Klima-, Energi- og Bygningsudvalget 2012-13

KEB Alm.del

Offentligt

Climate impact of potential shale gasproduction in the EUFinal Report

Report forEuropean Commission DG CLIMAAEA/R/ED57412Date 30/07/2012Issue 2

Climate impact of potential shale gas production in the EU

Customer:European Commission DG ClimaCustomer reference:CLIMA.C.1./ETU/2011/0039rConfidentiality, copyright & reproduction:This report is the Copyright of EC DGClimate Action and has been prepared byAEA Technology plc. under contract to DGClimate Action dated 21/12/2011. Thecontents of this report may not bereproduced in whole or in part, nor passed toany organisation or person without thespecific prior written permission of EC DGClimate Action. AEA Technology plc. acceptsno liability whatsoever to any third party forany loss or damage arising from anyinterpretation or use of the informationcontained in this report, or reliance on anyviews expressed therein.

Contact:Jonathan PerksAEA Technology plc.Gemini Building, Harwell, Didcot, OX11 0QRt: 0870 190 8435e: [email protected]AEA is a business name of AEA Technology plcAEA is certificated to ISO9001 and ISO14001Author:Compiled by Daniel Forster and Jonathan PerksApproved By:Daniel ForsterDate:30 July 2012Signed:

AEA reference:Ref: ED57412- Issue 1

DisclaimerThe views expressed in this report are purely those of the writer and may not in any circumstances beregarded as stating an official position of the European Commission.

AcknowledgementsThe report was compiled with the help of Andrew Waddelove, with contributions from Harry Croezen(CE Delft), Claire Dupont and Florent Pelsy (Milieu), Mark Johnson, Glen Thistlethwaite, Judith Bates,Sarah Choudrie, Rob Stewart, Lisa Beardmore and Rebekah Watson (AEA).

Ref: AEA/ED57412/Issue 2

ii

Climate impact of potential shale gas production in the EU

Executive SummaryAs readily accessible oil and gas reserves are becoming progressively limited the energy supplyindustry is increasingly turning to unconventional reserves which were previously too complex or tooexpensive to extract. In particular there has been a growing interest in Europe in the exploitation ofgas reserves trapped within shale rock. This is commonly referred to as ‘shale gas’.As with any drilling and extraction process shale gas extraction may bring environmental and healthrisks which need to be understood and addressed. In particular the potential contribution of shale gasproduction to greenhouse gas (GHG) emissions is a key area of interest. These impacts are thesubject of this report. The report has been commissioned by DG Climate Action of the EuropeanCommission and delivered by AEA, in collaboration with CE Delft and Milieu.Drawing upon existing research this report provides an examination of the potential climate impacts ofshale gas production in the EU. It begins with a review of existing estimates of GHG emissions fromshale gas production and of the potential options for abating emissions from shale gas processes.This evidence is then used to estimate the potential emissions that might be associated with shale gasexploitation in the EU. A brief review is also provided of the current legislative framework in the EU forcontrolling GHG emissions from shale gas operations. Finally the report provides an examination ofthe current GHG emissions reporting framework and explores the extent to which emissions fromshale gas operations would be captured within the existing reporting requirements. Where there areidentified gaps the report addresses the need for further reporting guidelines.The report does not explore the potential role of shale gas in the future energy supply mix, or anypotential implications of the exploitation of indigenous shale gas resources on the development ofrenewable or other energy sources in Europe. These issues are important considerations for energyand climate policy makers but are beyond the scope of this study. However, the results provided herecan be used as inputs to discussions around these issues.Shale gas exploitationIn the U.S. there has been a rapid growth in the exploitation of shale gas reserves, with productionincreasing by 48% between 2006 and 2010. Despite there being significant shale gas reserves inEurope, with technically recoverable shale gas resources estimated at approximately 18 trillion cubic3metres (m ), exploitation of shale gas to date has been limited and there is no commercial productionat present.The recent combination of higher natural gas prices, and the development of shale gas production inthe U.S., has increased interest in shale gas exploitation within Europe. As a result permission is nowbeing sought in several EU Member States for exploratory works with the explicit aim of bringingforward sites / projects for the extraction of shale gas.A number of the key processes involved in the extraction of shale gas reserves are similar toconventional natural gas. However, certain process steps are more specific to unconventional gasextraction and the scale and complexity of operations differ from conventional practices. In particular,the extraction of shale gas typically involves a process known as hydraulic fracturing (fracking) wherewater, chemicals and proppants are pumped at high pressure into the well in order to open fractures inthe rock and release the shale gas.Other aspects of shale gas extraction differ from conventional natural gas. For example, additionaldrilling is required for horizontal wells, along with much greater volumes of water required in thehydraulic fracturing process.Once production begins at the well the subsequent process steps in the exploitation of shale gas(processing, transportation, distribution) are largely comparable with conventional natural gas.GHG emissions from shale gas productionThe GHG emissions from shale gas production have been the subject of a number of studies since2010. These studies have yielded a large variation in the estimated impacts of shale gas. Somestudies, which have received a lot of media attention, have concluded that the lifecycle GHGemissions from shale gas may be larger than conventional natural gas, oil, or coal when used togenerate heat and viewed over the time scale of 20 years (Howarth et al, 2011). However the majority

Ref: AEA/ED57412/Issue 2

iii

Climate impact of potential shale gas production in the EU

of studies suggest that emissions from shale gas are lower than coal, but higher than conventionalgas, based on other assumptions. These estimates are discussed further in this report.In practice most of the existing studies have drawn upon a narrow set of primary data from shale gasoperations in the U.S. Differences in the estimated emissions frequently arise from the interpretationby the authors of the primary data, in addition to the different underlying assumptions used in theirGHG assessments. As new information sources have come to light this has led to new and improvedestimates of the GHG impacts. However a number of uncertainties remain including: the level ofemissions associated with the well completion stage; about levels of water re-use and treatment ofwaste water. Overall, the emissions from shale gas are dominated by the combustion stage.Significant emissions also arise from the well completion, gas processing and transmission stages, butthe overall significance of these pre-combustion stages is less. Emissions from exploration have notbeen taken into account in any previous studies.Drawing upon these studies, and their underlying data sources, a hypothetical analysis has beencarried out of the potential lifecycle GHG emissions that may arise from shale gas exploitation withinEurope. In our base case, which does not represent a preferred scenario, we have estimated the GHGemissions per unit of electricity generated from shale gas to be around 4% to 8% higher than forelectricity generated by conventional pipeline gas from within Europe. These additional emissionsarise in the pre-combustion stage, predominantly in the well completion phase when the fracturingfluid is brought back to the surface together with released methane. If emissions from well completionare mitigated, through flaring or capture, and utilised then this difference is reduced to 1% to 5%. Thisfinding is broadly in line with those of other U.S. studies which found that generation from shale gashad emissions about 2% to 3% higher than conventional pipeline gas generation.This study also considered sources of gas outside of Europe which make a significant contribution toEuropean gas supply. Based on our hypothetical analysis, and drawing upon existing LCA studies forconventional gas sources, the analysis suggests that the emissions from shale gas generation (basecase) are 2% to 10% lower than emissions from electricity generated from sources of conventionalpipeline gas located outside of Europe (in Russia and Algeria), and 7% to 10% lower than that ofelectricity generated from LNG imported into Europe.However, this conclusion is far from clear-cut. Under our ‘worst’ case shale gas scenario, where allflow back gases at well completion are vented, emissions from electricity generated from shale gaswould be similar to the upper emissions level for electricity generated from imported LNG and for gasimported from Russia. This suggests, where emissions from shale gas are uncontrolled, there may beno GHG emission benefits from utilising domestic shale gas resources over imports of conventional1gas from outside the EU . In fact, for some pipeline sources emissions from shale gas may exceedemissions from importing conventional gas.The relative comparison with coal is clearer cut. In our analysis, emissions from shale gas generationare significantly lower (41% to 49%) than emissions from electricity generated from coal. This is on thebasis of methane having a 100 year GWP of 25. This finding is consistent most other studies into theGHG emissions arising from shale gas.These conclusions are based on experiences drawn largely from the U.S. Whilst attempts have beenmade to take into account the different circumstances in Europe, and how this may influence overallemissions, this comparison is still largely hypothetical. Where the shale gas industry develops inEurope this information should be used to update the results of the analysis.Best available technologies for reducing GHG emissionsOne of the key assumptions which can influence the scale of emissions estimated in the life cycleanalysis is the assumed management practices and technologies employed at the shale gasextraction site. The use of best practice techniques has the potential to significantly reduce emissionsrelative to other practices.A large proportion of the best practice techniques that have been identified include measures whichhave been demonstrated, and are a regulatory requirement, in specific regions in North America (andwill be a regulatory requirement in the U.S. from 2015). It is reasonable to assume that thesetechniques will be applicable in Europe with the following caveats:1

When reporting emission on a production basis (as is the case with national emissions inventories under the United NationsFramework on Climate Change), emissions arising from shale gas operation within Europe will be captured within the EU’sGHG emission inventory. However, emissions from e.g. conventional gas processing outside of Europe will not be accounted forin the EU’s GHG inventory – and instead will be captured in the inventory of the regions in which they are produced

Ref: AEA/ED57412/Issue 2

iv

Climate impact of potential shale gas production in the EU

Geology: the effectiveness of certain techniques requires sufficient gas pressure, which maynot be the case at all locations in Europe.Infrastructure: at least initially any captured gas which doesn’t meet the required natural gasspecification would need to be processed further. This may be a constraint if the pipeline orprocessing infrastructure is not in place and suitable connections available for transferringcaptured gas do not exist.Availability and experience in equipment / technology: to capture the gas released on wellcompletion and re-fracturing activity. This may be an issue in initial stages of developmentuntil vendors develop suitable solutions.With respect to emissions resulting from flow back from well completions, the application of ReducedEmissions Completions has the potential to reduce emissions by around 90%. These technologieshave been used extensively in the U.S. both in response to regulations and existing drivers (e.g.economic value of captured methane). While there are some restrictions on the sites where thesemeasures can be used, in principle, they have the potential to deliver significant reductions inemissions from this stage in the process.Further emissions reductions can be achieved at other stages in the gas cycle. These measures arenot specific to shale gas and are also applicable to conventional gas sources. These includemeasures such as: more efficient compressors; improved leak detection or utilisation of gas stemmingfrom production testing.Legislation controlling GHG emissions from shale gas productionThe overview analysis of the EU legal acts identified as relevant to shale gas has shown that there arevery few requirements applicable specifically to GHG emissions from shale gas projects.The EIA Directive (85/337/EEC; 2011/92/EU (codified)) is the most relevant as it sets requirements asto the consideration of climate change effects and air emissions as part of a full EIA. It requiresMember States to ensure that developers supply certain information, such as a description ofestimated air emissions and significant environmental impacts resulting from the project, including airand climatic factors. Furthermore, the Directive provides for competent authorities to give an opinionon the information supplied which, as a minimum, should include a description of the measuresenvisaged in order to avoid, reduce and if possible, remedy significant adverse side effects.However, despite these requirements, many uncertainties remain as to whether Member States wouldrequire an EIA for shale gas operations and if so how Member States should implement the EIA. Forexample the way in which they would implement the methodology to be used to quantify GHGemission baseline scenarios.Directive 92/91/EEC concerning minimum requirements for improving the health and safety of workersin the mineral-extracting industries through drilling does not contain any provisions specifically relatingto GHG emissions. It does, however, set requirements to protect workers from harmful and / orexplosive substances. This would primarily apply to methane present in such concentration that itcould represent a risk in terms of flammability for workers.With regard to the Directive on Industrial Emissions (2010/75/EU) it is not clear in whichcircumstances it would apply to shale gas exploration and exploitation activities and whether itsmeasures on air emissions would cover methane contained within flow back.It is beyond the scope of this report to make specific recommendations on how to overcome thepotential shortfalls identified above.Finally, the EU ETS Directive (Directive 2003/87/EC) could provide precedents for the regulation ofshale gas emissions, through its treatment of venting and flaring, and emissions related to carboncapture and storage processes.In order to encourage the application of best available techniques the following could be furtherinvestigated:Consideration of the issues identified related to the scope of the EIA Directive with regard toshale gas exploration and exploitation activities (Annex I or II);Consideration of information requirements on measures taken by developers to limit GHGemissions under the EIA Directive, or other pieces of relevant legislation;Consideration of the need for measures to limit GHG emissions for shale gas exploration andexploitation;Ref: AEA/ED57412/Issue 2

v

Climate impact of potential shale gas production in the EU

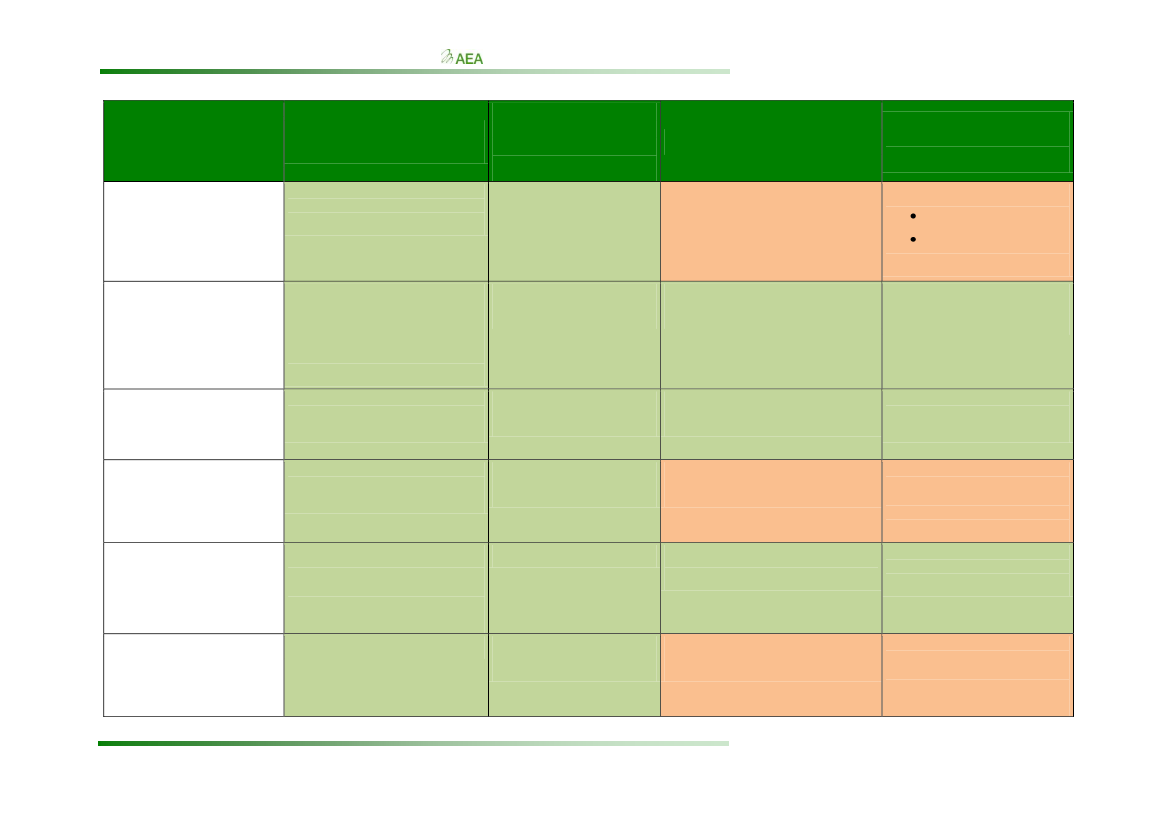

Consideration of the issues identified related to the scope of the Industrial Emissions Directivewith regard to shale gas exploration and exploitation activities;Consideration of the application of the emission limit values requirements under the IndustrialEmissions Directive to methane emissions from exploration and exploitation activities.Consideration could also be given to the application of emission limit values for methane emissionsfrom exploration and exploitation activities.However, in principle the legislation described above could provide a good approach with which toenforce best shale gas technologies, although this would likely need to be supplemented by BATreference documents, guidance specific to shale gas technologies and clarification on the applicabilityof key directives. Alternatives, such as voluntary agreements could also be considered, but additionalmeasures would be required to ensure they are rigorously applied.Assessment of the current GHG emissions reporting frameworkIn order to ensure the effective control of GHG emissions from potential shale gas development inEurope it is important to ensure that emissions, where they arise, are reported. This information isimportant for understanding the net impact of any shale gas installations, and for assessing theimpacts of control measures, and the potential for further controls.A review has been carried out of the adequacy of current GHG emissions reporting frameworks, underthe auspices of the UNFCC and IPPC, with the view to identifying areas where improvements may beneeded in relation to shale gas production.The review has identified no emission factors, GHG estimation methods, industry activity or emissionsdata specific to shale gas Exploration and Production (E&P) sources within the EU. However,information and reporting protocols from regulators in Canada and the U.S. provide estimationmethods and indicative emission factors for these sources that are specific to shale gas E&P whichcould be developed for application in the EU.IPCC Guidelines do not provide emission estimation methodology details or emission factors that areapplicable to calculate emissions from sources specific to shale gas E&P such as well completions,well work-overs and the related management of flow back fluid.The UNFCCC reporting format (CRF) does not require that countries specify GHG emissions fromshale gas E&P, or from any other specific technology or sub-sector. Emissions and activity data aretypically reported by countries at an aggregated level across all gas E&P sectors, with additionalmethodological detail provided within National Inventory Reports (NIRs). The level of detail providedregarding emission estimations within the NIRs is subject to the discretion of the inventory agency.Several process stages in shale gas E&P, including processing and compressing the gas fordistribution, require the same steps as with conventional gas. Therefore the current IPCC Guidelinesand national GHG inventory methodologies should be adaptable to allow inventory agencies to derivecomplete and accurate estimates for these sources. Development of appropriate emission factors(ideally at the gas-basin level) through gas sampling and compositional analysis will be required toensure that emission factors reflect the local shale gas composition.

Ref: AEA/ED57412/Issue 2

vi

Climate impact of potential shale gas production in the EU

Table of contents1Introduction ................................................................................................................................. 11.1Background to the study .................................................................................................... 11.2Objectives of the study ...................................................................................................... 21.3Report Structure................................................................................................................. 2Shale gas exploitation ................................................................................................................ 42.1Introduction ........................................................................................................................ 42.2Overview of shale gas production...................................................................................... 42.3Process stages for the extraction of shale gas .................................................................. 52.4Comparison of high volume hydraulic fracturing and conventional hydrocarbon extractionpractices ...................................................................................................................................... 10Greenhouse Gas (GHG) emissions from shale gas production ........................................... 143.1Introduction ...................................................................................................................... 143.2Compilation of the evidence base.................................................................................... 143.3Pre-production stage ....................................................................................................... 153.4Production and Processing Stage ................................................................................... 273.5Transportation and distribution ........................................................................................ 283.6Well plugging and abandonment ..................................................................................... 283.7Summary.......................................................................................................................... 28Best available techniques for reducing GHG emissions ...................................................... 334.1Introduction ...................................................................................................................... 334.2Pre-production ................................................................................................................. 334.3Production Stage ............................................................................................................. 374.4Well Plugging and Abandonment .................................................................................... 394.5Applicability to Europe ..................................................................................................... 414.6Management techniques ................................................................................................. 42

2

3

4

5Hypothetical estimation of the lifecycle greenhouse gas (GHG) emissions from possiblefuture shale gas exploitation in Europe ............................................................................................ 445.1Introduction ...................................................................................................................... 445.2Modelling the shale gas life cycle .................................................................................... 445.3Gas Life Cycle.................................................................................................................. 465.4Coal Cycle........................................................................................................................ 655.5Summary.......................................................................................................................... 666Legislation controlling GHG emissions from shale gas production ................................... 696.1Introduction ...................................................................................................................... 696.2Initial review of existing legislation ................................................................................... 696.3Case Studies.................................................................................................................... 78Assessment of current GHG emissions reporting framework ............................................. 997.1Introduction ...................................................................................................................... 997.2Study Approach ............................................................................................................... 997.3Evaluation of UNFCCC GHG Emission Reporting Frameworks and IPCC Guidelines 1007.4Summary........................................................................................................................ 1137.5Recommendations ......................................................................................................... 116References ............................................................................................................................... 118Glossary ................................................................................................................................... 123

