Forsvarsudvalget 2012-13

FOU Alm.del Bilag 77

Offentligt

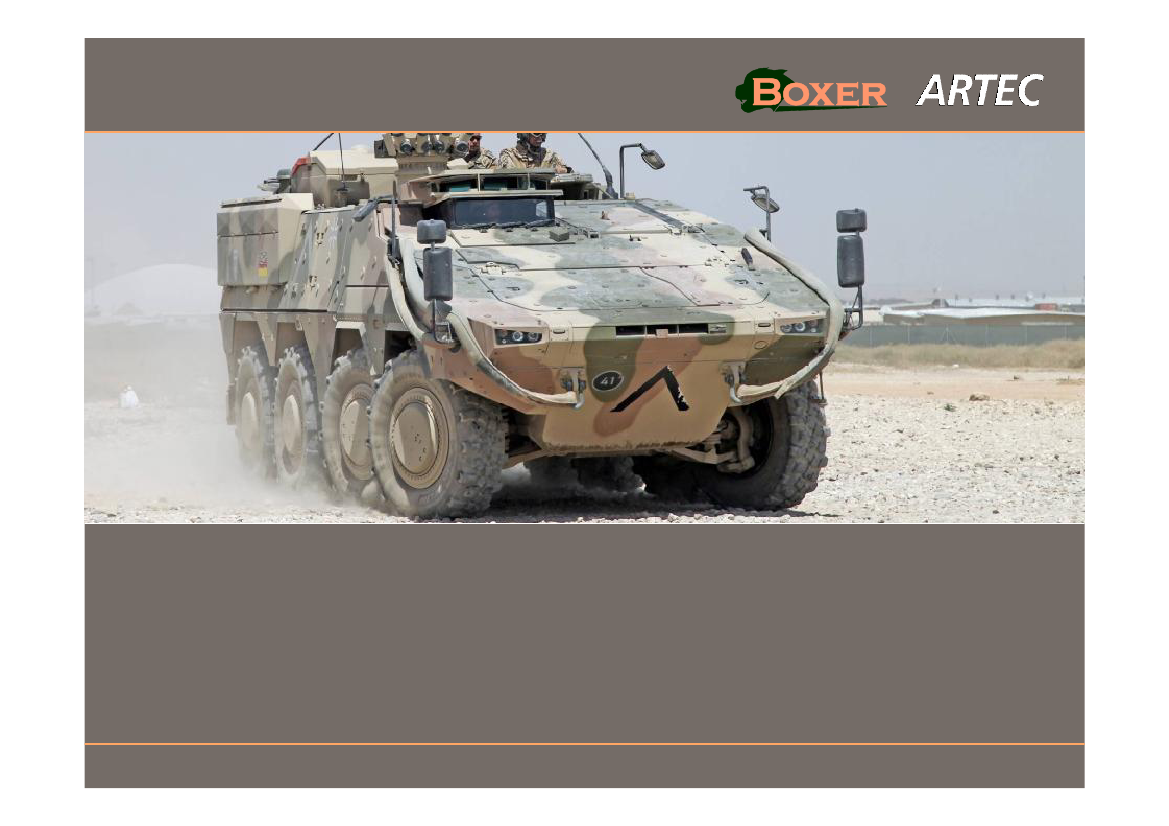

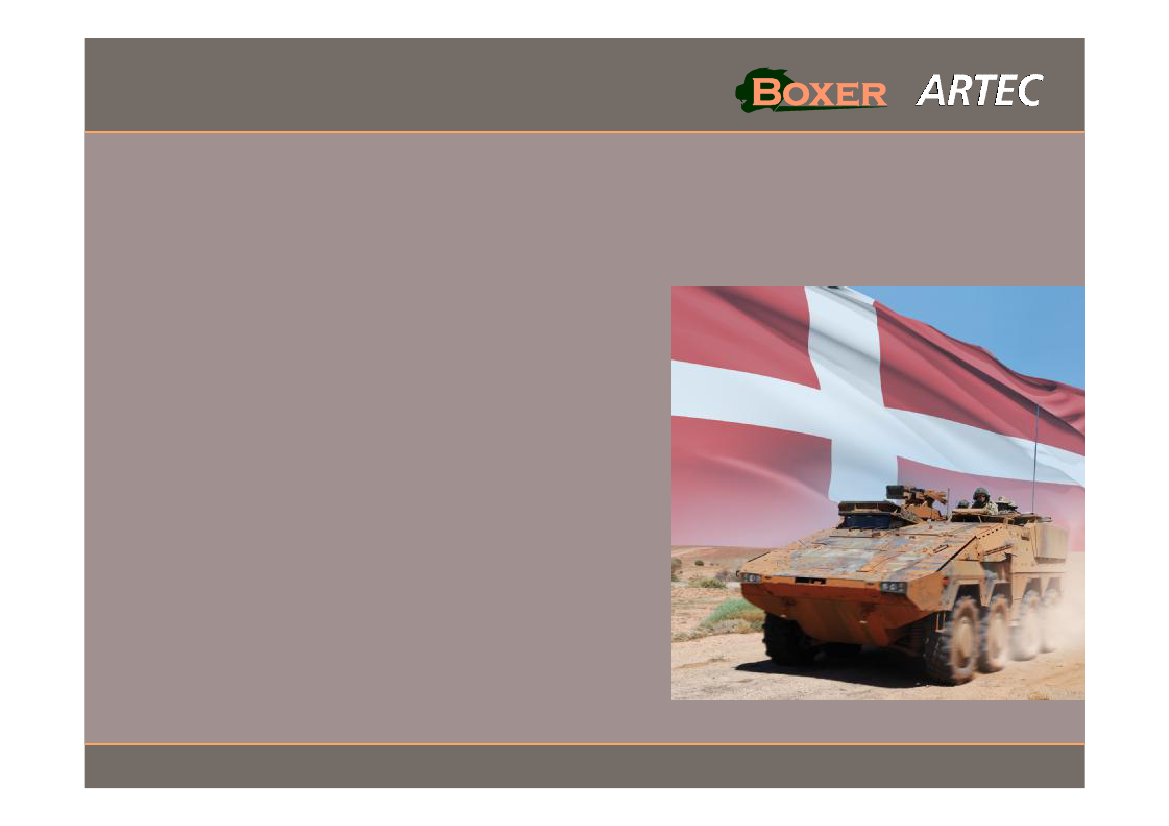

BOXER for the Danish Armed Forces – short briefingARTEC GmbHMunich, December 2012� ARTEC 20121

Executive Summary••••T oreplaceitsaged vehicles, Germany and the Netherlandscontracted developmentand delivery of 472BOXERvehiclesBOXERis a proven solution as itsdevelopmentisfinished, seriesvehicles are beingdeliveredand BOXER isdeployedtoAfghanistanin increasing numbers and versionsBOXERis a proven solution for a successful mission in terms ofprotection, payload,performance/mobilityandflexibilityUniquecompared to other vehicles,BOXER consistsof a (common)Drive Module–identical to all versions –and specific mission Modules,defining the version of thevehicleThe inherent flexibility ofBOXERprovides anunique portfolio of advantagescompared to all other vehicles in terms of– Procurement– Adaptation and growth and– Operation (domestic and theatre)Danish industrycould largelybenefit from BOXERalso due to its unique modularityand involvement of the leading German defence companies – Krauss-Maffei Wegmann,Rheinmetall and MAN� ARTEC 20122

•

•

1.

