Miljøudvalget 2012-13

MIU Alm.del Bilag 112

Offentligt

Investigation ReportC1/2010M

M/S LINDA (FIN), falling overboard of four containers intothe Baltic Sea, south of Gotland, on 6 February 2010Translation of the original Finnish report

This investigation report has been written to improve safety and prevent new accidents. The report does not ad-dress any possible responsibility or liability caused by the accident. The investigation report should not be usedfor purposes other than the improvement of safety.

OnnettomuustutkintakeskusOlycksutredningscentralenSafety Investigation AuthorityOsoite / Address:Sörnäisten rantatie 33 CFIN-00500 HELSINKI(09) 1606 7643+358 9 1606 7643(09) 1606 7811+358 9 1606 7811[email protected]www.turvallisuustutkinta.fiAdress:Sörnäs strandväg 33 C00500 HELSINGFORS

Puhelin / Telefon:Telephone:Fax:Fax:Sähköposti / E-post / Email:Internet:

Käännös / Översättning / Translation Minna Bäckman

____________________________________________________ISBN 978-951-836-344-9 (nid.)ISBN 978-951-836-345-6 (PDF)ISSN 1797-8122 (nid.)ISSN 2242-7724 (PDF)ISSN-L 1797-8122Multiprint Oy, Vantaa 2012

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

SUMMARY

Four containers fell into sea from the Finnish flagged M/S LINDA on Saturday morning 6 Febru-ary 2010. The incident occurred in the Baltic Sea, south of Gotland, while the vessel was on herway from Rotterdam, the Netherlands, to St. Petersburg, Russia.The LINDA operates in regular traffic between European ports. In addition to the customarycargo, a 40 foot container equipped with a refrigeration unit, so-called reefer container, wasloaded on her deck, in the first tier, in Poland, in the port of Gdansk. The reefer container hadbeen taken out of use. The container had been decided to be taken to Helsinki, where it was tobe sold so it could be used as something else than a transport unit. Nothing was loaded on thecontainer in the following port, Teesport. In Rotterdam, the port after Teesport, three containerswere loaded on the reefer in the second, third and fourth tiers. These containers weighed 25, 23and 26 tons respectively, making a total of 74 tons.When the LINDA was sailing from Rotterdam for St. Petersburg, a motorman noticed on Satur-day, 6 February 2010 at 8.20 that a stack of containers from the port side of the vessel had falleninto the sea and that remains of a reefer container were hanging on the vessel's side. The mo-torman informed the Officer of the Watch, who was on the navigating bridge, of his observation.The Officer of the Watch had not noticed the falling of the containers as it was dark. The exacttime of the fall, 07.56 vessel’s time, was obtained later from the registration of the vessel's CCTVcamera, which was located in the superstructure. According to the LINDA’s log, the vessel posi-tion at 08.00 was lat 57�00.6N and long 017�34.2E.Swedish authorities decided not to lift the containers as their understanding was that the possibleenvironmental damages would be small and restrict to a limited area. Baltic herring is fished inthe area, and its stock may decrease temporarily when the dangerous substances at some pointdissolve in seawater.It was found out in the investigation that it was not possible to identify the container, which hadbeen taken out of use and was deteriorated, as there was no marking on it indicating that loadingon it was not permitted. The identification of such a container rested only on the identificationtaking place on the basis of the number of the cargo unit. In Rotterdam three containers wereloaded on the deteriorated container even though there was in the instructions information aboutthe fact that nothing could be loaded on the reefer container in question. Information did thus notpass between the different actors. Divergences in the cargo information system do not passautomatically from one system to another, and some information must be conveyed directly be-tween the various parties involved.In the opinion of the Safety Investigation Authority of Finland, transporting a deteriorated con-tainer as cargo on a vessel requires that it is marked clearly enough as taken out of use. In addi-tion to the sides and ends of the container, the markings should also be visible on the top of thecontainer in which case it would be possible for the crane operator, too, to identify the faulty unit.The shipping company, the operator and the vessel have different cargo information systems inuse, and the information transfer between them is not flawless. The actors must make sure byother means that information on diverging cargoes or cargoes requiring special attention ispassed to all parties.I

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

CONTENTS

SUMMARY ......................................................................................................................................IGLOSSARY OF ABBREVIATIONS AND ACRONYMS ................................................................. VFOREWORD ............................................................................................................................... VII1 EVENTS AND INVESTIGATIONS .............................................................................................11.1 The vessel..........................................................................................................................11.1.1 General information ..................................................................................................11.1.2 Manning....................................................................................................................21.1.3 Navigating bridge and bridge equipment ..................................................................21.1.4 Engines and the engine room...................................................................................21.2 Cargo .................................................................................................................................31.2.1 General information ..................................................................................................31.2.2 Stowage planning .....................................................................................................31.2.3 Stowage method.......................................................................................................31.3 Incident...............................................................................................................................41.3.1 Weather conditions...................................................................................................41.3.2 Voyage and preparations for it..................................................................................41.3.3 The incident ..............................................................................................................51.3.4 Time and scene of the incident.................................................................................51.3.5 Measures after the incident ......................................................................................61.3.6 Damages to the vessel .............................................................................................61.3.7 Damages to cargo ....................................................................................................71.3.8 Registration equipment.............................................................................................71.4 Rescue activities ................................................................................................................81.4.1 Alerting activities.......................................................................................................81.4.2 Search activities .......................................................................................................81.5 Special investigations.........................................................................................................81.5.1 Investigations on the vessel and at the scene of the incident ...................................81.5.2 Contents of the containers which fell overboard and their effects on marineenvironment..............................................................................................................81.6 Rules and regulations guiding the operations ....................................................................91.6.1 National legislation – Container Act and Container Decree ......................................91.6.2 Operator’s orders....................................................................................................111.7 International agreements and recommendations .............................................................111.8 Quality systems................................................................................................................11

III

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

2 ANALYSIS ............................................................................................................................... 132.1 System interfaces ............................................................................................................ 132.2 Marking and identification of a container which has been taken out of use ..................... 132.3 Alerting and rescue activities and search for the container.............................................. 142.4 Effects of weather on the incident .................................................................................... 143 CONCLUSIONS ...................................................................................................................... 174 IMPLEMENTED MEASURES.................................................................................................. 195 SAFETY RECOMMENDATIONS ............................................................................................ 21APPENDICESAppendix 1. Statement by the Finnish Transport Safety Agency (in Finnish)