7

89

AppendicesAppendix 1: Literature for GHG emissions from shale gas production

Ref: AEA/ED57412/Issue 2

vii

Climate impact of potential shale gas production in the EU

Appendix 2: Knowledge review for reporting frameworks

Ref: AEA/ED57412/Issue 2

viii

Climate impact of potential shale gas production in the EU

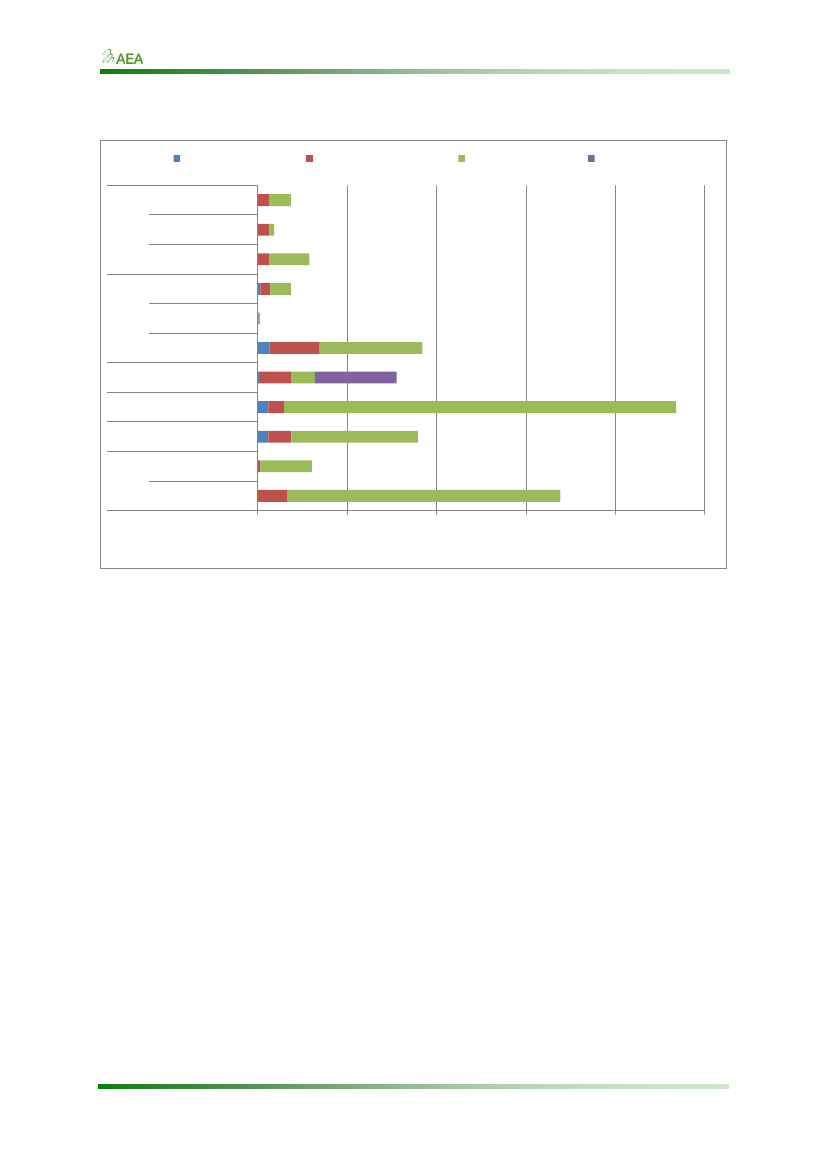

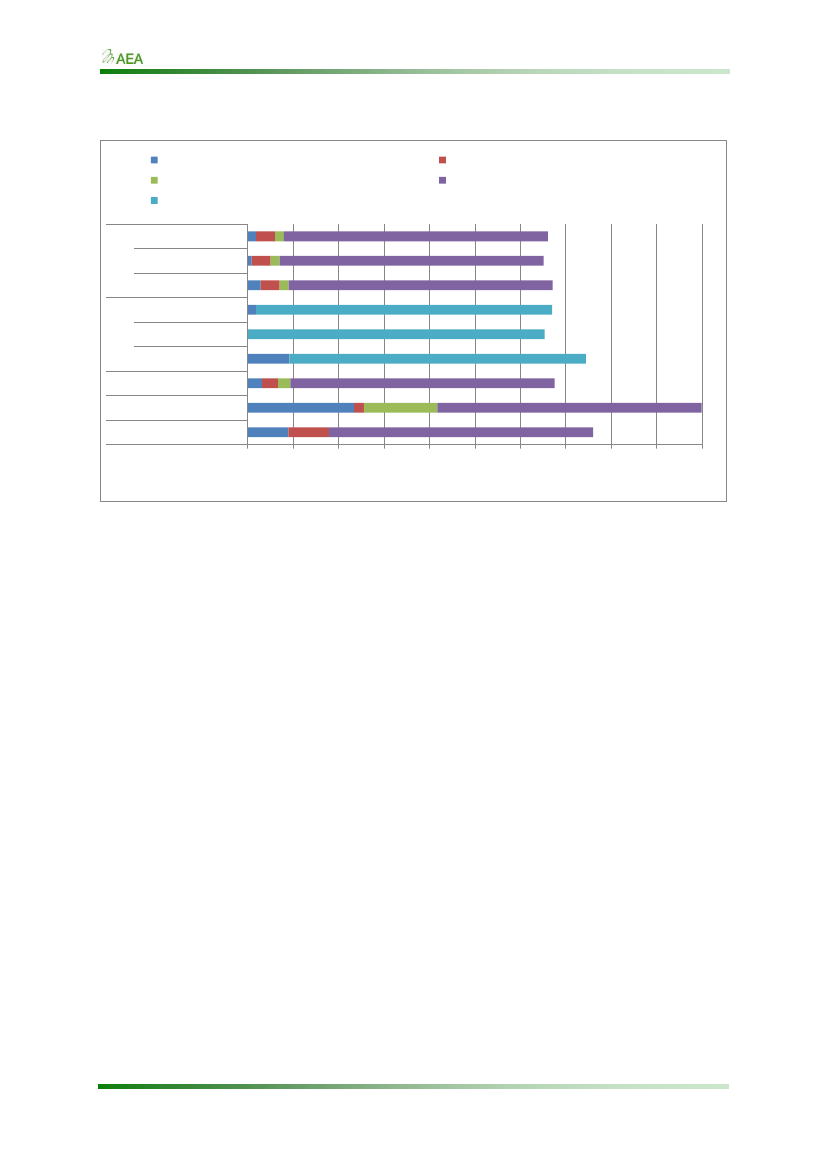

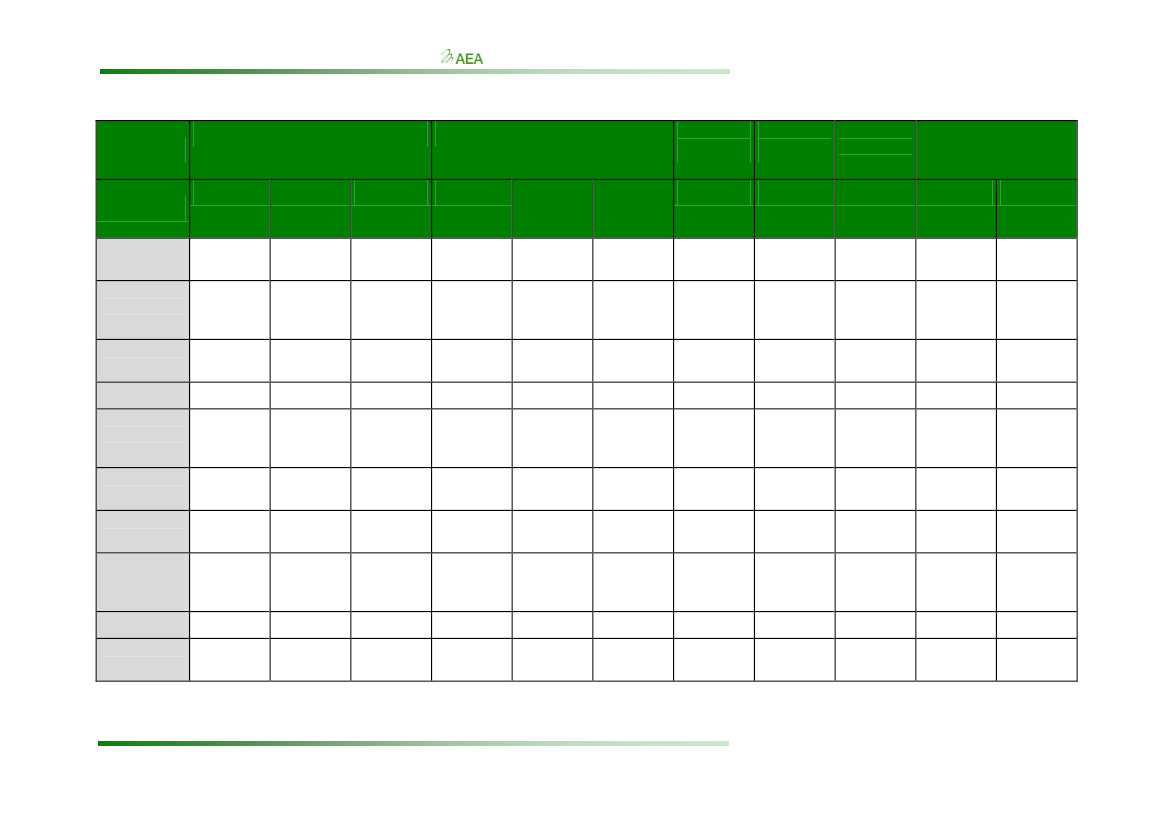

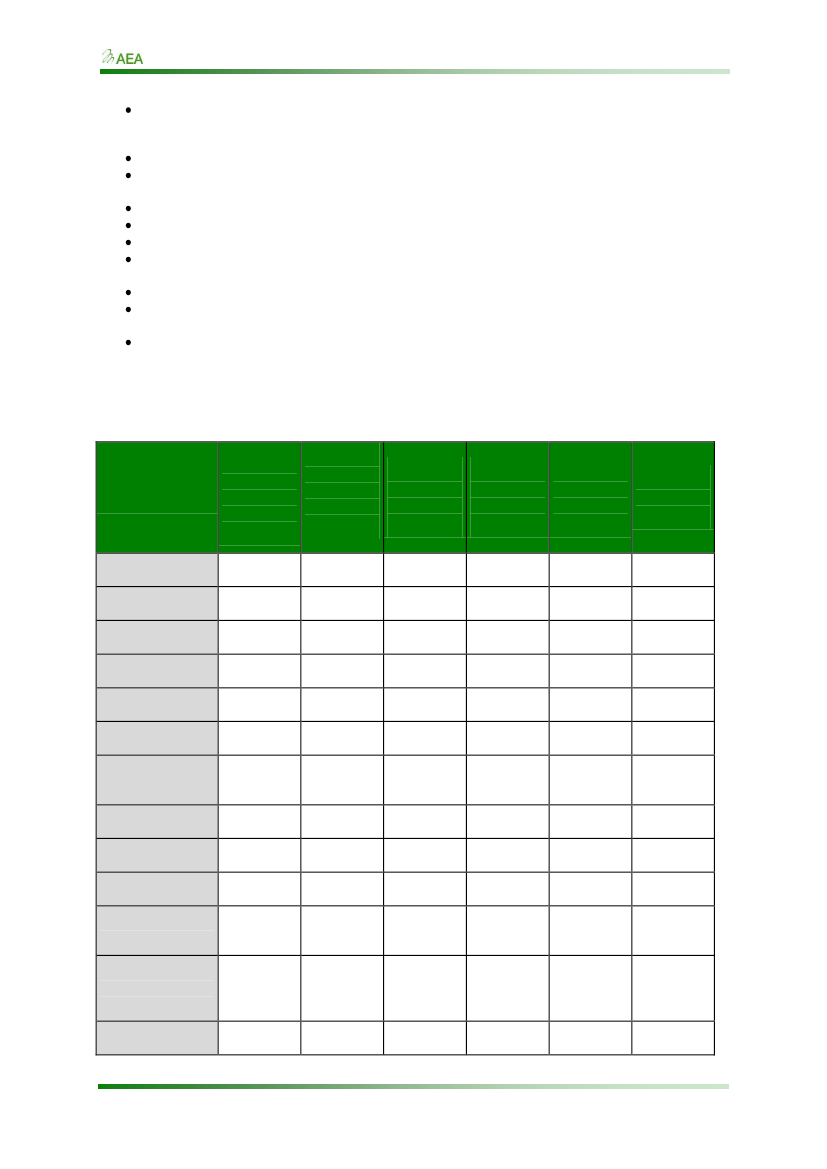

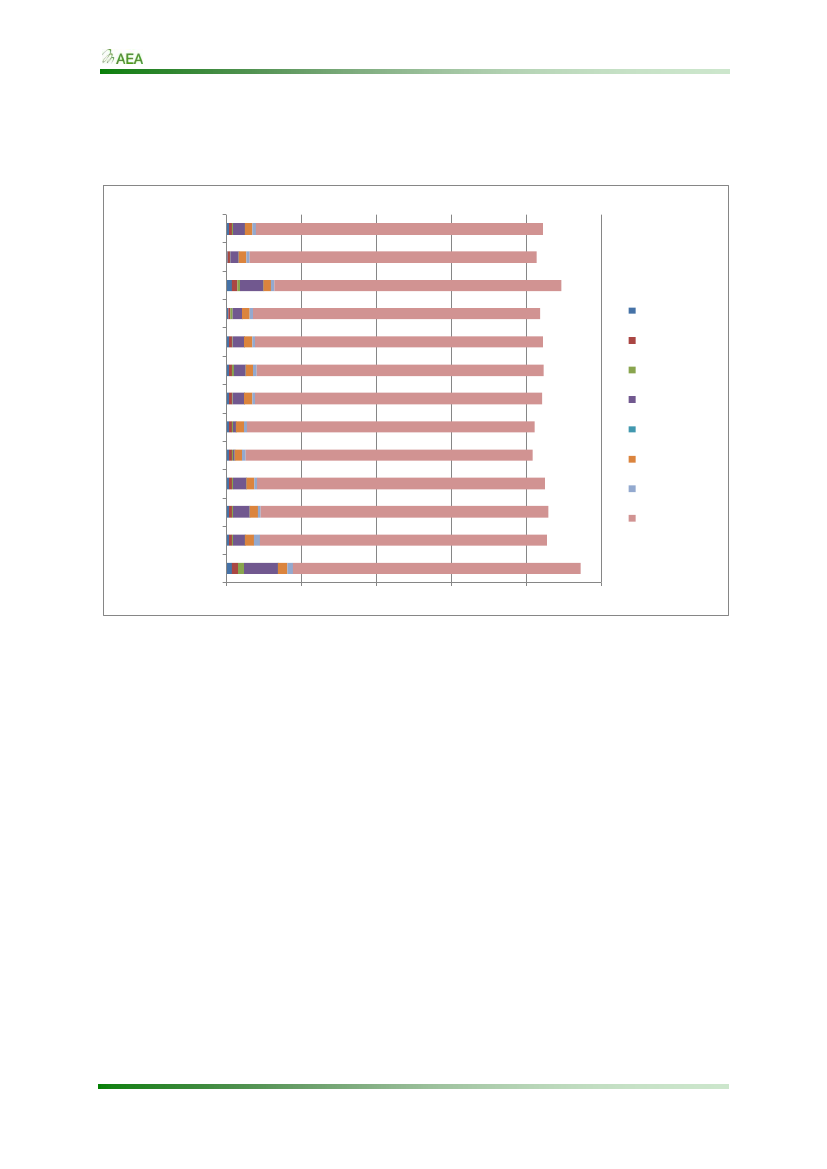

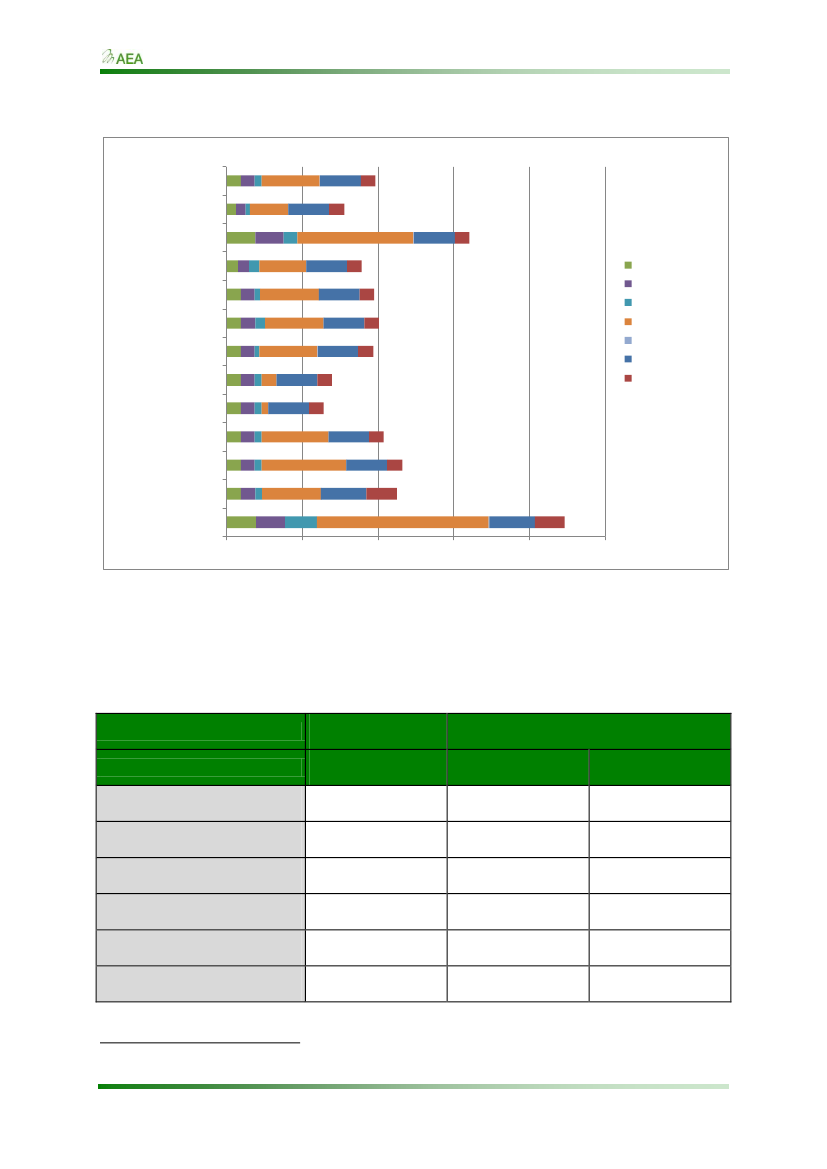

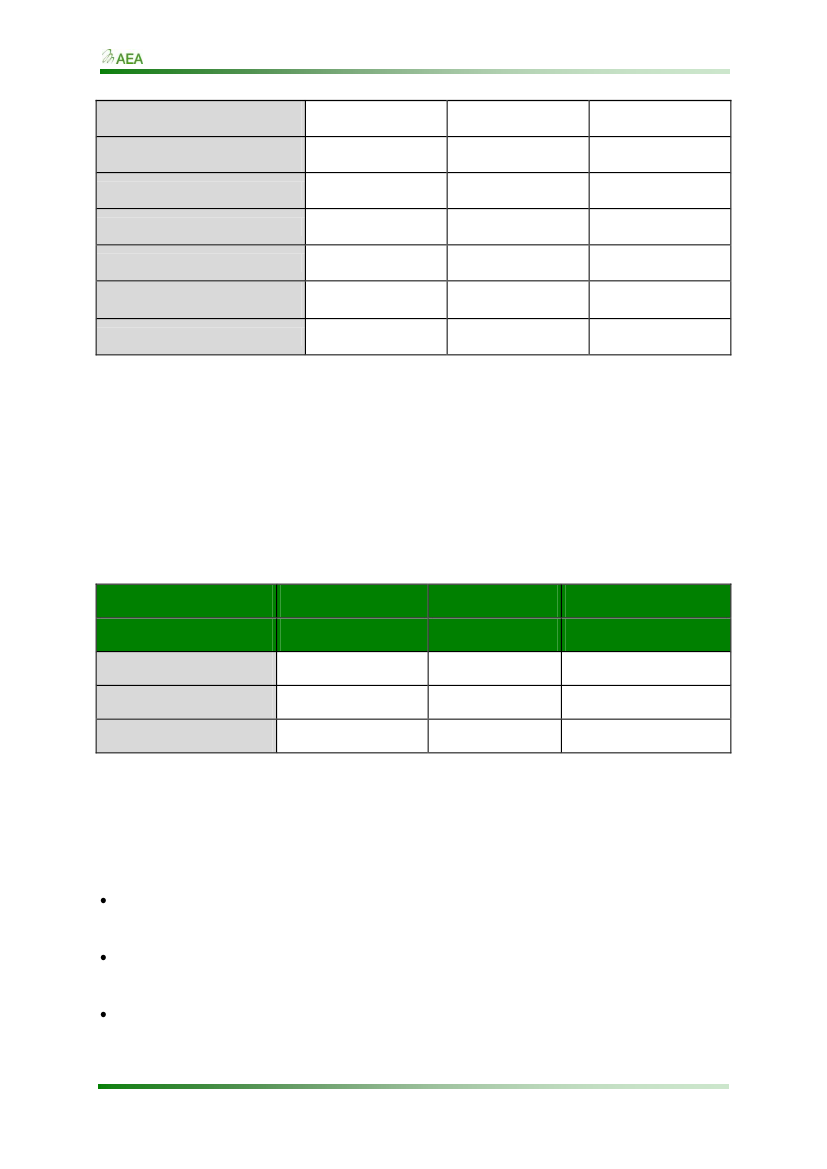

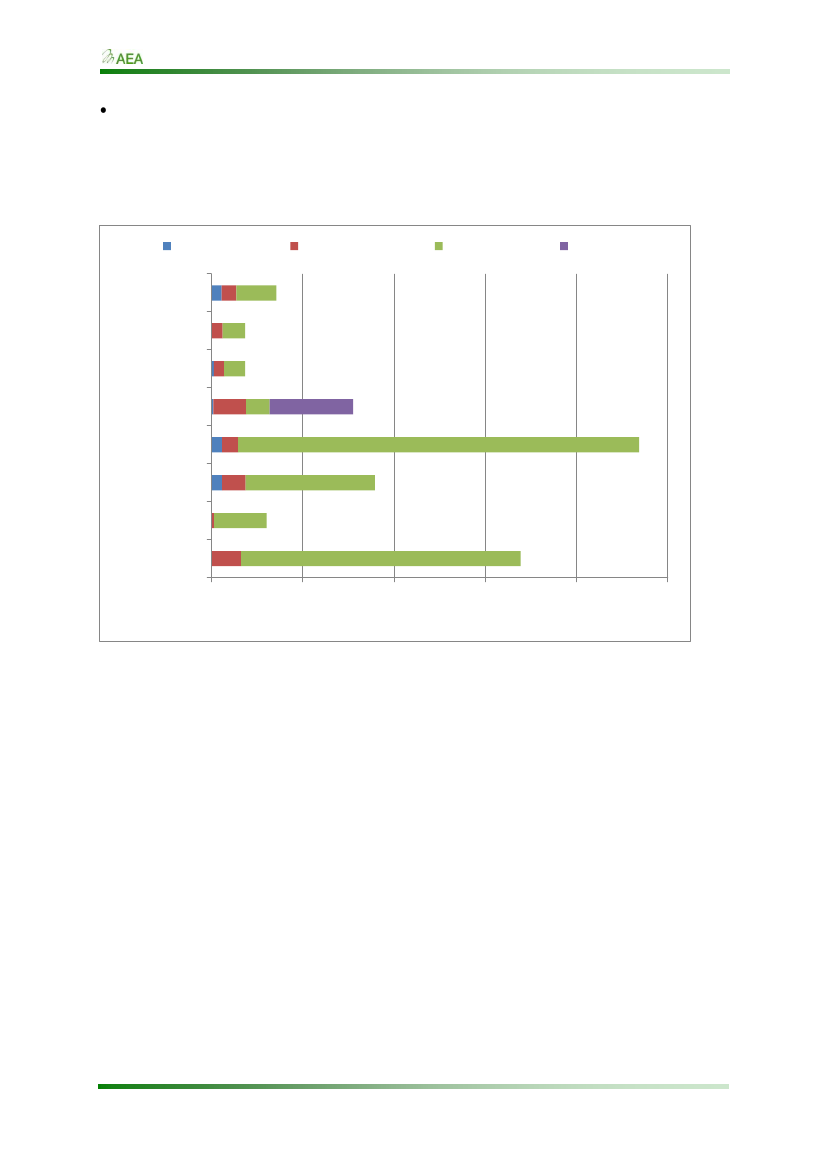

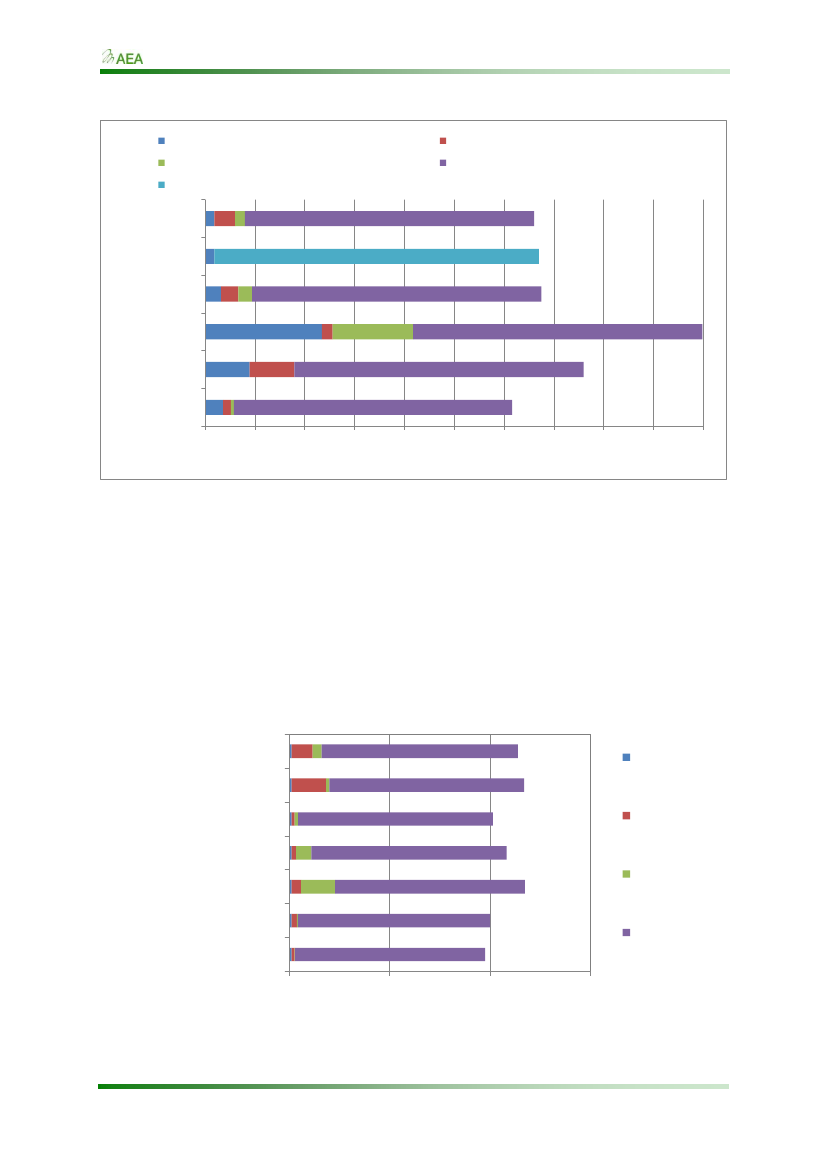

List of Figures:Figure 1: Schematic cross-section of the subsurface illustrating types of natural gas deposits (From:U.S. DOE, Energy Information Administration, 2011b) ........................................................................... 4Figure 2: Well development process ....................................................................................................... 5Figure 3: Stages in well development ..................................................................................................... 5Figure 4: Life cycle emissions from pre-production stages (gCO2eq/MJ gas combusted, using 100year GWPs for CH4 and N2O of the IPCC Fourth Assessment Report) .............................................. 30Figure 5: Total life cycle emissions for shale gas (CO2eq/MJ gas combusted using 100 year GWPs forCH4 and N2O of the IPCC Fourth Assessment Report) ....................................................................... 31Figure 6: Reduced Emissions Completion Equipment (U.S. EPA 2011d) ............................................ 35Figure 7: Lifecycle GHG emission from electricity production using shale gas (gCO2/kWh) ................ 60Figure 8: Lifecycle GHG emissions from electricity using shale gas – pre combustion stages only(gCO2/kWh) ........................................................................................................................................... 61Figure 9: Comparison of lifecycle GHG emissions from pre-production stages for shale gas from thisstudy and others .................................................................................................................................... 63Figure 10: Comparison of lifecycle GHG emissions for shale gas from this study and others ............. 64Figure 11: Total emissions from conventional gas (g/kWhe) ................................................................ 64Figure 12: Lifecycle emissions from coal and gas fired electricity generation ...................................... 68Figure 13: Lifecycle emissions from coal and gas fired electricity generation, with future improvementsin electrical efficiency............................................................................................................................. 68Figure 14: Shale Gas E&P Processes, Emission Sources and GHG Inventory Impacts ................... 108

