Transportudvalget 2013-14

TRU Alm.del

Offentligt

Surveillance ReportPackage / Item:

Bascule span to the Railway bridge “Jernbanebroen over Limfjorden”MT Højgaard

Supplier:Purpose of visit:Location /Address:

Production & Quality Surveillance – Steel structureTarconTarnobrzegPoland2011-09-15 to 2011-09-16SISj/MHO/IDIDSDU2012-07-20SISJ/IDRambøll

Date of Visit / Review:Inspector:Checked:Approved:Date issued:Distribution:

Copy to:

Torben Ulrik JallerBent JensenKenneth SørensenKnud V ChristensenFinn Juel HansenPer Gehlert

Jesper LawaetzMogens Højen OlsenSimon Sterndorff JessenSøren DuusInge Damsgaard

BanedanmarkBanedanmarkBanedanmarkBanedanmarkMT HøjgaardMT HøjgaardMT HøjgaardRambøllRambøllRambøllRambøll

IntroductionThis report is the result from the first visit of the client’s supervision and control (performed by Rambøll) at Tarcon inPoland in the period of the 18-19th July 2012. The purpose of the visit was to follow up on the quality documentation andquality plan for steel structure that is required in connection with execution of the new bascule span to the Railway bridge“Jernbanebroen over Limfjorden”. For further details concerning the subject and content please refer to the documentLF00011-1-ID dated 2012-06-21 concerning QA-STEEL MANUFACTURING.

Page 1 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

SummaryOverall the impression is that Tarcon is capable to perform large and complicated steel structures. The shop seemed wellorganized and with competent staff.During the inspection Rambøll observed, that the standard for execution of steelworks EN 1090-2 was reasonably usedand implemented in the shop. Furthermore the standard EN/ISO 3834-2 for "Comprehensive Quality Requirements" wasreasonably implemented for the welding of steel structures.Tarcon has several welding engineers IWE or EWE to perform the daily welding coordination in the shop.Rambøll had a few major comments to some missing verification of the WPS` and the missing QA plan. These items arevery urgent and need to be corrected as soon as possible.Total time for the inspection was 6 hours at the shop.

ReportParticipants from Tarcon

Romuald PaweletKarol VdjcickiGregour PanekMarcin KoscielniakPiotr KopeiChief of project engineeringProject managerWelding engineerProduction managerQA-responsible

Information of the subcontractor Tarcon

Number of metal workers, welders and painter:400 in total, 100 welders, 20 painters, 4 sandblastersProduction per year in tons steel:500-800 T per month.Production facilities:Approximately 100x100m shop with several travelling crane, own paint shop and sandblasting shop.\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 2 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

Shops with several travelling craneMaterialsDelivery requirements:MT Højgaard has forwarded inspection documents according to EN10204 before the meeting. Based upon a trial test,Rambøll has no comments, the steel qualities are S355J2N according to EN10025 and technical delivery conditions EN10163 for surface conditions are mentioned.Shop drawings and constructionShop drawings:Examples of shop drawings from MT Højgaard Vietnam and cutting drawings from Tarcon were shown at the meeting. Onthe drawing note Rambøll shall be changed to MT Højgaard Vietnam. Based upon a trial test, Rambøll has no furthercomments.

Shop drawings from MT Højgaard Vietnam

Time schedule for productionTime schedule for:Stage of progress - approximately 5 % cutting is finished.

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 3 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

Cut plates for this project

Cutting/single part drawing from TarconNumber of metal workers, welders and painter on the job:Approximately 5 persons.Erection, installation transportWay of transport:By truck from Tarcon to Aalborg, the bridge will be divided in 6 parts with maximums of 4.5x3x17m, brackets are underconsideration.JointsField welded joints:Tarcon/MT Højgaard shall forward a verified WPS for site welds. This shall include necessary weather protection suitablefor the decided weld process. Tarcon informed Rambøll that joint preparation including sandblasting will be finished atshop. The steel profiles will be covered by adhesive plastic. The description of an appropriate treatment of the field weldzone will be forwarded.Bolted joints:If bolted joints are chosen at transversal beams under track, Rambøll was informed that Tarcon delivers the plates andMT Højgaard delivers the bolts.

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 4 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”QA and execution in shopImplementation of EN 1090-2:The standard seems to be well implemented and known in the shop.

EN 1090-2 on the QA inspectors table, it seemed well usedSuitability of equipment for thermal cutting:Gas cutting with propane gas is used; the quality seems to be acceptable. Plates thinner than 12 mm are cut by shearingand additionally grinded. Tarcon were aware of the risk of hardening when cutting thick plates. Rambøll was informed thatwater cutting at a subcontractor is used at thick plates to avoid preheat at gas cutting.Comment after the meeting: According to VD-AAB-Steel work section 3.2.4 shearing is only permitted for 8 mm platesand minor plate thicknesses. I.e. shearing is not permitted on this project.Traceability – principle of marking of items:Rambøll was informed of the procedure for traceability, and find it acceptable.Hard stamps are not allowed according to VD, AAB Steelworks section 3.2.1. Pen markers shall be used for welder'ssignature on the steel surfaces. Rambøll was informed that welders ID additionally will be noted on the productiondrawings.