IV

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

GLOSSARY OF ABBREVIATIONS AND ACRONYMS

Abbreviation /acronymAISCSChPaIn EnglishAutomatic Identification SystemConvention for Safe ContainersHectopascalThe unit of pressure, describes theprevailing atmospheric pressureA corporation of container lessors,which has published a guide definingthe condition and the need for repairof a container; the publication is usedwhen inspecting containersInternational code dealing with themarine transport of dangerous goodsExplanationIICL-5

Institute of International ContainerLessors

IMDGknkVAkWMSTdwTEUUNUTC

International Maritime DangerousGoods CodeKnotKilovoltampsKilowattMotor ShipTons DeadweightTwenty-Feet Equivalent UnitUN (United Nations) numberUniversal Time Coordinated

20-feet containerA four-digit number, on the basis ofwhich the transported dangeroussubstance can be identified

V

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

FOREWORD

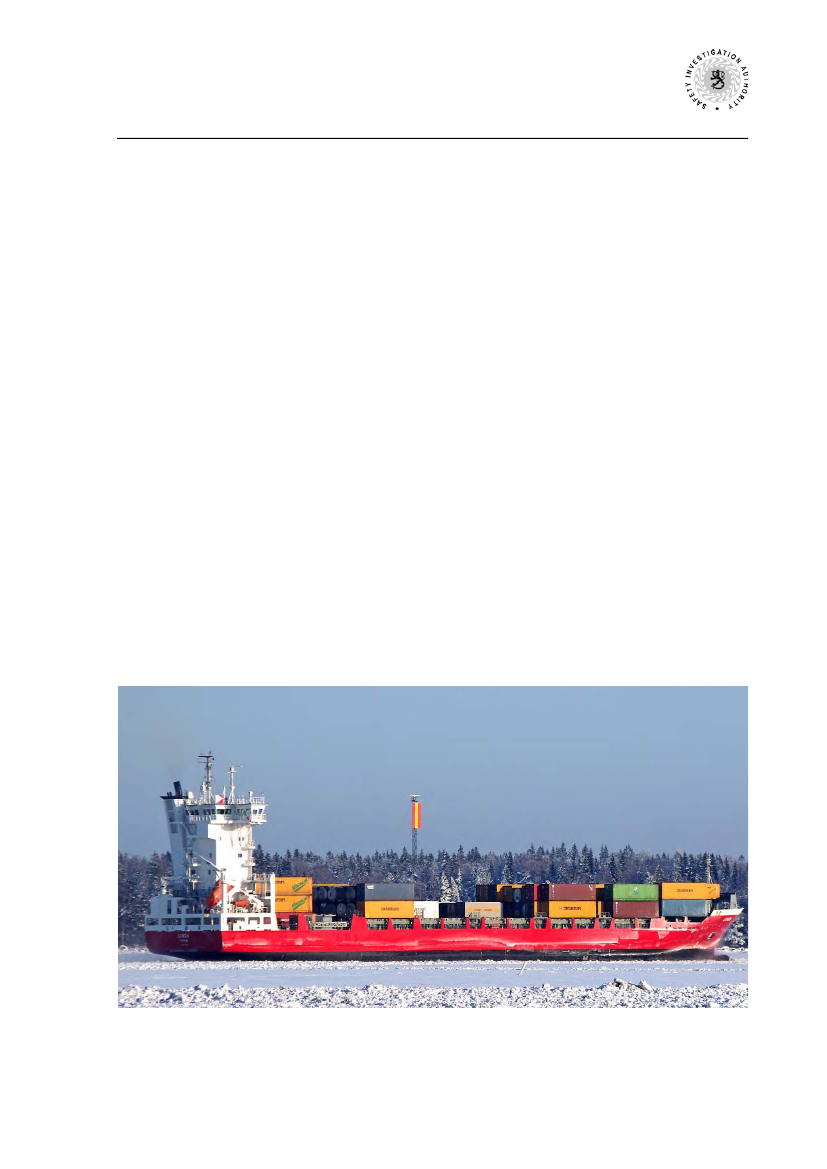

Four containers fell overboard from the Finnish flagged M/S LINDA into the Baltic Sea, south ofGotland, on Saturday morning 6 February 2010 while the vessel was on her way from Rotterdam,the Netherlands, to St Petersburg, Russia. The duty officer of the Safety Investigation Authority ofFinland (hereafter referred to as the SIA) received information on what had happened from aMaritime Inspector at 13.50 on the day of the accident. The investigator who was then the dutyofficer initiated a preliminary investigation of the incident.On the basis of the preliminary investigation, the SIA decided on 11 February 2010 to appoint anInvestigation Group to investigate the accident. SIA investigator, Captain RistoRepowas ap-pointed as a team leader per his consent, and Principal Lecturer, Captain TapaniSalmenhaaraand M.Sc (Tech.) VilleGrönvallwere appointed as member investigators. The investigation re-port has been translated into English by M.A., M.Pol.Sc. MinnaBäckman.The SIA investigators visited the vessel on 9 February 2010 after it had arrived from St. Peters-burg to Vuosaari in Finland, and interviewed the Master and the Officer on the vessel as well asexamined the remains of the container which had been bottommost in the fallen container tier.The final draft of the investigation report was sent to concerned parties for statements and com-ments. The statements and comments received within the prescribed time have been taken intoconsideration in the final report.The sources used in the investigation are filed at the SIA.The investigation was finalised on 10 October 2012. The time used in the investigation report isFinnish time (UTC+2).Figure 1.

M/S LINDA

(� Oy Langh Ship Ab)

