it is not possible to make this control later. This control is also important toregistered where Tarkon deviates from the WPS`s.Qualification test of welders according to EN 287:At the inspection in the shop Rambøll made a trial based test to check that the welders working on the project arecertified by EN287 and present on the newest welder list. Welder Andrzej Kianowski with welder number S18 and PawelPluta with welder number S17 were checked. At the shop Rambøll received the newest welder list and the checkedwelders were stated on the new list, and they are both certified to weld in the checked welding position. At the finaldocumentation shall Tarcon include the welder list including certificate. Based on a trail test Rambøll has no furthercomments.Tack welds:By a trial based testing Rambøll found that tack welds was made minimum 50 mm long and was removed before the finalwelds is performed. Rambøll has no comments.

Does the individually welder possess the WPS?The project specified WPS`s were shown by the production manager, and they were placed on a table in the productionshop.

\\Dkramaalfil01\sagarkiv\2012\12518016G\dok\MB00018-1-SISJ.docx

Page 6 of 7

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”The folder containing the project specified WPS`sSurface irregularities:Based on a trial based test at the shop, the surfaces irregularities are repaired.Sub-contractorsTarcon informed Rambøll that they considered using subcontractors for the details concerning the main bearings.Rambøll asked that information on the subcontractor will be forwarded to Rambøll...Surface treatmentPaint system:Tarcon has got an approval for the painting system. The paint wasn’t delivered yet.Rambøll has required that a test plates according to En 12944 is forwarded before the paint work on the bridges sectionsstarts.

\\Dkramaalfil01\sagarkiv\2012\12518016G\dok\MB00018-1-SISJ.docx

Page 7 of 7