Background and status of the German -Netherlands BOXER-Programme

� ARTEC 2012

3

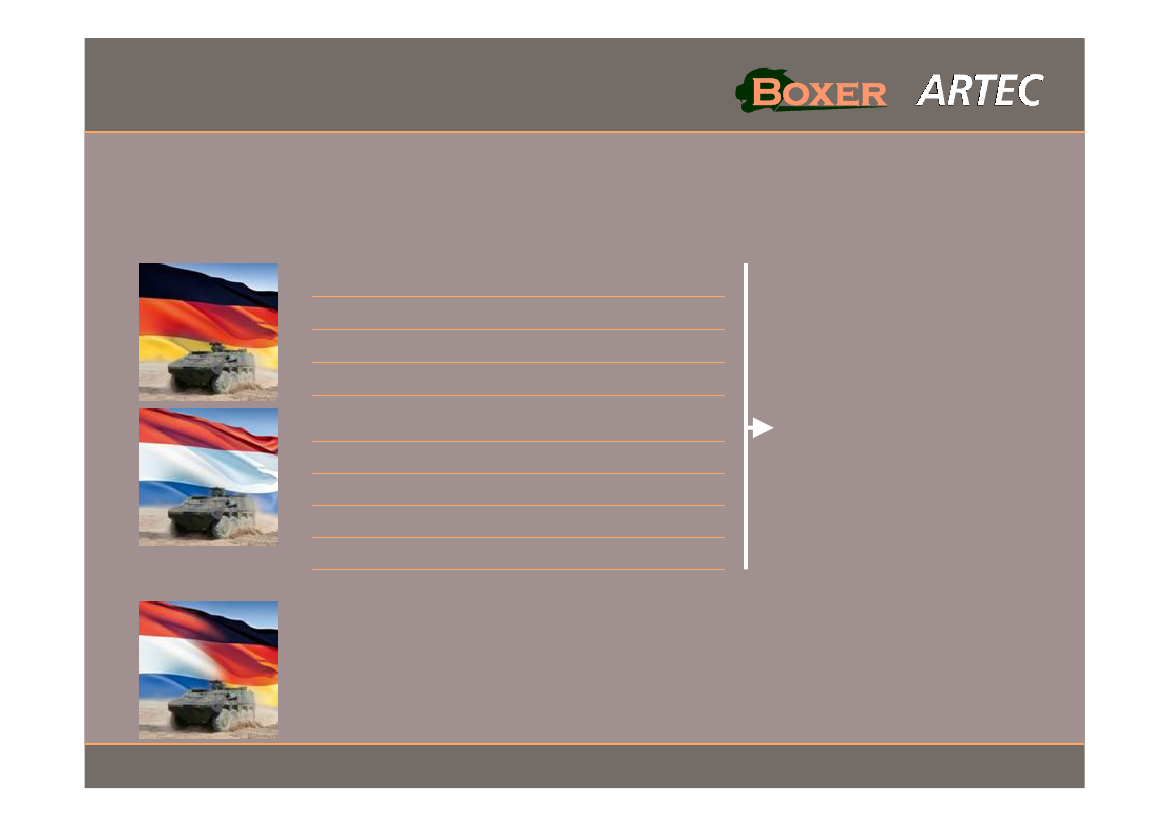

To replace its aged vehicles, Germany and the Netherlandscontracted development and delivery of 472 BOXER vehicles125 Armoured Personnel Carrier65 Command Post Vehicle72 Armoured Medical Treatment Vehicle10 Driver Training Vehicle60 Command Post Vehicle52 Ambulance (MedEvac)27 Cargo Vehicle53 Engineer Group Vehicle8 Driver Training Vehicle

472 Vehicles

Initial In-Service Support Package (Spares, TechnicalDocumentation, S&TE, Training Equipment)Delivery since 2009� ARTEC 20124

BACKUP

The German Army decided to replace its M113 and FUCHSwith BOXER, operating alongside LEOPARD 2 and PUMA IFVGerman Army combat systems

LEO 2

LEO 2

M113BOXERFUCHS

MARDER� ARTEC 2012

PUMA5

BACKUP

The NL Army also decided to replace its M577 and YPRsupport vehicles with BOXER, operating alongside CV-90The Netherlands Army combat systems