VII

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

EVENTS AND INVESTIGATIONS

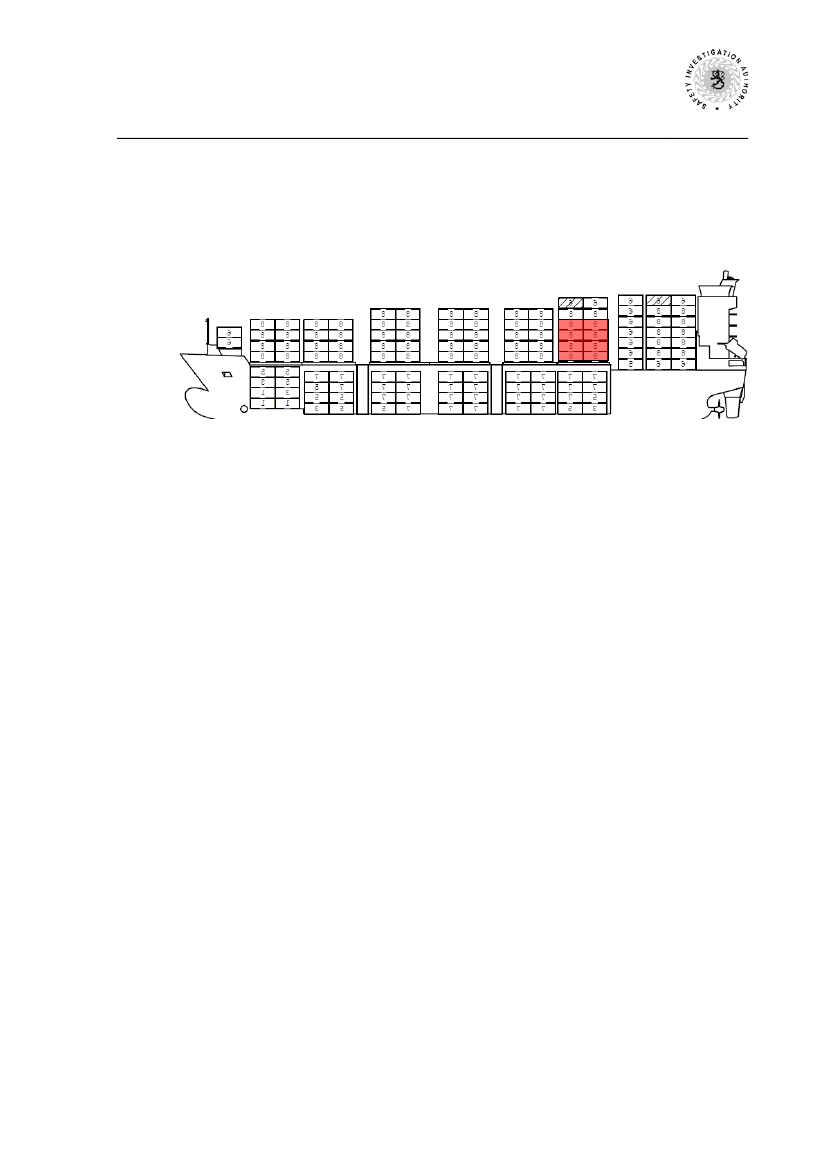

The vesselGeneral informationFigure 2.

A layout drawing of the cargo spaces on M/S LINDA. The red rectangle in-dicates the location of the fallen container stack on the outermost bay on theport side of the vessel.(� Oy Langh Ship Ab)M/S LINDAFinlandOy Langh Ship AbContainerships Ltd OyJ.J.Sietas Hamburg, 2007, type 174aGermanischer Lloyd +100 A 5 E 4 “Multi purpose ves-sel” “Equipped for Carriage of Containers” “IW” “NAV-0” “SOLAS II-2, Reg. 19” “G” + MC E4 AutOJML93543251 A Super9131420511487 Tdw141.20 m21.55 m8.6 m17.7 kn907 TEUWärtsilä 8L46C, 8400 kWshaft generator 2150 kVA800 kW

Name:Flag state:Owner:Freighter:Construction place and time:Class:

Call sign:IMO number:Ice classification:Gross tonnage:Net weight:Deadweight:Length:Breadth Loa:Draught:Speed:Container capacity:Engines:Generation of electricity:Bow thruster:

1

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

1.1.2

ManningThe vessel had a ten-person crew which consisted of:the Master (FIN)the Chief Officer (FIN)the Officer (EST)the Chief Engineer (FIN)the First Engineer (EST)the Boatswain (FIN)the Repairman (EST)an Able-bodied Seaman (FIN)an Ordinary Seaman (FIN) anda Cook (FIN).

In addition to the regular crew, there were three Finnish trainees on the vessel.1.1.3Navigating bridge and bridge equipment

Figure 3.

A photograph of the vessel’s wheelhouse.

The vessel’s navigating bridge is a so-called Optimale Brücke and it is equipped withmodern bridge equipment including navigational and communication appliances. Thenavigating bridge and its equipment did not play any role in the incident.1.1.4Engines and the engine roomThe main engine of the vessel is a Wärtsilä 8L46C, the effect of which is 8400 kW. Theelectricity is produced with a shaft generator, the output of which is 2150 kVA. The effectof the bow thruster is 800 kW.The machinery systems of the vessel did not have an effect in the incident.

2

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

1.21.2.1

CargoGeneral informationThe LINDA only transports containers and her container capacity is 907 TEU. The ves-sel operates in regular traffic between European ports. In the ports of call the cargo unitsintended for that particular port are discharged first. After this the units which are to betransported to the other ports along the line are loaded. Along the route, some of thecargo units remain onboard if the port of call is not the port of destination. The vessel isthus almost always fully laden. The ports along the LINDA’s route in order, starting fromHelsinki are Helsinki, Gdansk (Poland), Teesport (Great Britain), Rotterdam (the Nether-lands) and St. Petersburg (Russia).

1.2.2

Stowage planningMeasures related to cargo handling are carried out according to a separate, pre-plannedoperational programme. Containerships uses its own software for the management ofcargo units. The programme software covers the entire transport chain and equipment.With this system the company aims at as effective planning as possible and at monitor-ing the location of their equipment and its condition at the different stages of the trans-port chain. The programme software used by the shipping company also identifies de-fect cargo units. Information on a defect cargo unit does no transfer automatically to thevessel’s stowage software, but the information transfers to the vessel as separate infor-mation.The LINDA uses her own stowage software. In different ports the units to be loaded anddischarged can be moved ashore and back onboard in such a way the vessel’s stabilityand stresses remain within set limits. With the help of the stowage software the vesselcan optimise the placing of the transported cargo units on the vessel. In addition tocargo optimising, stowage planning aims at good seaworthiness and fuel economy. Thestowage plan itself is an Excel-based spreadsheet report.