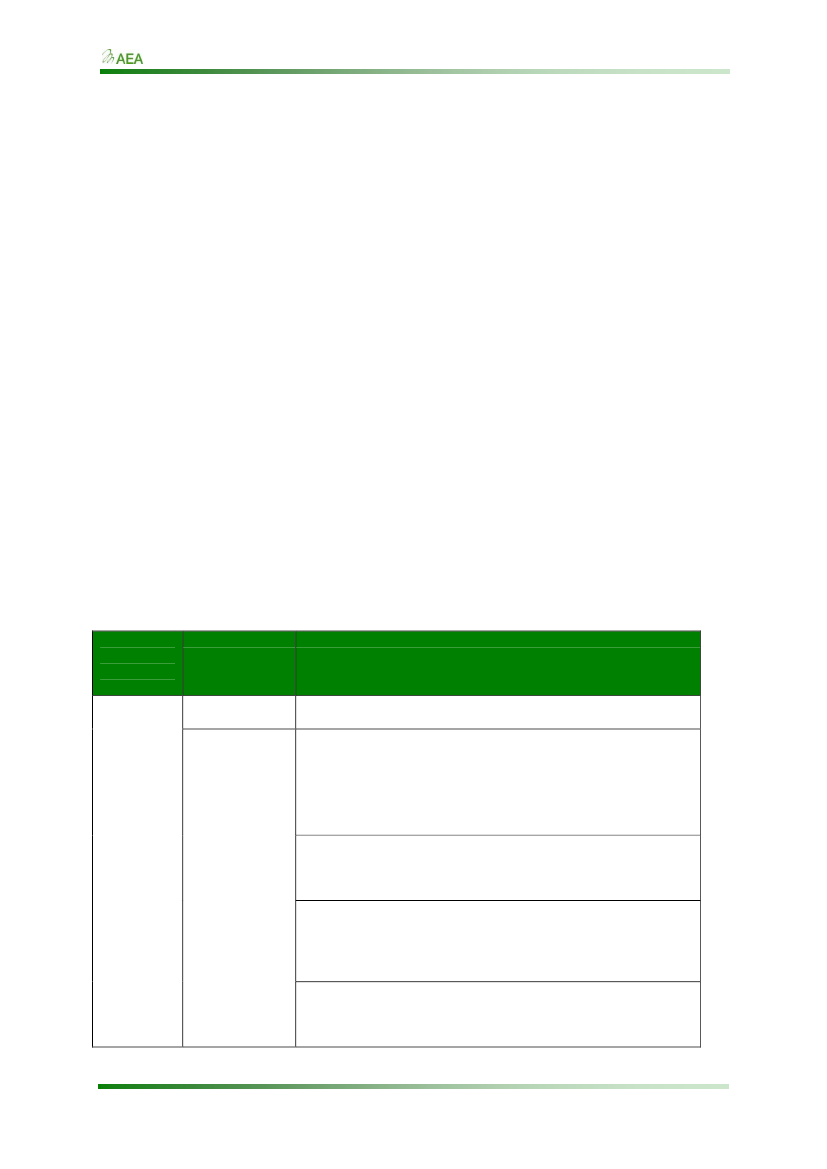

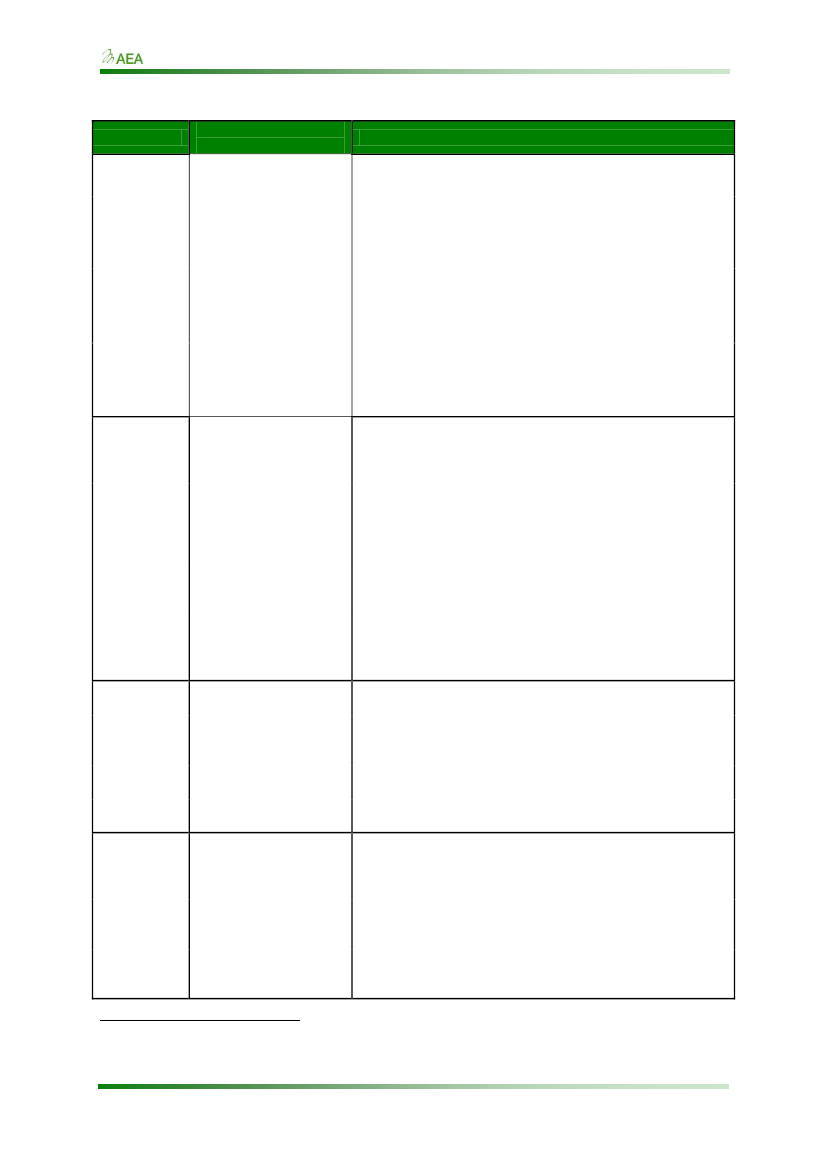

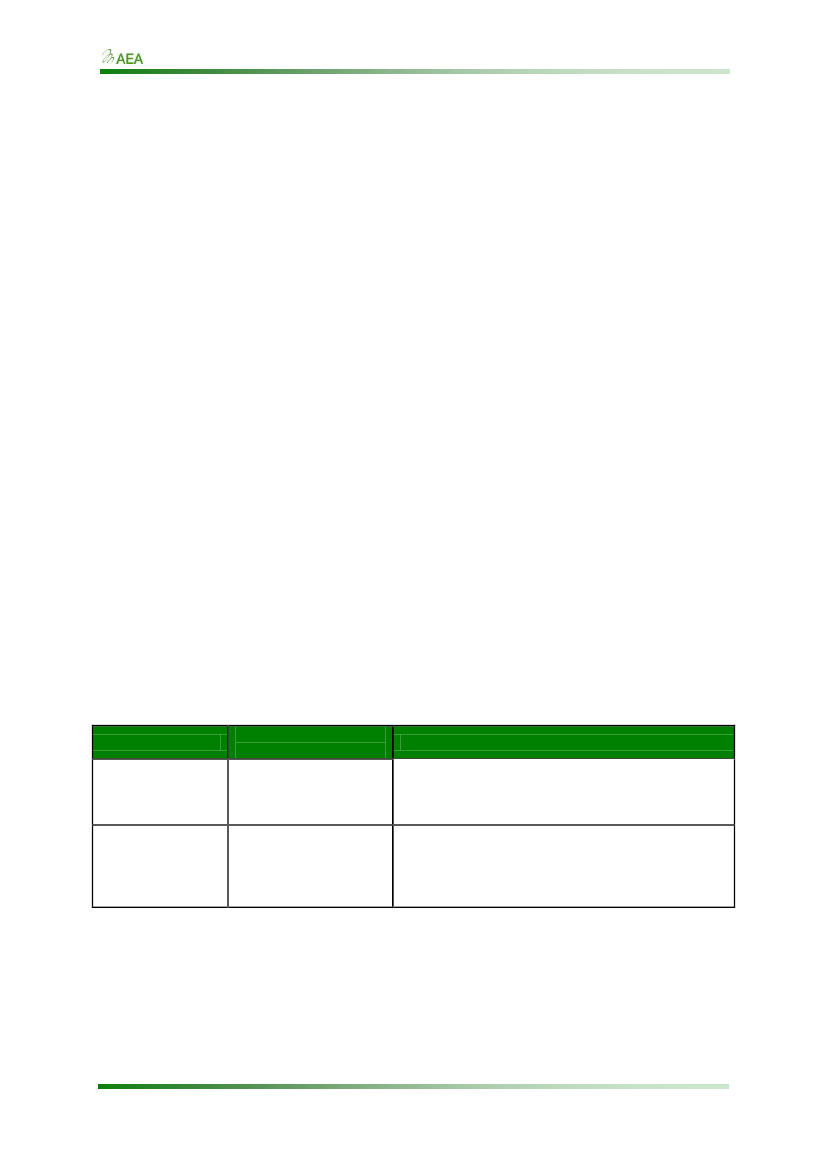

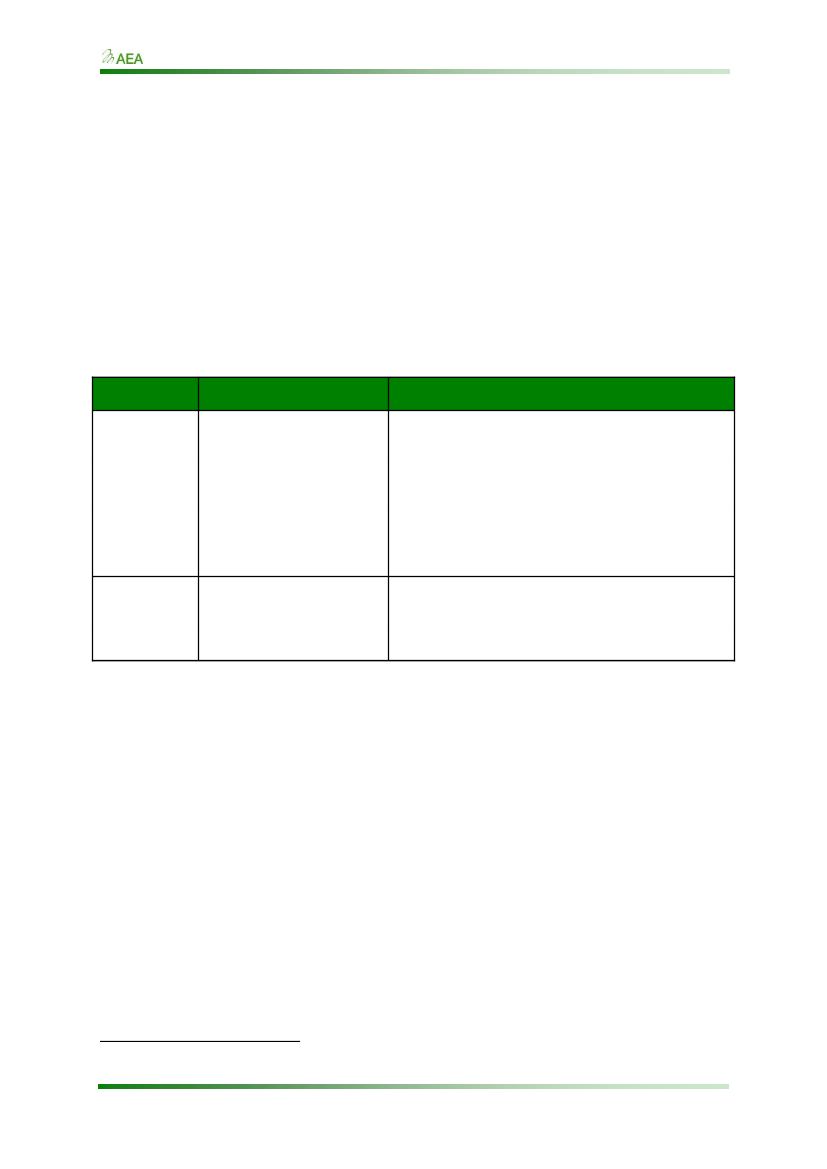

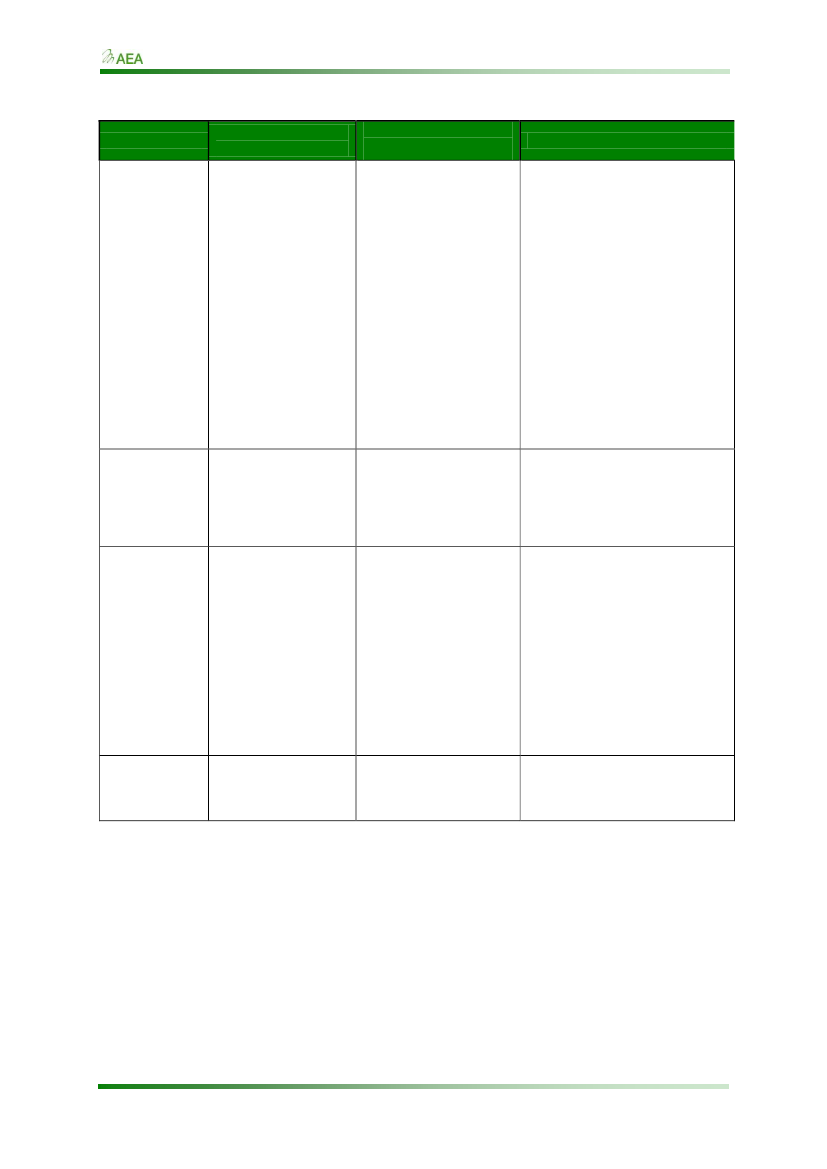

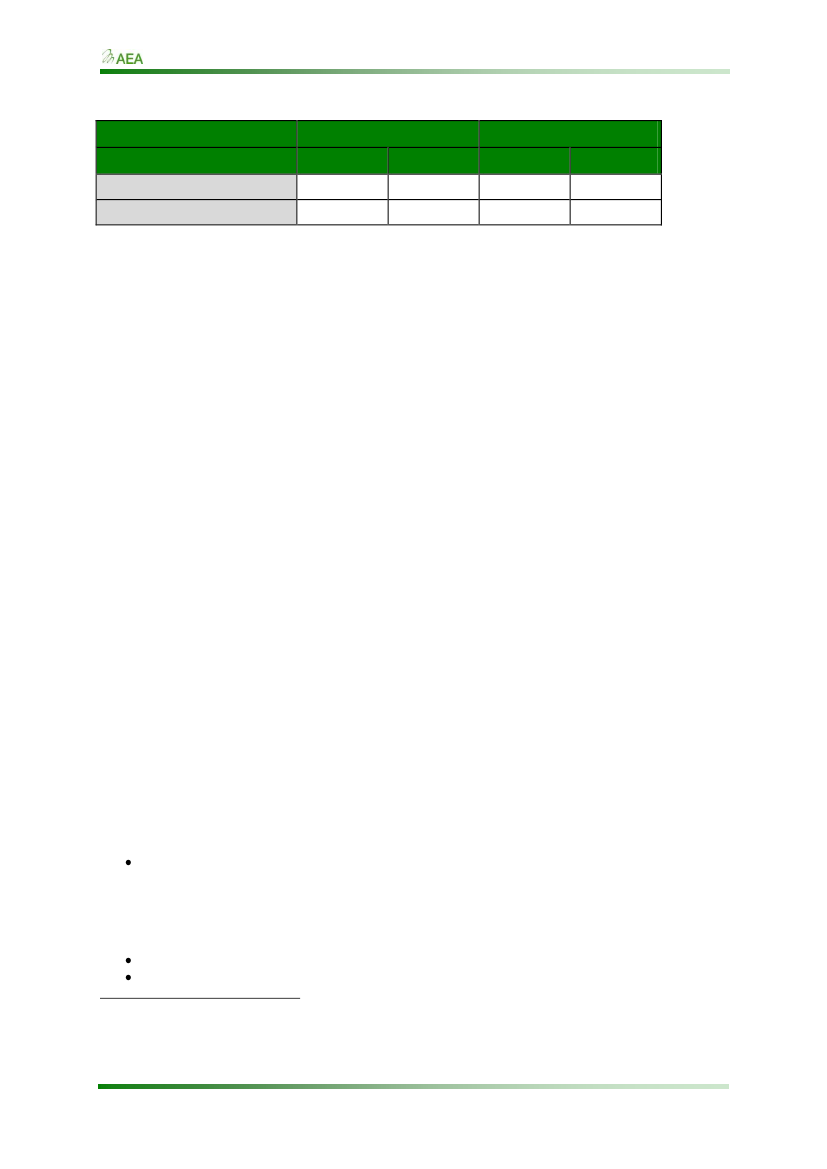

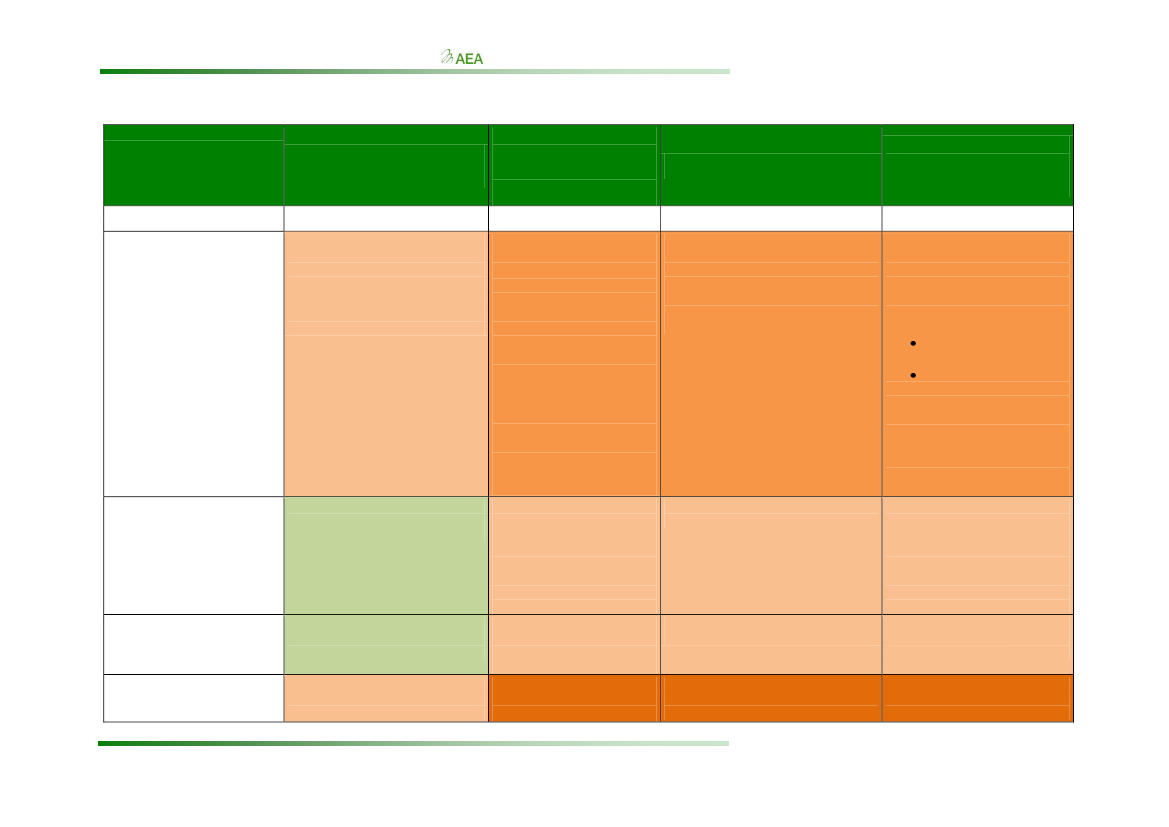

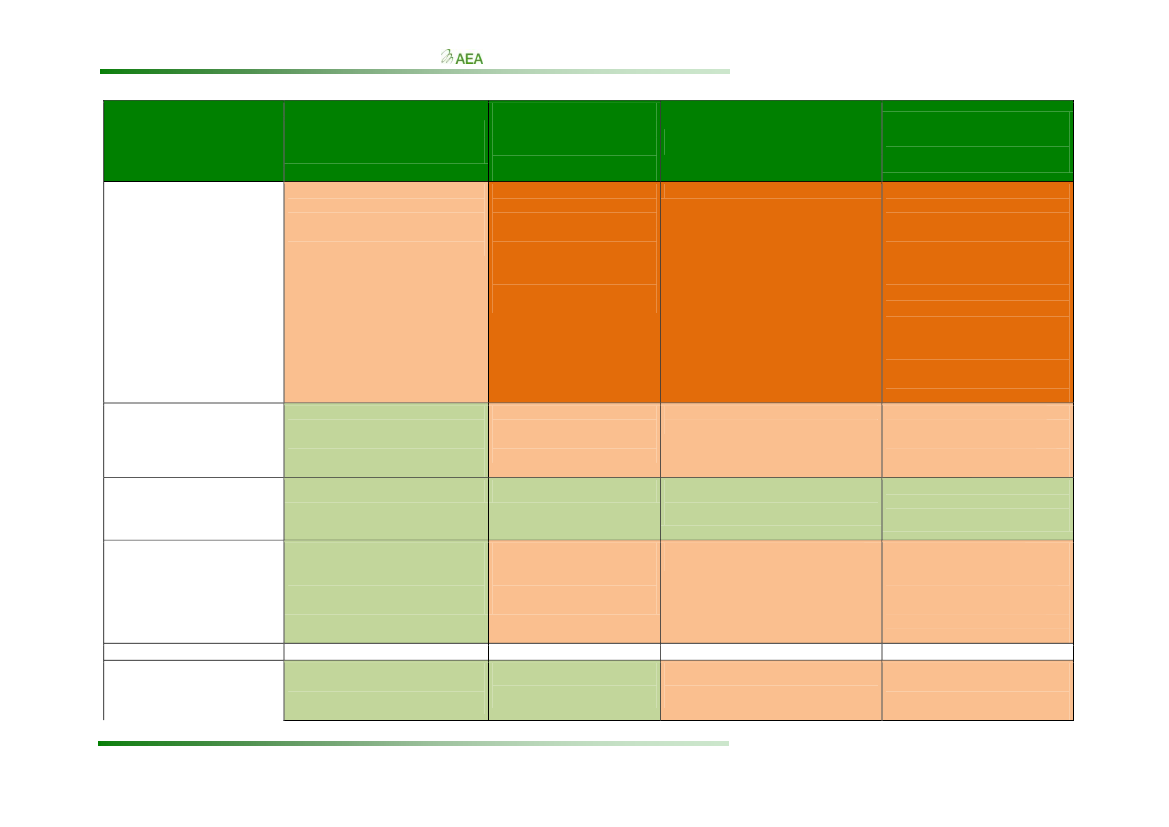

List of Tables:Table 1: Estimated shale gas recoverable resource for select basins in Europe ................................... 1Table 2: High Volume Hydraulic Fracturing: Stages, Steps, and Differences from ConventionalHydrocarbon Practices .......................................................................................................................... 10Table 3: Existing estimates of emissions associated with site preparation ........................................... 16Table 4: Existing estimates of emissions associated with drilling ......................................................... 17Table 5: Existing estimates of emissions associated with transport of materials .................................. 20Table 6: Existing estimates of emissions associated with resource use ............................................... 21Table 7: Existing estimates of emissions associated with treatment of waste water ............................ 22Table 8: Existing estimates of emissions associated with flow back .................................................... 24Table 9: Typical emission from the production stage ............................................................................ 27Table 10: Typical emissions from activities used during the production stage ..................................... 27Table 11: Summary of life cycle emissions estimates for shale gas (g CO2/MJ) .................................. 32Table 12: Gas use for treatment and fugitive emissions (% of gas throughput) ................................... 51Table 13: Emissions from gas treatment (kg/GJ gas delivered) ........................................................... 52Table 14: Gas use for treatment and fugitive emissions – LNG (% of gas throughput) ........................ 54Table 15: Emissions from LNG gas processing (kg/GJ) ....................................................................... 54Table 16: Examples of LNG installation specific energy consumptions and fugitive emissions .......... 54Table 17: Emissions from Pipeline transmission (% of gas throughput) ............................................... 55Table 18: Emissions from Pipeline transmission (kg/GJ) ...................................................................... 55Table 19: Comparison of emissions estimates from LNG transport from alternative sources. ............. 56Table 20: Emissions from LNG transport (% of gas throughput) .......................................................... 57Table 21: Emissions from LNG transport (kg/GJ) ................................................................................. 58Table 22: Parameters varied in each scenario ...................................................................................... 59Table 23: Lifecycle emissions for electricity generation from shale gas (g CO2/kWh electricity) .......... 61Table 24: Influence of GWP for methane on lifecycle emissions for electricity generation from shalegas (g CO2/kWh electricity) ................................................................................................................... 62Table 25: Lifecycle emissions from coal fired electricity generation (g CO2eq/kWh) ............................ 66Table 26: EIA relevant for shale gas exploration and exploitation ....................................................... 97Table 27: Shale Gas Sources – Gap Analysis for UNFCCC Reporting and IPCC Guidance ............. 104Table 28: Typical emission factors for unconventional gas E&P ........................................................ 112