M577(variant of M113)BOXERYPR-765(support vehicle)

YPR-765(infantry vehicle)� ARTEC 2012

CV-906

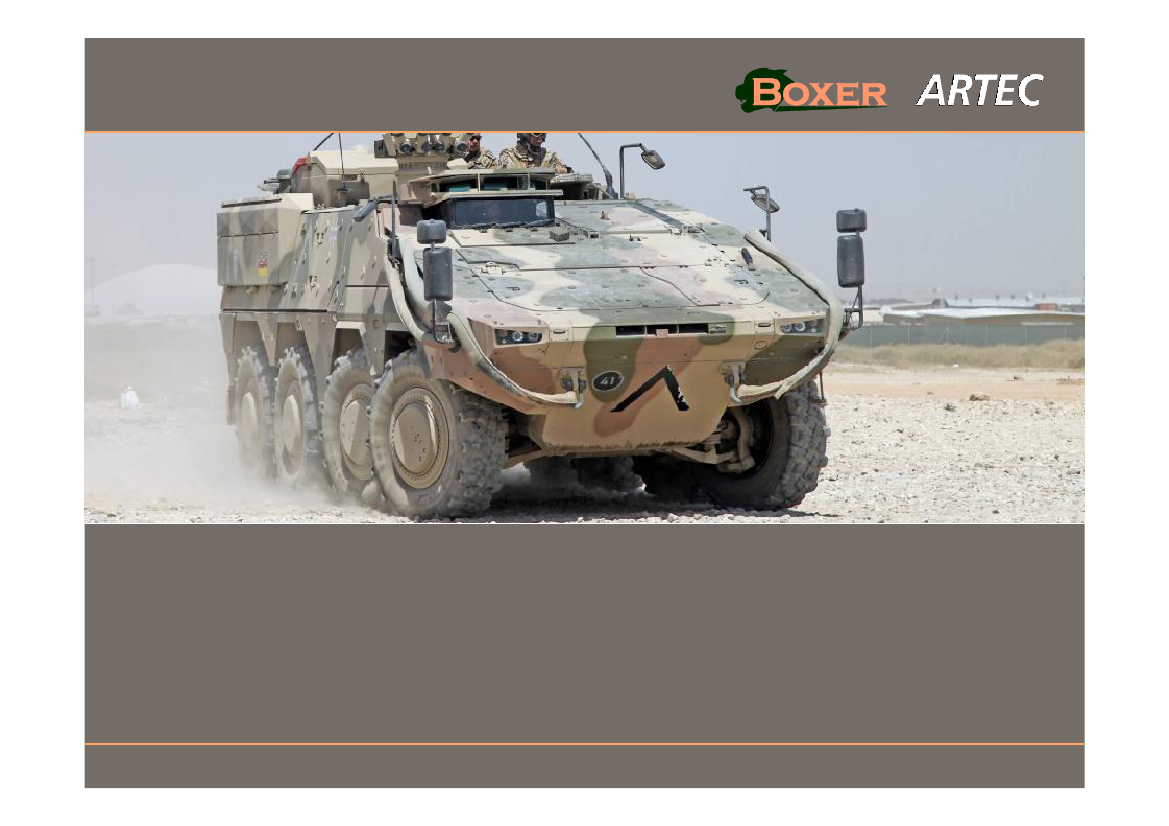

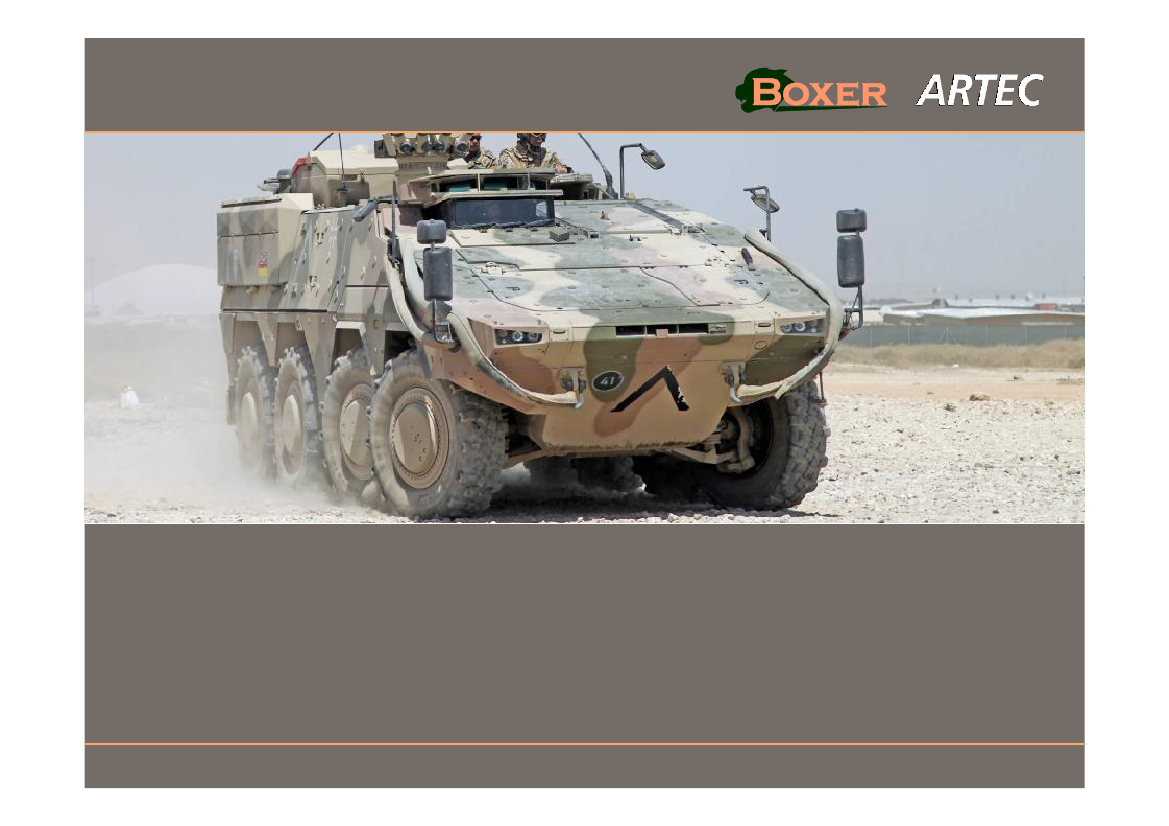

Development is finished, series vehicles are being delivered,BOXER is deployed to Afghanistan – a proven solutionCurrent status of DE/NL-Programme•Developmentfor common parts and mostMission Modulesfinished•Series deliveryaccording to contractsince 9.2009 – 180 vehicles delivered in 4versions until end 2012• TheGerman Armyconducted a trial inAustraliabegin 2010 – preparation foroperation in theatre• Industry conducted a desert trial 2010 inthe United Arab Emirates•Deploymentof BOXERto Afghanistansince summer 2011– with increasingnumbers of vehicles and versions� ARTEC 20127

2.

BOXER’s capabilities

� ARTEC 2012

8

A confident statement: BOXER is the perfect solution for asuccessful mission, meeting all requirements of Danish ArmyPROTECTIONagainst• all types of mines• in-/direct ballisticprojectiles• detection

PAYLOAD• 14 - 17.5 m� ofprotected volume• Built-in growthpotential

• Excellent mobilityon the road and crosscountry• High performancepower-pack

• Modular principle ofDrive and Missionmodules• Easy maintaining• Fit for the future

PERFORMANCE

FLEXIBILITY

� ARTEC 2012

9

Protection – survivability without compromise, meeting allrequirements of the Danish Armed Forces and beyondScope of possible protectionNBCBombletsHand-heldAnti tank weaponArtillery fragments