1.2.3

Stowage methodMoving the containers from the vessel and to the vessel starts immediately after thevessel has moored to the quay. On the vessel the crew or stevedores unfasten thecargo from its securings before it is moved. The containers are hoisted by the containercranes located on the quay. The units to be loaded have been placed on the loadingfield in a so-called work queue, from which the crane picks the units onboard the vesselin a pre-planned order. Respectively, the cargo units onboard the vessel are dischargedaccording to the work queue, in the order indicated by the plan. The cargo units to behandled are identified by the number on the container.In the terminals owned by Containerships the aim is to perform the loading and dis-charging as efficiently as possible. A figure indicating the capacity of the port’s cranes tohandle units in an hour is considered to be the efficiency indicator in the handling of con-tainers. Container cranes are exceptionally quick. The containers to be loaded are wait-

3

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

ing on the quay under the crane. The crane moves containers in both directions. Theaim is that the crane is not empty to either direction.The vessel’s crew takes care of the securing of the cargo. The securing is based on theinstructions in the cargo securing manual1which the vessel is required to have.The vessel’s cargo securing manualMcGregor Ltd has compiled the vessel’s cargo securing manual. It has been approvedby the classification society Germanischer Lloyd and the Finnish Maritime Administrationin 2007. The cargo securing manual provides comprehensive instructions on how to se-cure different kinds of cargoes, but it does not give instructions on the placing of cargounits.1.31.3.1IncidentWeather conditionsAccording to the ship’s log, at 8.00 the wind blew from south with force 4 (5.5–7.9 m/s),the weather was cloudy, the temperature -2� C, the atmospheric pressure was rising andat 8.00 it was 1027 hPa2.According to the nearest weather station, Visby, the temperature ashore was -3 �C, windfrom southeast approx. 5 m/s at 8.00. It did not rain but it was cloudy.1.3.2Voyage and preparations for itThe LINDA arrived from Helsinki to Poland, to the port of Gdansk on Friday night on 29January 2010. Some of the cargo was discharged in Gdansk, after which containers in-tended to the following ports were loaded on the vessel. In addition to the actual cargo,a discarded 40’ reefer container owned by the Containerships Ltd was loaded on thevessel’s deck, in the first tier on the cargo hatch in position number 230882 (Bay 23,Row 08 and Tier 82). The container equipped with a refrigeration unit had been takenout of traffic use eighteen months earlier and it had been on the quay in Gdansk. Now ithad been decided that the container would be taken to Helsinki, where it was to be soldto be used as something else than a transport unit. After midnight, before the departureof the vessel and before the reefer container was stowed, the senior operator of the ste-vedoring company and the Officer of the vessel signed a damage report3on the con-tainer. The voyage towards the next port, Teesport, started at 05.25 on Saturday 30January 2010.The vessel arrived at the Teesport anchorage somewhat after midday on Monday 1February 2010 and remained there waiting for a free berth. A pilot boarded the vessel at00.56 the following night, and the vessel moored at the quay on Tuesday night at 01.45.1

23

IMO Cargo Securing Manual (Solas Chapters VI/VII, MSC/Circular.745 - Guidelines for the Preparation of the Cargo Secur-ing Manual)1 hPa = 100 Pa, the unit of pressure in the SI system is Pascal, PaContainerships Ltd Container Damage Report, Ms Linda, Voyage 6509, Container number SCZU 495261-8:Left rear sidecorner dented and a torn hole on left side the container.

4

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

The cargo operations were carried out 02.15–17.45. In the Port of Teesport, 247 TEUunits weighing 2979.34 tons in total were loaded on the vessel in accordance with thestowage plan. In addition, there were approx. 140 empty containers on the vessel. Thetotal weight of the vessel’s cargo was 3272.44 tons.In the Port of Teesport nothing was loaded on the discarded reefer container which hadbeen loaded in place number 230882 in Gdansk. The vessel left Teesport for Rotterdamon Tuesday evening at 18.20.The vessel arrived at Rotterdam Arreste South terminal on Wednesday 3 February 2010at 11.05, and the load operation was commenced at 11.40. When the containers ad-dressed to Rotterdam had been discharged, 40 20’ containers, 4 30’ containers, 69 40’containers and 31 45’ containers were loaded onboard the vessel. The total weight ofthese containers was 3379 tons. In Rotterdam three containers were loaded in the sec-ond, third and fourth tier on the damaged reefer. These containers weighed 25, 23 and26 tons respectively, making a total of 74 tons.The loading in Rotterdam was completed on Thursday 4 February 2010 at 06.20. Thevoyage towards the next port on the line, St. Petersburg, was started on Thursday at07.00. Draught in the bow was 8.3 metres and in the aft 8.35 metres. The metacentricheight (GM) was 0.62 metres. The value fulfils stability requirements and is normal, andit does not cause exceptional accelerations when the vessel rolls in the sea.The vessel arrived at the Brunsbüttel lock in the North Sea end of the Kiel Canal on Fri-day 5 February 2010 at 03.05. When the vessel was in the canal, the condition and se-curing of the IMDG4cargo units were checked and they were found to be in order in allrespects. At 10.17 the vessel passed the Holtenau lock and started its voyage to theBaltic Sea.1.3.3The incidentOn Saturday 6 February 2010, the LINDA had passed the southern point of Öland andcontinued her voyage towards the Gulf of Finland. The First Officer of the vessel waskeeping watch at 04.00–10.00.A motorman was on his way to the vessel’s bow in the morning at 8.20, when he noticedthat a stack of containers from the port side of the vessel had fallen into the sea and thatremains of the reefer container were hanging on the vessel's side. The motorman in-formed the OOW who was on the bridge of his observations. The falling overboard ofthe containers was not noticed on the vessel when it actually happened.1.3.4Time and scene of the incidentThe exact time for the falling, 07.56 vessel’s time, was obtained later from the registra-tion of the vessel's CCTV camera located in the superstructure. According to theLINDA’s log, the vessel position at 08.00 was lat 57�00.6N and long 017�34.2E.4

International Maritime Dangerous Goods Code, an international guideline to the safe transportation or shipment of danger-ous goods or hazardous materials by water on vessels.