Ref: AEA/ED57412/Issue 2

ix

Climate impact of potential shale gas production in the EU

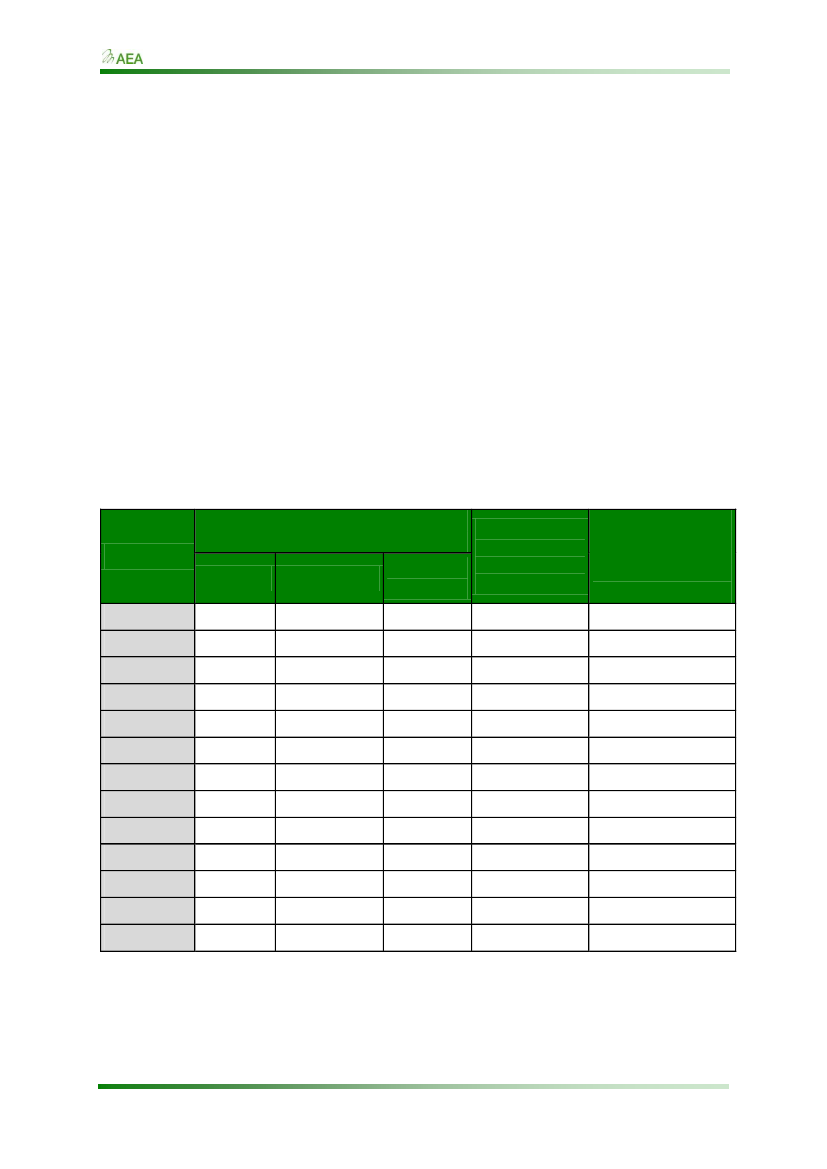

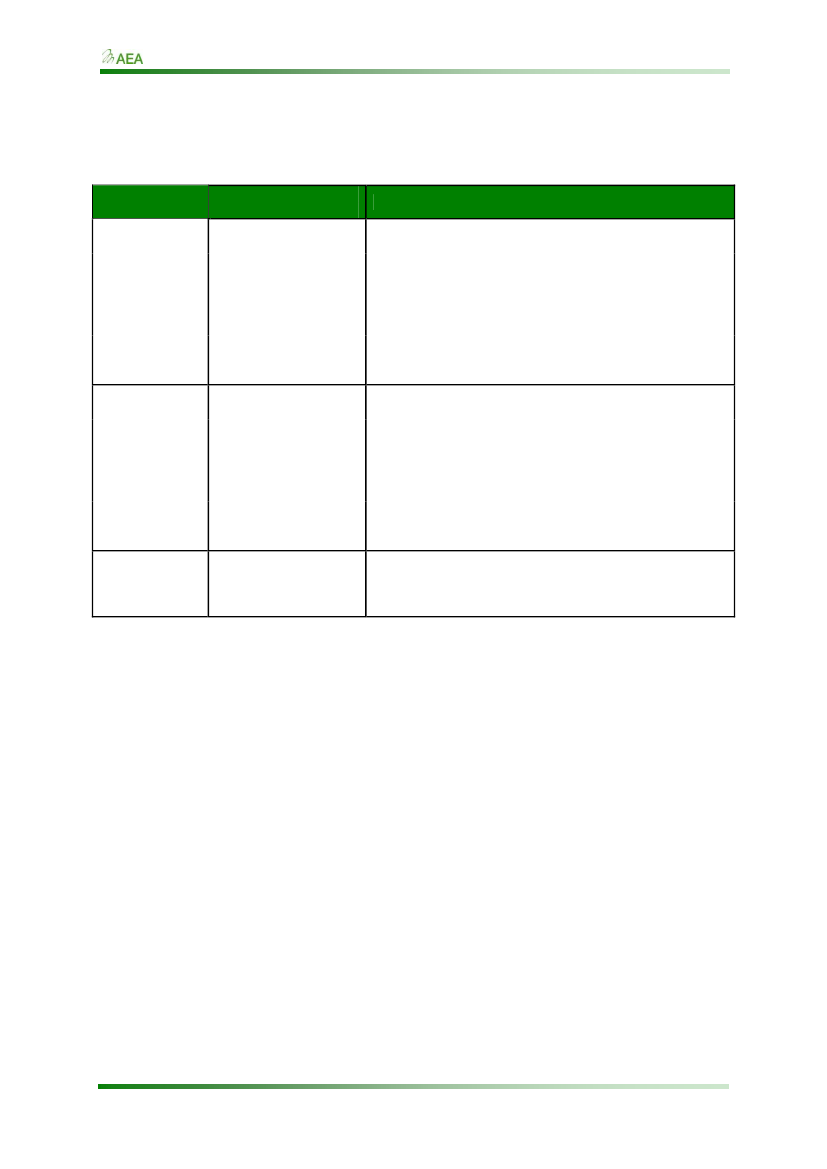

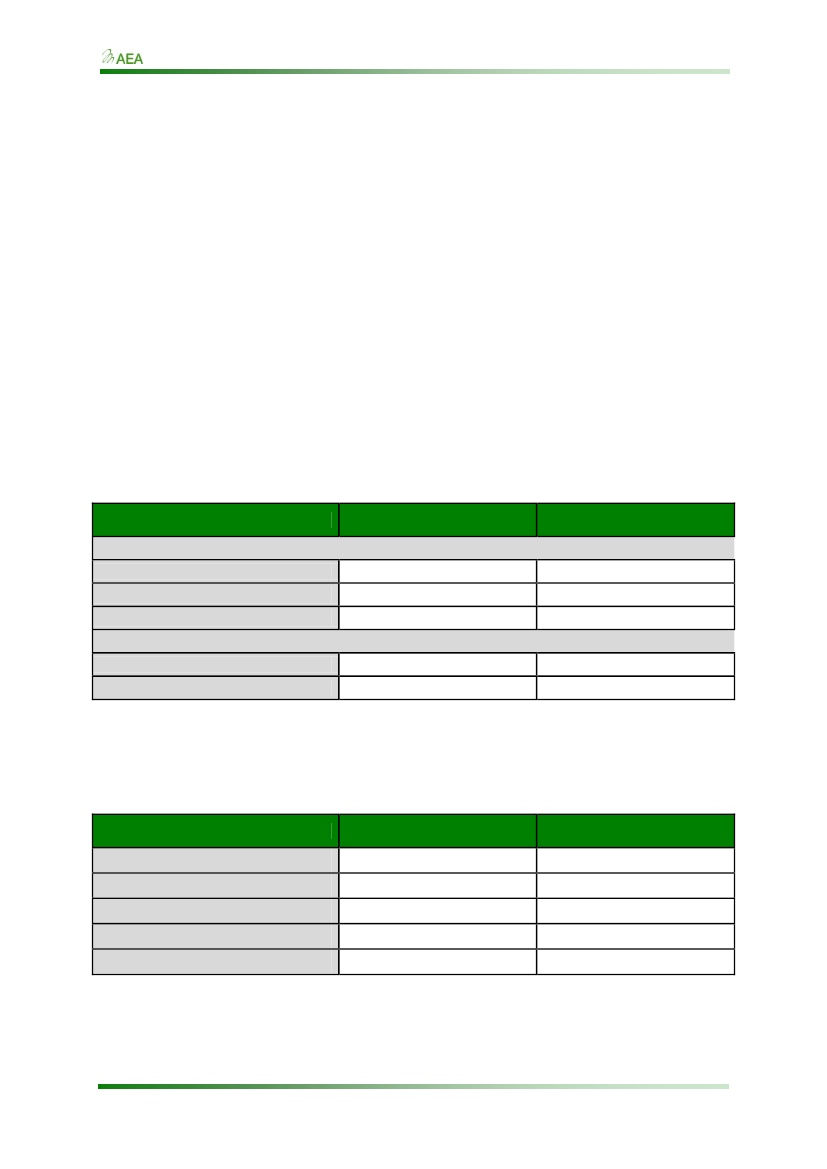

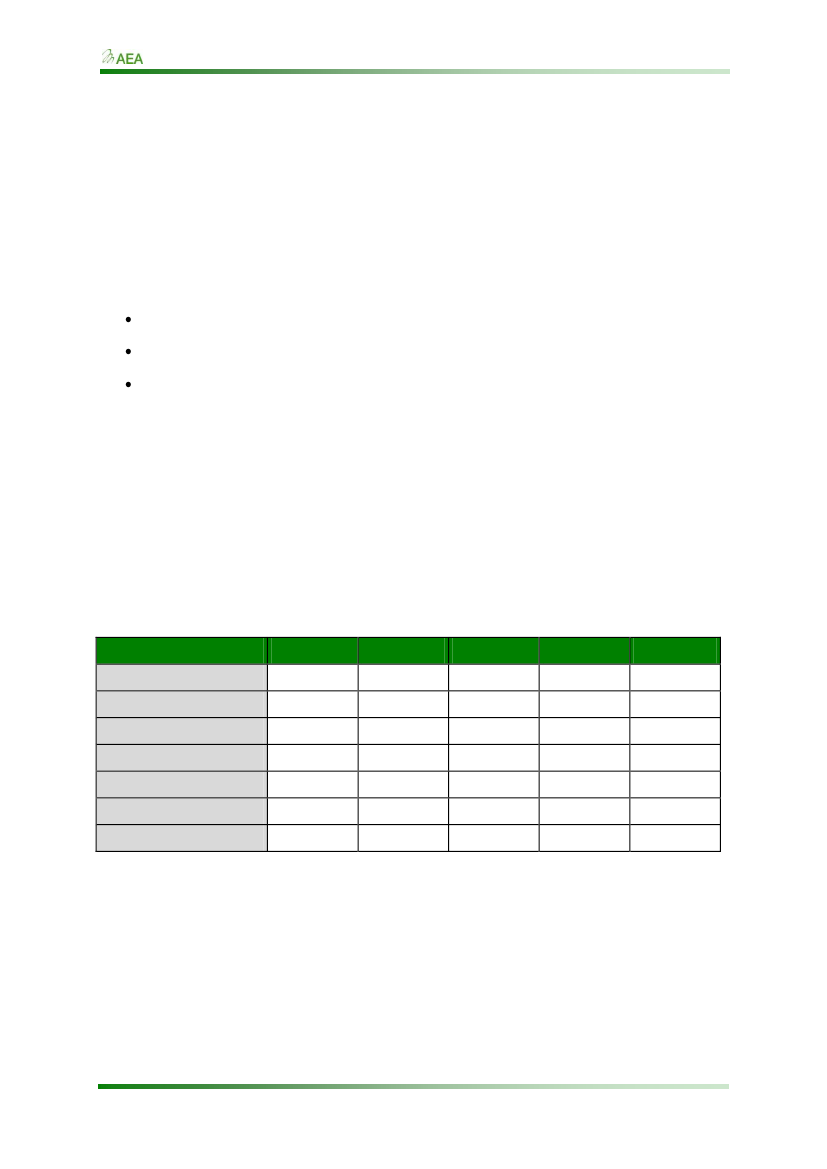

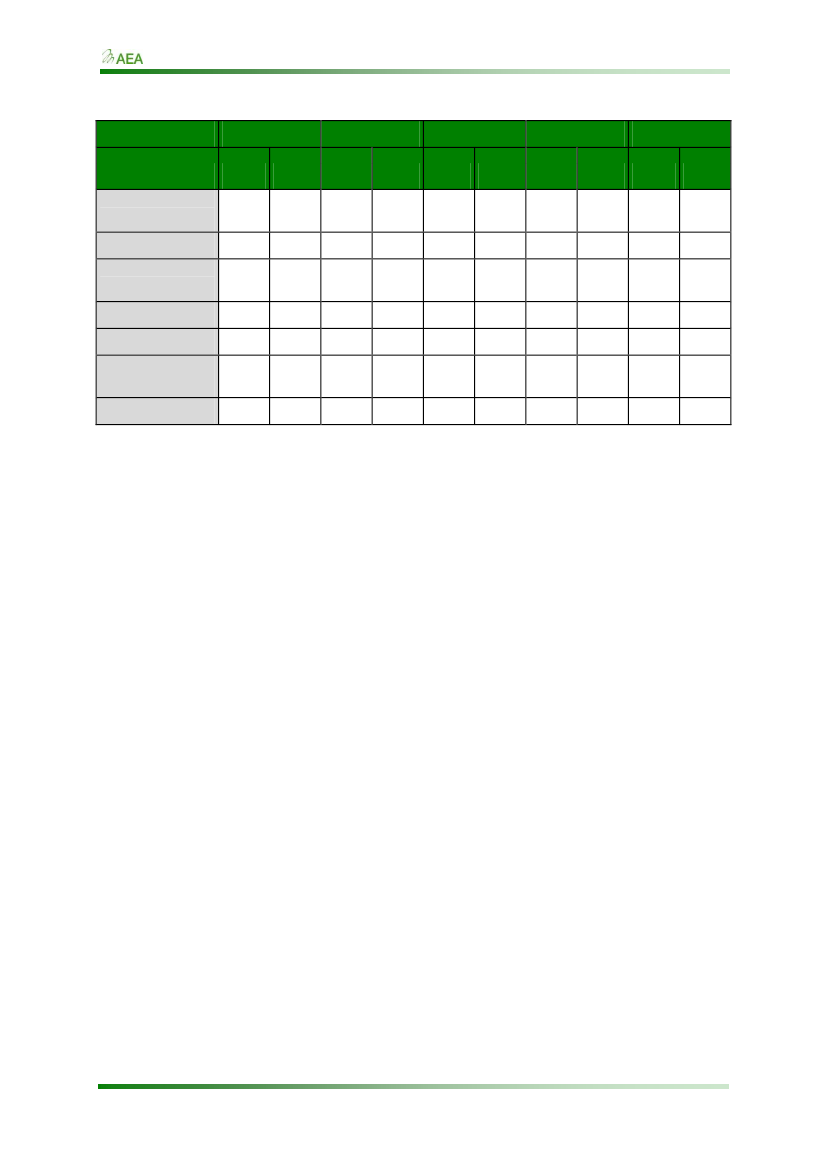

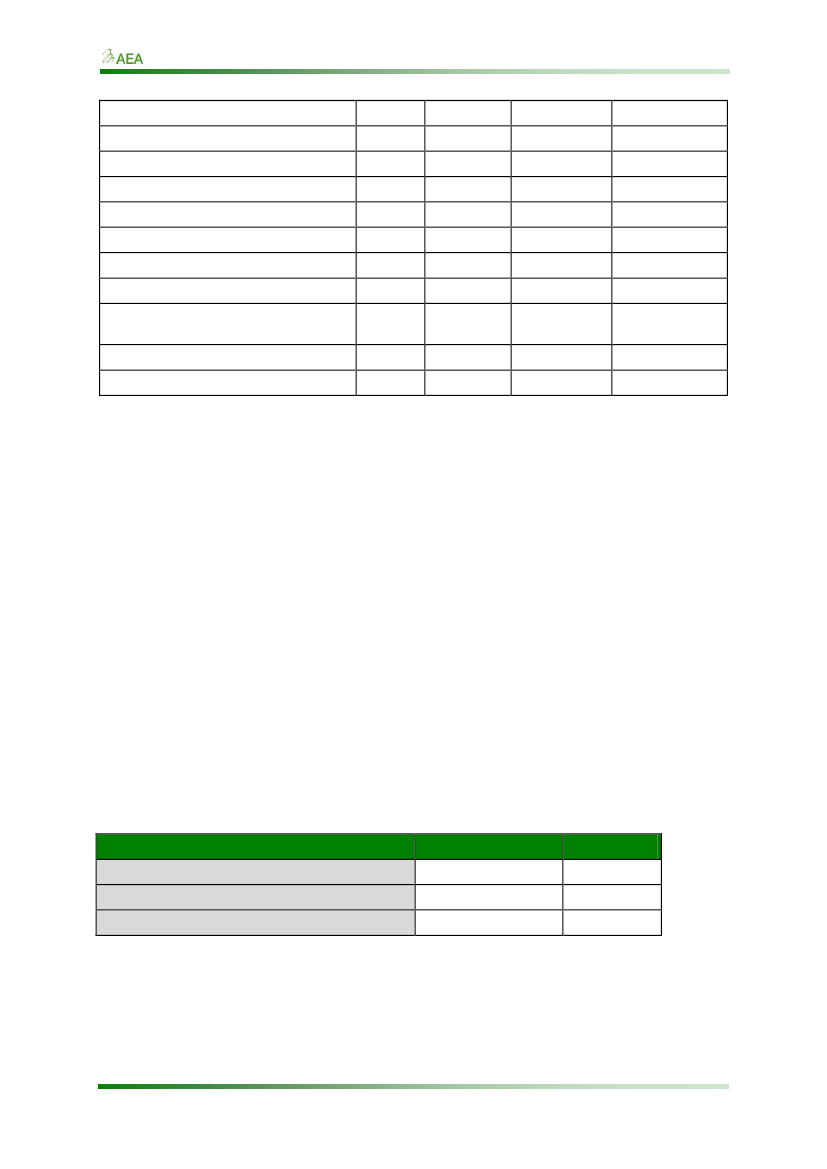

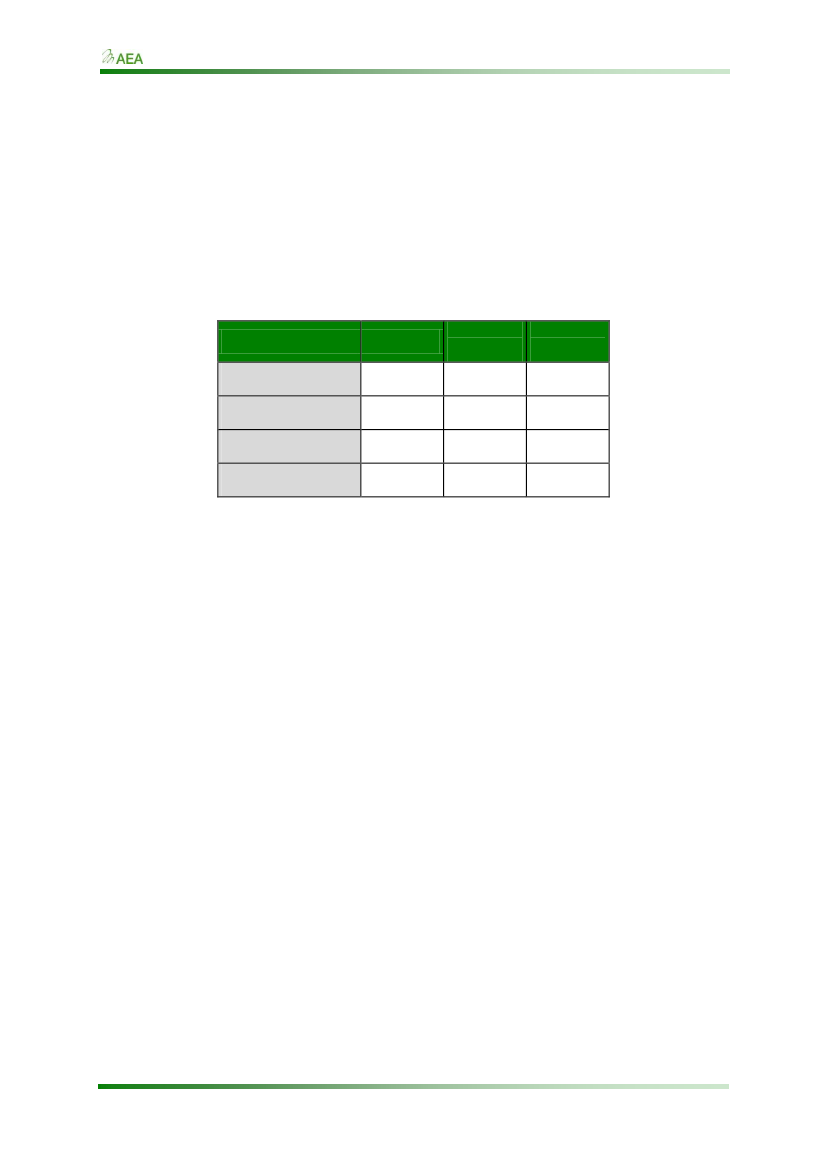

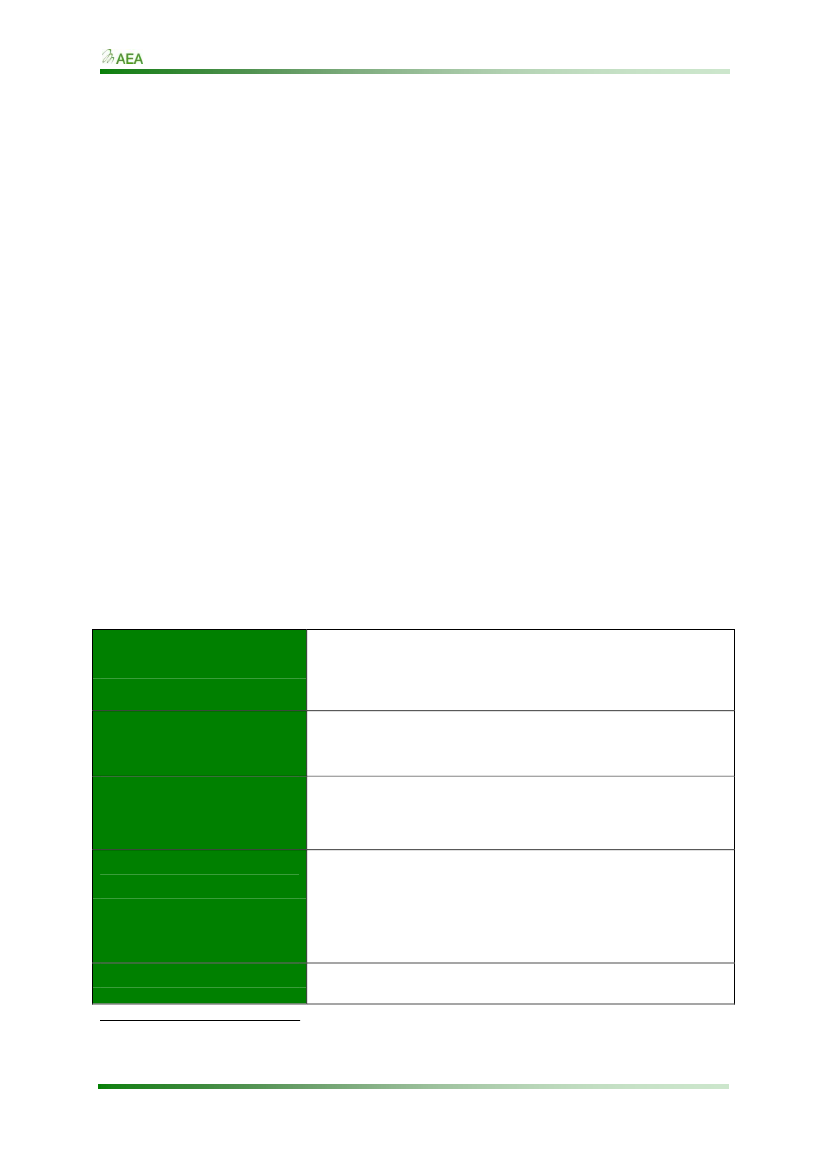

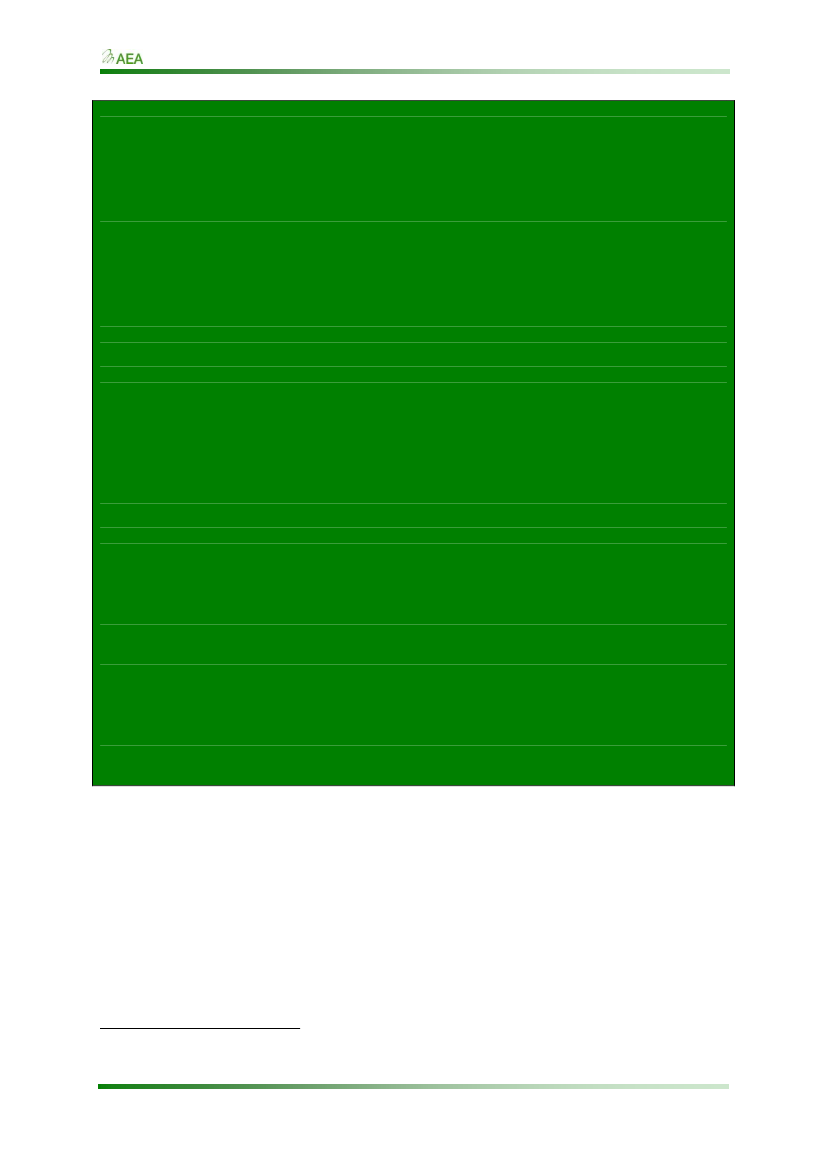

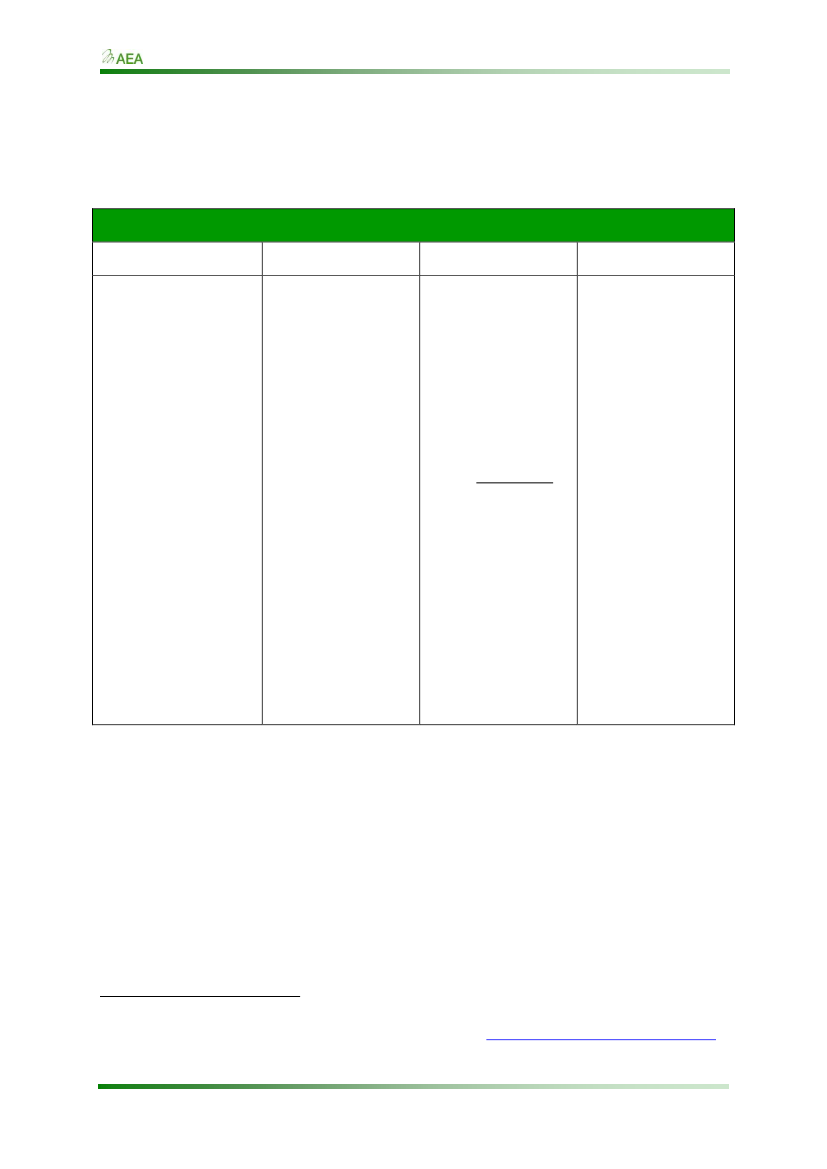

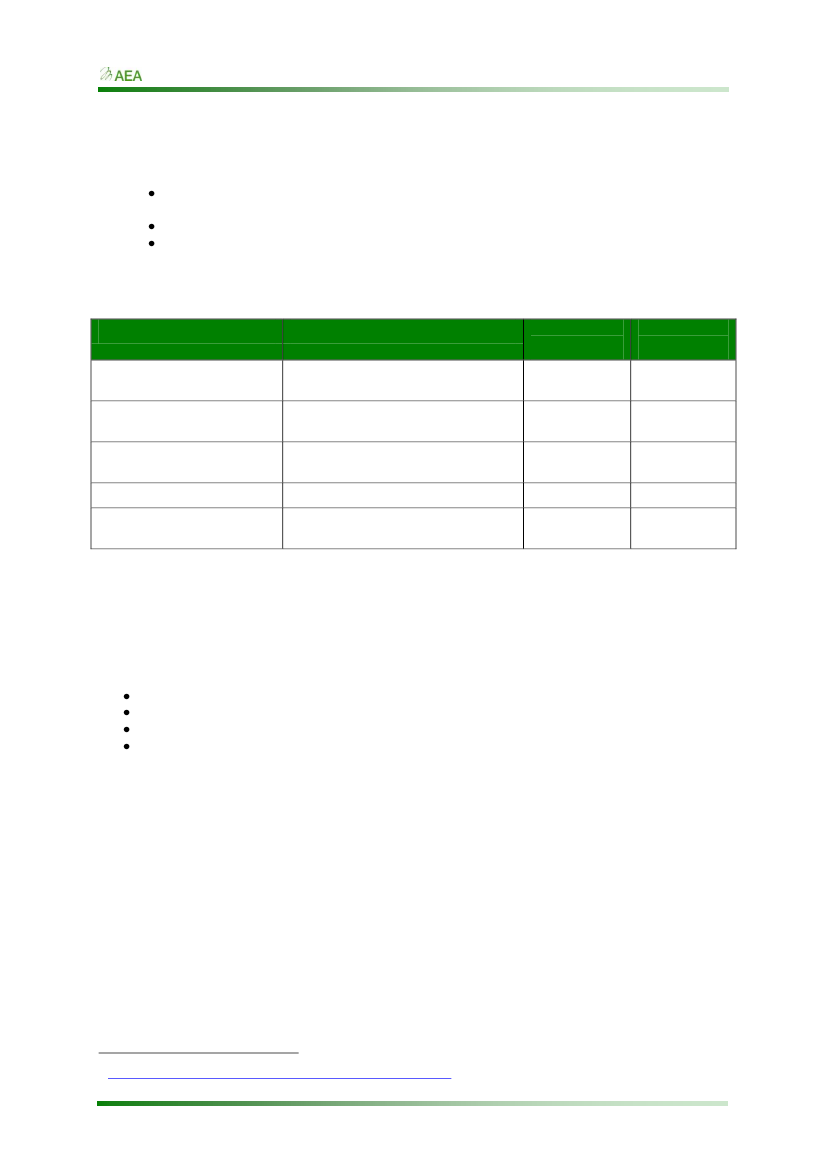

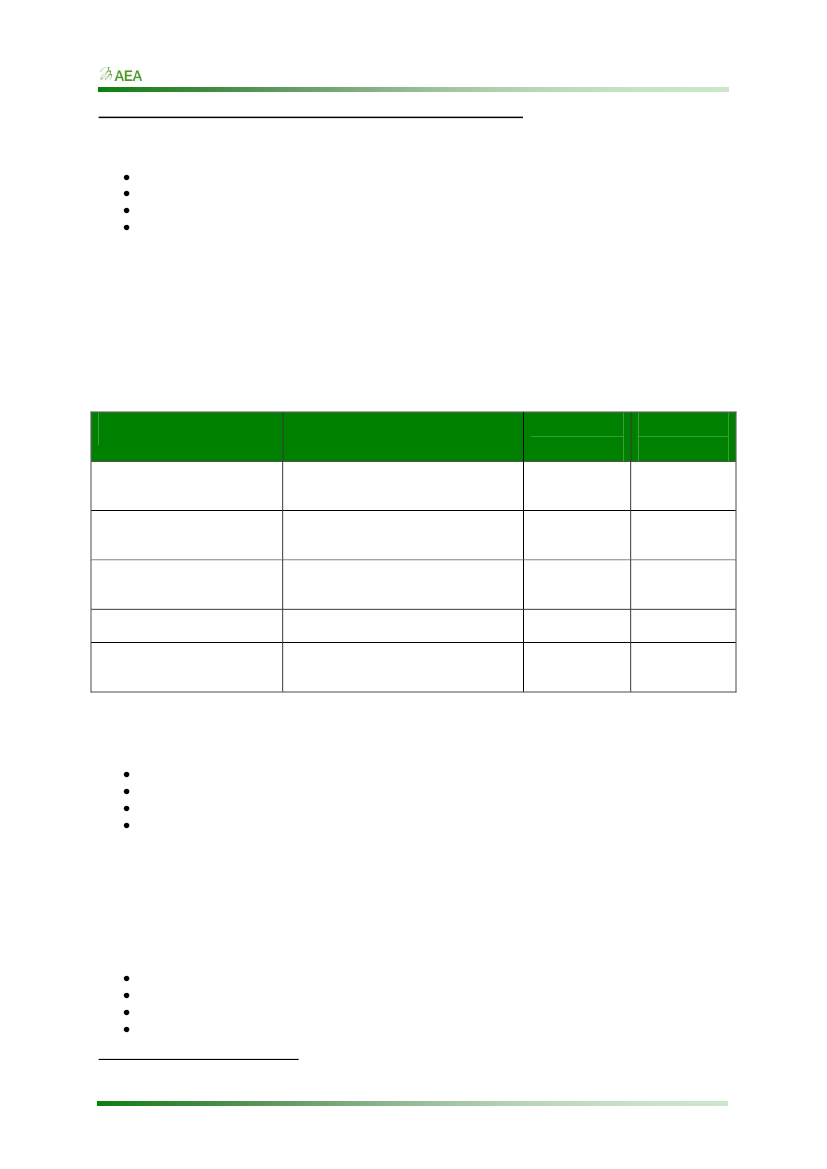

1 Introduction1.1 Background to the studyAs readily accessible oil and gas reserves are becoming progressively limited the energy supplyindustry is exploring the potential of unconventional reserves which were previously too complex ortoo expensive to extract.The United States of America (U.S.) is ahead of the rest of the world in this energy field. Extraction ofcoal bed methane and gas extraction from sandstone and shale represents a growing proportion ofthe energy mix in the U.S. In 2010, Shale gas represented ~23% of total U.S. dry gas production.From 2006 – 2010 shale gas production increased by 48% and is projected to account for 47% ofU.S. production in 2035 (U.S. DOE, Energy Information Administration, 2011a). The U.S. has3accessible reserves of over sixty trillion m of natural gas, amounting to over one hundred years’ ofU.S. consumption at current levels. The total technically recoverable shale gas resource is estimated3to be 13 trillion m (U.S. DOE, Energy Information Administration, 2012).Table 1 (U.S. DOE, Energy Information Administration, 2011b) shows the estimated technicallyrecoverable resources for selected basins in Europe, compared to existing reported reservesproduction and consumption, during 2009. This indicates that technically recoverable shale gasresources in Europe are of a similar scale to those technically recoverable in the U.S.Table 1: Estimated shale gas recoverable resource for select basins in Europe(1)

2009 Natural Gas Market (trillion cubicmetres, dry basis)StateProduction ConsumptionFranceGermanyNetherlandsNorwayU.K.DenmarkSwedenPolandTurkeyUkraineLithuaniaOthersTotal(1)(2)

Imports(exports)98%84%(62%)(2156%)33%(91%)100%64%98%54%100%50%

Proved NaturalGas Reserves(trillion cubicmetres)0.0060.181.392.040.2550.059

TechnicallyRecoverable ShaleGas Resources(trillion cubicmetres)5.100.230.482.40.570.651.16

0.000850.01440.07900.1030.0590.0085-0.00590.000850.020-0.0140.305

0.0490.0930.0490.00450.0880.00450.00110.0160.0350.0440.00280.0270.365

0.1640.0061.10

5.300.421.190.113

(2)

0.0775.27

0.5413.0

Dry production and consumption.Romania, Hungary, Bulgaria.

In Europe the estimates of technically recoverable shale gas reserves are continuing to evolve. Theseestimates have been informed by the exploratory works for shale gas production that have begun inseveral Member States. In the UK there are indications that recoverable reserves could potentially beof a similar scale to those of Poland and France (Cuadrilla Resources Ltd, 2011). However in PolandRef: AEA/ED57412/Issue 2

1

Climate impact of potential shale gas production in the EU

recent estimates suggest that recoverable shale gas reserves represent a much lower volume than2previously thought, and potentially as much as 85% less than U.S. Energy Department estimates ,3with some companies ending exploration activities . In France, shale gas developments have madelittle progress. The process of hydraulic fracturing is banned. However a committee has been set upwhich will assess the environmental risks of hydraulic fracturing and provide an opinion on theconditions for the implementation of research projects under public supervision.(Decreen� 2012-385of 21 March 2012 and Law n� 2011-835 of 13 July 2011).As with any drilling and extraction process shale gas extraction may bring environmental and healthrisks which need to be understood and addressed. In particular the contribution that potential shalegas production may make to climate change is a key issue. The European Commission (EC) hascommissioned a number of studies to investigate the possible consequences of exploiting shale gas.This study is aimed at exploring the evidence base for GHG emissions from shale gas and possibleways to mitigate these emissions through legislation and reporting mechanisms.

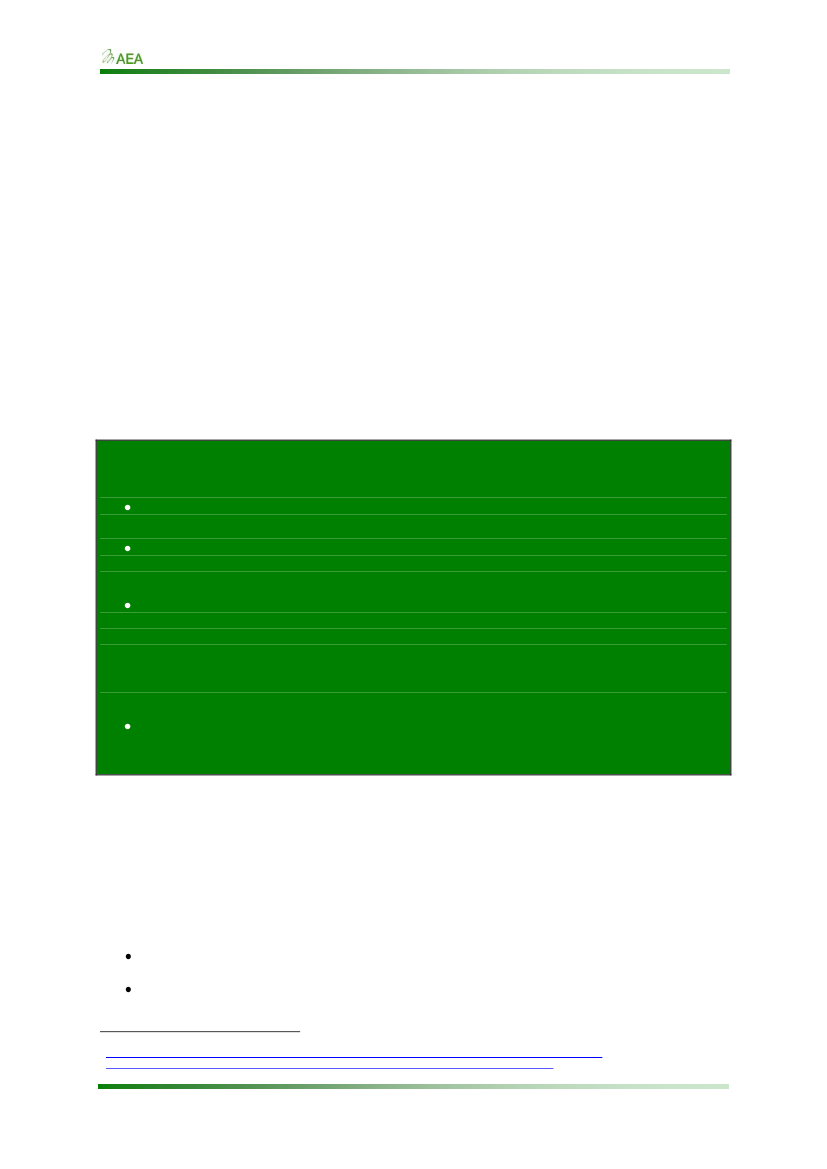