Medium calibreautomatic cannonHeavy machine gunAP mineAT mine� ARTEC 201210

BACKUP

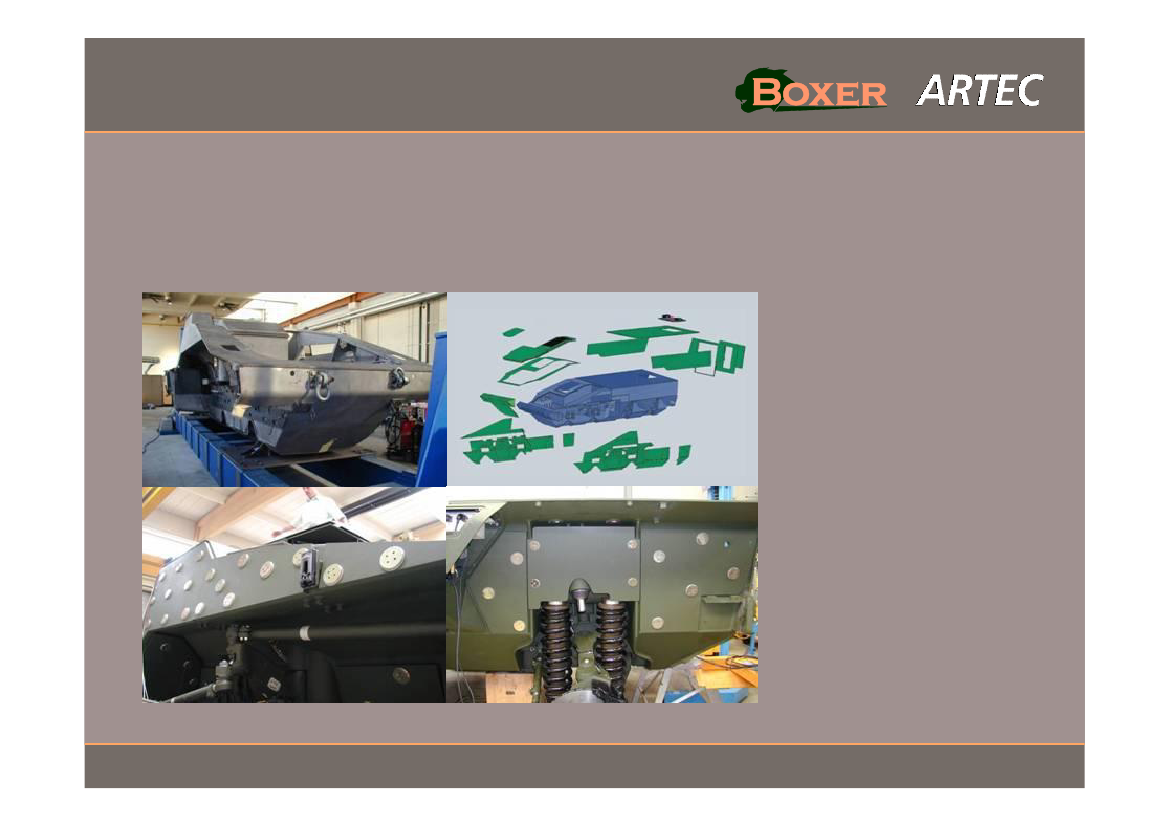

The protection concept provides an unique flexibility –different protection kits can easily be mountedCapabilities and Solutions – hull & modular armour•Dismountingprotectionfor trainingand domestic operation–reducing wear & tear• Mounting ofprotectionfor vehiclesin theatre• Mountingspecialprotection kitsforspecific vehicles•Easy and cost efficientadaptationtonewtechnologiesas onlyarmour plates have tobe exchanged