5

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

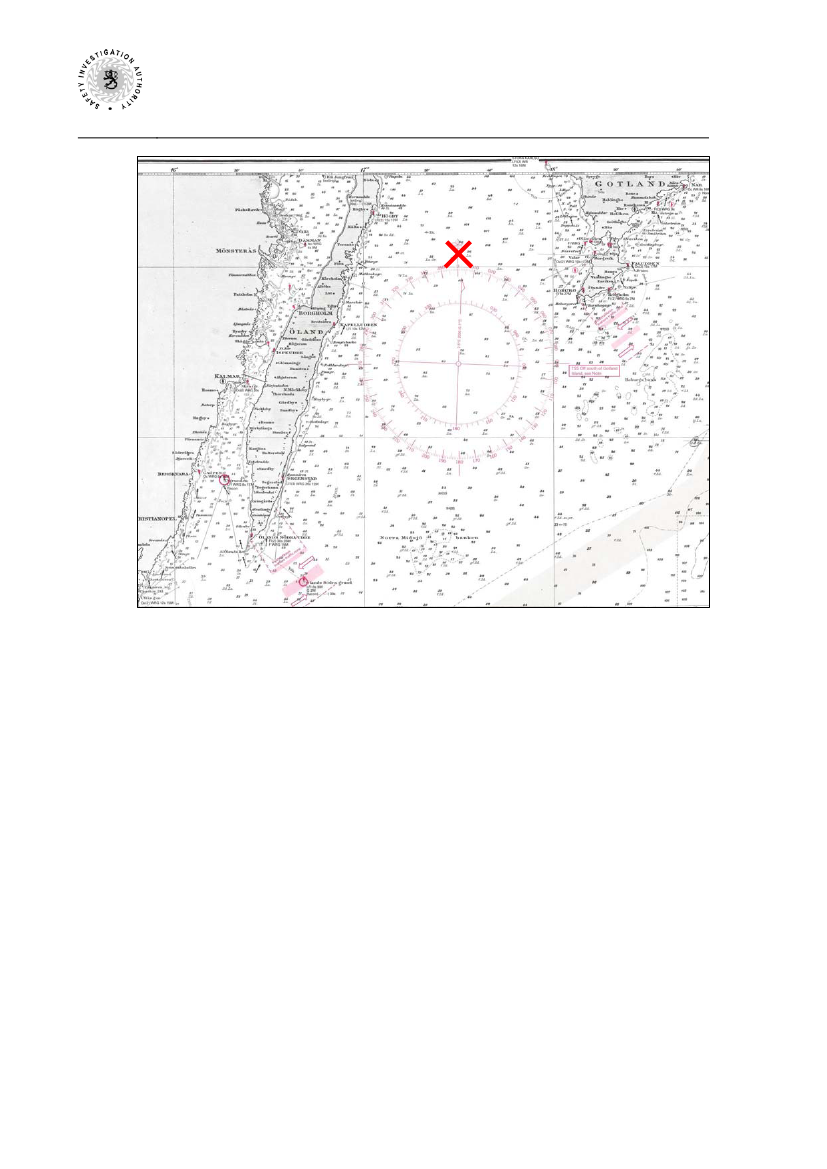

Figure 4.

The scene of the incident has been marked in the figure with a red cross.(� Swedish Maritime Administration 2012)

1.3.5

Measures after the incidentWhen the falling overboard of the cargo had been noticed on the vessel, the OOW in-formed the Master of the matter and phoned the MRCC Turku. The MRCC Turku in-formed the Swedish maritime rescue authorities of the incident, and they sent a helicop-ter unit to investigate the situation.A helicopter from the Swedish Coast Guard videotaped of the remains of the reefer con-tainer at 11.18 UTC, i.e. at 13.18 vessel’s time. On the basis of the coordinates in therecord, the position of the remains was then lat 57�02.55N and long 17�30.03E. Re-mains of the reefer container had drifted to the distance of approx. three nautical milesfrom the presumed place of falling. The other three containers had already sunk.

1.3.6

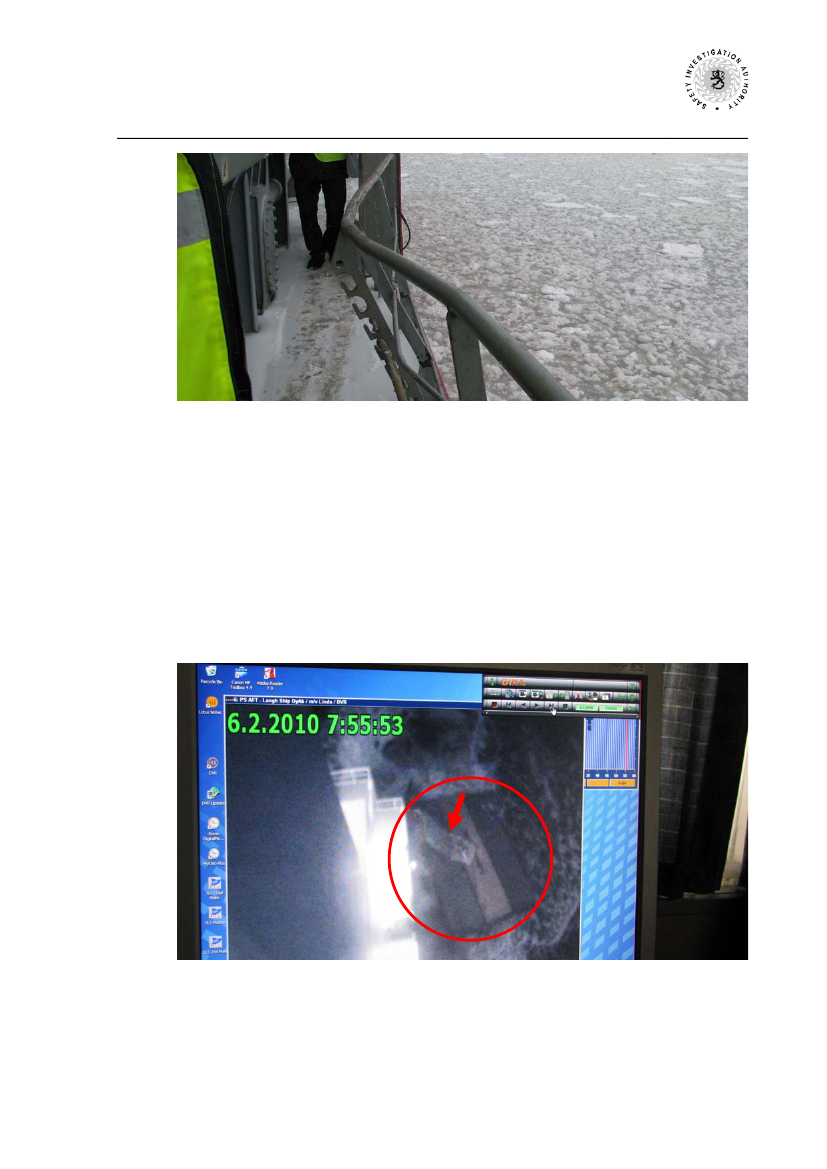

Damages to the vesselWhen falling overboard, the containers damaged the vessel's port side railing at a lengthof approx. 4 metres (Figure 5). The vessel did not suffer any other damages.

6

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

Figure 5.