1.2 Objectives of the studyThe objective of this study is to provide state-of-the-art information to the European Commission onthe potential climate implications of possible future shale gas production in Europe.Four specific objectives were set out in the Invitation to Tender, as shown below.Study ObjectivesThe objectives of this study are to:Summarise and evaluate available knowledge on shale gas extraction technologiesand practises and the related GHG emissions;Analyse the suitability of EU legislation and propose EU wide policies that couldenforce the use of the most advanced technologies and practices to reduce GHGemissions;On the basis of the evaluation of the available data, provide an estimate of life cycleGHG emissions of electricity production using shale gas, taking into account all pre-production and production phases of shale gas extraction, and specifying both directGHG emissions, indirect emissions from fossil fuels used to extract and transport thegas as well as fugitive emissions and venting. The life cycle GHG emissions should bebased on current and future European power generation efficiencies as compared withlife cycle emission estimates using other fossil fuels;Provide an assessment of the adequacy of GHG emissions reporting frameworks tocover fugitive emissions of the production of shale gas and, if needed, proposemeasures for its improvement.The study does not have an objective to explore the potential role of shale gas in the future energysupply mix, or any potential implications of the exploitation of indigenous shale gas resources on thedevelopment of renewable or other energy sources in Europe. These issues are importantconsiderations for energy and climate policy makers, but are beyond the scope of this study.However, the results provided here can be used as inputs to any discussions around these issues.

1.3 Report StructureIn addition to this introductory chapter, the report is organised into the following chapters:Chapter 2: Shale gas exploitation, provides an overview of shale gas production and theprocesses involved;Chapter 3: Greenhouse gas emissions from shale gas production, provides a review ofexisting estimates of emissions from shale gas operations;

23

http://www.bloomberg.com/news/2012-03-21/poland-may-have-768-billion-cubic-meters-shale-gas-reserves-1-.htmlhttp://finance.yahoo.com/news/exxonmobil-ends-shale-gas-exploration-poland-113831058--finance.html

Ref: AEA/ED57412/Issue 2

2

Climate impact of potential shale gas production in the EU

Chapter 4: Best available techniques for reducing GHG emissions, explores potentialemissions abatement options;Chapter 5: Hypothetical estimation of the lifecycle GHG emissions from shale gas exploitationin Europe, provides a first estimate of the potential emissions that may be associated withfuture shale gas operations in Europe;Chapter 6: Legislation controlling GHG emissions from shale gas production, provides aninitial review of potential legislative options for controlling any potential emissions from shalegas operations;Chapter 7: Assessment of current GHG emissions reporting framework, explores howemissions from shale gas operations may be reported within existing frameworks;Chapter 8: References, lists the main references;Chapter 9: Glossary, provides a glossary of key terms.

Ref: AEA/ED57412/Issue 2

3

Climate impact of potential shale gas production in the EU

2 Shale gas exploitation2.1 IntroductionThis chapter provides an overview of shale gas exploitation, including the market context, and asummary of the key process stages required for its extraction.

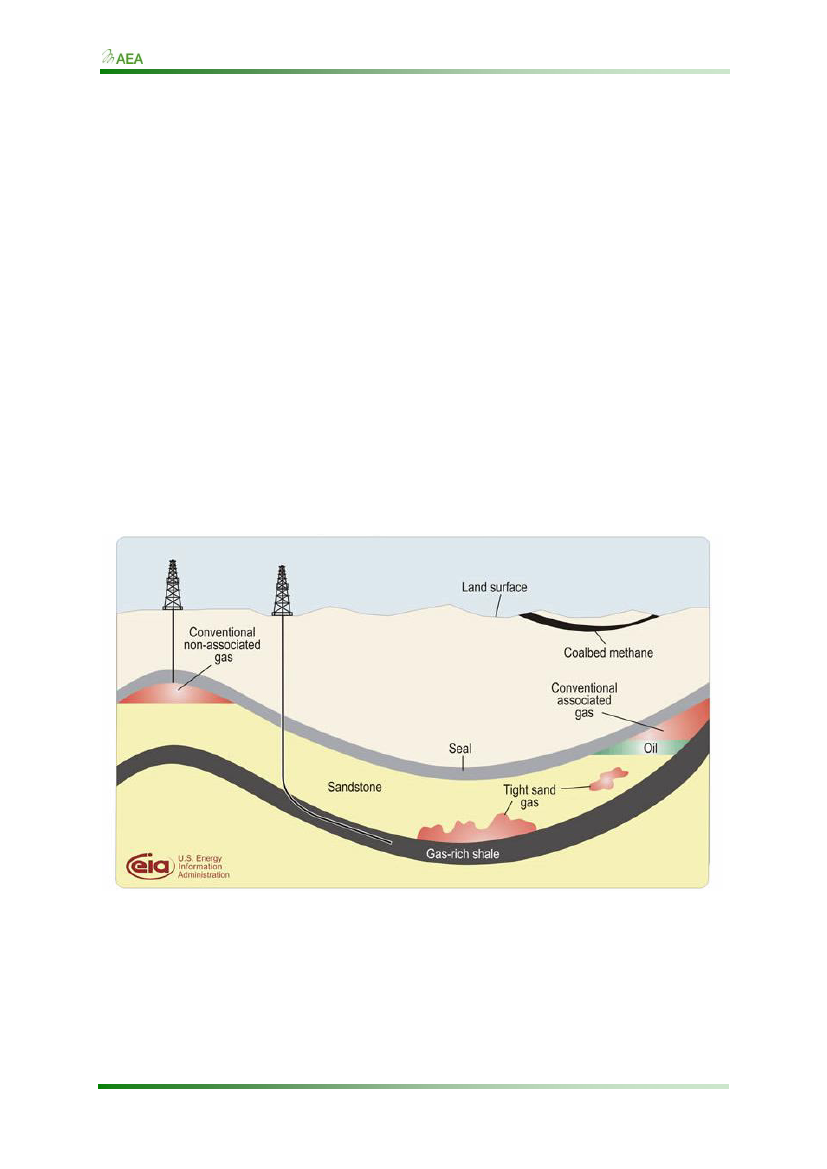

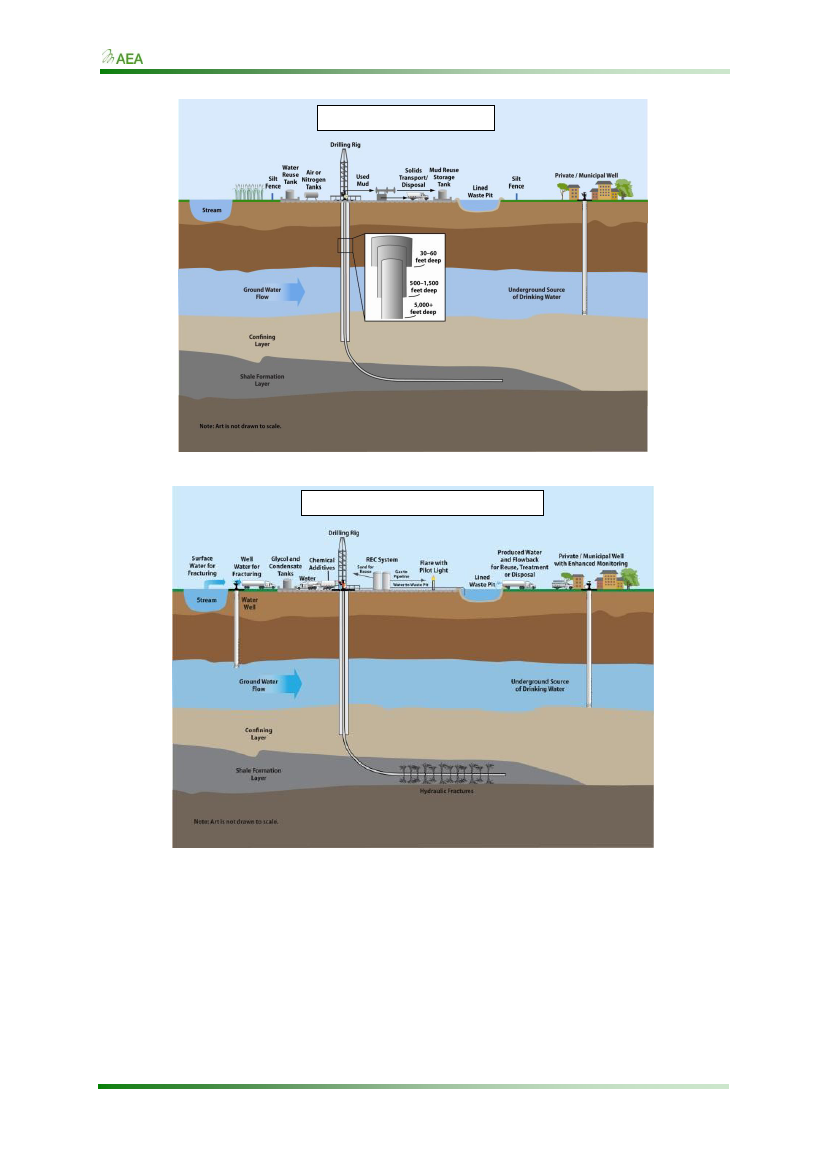

2.2 Overview of shale gas productionConventional gas refers to gas trapped in multiple, relatively small, porous zones in rock formations.This gas is often difficult to find but, once discovered, is typically the easiest and most cost-effective toextract. Conventional reservoirs (rock formations where gas is found) are typically in sandstone,siltstone and carbonate (limestone) (British Geological Survey, 2011).Shale gas, along with tight gas and coal bed methane, is an example of unconventional natural gas.The term “unconventional” in this context refers to the characteristics of the reservoir, or bearing rockformation, from which the gas is extracted. The term does not refer to the characteristics orcomposition of the gas itself which is similar in composition to “conventional” natural gas. Figure 1schematically illustrates the location of these different types of natural gas deposits.Figure 1: Schematic cross-section of the subsurface illustrating types of natural gas deposits(From: U.S. DOE, Energy Information Administration, 2011b)

‘Gas shales’ (also known as shale beds) are formations of organic-rich shale, a sedimentary rockformed from deposits of mud, silt, clay, and organic matter. As shown in Figure 1, the gas shales(shales) are continuous deposits over large areas (stretching over thousands of square kilometres(U.S. EIA 2011), which have very low permeability and low natural production capacities.The low permeability of the rock means that substantial quantities of natural gas can be trapped withintheir pores, but the shales must be artificially stimulated (fractured) to enable its extraction.Techniques such as directional / horizontal drilling and hydraulic fracturing have been developed inorder to facilitate the extraction of the gas from the shales.