Examples of items numbers on plates.

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 5 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

Hard stamps used on another projectsSharp edges to be rounded to radius 2 mm:Rambøll was informed that Tarcon is aware of this requirement. This will be checked at next inspection.Pressure test:Pipes and box profiles shall be closed and pressure tested, according to BD-SAB section 2.1.Procedure for flame straightening:Rambøll received a procedure for flame straightening. Tarcon needs to perform inspection report for each flamestraightening according to EN1090-2 section 6.5.3. Rambøll has no further comment based on a trial test.Contractors plan of QA:Rambøll was informed that a QA plan will be forwarded at the end of week 30. After the meeting Rambøll has thefollowing comment: Tarcons QA plan should have been forwarded before the start of the production, urgent.NDT:NDT will be performed according to EN/ISO 17635. Certificates for level 2 and 3 inspectors have been forwarded toRambøll. Tarcon informed that the examination organization is independent of the production.Examination methods, extent of NDT, test methods; MT, UT and VT at butt welds, test methods MT and VT at fillet welds.The NDT personal are aware of necessity of inspection lots. Extend of NDT shall be according to EN 1090-2 table 24.NDT-planRambøll received a copy of the NDT plan. Rambøll has no comment based on a trial test.NDT-reportsWill be checked at next inspection.Minimum hold times before execution of NDTRambøll was informed that NDT will be executed minimum 24 hours after welding.Tension force perpendicular to surface:UL-examination according EN 10160, where shown on the project drawings from Niras, class S2 is required. This will bechecked at next inspection.

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 6 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”Welding procedures, welding planWPS:Tarcon showed WPS and WPQR verification tests for the project. Rambøll had the following comments:WPS no. KAT 10-707 is verified according to DnV. This differs to the required EN 15614. Tarcon shall perform adeviation report.The welding engineer showed a WPS for butt welds in 50 mm plates with a preheating of 150 degrees celcius.The welding engineer informed Rambøll that butt welds in 20-40 mm plates will be performed with preheating ofapproximately 75 degrees celcius. A WPS for this type of welding was missing. Tarcon shall forward anadditional WPS for butt welds in 20-40 mm plates.On WPS no. 87/09 and no. 24/09, shall the travel speed, heat input and allowable wearing (maximum width ofrun) be stated. This shall be according to the WPQR. This comment governs for all WPS where relevant.During the next visit at the shop, Rambøll will inspect that the welding inspector or the welding engineer from Tarcon willcheck the essential parameters for the welding process. Reference is made to EN ISO 3834-2 section 14.3 ( check ofcurrent, arc voltage, travel speed, preheat and welding sequence etc.). Rambøll will furthermore inspect, that the abovementioned check are reported and documented.

Weld plan:Rambøll received a welding plan from Tarcon. After the meeting Rambøll has the following comments.The welding engineer informed Rambøll that an additional drawing will be performed for showing WPS numbersand welding sequences.The welding plan shall fulfill the requirement in EN 1090-2 section 7.2.2 and EN ISO 3834-2 section 10.1 andinclude; Preheat of tack welds, removal of tack welds when performing final welds, minimizing of distortions,sequence of welding, intermediate NDT checking, turning of components during welding, welding positions,avoid of lamellar tearing, acceptance criteria level B+ for welds (highest level)Ref. to WPS no. 16/9 shall be changed to WPS no. 138/10 on the welding plan by Tarcon.During the inspection Rambøll had some serious comments to the WPS’s and the WPQR’s. At latest the 26. th of Julyand before proceeding of the weldings on the actual project MT Højgaard / Tarcon shall forward the revised welding planincl. WPS’s and WPQR’s. to Rambøll.Calculation of preheat temperature according to EN 1011-2:The welding engineer showed DS/EN 1011-2 for calculation of preheat temperature. Rambøll has no comment.Deformations of plates and profiles caused by weldings, overlength at shopdrawings:The welding engineer is aware of the necessary compensation for weld creep and welding sequence for minimizingdeformation.Qualification test of welders according to EN 287:Tarcon has before the meeting forwarded a list of certified welders and examples of welder certificates. Rambøll has nocomments for this. Rambøll will follow up on this subject at next inspection.Tack welds:Rambøll informed that tack weld shall be removed when performing final welds, this shall be stated on the shop drawings.The length of tack welds shall be minimum 50 mm according to EN 1090-2 section 7.5.7. The tack welds shall bepreheated according relevant WPS.