The railing damaged by the fallen container stack on the port side of thevessel.

1.3.7

Damages to cargoIn addition to the containers which fell overboard there were no other damages to thecargo or transport units.

1.3.8

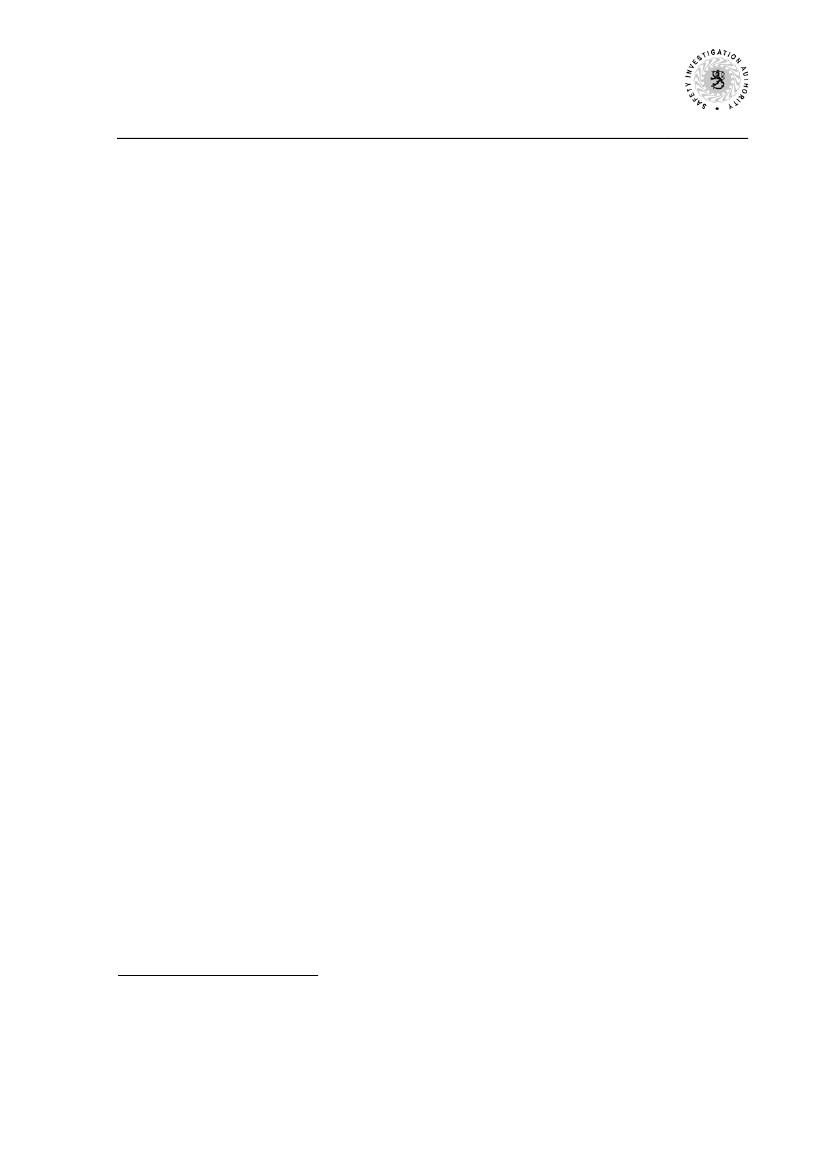

Registration equipmentThe vessel has CCTV cameras on the boat deck on both sides of the accommodationspaces. The port side camera recorded the containers in the sea after they had fallenoverboard. The containers which contained cargo were attached to each other as oneblock. For example the roof of the broken reefer was also attached to this block.

Figure 6.

A picture recorded by the vessel’s CCTV camera photographed by a cam-era from a display on the vessel. The block formed by the three containersattached to each other can be seen in the picture (the red circle). The roof ofthe broken reefer container is on this block (the red arrow). The wall of thereefer container drifts somewhat behind the block.

7

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

1.4

Rescue activitiesActual rescue activities were not initialised, because from the vessel’s point of viewthere was nothing else to do than to inform the rescue authorities.

1.4.1

Alerting activitiesA notification on the incident was made from the vessel to the MRCC Turku, whichtransmitted the information to the Swedish authorities.

1.4.2

Search activitiesAfter receiving information on the fallen cargo via the MRCC Turku, the Swedish mari-time rescue authorities sent a helicopter to the scene. Both the LINDA and the remainsof the broken reefer container in the sea were videotaped from the helicopter. The othercontainers which had fallen overboard were not to be seen on the surface of the sea.

1.51.5.1

Special investigationsInvestigations on the vessel and at the scene of the incidentWhen the LINDA arrived at the Port of Vuosaari in Finland, the SIA investigators initiatedan investigation on the incident. The vessel’s personnel were interviewed and the re-mains of the container were photographed. The records of the vessel’s CCTV camerawere obtained to be used in the investigation.The reefer container marked with the identification SCZU495261-8 was already usedwhen it was bought by Containerships Ltd. It had been manufactured in 1992 by GESeaCo. After April 2008, it had been used as a transport unit until it had been unloadedempty from the vessel in Gdansk in Poland on 8 November 2008. After more than ayear, on 18 December 2009, the container got the status “Awaiting Sale". On 30 Febru-ary 2010 the container was loaded on the deck of the LINDA.

1.5.2

Contents of the containers which fell overboard and their effects on marine envi-ronmentIn addition to the broken reefer container, the three containers which were laden on thereefer container fell into the sea:CSFU 964448-6, year of manufacture 2005NEVU 796664-6, year of manufacture 2002GESU 401119-0, year of manufacture 2002Of the containers mentioned above, the container CSFU 964448-6 contained the follow-ing harmful substances:UN number 1325,IMDG class 4.11 solid, powdery substance in cardboard boxes 6508kg, trade nameTrioxan Fluessig.The substance is flammable, irritates respiratory pas-sages and is possibly dangerous to foetuses. 175g/l (25�C) has been reported as the