Ref: AEA/ED57412/Issue 2

4

Climate impact of potential shale gas production in the EU

Directional / horizontal drilling allows the well to penetrate along the hydrocarbon bearing rock seam.This maximises the rock area that, once fractured, is in contact with the well bore and so maximisesthe well production in terms of the flow and volume of gas that may be collected. These techniquesoriginate in the U.S.

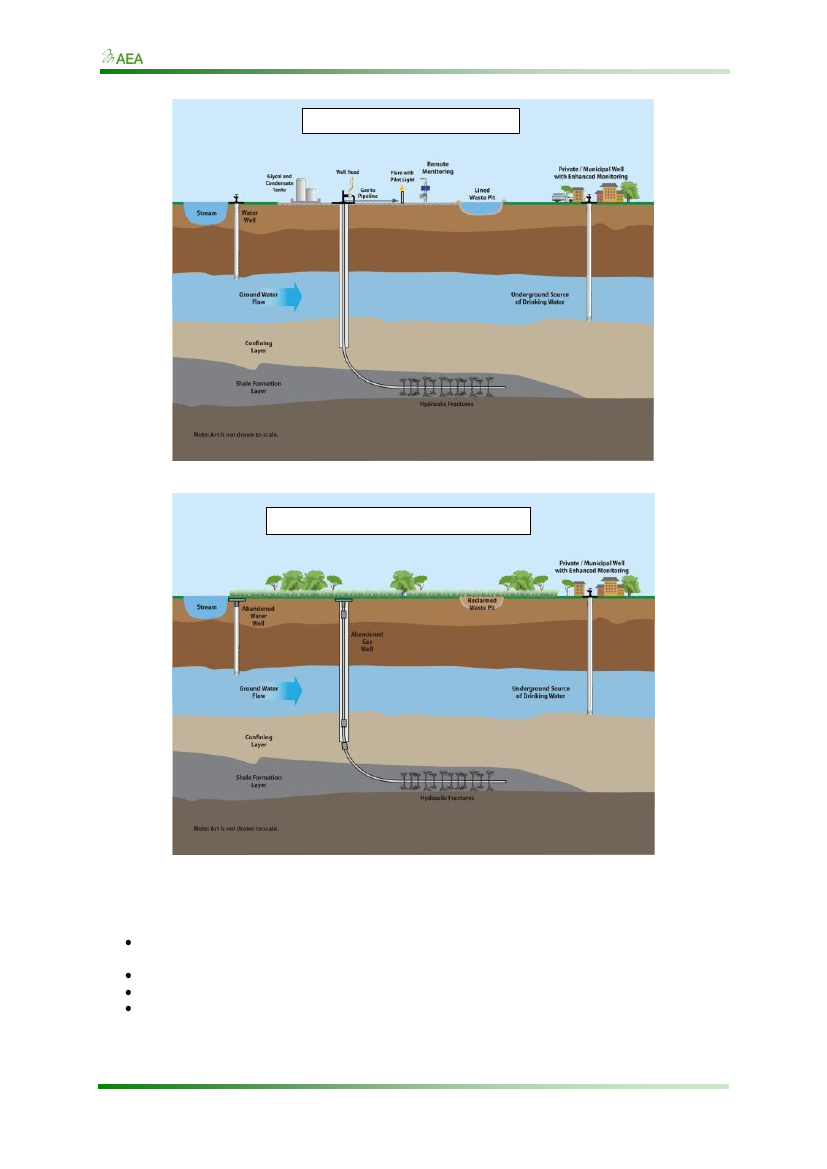

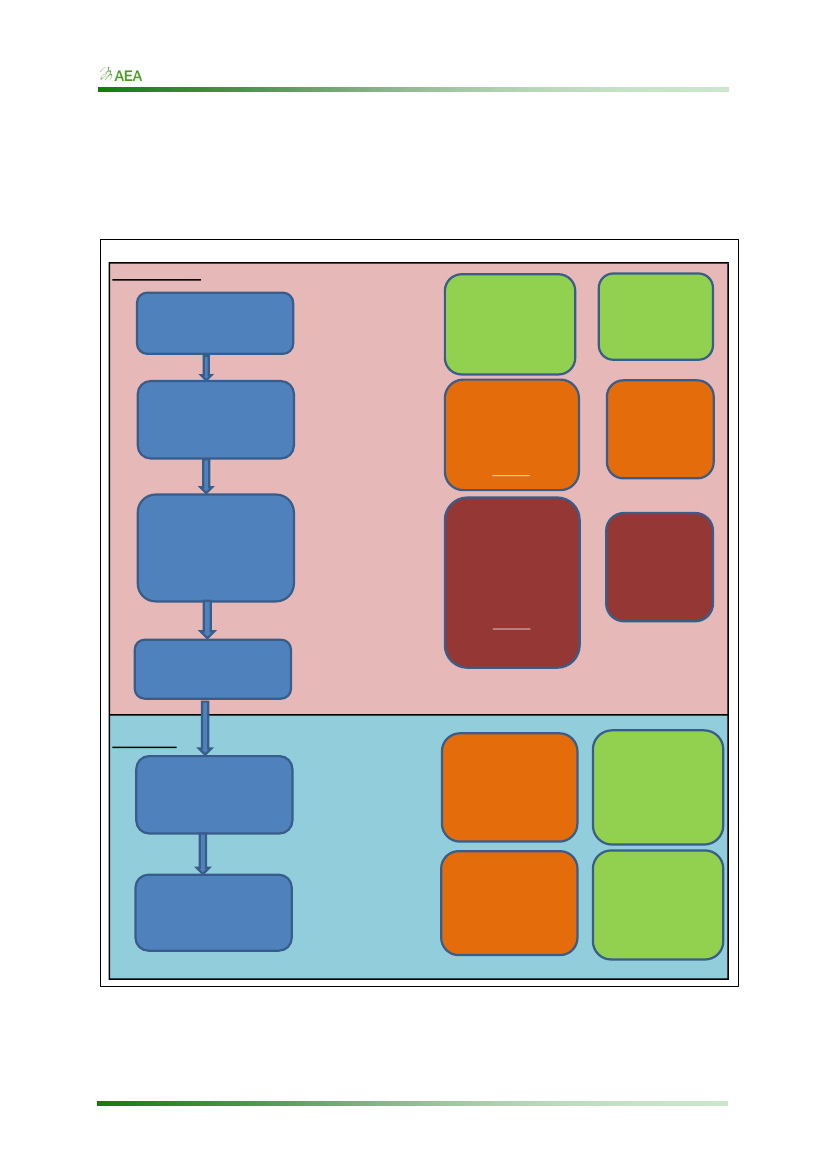

2.3 Process stages for the extraction of shale gasFor an individual unconventional gas well, the process of well development is as follows (adaptedfrom NYSDEC 2011 p5-91 to 5-137):Figure 2: Well development process

Site Preparation

Drilling

Hydraulic Fracturing

Well completion

Production and Processing

Well Plugging andAbandonment

Figure 3 provides an illustration of the principal stages in the hydraulic fracturing process.Figure 3: Stages in well developmentSite preparation

Ref: AEA/ED57412/Issue 2

5

Climate impact of potential shale gas production in the EU

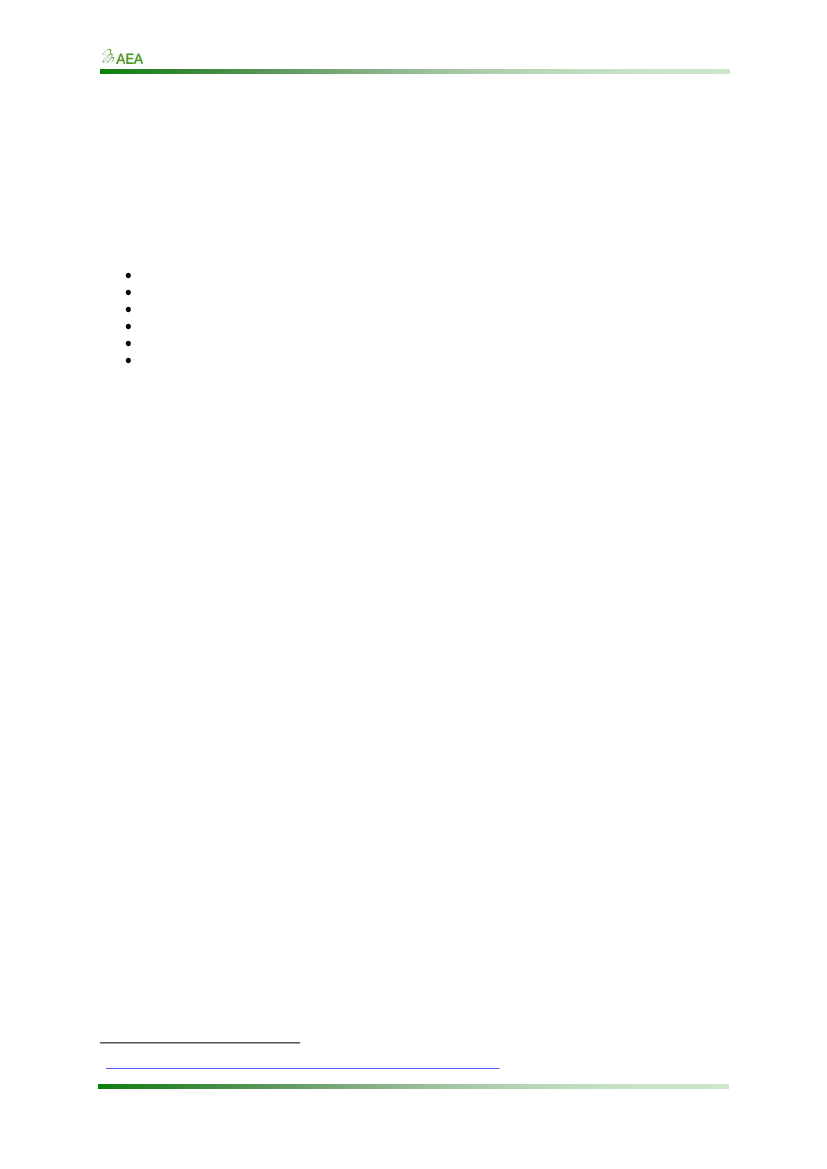

Drilling

Hydraulic Fracturing and Well completion

Ref: AEA/ED57412/Issue 2

6

Climate impact of potential shale gas production in the EU

Production and Processing

Well Plugging and Abandonment

Note: Figures are illustrative, and not necessarily representative for a specific development site.

In estimating the GHG emissions in this report we have defined the stages as:Pre-production, which includes site preparation / drilling / hydraulic fracturing / well completion/ waste and waste water treatment;Production and processing;Transport and distribution;Well plugging and abandonment.These process stages are described briefly below.

Ref: AEA/ED57412/Issue 2

7

Climate impact of potential shale gas production in the EU

2.3.1 Pre-production stageThis stage includes all of the activities required to prepare the site for shale gas extraction. Thisincludes: site preparation; drilling; initial hydraulic fracturing and associated flow back; waste andwaste water treatment.

2.3.1.1Site preparationThis process involves the establishment of appropriate supporting infrastructure for the well. Thisstarts with the initial site investigation and includes the construction of a well pad and the supportinginfrastructure, including:Access roads;Well pad;Drilling rigs;Gas storage and processing facilities;Pipelines and compressors to transport the gas off-site;Water storage and treatment facilities.This type of construction is typical for industrial sites including conventional gas production.

2.3.1.2DrillingAs outlined in Section 2.1 the extraction of shale gas requires both vertical drilling and horizontaldrilling. The vertical drilling process is very similar to drilling for conventional fossil fuels. A temporarydrill head is brought to the site and erected over the well head. Typically compressed air or freshwatermud is used as the drilling fluid. The depth of drilling will depend on the geology, but may reachdepths of 2km. Horizontal drilling requires a larger temporary drilling rig and may extend from the well3head for more than 1km (NYSDEC, 2011). This will generate cuttings in excess of 140 m (Brodericket al, 2011). This amounts to approximately 40% more drill cuttings compared to a vertical well(NYSDEC, 2011).Once the well is drilled it is cased to seal it from the surrounding rock. Typically the casing is in theform of, depending on depth, one or more steel pipes lining the inside of the drilled hole which arecemented in place. The well is then fitted with a well head which is suitably designed and pressurerated for the hydraulic fracturing operations.

2.3.1.3Hydraulic fracturingHydraulic fracturing (fracking) is the process used by gas producers to stimulate wells and recovernatural gas from sources such as coal beds and shale gas formations. During hydraulic fracturing,fluids (usually consisting of water and chemical additives) together with a ‘proppant’ are pumpeddown the well at high pressure. When the pressure exceeds the rock strength the fluids open orenlarge fractures. These fractures can extend a few hundred metres away from the well. As thefractures are created the propping agent enters the fractures. This prevents them from closing whenthe pumping pressure is released.The fracturing fluids are primarily water-based fluids mixed with additives. Chemical additives aremixed with base fluids. This modifies the fluid mechanics to increase performance of the fracturingfluid but also to prevent corrosion to the well pipes. The composition of fracturing fluids vary, King(2012) states that the proppant makes up 1% to 1.9% of the total volume. NYSDEC (2011) gives theproppant between 8% and 15%. Fracturing fluid performance can be measured by several differentstandards, but most typically, is measured by the ability of the fluid to place proppant into thefractures.The proppant is needed to ‘prop’ open the fractures once the pumping of fluids has stopped and thepumping pressure is reduced. Sand is commonly used as the proppant, but in the U.S. there has4been a move away from sand into specialised fracturing beads and propping agents .Once the fracture has initiated additional fluids are pumped into the wellbore to continue thedevelopment of the fracture and to carry the proppant deeper into the formation. The additional fluidsare needed to maintain the downhole pressure necessary to accommodate the increasing length of

4

http://ceramics.org/ceramictechtoday/2011/12/15/engineered-proppants-for-hydrofracturing/

Ref: AEA/ED57412/Issue 2

8

Climate impact of potential shale gas production in the EU

the opened fracture. This ensures that the fracture remains open and that any gas that exists can flowinto the well.In terms of the quantities of water required, NYSDEC (2011) suggest that each stage in a multi-stage3fracturing operation requires 1,100 - 2,200 m of water, so that the entire multi-stage fracturing3operation for a single well could requires around 9,000 - 29,000 m of water. Industry sources INGAA3Consulting (2008) and Naturalgas.org (2010) suggest up to 13,200 m of water is required per well forhydraulic fracturing with existing technologies.In addition to the initial hydraulic fracturing stage, the process may over time be repeated severaltimes to extend the economic life of the well.

2.3.1.4Flow back and waste water treatmentAfter hydraulic fracturing is completed a proportion of the injected fracturing fluid, depending on thegeological formation, rises to the surface. This recovered fluid is called flow back fluid (flow back). Inaddition to flow back, naturally occurring water, termed Produced Water, flows to the well head. Thisliquid, combining flow back and produced water, is collected and sent for treatment and disposal orre-use where possible.Specifically flowback fluid refers to fluid returned to the surface after a single hydraulic fractureprocess has occurred, but before the well is placed into production. It typically consists of returnedfracturing fluids in the first few days following hydraulic fracturing. This is progressively replaced byproduced water.Within the flowback fluid there is a varying content of water. As this is returned to the surface it can beclassified either as water, i.e. that which will be used in further hydraulic fracturing stages, or as wastewater, i.e. that which is unsuitable for reuse and is discharged from the site for treatment or recycling.The volume of water that can be recycled is variable. Yoxtheimer (2012) states that 77% of flow backwater is estimated to have been recycled in the U.S. in 2011, however in the Barnett shale,approximately 1% - 2% of water is recycled; in the Fayetteville shale where there is only 10%flowback, most of that is re-used but that is atypical. The flow back fluid, in addition to water, containsa combination of sand, hydrocarbon liquids and natural gas (see Section 2.2.1.3). Where the waterwithin the flow back fluid cannot be reused, it requires disposal. The waste water may be disposeddirectly by injection into a used well, or transported for treatment at a waste water treatment facility.Produced water is fluid displaced from the shale formation, and can contain substances that are foundin the formation. This may include dissolved solids (e.g. salt), gases (e.g. methane, ethane), tracemetals, naturally occurring radioactive elements (e.g. radium, uranium), and organic compounds,Produced water will typically begin to flow to the well head following an initial hydraulic fracture andmay continue to flow to the well head for the duration of gas extraction. Because of the nature, andcontent, of produced water it is typically collected in tanks for later treatment.

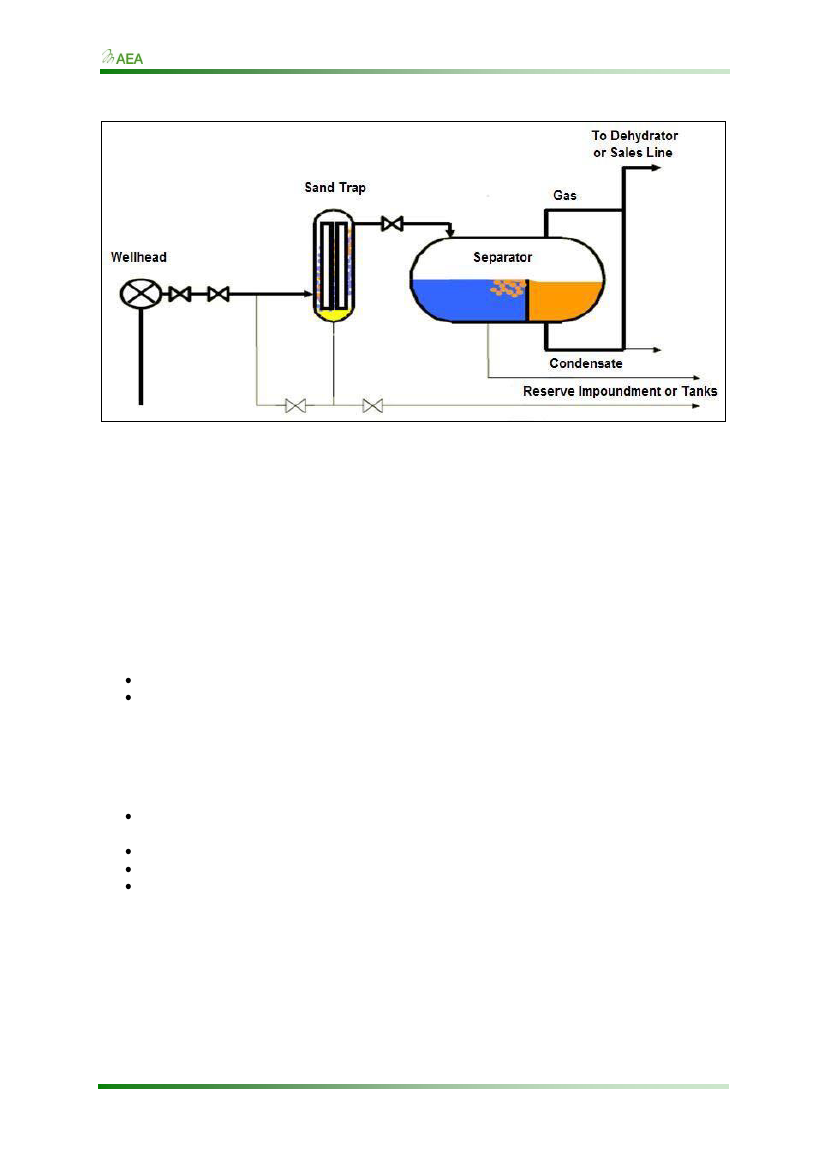

2.3.2 Production and processingOnce the drilling and hydraulic fracturing phases are complete a production well head is installed inorder to collect the gas and transfer it to a processing plant prior to distribution. The distance overwhich this occurs will vary depending on the location of the site.

2.3.2.1Production timescalesShale gas wells initially produce a large amount of gas (the free gas in the rock) but this reducesrapidly, typically over a period of several years. The average economic lifetime of wells, which will beinfluenced by the price of gas, is likely to be 10 - 15 years. A study of actual production rates in theBarnett Shale found that the average well lifespan is 7.5 years (Berman, 2009). For the Marcellusshale gas industry, it is estimated that the production rate will decrease by 80% in the first five yearsand by 92% by 10 years, falling another 3% per year thereafter (NYSDEC, 2011).

2.3.2.2Re-fracturingDuring the commercial operation of a shale gas well the operators may extend the operational life ofthe well, or increase its production over a specific time period, by repeating the hydraulic fracturingprocess (known as re-fracturing / re-fracking). This process is very similar to the hydraulic fracturingprocess described above.

Ref: AEA/ED57412/Issue 2

9

Climate impact of potential shale gas production in the EU

2.3.2.3ProcessingThe chemical composition of the shale gas produced depends on the geology of the shales. Typicallythe gas consists of methane (CH4), heavier hydrocarbons and carbon dioxide (CO2). During thisprocess stage the heavier hydrocarbons and carbon dioxide are removed and the remaining methaneis compressed for distribution. The gas is also dehydrated, commonly using glycol dehydrators, toremove the water content. This process is essentially no different from the production of conventionalgas. Also the mix of the recovered gas will affect the calorific value of the gas and therefore theoverall emissions intensity from the well.

2.3.3 Transport and distributionThis stage involves the distribution of the gas in pipelines. This process stage is essentially nodifferent from the supply of conventional gas except that the route from the well to the end user maybe different e.g. in the case of indigenous production shorter than in the case of imported natural gas.

2.3.4 Well plugging and abandonmentOnce the well has reached the end of its economic lifetime (or if a well does not produce any gas) itmust be properly decommissioned and plugged in order to protect the surroundings and subterraneanenvironment. This involves the removal of all the equipment at the well site and any distributioninfrastructure. The well is then plugged with cement in order to prevent further fugitive emissions. Thisis essential to ensure that the well is left in a safe and stable condition for the future.