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 7 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

To short tack welds on profiles to another projectRambøll was informed by the welding engineer that tack welds will be performed by welders certified according to EN287.Does the single welder possess the WPS?The WPS`s were shown by the production manager, and were placed on a table in the production shop.

WPS from another project was placed on a table in the production shopStorage and handling of welding consumables:Will be checked at next inspection.Surface irregularities:The welding engineer showed Rambøll a WPS for weld repair of surface irregularities. Rambøll has no comment basedon a trial test.Stray arches:Stray arches should be avoided, if they occur they should be grinded and examined by MP and VT according to EN 1090-2 section 7.5.17.

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 8 of 9

Surveillance ReportBascule span to the Railway bridge ”Jernbanebroen over Limfjorden”

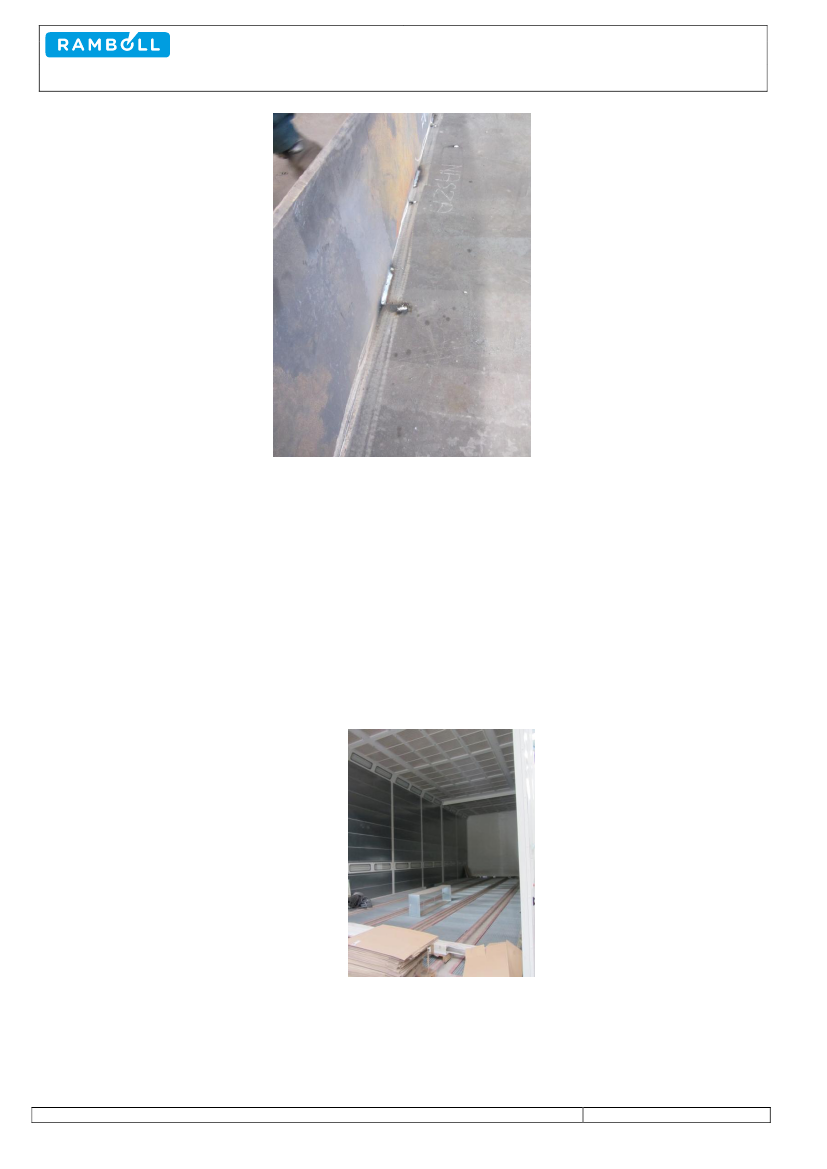

Stray arches on another projectSub-contractorsTarcon informed Rambøll that no subcontractors will be used on this project.Surface treatmentPaint system:Tarcon showed a proposal for a Hempel paint system, for C5-M high. A project specified system will be forwarded soon.This will include RAL color and gloss.Rambøll was informed that sandblasting will be performed with cupper slag, SA2½, to a roughness according to the paintsystem. Each paint layer will have different color and Tarcon was aware of additional brush paint at corners etc. to securesufficient paint layer.Test plates according to En 12944 will be forwarded.Paint shop:The sandblasting shop and paint shop were inspected at Tarcon, and Rambøll had no comment.

Separate paint shop

\\DKRAMAALFIL01\SAGARKIV\2012\12518016G\dok\LF00013-1-ID.docx

Page 9 of 9