8

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

water solubility of the substance and its toxicityto fish:LC50 4,000mg/l (Leuciscus idus)ide5and LC50, 16,350 mg/l (Cyprinodon variegatus) sheepshead minnow6.Inverte-brates living in water:EC50 ›1,000 mg/l, water fleas.UN number 3082,(Poly(hexamethylenebiguanide)hydrochlorine)IMDG class 9 III Ma-rine pollutant, trade name Vantocil TG. 200 plastic containers á 25 kg, 5000 kg in total.The substance is very toxic to marine organisms and may cause significant damage tomarine environment in the long term. The liquid is somewhat denser (1.04) than sea-water, and it dissolves in water. The liquid is very toxic to fish, invertebrates and algae.UN number 3082,(N-Cocoalkyl-NN-Dimethylamineoxide)IMDG class 9 liquid, 40drums, net weight 8000 kg. Trade name Barlox 12. Stabilising emulsion substancewhich irritates skin and is very dangerous to eyes; also very toxic to marine organisms.The substance dissolves in water.The information about the substances presented above was available for the authoritiessoon after the incident. The position where the containers sank is not located in theSwedish territorial waters, but it is, however, in the Exclusive Economic Zone, EEZ ofSweden.The Swedish authorities7decided not to lift the containers as their understanding wasthat the possible environmental damages would be small and restricted to a limited area.Baltic herring is fished in the area, and its stock may decrease temporarily when thesubstances at some point dissolve in seawater.1.61.6.1Rules and regulations guiding the operationsNational legislation – Container Act and Container DecreeContainer ActContainer Act8which came into force 1 January 1999 is applied to containers used in in-ternational traffic.According to section 5 in the act, the owner9of the container has the duty to make cer-tain that the container is in safe condition. The inspection of containers is carried out inthe way prescribed in the Container Decree10if the registered office or principal place ofbusiness of the owner of the container is in Finland.According to section 3 in the Container Act, the structural strength and equipment of acontainer must be approved before it may be used in international traffic. The approvalcriteria are prescribed in the Container Decree. A safety sign (a CSC sign) in accor-dance with the Convention for Safe Containers (CSC) is attached to an approved con-5678910

DIN 38412 Part 15, staticFish test acute, staticInformation obtained from the Swedish Transport Agency, Maritime DepartmentL 23.10.1998/762The owner can transfer his duty to exercise proper case to the lessor of the container or other holder by agreement.A 23.12.1998/1145

9

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

tainer, as prescribed in section 4 of the Act. The supervising authority must make surethat the appropriate safety sign is attached to the container.An inspection body approves a container type or a single container and supervises thetests performed on containers as well as approves upon the owner's suggestion an in-spection programme which complies with the Decree. The inspection body is approvedby the Finnish Safety and Chemicals Agency (Tukes).If a safety sign is missing from a container in use or the container has not been in-spected in accordance with what has been prescribed or if the container on the accountof its structure or condition may cause apparent danger to safety, the supervising au-thority may by virtue of sections 14 and 15 in the Act immediately forbid the use of thecontainer.According to section 611in the Container Act, the Customs, the Border Guards, the po-lice authorities and occupational safety and health authorities and the Finnish TransportSafety Agency act as supervising authorities and oversee that the Act and provisionsare complied with.There is no standardised way to mark containers which have been taken out of trafficdue to their bad condition.Container DecreeAs the Container Act, the Container Decree also came into force on 1 January 1999.The Decree stipulates more detailed provisions on the execution of the Container Act,i.e. the criteria for the approval and commissioning of a container are specified. The De-cree also stipulates what inspections a container must undergo and how often these in-spections are carried out.The approval of a container requires that the container fulfils CSC requirements as to itsstructural strength and equipment. A safety sign (CSC sign) is attached to the containerto indicate that it fulfils the requirements. According to section 8, chapter 3 (Safety Sign)in the Container Decree, the owner of the container must remove the safety sign if thecontainer has been taken out of use or if it has not been kept in a condition required bythe CSC.According to section 11 in Chapter 4 (Inspections), the owner of the container must in-spect the container or have it inspected according to the inspection programme ap-proved by the inspection body. The inspections must be carried out with intervals re-quired by the operating conditions of the container. The first inspection must, however,be carried out within five years of the date of manufacture of the container and after thisthe container must be inspected again with the interval of max. 30 months. Whether thecontainer has such defects which may cause a risk of accident must be examined inconnection with the inspections. The condition of the bearing structures and structuresessential for safety must be especially ascertained.

11

From the beginning of year 2010, the duties of the Maritime Administration were transferred to the Finnish Transport Agencyand to the Finnish Transport Safety Agency, which began their operation at the turn of the year. Because of this, the section6 (2) in the Container Act was changed by Amendment 22.12.2009/1296.

10

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

1.6.2

Operator’s ordersAccording to the internal practice of Containerships Ltd, other units are not to be loadedon a damaged container.

1.7

International agreements and recommendationsConvention for Safe Containers, CSCAn international convention on safe containers was concluded in Geneva on 2 Decem-ber 1972. The convention is also known by the name CSC (Convention for Safe Con-tainers) and its primary objective is to assure the safety of the persons involved in thehandling and transport of containers by defining generally approved strength require-ments on the structure of containers and test methods to be used. The convention cameinto force in 1977.The minimum inspection requirements are defined in the CSC. After meeting these re-quirements the container qualifies for international traffic. The CSC safety signs on con-tainers indicate that the containers are appropriately inspected and fulfil the conventionrequirements.There is no internationally standardised way to mark containers which have been takenout of traffic.Finland became a CSC member state on 1 January 1999, at the same time when theContainer Act and Decree came into force.IICL GuideThe IICL stand for the Institute of International Container Lessors, and it was founded in1971. The IICL has created the criteria for the seaworthiness of containers. The IICLGuide is the most widely spread guide for the determination of the condition of a con-tainer. It defines in what kind of condition containers must be in order to serve flawlesslyas transport units in sea carriage.The objective of the fifth generation guide, the IICL-5, is to act as a supplement to theCSC and national laws and regulations when determining the condition and need for re-pair of containers.

1.8

Quality systemsThe vessel and the shipping company have an enterprise resource planning systemwhich includes a safety management system in accordance with the ISM Code12.