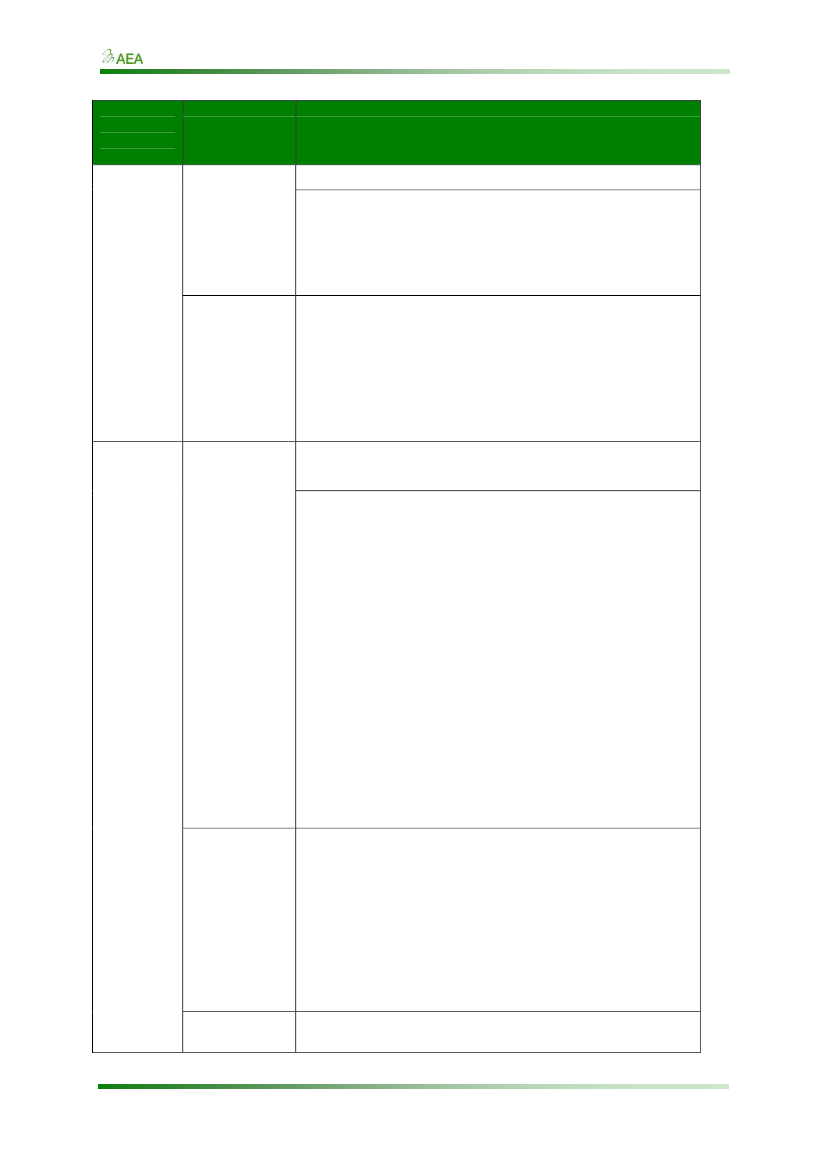

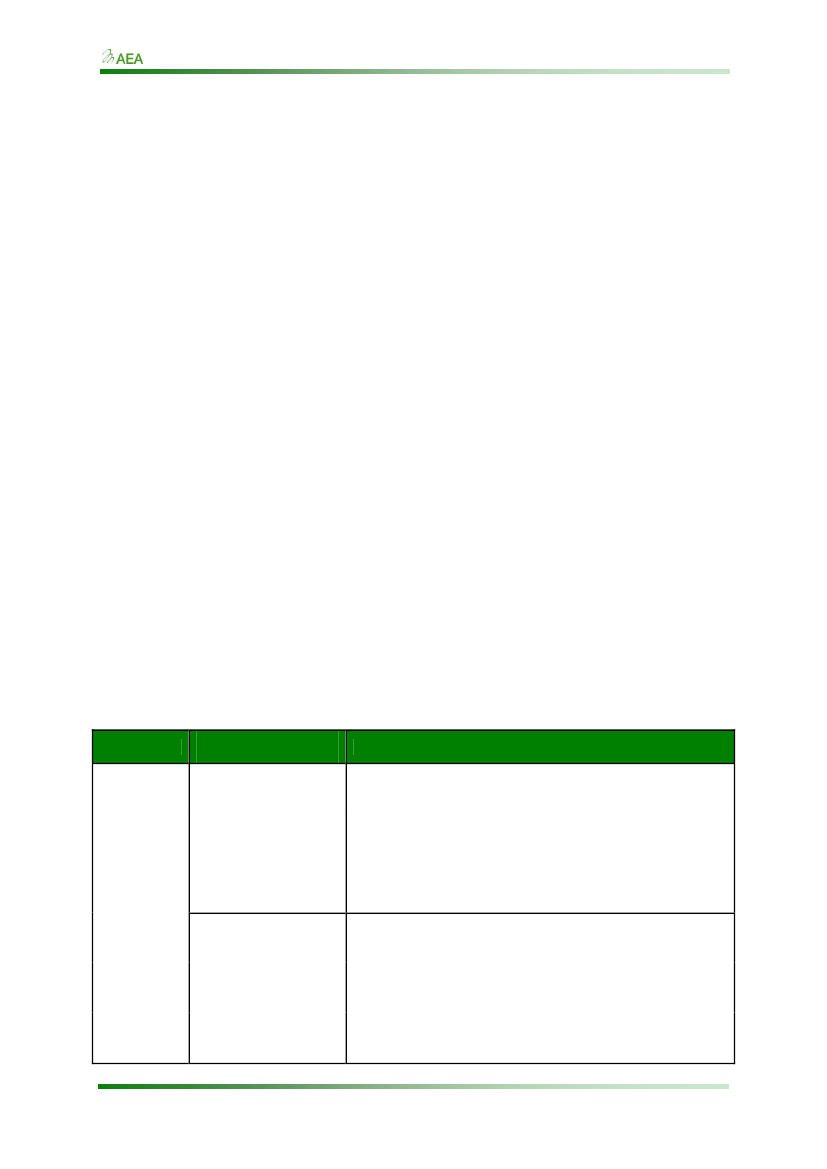

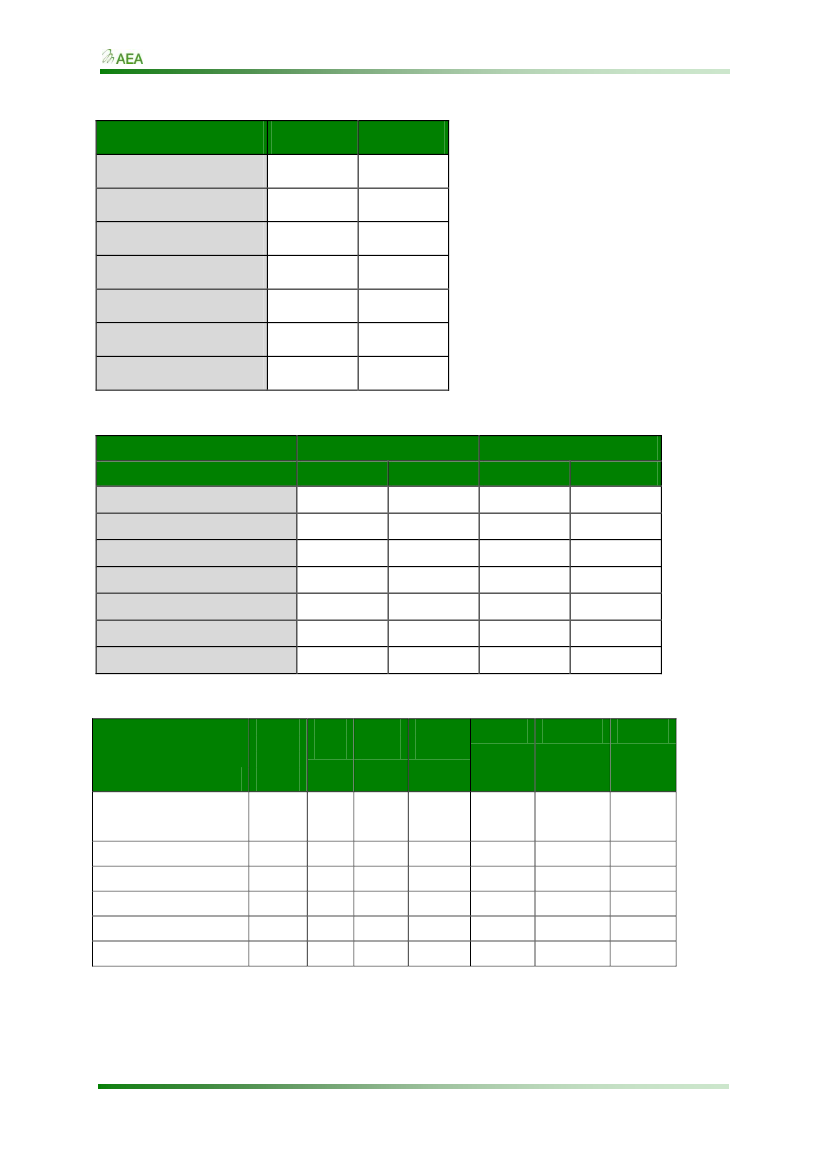

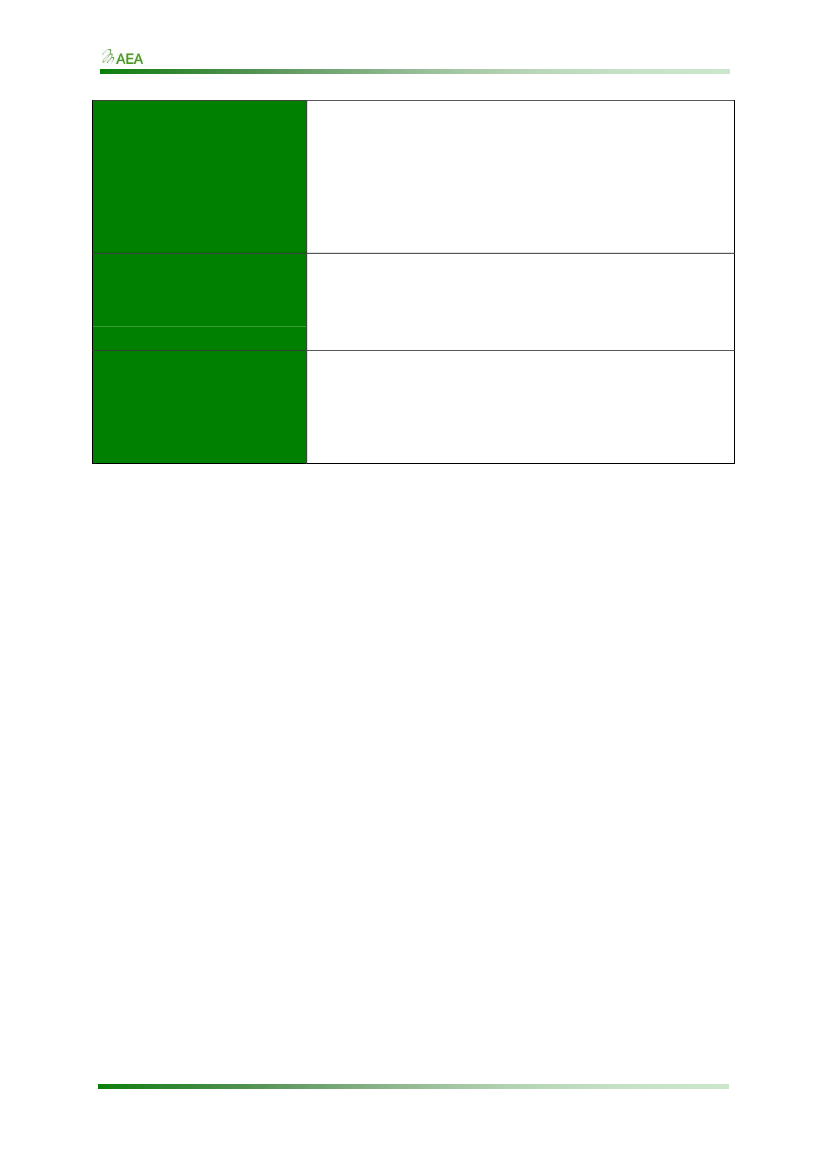

2.4 Comparison of high volume hydraulic fracturing andconventional hydrocarbon extraction practicesTable 2 sets out the stages of a high volume hydraulic fracturing activity and summarises thedifferences between this and conventional hydrocarbon production (adapted from U.S. EnvironmentalProtection Agency (U.S. EPA, 2011a and NYSDEC, 2011).Table 2: High Volume Hydraulic Fracturing: Stages, Steps, and Differences from ConventionalHydrocarbon PracticesDevelopme StepDifferences from Conventional Hydrocarbon practicesnt &ProductionStageSiteSelectionandPreparationSite identificationSite selectionNoneNoneNoneNoneNoneMore space required during hydraulic fracturing for tanks / pitsfor water / other materials required for fracturing process(NYSDEC, 2011).More lorry movements during hydraulic fracturing thanconventional production sites due to need to transportadditional water, fracturing material (including sand / ceramicbeads) and wastes.Obtaining large volumes of water (9,000 to 29,000 m per well)(NYSDEC, 2011).Disposing of large volumes of contaminated water (9,000 to3

Ref: AEA/ED57412/Issue 2

10

Climate impact of potential shale gas production in the EU

Development &ProductionStage

Step

Differences from Conventional Hydrocarbon practices

25,000 m per well) (Derived from Broderick et al, 2011).Storage of large volumes of water (9,000 to 29,000 m perwell).Will require sufficient trucks / tanks onsite to manage flow back3(e.g. 250 - 625 trucks at 40 m per truck) (derived fromNYSDEC, 2011).Site preparationInstallation of additional tanks / pits sufficient to accommodate3up to 29,000 m of make-up water.6 - 10 wells / pad (NYSDEC, 2011) compared to 1 well / padfor conventional production.Fewer well pads / hectare: 1 multi-stage horizontal well padcan access c. 250 hectares, compared to c.15 hectares for avertical well pad (NYSDEC, 2011).Well Design, Selection ofConstruction horizontal vs.andvertical wellDevelopmentWell drillingBoth conventional and unconventional wells are drilled throughwater bearing strata and require same well design standards.Horizontal drilling produces longer well bore (vertical depthplus horizontal leg) requires more mud and produces morecuttings / well. Typically 40% more mud and cuttings forhorizontal well, depending on depth and lateral extent(NYSDEC, 2011).Horizontal drilling requires specialist equipment: larger dieselengines for the drill rig uses more fuel and produces moreemissions. Equipment is on site for a longer time (typically 25days for horizontal well compared to 13 days for vertical well;NYSDEC, 2011).However, horizontal wells provide a more efficient means toaccess gas reserves than conventional vertical wells, otherfactors being equal (U.S. EPA, 2011a). Consequently,horizontal drilling from a limited number of well heads would inprinciple be preferable to vertical drilling from a larger numberof well heads. In practice horizontal drilling techniques arenormally used to open up reserves, which would not otherwisebe viable with vertical drilling techniques, and so thiscomparison is not directly relevant.CasingCasing material must be compatible with fracturing chemicals(e.g., acids).Casing material must also withstand the higher pressure fromfracturing multiple stages.3

3

Cementing

Hydraulic fracturing has the potential to damage cement: maypose a higher risk during re-fracturing, although unclear at

Ref: AEA/ED57412/Issue 2

11

Climate impact of potential shale gas production in the EU

Development &ProductionStage

Step

Differences from Conventional Hydrocarbon practices

present (U.S. EPA, 2011a).WellCompletionHydraulicFracturing:Water sourcingRequirement to abstract and transport water to wellhead forstorage prior to hydraulic fracturing operations.

HydraulicFracturing:ChemicalSelection

Current U.S. information indicates that the composition ofchemicals used in high volume fracturing is similar to that usedin conventional fracturing (NYSDEC, 2011). The compositionof fracturing fluids to be used in the EU is uncertain. Lessharmful additives are being developed and used at lowerconcentrations in both conventional and unconventionalapplications (King, 2011).Transport of large volumes of water, chemicals and proppant3to well pad (up to 25,000 m ).More chemical storage required for high volume hydraulicfracturing (as for transportation above).Mixing of water with chemicals and propping agent (proppant).

ChemicalTransportationChemicalstorageChemical Mixing

HydraulicFracturing:PerforatingcasingHydraulicFracturing: Wellinjection ofhydraulicfracturing fluid

Conventional wells are hydraulically fractured in NorthAmerica, although this is uncommon in Europe. The amountand extent of perforations may be greater for high volumehydraulic fracturing.Monitoring requirements and interaction of fracturing fluid withformation also occur in conventional wells but more extensivein high volume fracturing due to longer well length in contactwith formation (up to 2,000 metres for high volume hydraulicfracturing compared to up to a few hundred metres forconventional well depending on formation thickness).More equipment required: series of pump trucks, fracturingfluid tanks, much greater intensity of activity.

HydraulicFracturing:Pressurereduction in well/ to reverse fluidflow recoveringflow back andproduced water

‘Flow back’ of fracturing fluid and produced water containingresidual fracturing chemicals, together with materials of naturalorigin: brine (e.g., sodium chloride), gases (e.g., methane,ethane, carbon dioxide, hydrogen sulphide, nitrogen, helium),trace elements (e.g. mercury, lead, arsenic), naturallyoccurring radioactive material (e.g. radium, thorium, uranium),and organic material (e.g. acids, polycyclic aromatichydrocarbons, volatile and semi-volatile organic compounds)(U.S. EPA, 2011a).In principle no difference to conventional wells. However,potential for impacts in areas which would not otherwise becommercially viable.

Wellcompletion(continued)

Connection ofwell pipe toproductionpipelineReduced

Larger volume of flow back and sand to manage than

Ref: AEA/ED57412/Issue 2

12

Climate impact of potential shale gas production in the EU

Development &ProductionStage

Step

Differences from Conventional Hydrocarbon practices

EmissionCompletionWell padremovalWellProductionConstruction ofpipeline

conventional wells (9,000 to 25,000 m per well) (Derived fromBroderick et al, 2011).Larger well pad (with more wells / pad) with more ponds andinfrastructure to be removed, as described above.Exploitation of unconventional resources may result in arequirement for gas pipelines in areas where this infrastructurewas not previously needed.Produced water will contain decreasing levels of fracturingfluid as well as hydrocarbons.Conventional wells are often in wet formations that requiredewatering to maintain production. In these wells, producedwater flow rates increase with time. In shale and otherunconventional formations, produced water flow rates tend todecrease with time.

3

Production

Well SiteClosure

Remove pumpsand downholeequipmentPlugging to sealwell

Closure of unconventional wells is similar to closure ofconventional wells.

Post-closure Potential formethaneseepage tooccur in thelong-term ifseals or linersbreak down

Closure of unconventional wells is similar to closure ofconventional wells.

Ref: AEA/ED57412/Issue 2

13

Climate impact of potential shale gas production in the EU

3 Greenhouse Gas (GHG) emissionsfrom shale gas production3.1 IntroductionThe GHG emissions associated with shale gas production have been the subject of previous life cycleassessment (LCA) studies. A review of these studies has been carried out in order to betterunderstand the potential scale of emissions, the main emission causing activities, and the reasons forany differences in previous estimates.

3.2 Compilation of the evidence baseMuch of the current evidence base originates from the U.S. There is little European evidence assignificant shale gas operations are, with the exception of limited exploration activities, not yetoperational in Europe and typical practices are yet to be established.Most studies estimating the GHG emissions from shale gas production are relatively recent, with thenumber of studies growing steadily over the past 2 years. As far as possible, the analysis presentedrepresents the state of research at the time of writing. It is important to note that certain limitationsand uncertainties in the evidence base remain. These are discussed further below.In practice, there are a small number of LCA studies that are regularly referenced by the widerliterature. These include the studies by Broderick et al (2011); Howarth et al (2011); Jiang et al(2011), Santoro et al (2011); and Stephenson et al (2011). With the exception of Santoro et al (2011),all of these papers have been published in peer-reviewed journals or publications. Other studies havebeen prepared by government agencies. For example, Skone et al (2011) is a report prepared by theU.S. Department of Energy National Energy Technology Laboratory. These studies form the basis ofthe review conducted for this report.The LCA studies reviewed draw upon a wider pool of primary research and data on specific shale gasoperations and practices. These sources are used to support the assumptions that are made by thestudy authors in their emissions modelling. The source of these primary studies is diverse, andincludes industry estimates, as well as estimates by governments and their agencies. Some of themain studies were referenced in the previous chapter, including reports from the U.S. EPA (2011b)and NYSDEC (2011). These studies have typically not been independently peer-reviewed, although inthe case of the government studies may have been subject to formal consultation with stakeholders.The estimates also frequently originate from specific sites or regions, so may not be fully applicable toother locations.The following sections describe our findings for each of the process stages described in Section 2.2.As with the original LCA studies the GHG emissions have only been considered from the perspectiveof normal state operating conditions, therefore fault conditions have not been considered.

3.2.1 Methodological basisIn order to provide a useful comparison of the different studies it is important to as far as possiblepresent the results on an equivalent basis. This includes presenting the results in consistent units.This has been the aim in the summary presented below. This has required some conversion of thevalues presented in the original studies. The conversions that have been made in order to facilitatethis comparison are described further in Appendix 1.One important assumption that is important to correct for is the assumed Global Warming Potential(GWP) of methane. This reflects the relative potency of methane as a GHG, and its lifetime. Methaneis a more potent GHG than CO2but has a shorter lifetime in the atmosphere, a half-life of about fifteenyears, versus more than 150 years for CO2. As a result, there are different ways to compare the effectof methane and CO2on global warming. One way is to evaluate the GWP of methane, compared toRef: AEA/ED57412/Issue 2

14

Climate impact of potential shale gas production in the EU

CO2, averaged over 100 years. The 4 Assessment report of the IPCC (IPCC, 2007) gives a value of25 (on a mass basis) for this 100-years GWP, revised up from their previous estimate of 21. Thisvalue is relevant when looking at the long-term relative benefits of eliminating a temporary source ofmethane emissions versus a CO2source (IEA, 2012).Averaged over 20 years, the GWP, estimated by the IPCC, is 72. This figure can be argued to bemore relevant to the evaluation of the significance of methane emissions in the next two or threedecades, which will be the most critical to determine whether the world can still reach the objective oflimiting the long-term increase in average surface temperatures to 2 degrees Celsius (IEA, 2012).Moreover, some scientists have argued that interactions of methane with aerosols reinforce the GWPof methane, possibly bringing it to 33 over 100 years and 105 over 20 years (Shindell, 2009). Theserecent analyses are under review by the IPCC.Since different studies may apply different GWP values for methane when expressing the results incarbon dioxide equivalents (CO2eq), it is important to make this clear when making comparisons. Inthe results presented below emissions are presented in CO2eq using GWP (100 years) of 25. Somefurther exploration of the potential influence on the assumed GWP on the overall results is presentedin the summary section at the end of this chapter.

th

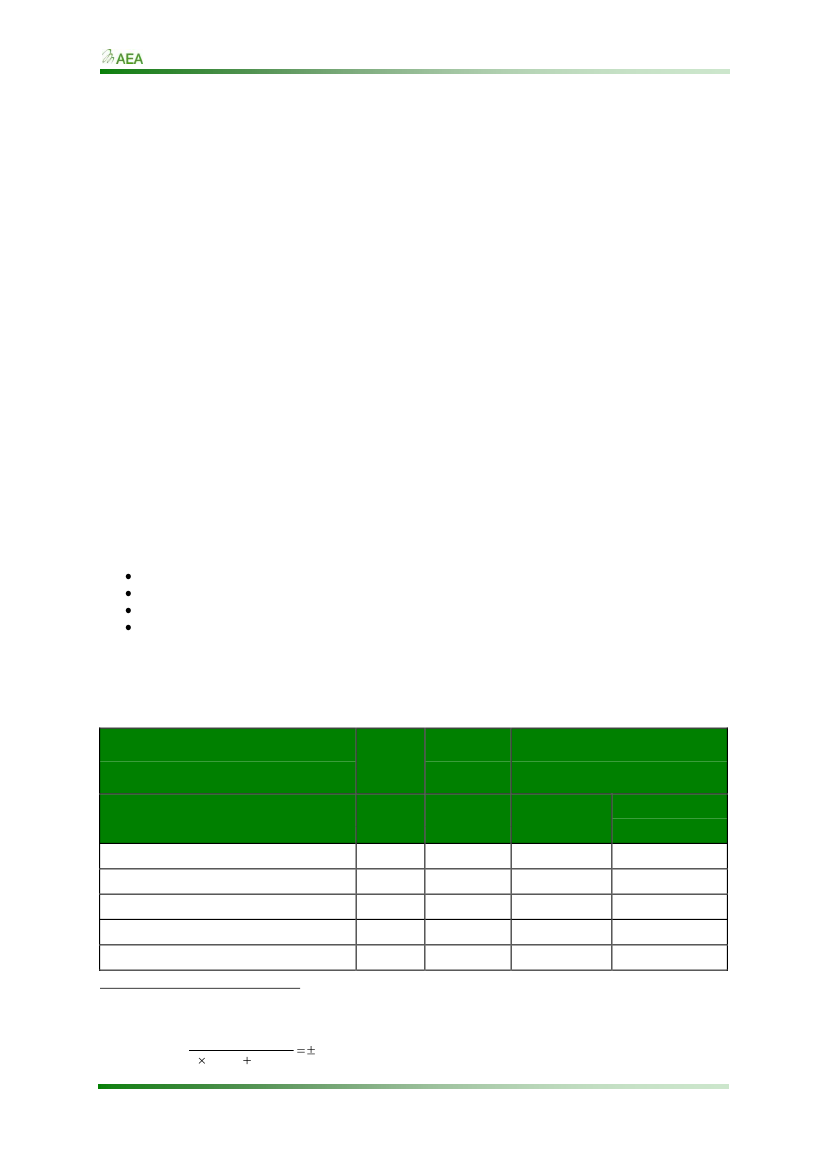

3.3 Pre-production stagePre-production comprises a number of subsidiary activities. These include:Site preparation (access road and well pad production);Drilling;Hydraulic fracturing.Well completion and waste water treatment.GHG emissions can arise from each of these activities. The main sources of emissions and therelative scale of emissions are discussed further below. The estimates are based upon publishedliterature. Where possible comparisons between different studies have been made and differences inthe results explained. However, due to a lack of transparency in the calculations or differences inapproach, it has not been possible to make direct comparisons in all cases.For each of the sub-stages a summary of the estimates is provided in the tables that follow. Inpresenting the results the emissions estimates have been calculated as absolute values in consistentunits (per well pad). This corrects for the different assumptions that have been made in the studiese.g. the productivity of the wells.

3.3.1 Site preparation3.3.1.1Emission sourcesGHG emissions associated with the site preparation include energy-related emissions from the use ofequipment to clear the site (e.g. clearing vegetation) and from the construction of necessary transportinfrastructure (e.g. roads). Emissions associated with changes in land use type (e.g. removal ofcarbon stocks) are also relevant. Indirect emissions can also be associated with the materials used inthe site preparation activities (e.g. embedded emissions in construction products), and are discussedfurther below.

3.3.1.2Emission estimatesThe estimated emissions will relate to the particular characteristics of the site of the well. The energyused in land clearance and the construction of transport infrastructure will be related to the size of thesite and the proximity of existing infrastructure. Likewise the emissions associated with changes incarbon stocks will depend on the existing land use type.In Table 3 existing estimates of the emissions from site preparation are compared.

Ref: AEA/ED57412/Issue 2

15

Climate impact of potential shale gas production in the EU

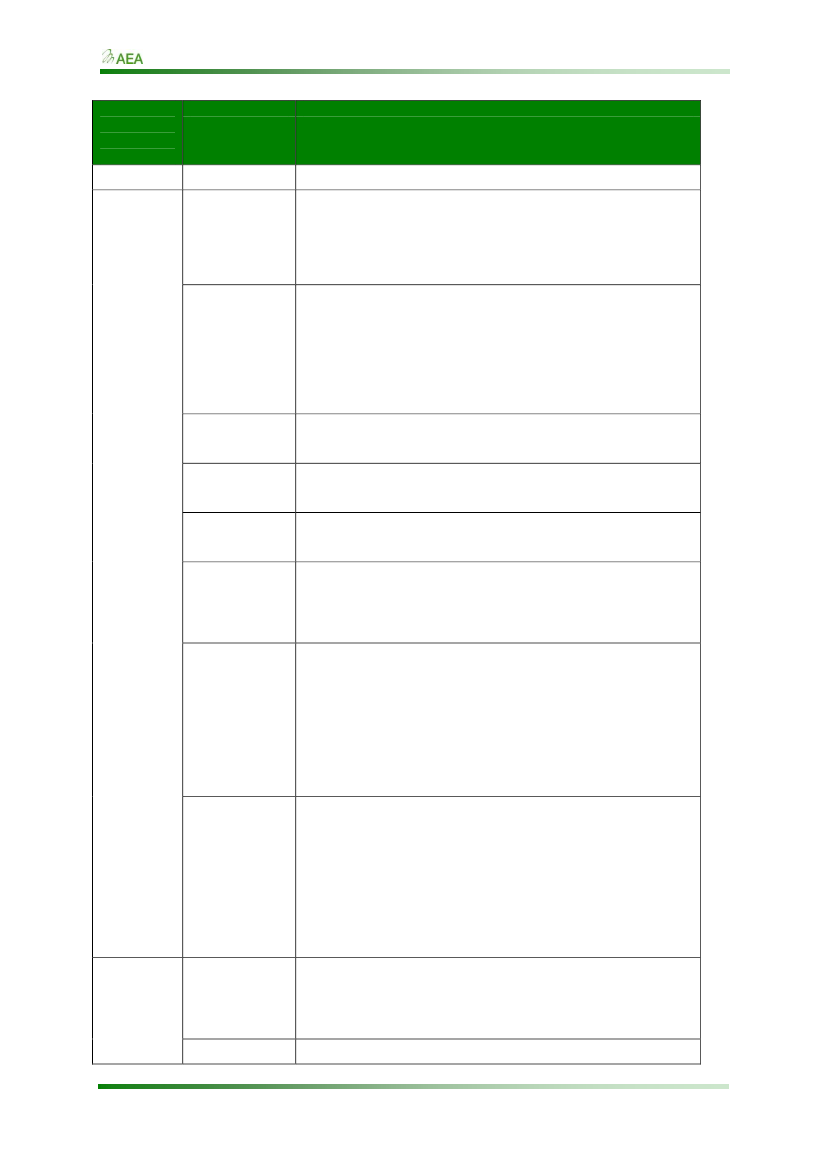

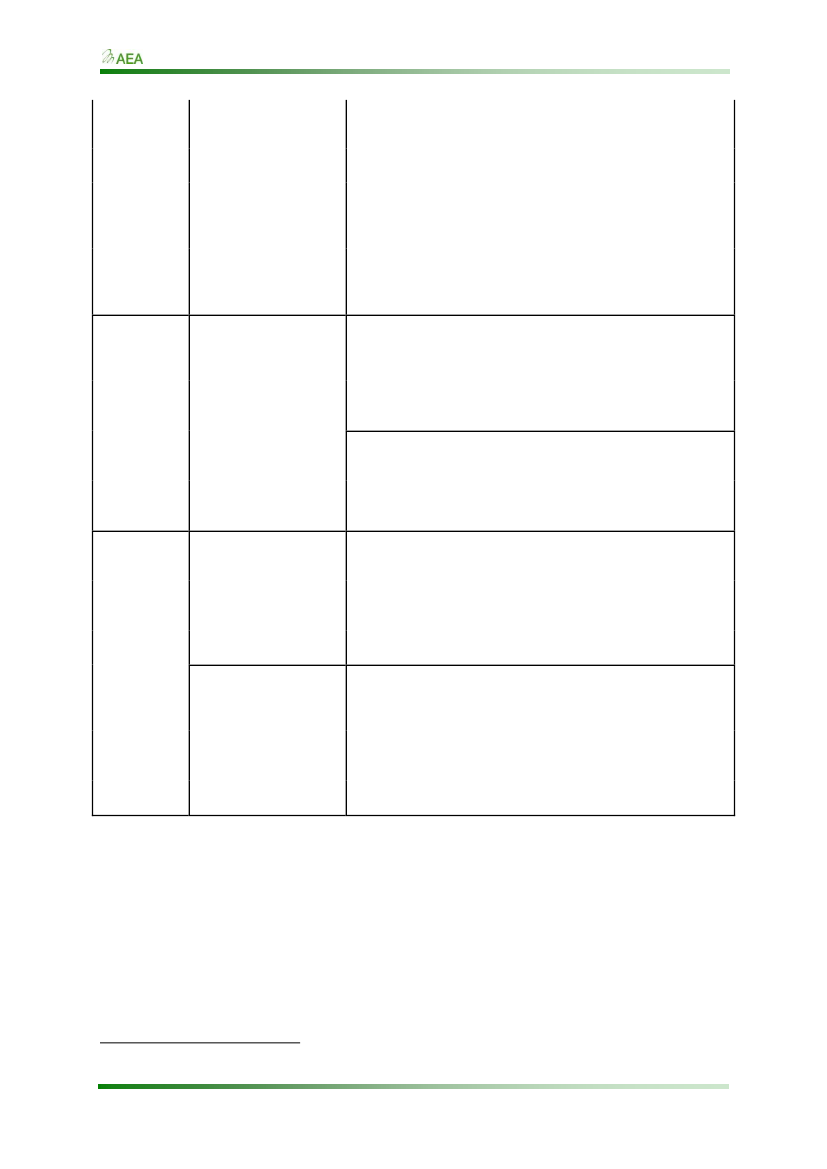

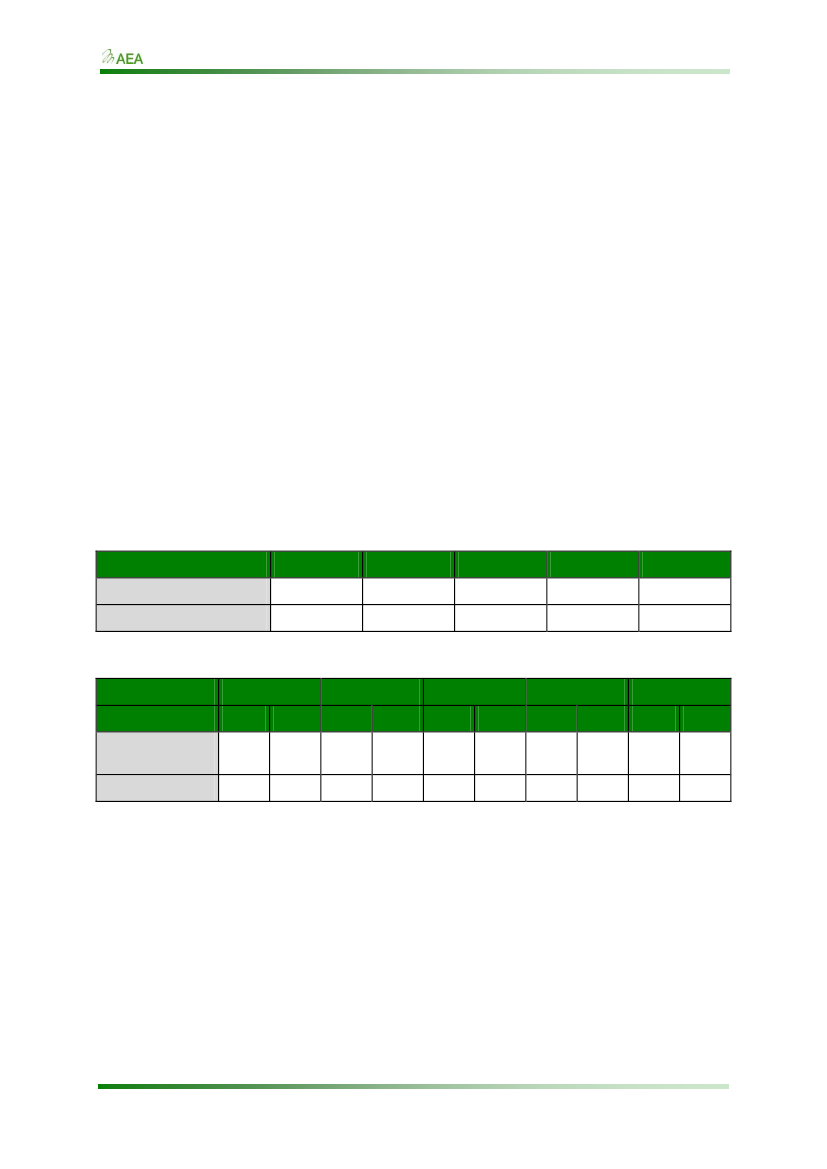

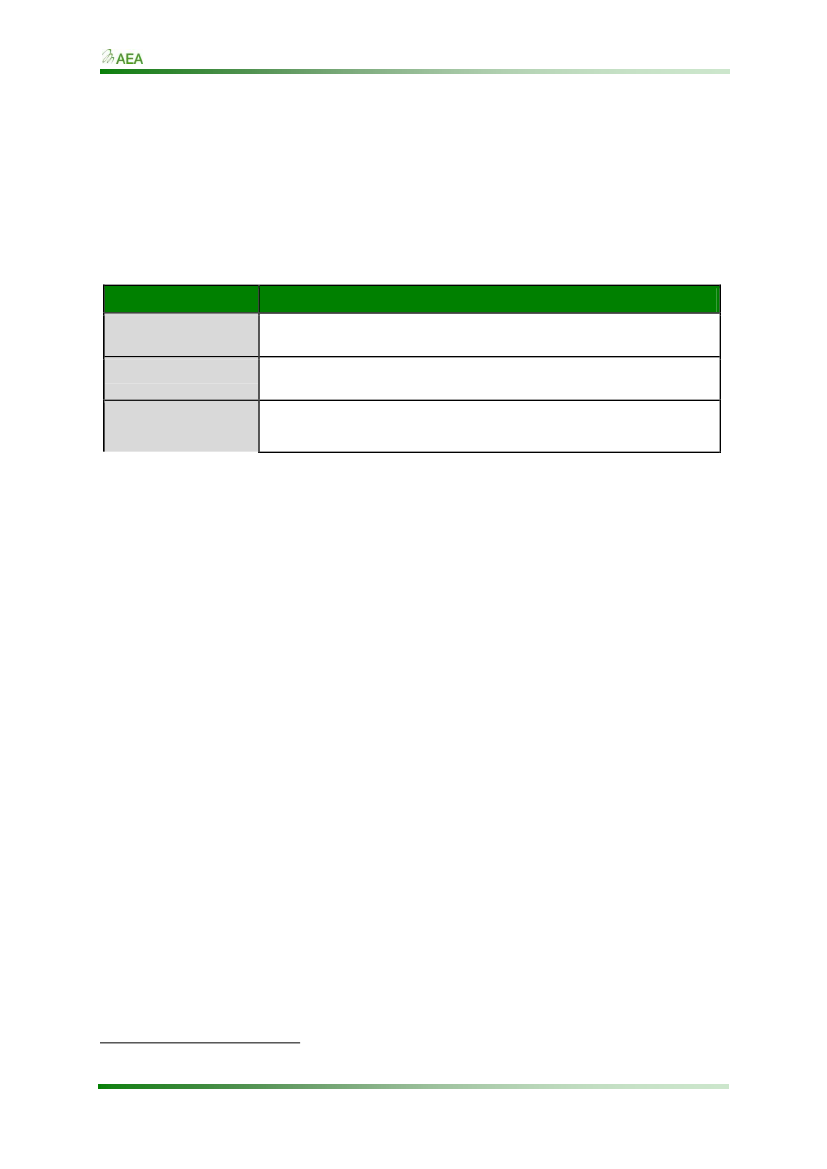

Table 3: Existing estimates of emissions associated with site preparationSourceEmissions estimate(per well) (tCO2eq)Relevant assumptions and methodologyBased on a Marcellus shale gas well pad.Vegetation clearance:Estimated area cleared multipliedby vegetative carbon storage to obtain carbon loss fromland use change. Area of well pad assumed was 2.0 ha.Area of access roads assumed was 0.6 ha.Well pad and access road construction:Detailed costestimate used to inform an EIO-LCA model.Based on a Marcellus shale well pad.Vegetation clearance:Assumes 5 ha per site, or 0.62per well (including access roads, and the areas requiredfor gathering line construction). Includes initial carbonloss, and foregone carbon sequestration.Disturbances:Combustion emissions are based on1,235 GJ ha for bulldozers and 98 GJ ha for excavators.Stephenson etal (2011)Not ReportedLand use change emissions associated with accessroads and well pad construction were assessed butfound to not make a material difference.

Jiang et al(2011)

330 - 390

Santoro et al(2011)

158

The estimates provided by Jiang et al (2011) and Santoro et al (2011) are similar in scope, but Jianget al (2011) estimate emissions that are nearly double those from Santoro et al (2011). This is despiteJiang et al (2011) assuming a smaller land area. This variation therefore relates to methodologicaldifferences. The Santoro et al (2011) estimate (as presented above) only includes emissions fromenergy use. However, the Extended Input-Output (EIO) methodology used by Jiang et al (2011) willinclude a wider range of impacts as it is based upon total expenditure associated with construction,and it is not restricted to just fuel related impacts.GHG emissions from this sub-stage are dominated by carbon dioxide from energy use, with somesmall amounts of methane and nitrous oxide emissions also arising from combustion. Land useclearance is also associated with sequestrated carbon.

3.3.1.3Uncertainties and data gapsThe main uncertainties relate to the representativeness of results from one site to the next. Sitespecific characteristics have an important influence on the overall results.There are also certain methodological uncertainties. For example, the emissions associated withvegetation clearance and other land use changes are the subject of debate.The importance of these assumptions can be related to the overall significance of the site preparationstage in the total life-cycle impacts. As described below, these emissions are generally small incomparison to other stages in the life cycle.

3.3.1.4Applicability of estimates to the EUThe estimates are applicable to the EU as similar practices will be required for the development ofshale gas wells in Europe. However, due to the generally higher population densities in Europe, it isargued by some that shale gas developments might have a smaller overall land-footprint compared toUS practices, or to conventional gas developments in Europe as developers may be under more

Ref: AEA/ED57412/Issue 2

16

Climate impact of potential shale gas production in the EU

pressure to reduce the impact of well developments on the landscape, although this would requirefurther analysis. At the same time, developments may be closer to existing infrastructure. Forexample, Broderick et al (2011) refer to plans by Cuadrilla for exploration and production (E&P) fromthe Bowlands Shale in the UK, quoting a well pad size of 0.7ha, which will contain 10 wells.

3.3.2 Energy use in drilling and pumping3.3.2.1Emission sourcesEmissions arise from the energy used in the drilling of the well bore, and in the pumping of water andother material during hydraulic fracturing.During the drilling phase a temporary drilling rig is brought to the well pad and erected on site. Energyfor the drilling operation (and all ancillary support activities such as well pad lighting and crewhousing) is normally provided by large, diesel-fired internal combustion engines. In some instancesthe drilling rig may be powered by the local electric grid instead of diesel engines. The drilling rigengines are a source of combustion-related pollutants including CO2. The quantity of fuel consumed,and the associated emissions, will depend upon the length of the well bore. Each horizontal wellboremay be around 1,000 to 1,500 metres in lateral length but can be more (NYSDEC, 2011). This step ofthe process is the same for conventional and unconventional gas wells, with the exception ofhorizontal drilling, which is specific for shale gas wells.Hydraulic fracturing is essential for shale gas production. It involves the high pressure injection of thefracturing fluid into the well. The process is typically powered by large, diesel-fired internal combustionengines.The fracturing phase requires significantly more energy to fracture the formation than required to drillthe wellbore. Depending on the number of fracturing phases involved in stimulating the formation thisstep may last from several days to several weeks. For example a multi-stage fracturing operation for a1200 metre lateral well typically consists of eight to thirteen fracturing stages (NYSDEC, 2011).

3.3.2.2Emission estimatesExisting estimates of emissions from drilling and hydraulic fracturing are based upon bottom upestimates of the quantity of fuel required, or total power requirements, which is then applied to anappropriate emissions factor. The most important assumption in this calculation is therefore theassumed fuel and / or power requirements, which in turn relate to the specific characteristics of thesite (e.g. depth and lateral length of the well and number of wells).In Table 4 existing estimates of the emissions from drilling and hydraulic fracturing are compared. Toease comparison, results are presented as absolute emissions per well.Table 4: Existing estimates of emissions associated with drillingSourceEmissions estimate(per well) (tCO2eq)Relevant assumptions and methodologyEmissions from drilling:Vertical drilling depth 2,600metres, Horizontal drilling length 1,200 metres.610 - 1,100Power of drilling rig assumed to be 2,500 to 6,600 HP, will adrilling time of 210 to 380 hours.Lifecycle diesel engine emission factor of 635 g CO2eq perHP–hr.Emissions from pumping:Pumping energy multiplied byemission factor.230 - 690Power of pumping equipment assumed to be 34,000 HP,with a pumping time of 10 to 30 hours.Lifecycle diesel engine emission factor of 635 g CO2eq perHP–hr.

Jiang et al(2011)

Ref: AEA/ED57412/Issue 2

17

Climate impact of potential shale gas production in the EU

Total well length of 3,878 metres, consisting of 2,678 metresdepth and 1,200 metres of lateral length.Energy use based on a single well.Santoro et al(2011)1,426Emissions from drilling:Includes prime movers - thedrilling rig's main power source. Drilling time is assumes tolast 4 weeks with engines running 24hr/day.Emissions from pumping:Use of pumps with power of9,300 HP. Fracturing time is assumed to last 70 hours ofpump engine time.Emissions from drilling:Assumed to be the same asconventional wells. Assumes 15 days at 12 hours operationper day.Emission calculated on basis of 4,500 HP engines, with fuelconsumption of 250g/kWh.Emissions from pumping:Assumes 2 hours per operationand 15 operations per well.Emissions calculated on basis of 12,250 HP engines, withfuel consumption of 250g/kWh.Emissions from drilling:Horizontal drilling of 1,000 –1,500 metres. Vertical drilling is excluded from the estimate.49 to 74Fuel use of 18.6 litres of diesel per metre drilled, whichequates to an emission factor of 49kgCO2/m.Diesel emission factors of 2.64 kg CO2/litre.Broderick etal (2011)*Emissions from pumping:Based on average fuel usagefrom hydraulic fracturing on a horizontally drilled well in theMarcellus Shale.295Assumes total fuel use of 109,777 litres of diesel fuel perwell.Diesel emission factors of 2.64 kg CO2/litre.Notes: * Estimate for Marcellus Shale used for consistency with other studies.With the exception of the Broderick et al (2011) study the estimates of emissions from drilling andpumping are of a similar order. The estimates from Santoro et al (2011) are within the range providedby Jiang et al (2011). The estimates from Stephenson et al (2011) are just below the lower rangeprovided by Jiang et al (2011). The range in the estimates appears to be driven by the assumptions5relating to the HP and time required for drilling and pumping (hours).The estimate from Broderick et al (2011) is lower than the other estimates, particularly for drilling. Thiscan, in part, be explained by methodological differences. For example, Broderick et al (2011) onlylook at additional impacts so only included horizontal drilling and not vertical drilling. However, evenallowing for this adjustment, the estimates appear a little low in comparison with the other estimates.

Stephensonet al (2011)

771

5

1HP = 746 watts

Ref: AEA/ED57412/Issue 2

18

Climate impact of potential shale gas production in the EU

All estimates assume the equipment is diesel fuelled, so the GHG emissions are dominated by CO2from combustion.

3.3.2.3Uncertainties and data gapsThe main uncertainty relates to what should be assumed in terms of a typical depth of well and thelateral length. Clearly the emissions from energy use in drilling will relate directly to theseassumptions. Assumptions with respect to the drilling effort required, which may in turn relate to thegeological characteristics (e.g. the strength of the shale formation), and design of the well pad (e.g.number of wells per pad) may also be important.

3.3.2.4Applicability of estimates to the EUThe approach used to estimate the results above are applicable to the EU. However, the resultsthemselves should be adjusted to reflect European shale gas fields.

3.3.3 Energy use in transportation3.3.3.1Emission sourcesHydraulic fracturing consumes large quantities of water (as described in Section 2.3.1.3), sand andchemicals for the proppant fluids. Transportation of the materials will be associated with GHGemissions from vehicle movements, assuming current vehicle technologies, and conventionaltransport fuels.The fuel consumed in the transportation of the water and chemicals, and the associated emissions,will depend on the quantities of materials that are required and the distances that the materials needto be moved. These characteristics are site specific in nature. For example, in some locationsoperators may be licensed to abstract water directly from surface or ground water sources, but atother sites the water needs to be delivered by tanker truck or pipeline.

3.3.3.2Emission estimatesIn Table 5 existing estimates of the emissions from the transport of water and chemicals arecompared.

Ref: AEA/ED57412/Issue 2

19

Climate impact of potential shale gas production in the EU

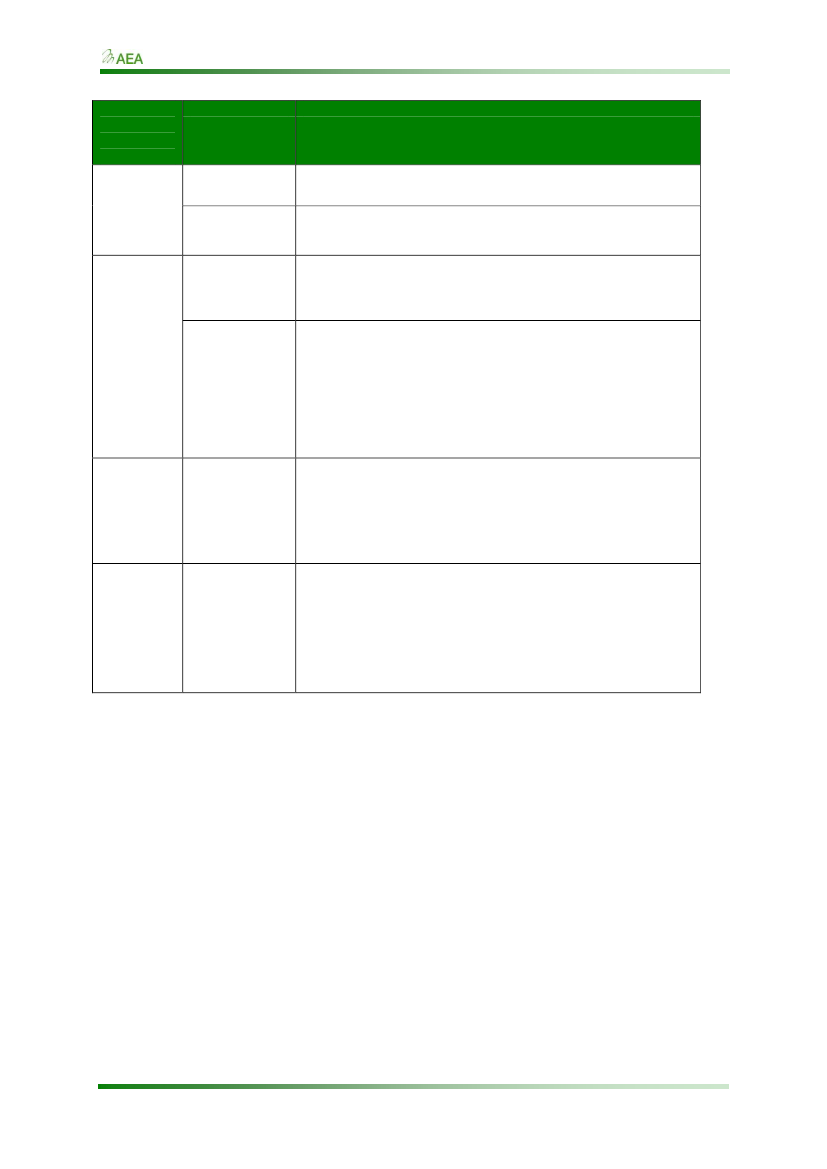

Table 5: Existing estimates of emissions associated with transport of materialsSourceEmissions estimate(per well) (tCO2eq)Relevant assumptions and methodologyAssumed water use of 9,000 – 27,240 m3fracturing, and 454 m for drilling.36

per well for