12

International Safety Management Code

11

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

ANALYSIS

System interfacesContainership Ltd has one own vessel in traffic and in addition to her, other vessels oncharter. The LINDA is in long-term charter in Containership traffic.According to the investigators’ experience and understanding, the mode of operationsand operational culture on the chartered vessels are not always exactly similar to thoseon the “own” vessels. The vessel has two “masters”. The culture and practices of thevessel’s owner shipping company can be seen in the personnel’s mode of operations. Inthis case, nothing differing from the normal mode of operations of the vessel's crew hascome to the investigators knowledge.When a container reaches the end of its lifespan in the transport chain, a new user is of-ten found to it. The reefer which caused the incident had been taken out of use becauseof its bad condition as early as in November 2008. In December 2009 the container hadbeen entered into the information system with the reference "Awaiting sale" and a dam-age report in writing had duly been made on 30 January 2010 when the unit was loadedon the deck of the LINDA. The report was signed by the vessel’s Officer and by a senioroperator from the stevedoring company.2.2

Marking and identification of a container which has been taken out of useThere is no internationally standardised way to mark containers which have been takenout of traffic due to their bad condition. Such containers are, however, transported, andthe only indicator available is the number of the container. Therefore the identification ofthe deteriorated containers transported as cargo on vessels is based on the cargo listand the number of the unit. It may be difficult to identify such units when the dischargingand loading take place at the same time.The vessel and the shipping company both had their own systems to manage cargounits. In addition to this, an outside stevedoring company was responsible for cargo op-erations in such ports where Containerships did not have their own terminal. There wereinterfaces between the different actors for the transmission of information. Some piecesof information passed automatically and some manually.In the accident case the discarded container had been loaded on the vessel in Poland tobe used in other than transport purposes in Finland. The poor strength of the containerwith reference to loads was known in the port of loading and the vessel was aware ofthe inferior condition of the unit. The damage report signed by the shipping companyand the vessel’s Officer is an indication of this.The vessel’s route ran from Gdansk, Poland, to Teesport, Scotland, and from there fur-ther to Rotterdam. Because stowage planning is carried out in ports, the informationabout the defect container laden in Poland did not reach the persons who planned stow-age in Rotterdam, but the information and documentation on the damaged containerwas only available on the vessel.

13

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

Obstacles in the transfer of information from one system to another or from one respon-sible person to another could be detected between the parties involved in loading andbetween the interfaces of the different stages of the transport chain. In practice, thedamages of the container which had been loaded in Poland were only known in the portof loading, i.e. Gdansk, and by the vessel's Chief Officer. In Rotterdam containers wereloaded according to the normal practice. Information about the defect container did notreach the persons who were responsible for cargo handling.Vessels in container traffic typically have a tight schedule and port calls are of short du-ration. A figure indicating the capacity of the port’s cranes to handle units in an hour isconsidered to be the efficiency indicator in the handling of containers. The dischargingand loading of cargo units are based on a plan and the supervision of the measures israndom and carried out by the vessel’s personnel. The vessel’s deck crew participatesin the securing of the cargo unit transported on the deck, but not in the placing of cargoor identification of the units. This is a common practice in container traffic.The loading of the vessel started in Rotterdam at 11.40 on 3 February 2010 and endedthe next morning at 06.20. Information on when the detoriated reefer container wasloaded is not available. Because the loading took approx. 18 hours, it can be presumedthat the persons responsible for the loading have changed during that time and informa-tion on the defect container was not transmitted to the responsible persons13in the fol-lowing work shift(s). The systems are not technically linked to each other and the possi-ble restrictions on the containers to be loaded or their placing are based on the informa-tion only the vessel’s Officer has.2.3Alerting and rescue activities and search for the containerAfter the falling overboard of the containers had been noticed on the vessel, the Mastermade a notification on the incident. After receiving information on the fallen cargo via theMRCC Turku, the Swedish maritime rescue authorities sent a helicopter to the scene.Both the LINDA and the remains of the broken reefer container in the sea were video-taped from the helicopter. By then the containers containing dangerous cargo had al-ready sunk. Other marine traffic was also warned of the fallen containers.The Swedish authorities later localized the position where the containers sank. The posi-tion is within the Swedish economic water area but not in the territorial waters of Swe-den. The investigation does not take a stand on the leaving of the units on sea bottom inthe area in question. It is probable that at least part of the dangerous substances in thecontainers dissolves in the sea as the time passes.2.4Effects of weather on the incidentAccording to the entries in the ship’s log, the weather was normal in the southern part ofthe Baltic Sea considering the time of the year. The swell of sea was not significant, andthe vessel did not roll on high accelerations. The metacentric height (GM), which is

13

The vessel’s deck officers and the foremen of the stevedoring company.

14

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

based on stability calculations and which was at the required lower limit14, is also an in-dication of this. On basis of weather information and the vessel’s stability calculations itcan be concluded that the weather did not have a significant effect on the incident.

14

Min GM 0.15m (SOLAS II-1). The GM value describes the vessel’s stability with small heeling angles. A large GM value isan indication of the vessel’s good stability, but it also causes strong accelerations when the vessel rolls.

15

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

CONCLUSIONS

On the basis of the observations, the Investigation Commission has come to the follow-ing conclusions:A container, the structure of which has become weak, must be taken out of traffic. Thishad been done. A deteriorated container which had been taken out of use was loadedon the vessel to be transported to be used for some other purpose.It was not possible to identify the container,which had been taken out of use and wasdeteriorated, as there was no marking on it indicating that loading on it was not permit-ted. The identification of deteriorated container is currently based only on the identifica-tion taking place on the basis of the number of the cargo unit.In Rotterdam three containers with a total weight of 74 tons were loaded on the deterio-rated container even though there was in the instructions information about the fact thatnothing was to be loaded on the reefer in question. Information did thus not pass be-tween the different actors. Divergences in the cargo information system do not passautomatically from one system to another, and some information must be conveyed di-rectly between the various parties involved.17

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

IMPLEMENTED MEASURES

No safety actions that could prevent this kind of incident from reoccurring were broughtto the attention of the investigation.19

C1/2010MM/S LINDA (FIN), falling overboard of four containers into the Baltic Sea, south of Gotland, on 6February 2010

SAFETY RECOMMENDATIONS

Marking of cargo unitsTransporting a deteriorated container as cargo on a vessel requires that it is markedclearly enough as taken out of use. In addition to the sides and ends of the container,the markings shouldalso be visible on the Top of the containerin which case it would bepossible also for the Crane operator to identify the deteriorated unit.Thus the SIA recommends to the General Industrial Federation in Finland, that:1. it would act in the international development work for standadization in suchway that the ISO Standard 6346: 1995 “Freight containers - Coding, identifica-tion and marking” woud be changed in way mentioned above.Flow of informationThe shipping company, the operator and the vessel have different cargo informationsystems in use, and the information transfer between them is not flawless. The actorsmust make sure by other means that information on unusual cargoes or cargoes requir-ing special attention is passed to all parties.Helsinki, 10 October 2012

Risto Repo

Tapani Salmenhaara

Ville Grönvall

21