� ARTEC 2012

11

Payload – ready for the future by providing growth potential

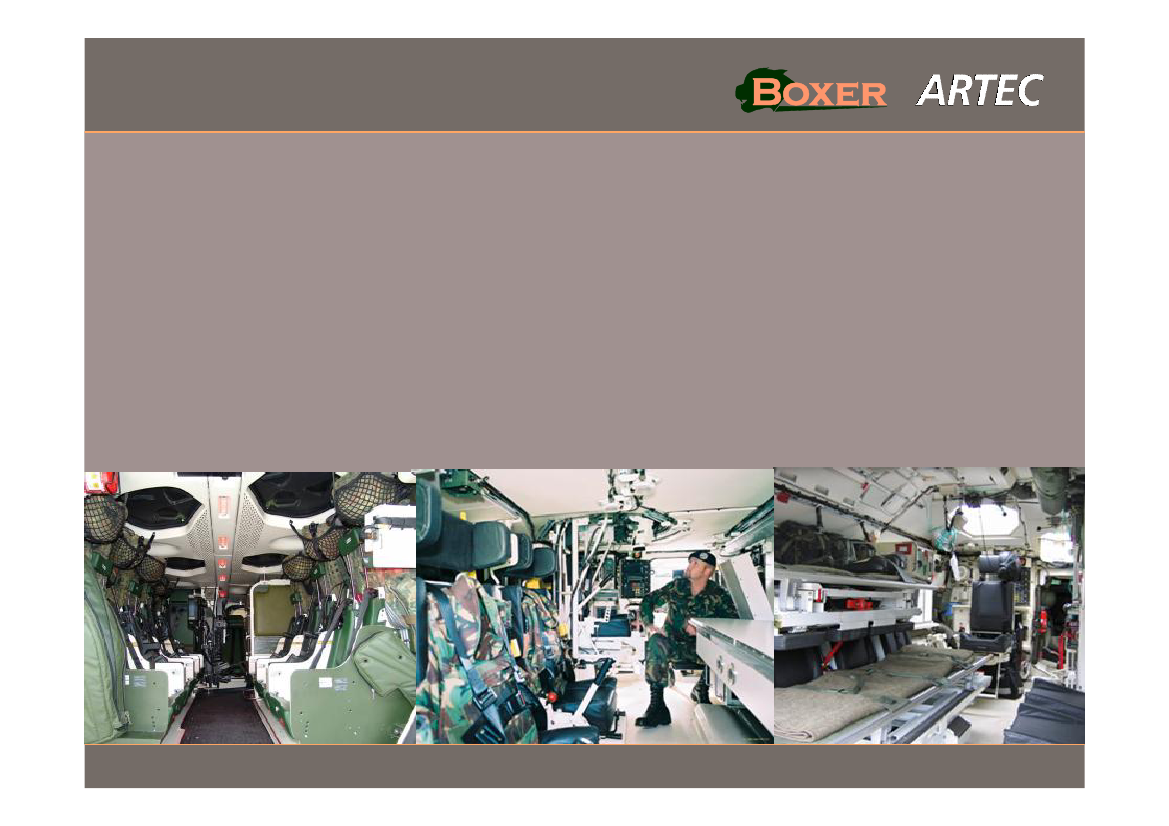

• 14 (flat roof) to17.5 m�(high-roof)protected volume –German APC carriesequipment for 10 soldiers for 10 days (!)•Growth potentialprovided by design• Payload in total up to 9 t for protection, crew and equipment• Remarkable payload allows forcustomer-tailored solutions

� ARTEC 2012

12

Performance – proven to operate alongside the LEOPARD 2

• Easy manoeuvrability, maximum speed>100 km/hand a range>1,000 kmon roads•Excellent off-road mobilitythrough– Powerful V8 530 KW multi-fuel engine(power-to-weight ratio: 16.1 kW/te –like LEOPARD 2)– Permanent all wheel drive– Differential locks– All-around independent suspension– Central Tyre Inflation System– Optimal damage protected arrangementof Running Gear and Steering• Combat wheels withintegrated run flatsystemprovide the necessary residualmobility in case of puncture� ARTEC 201213

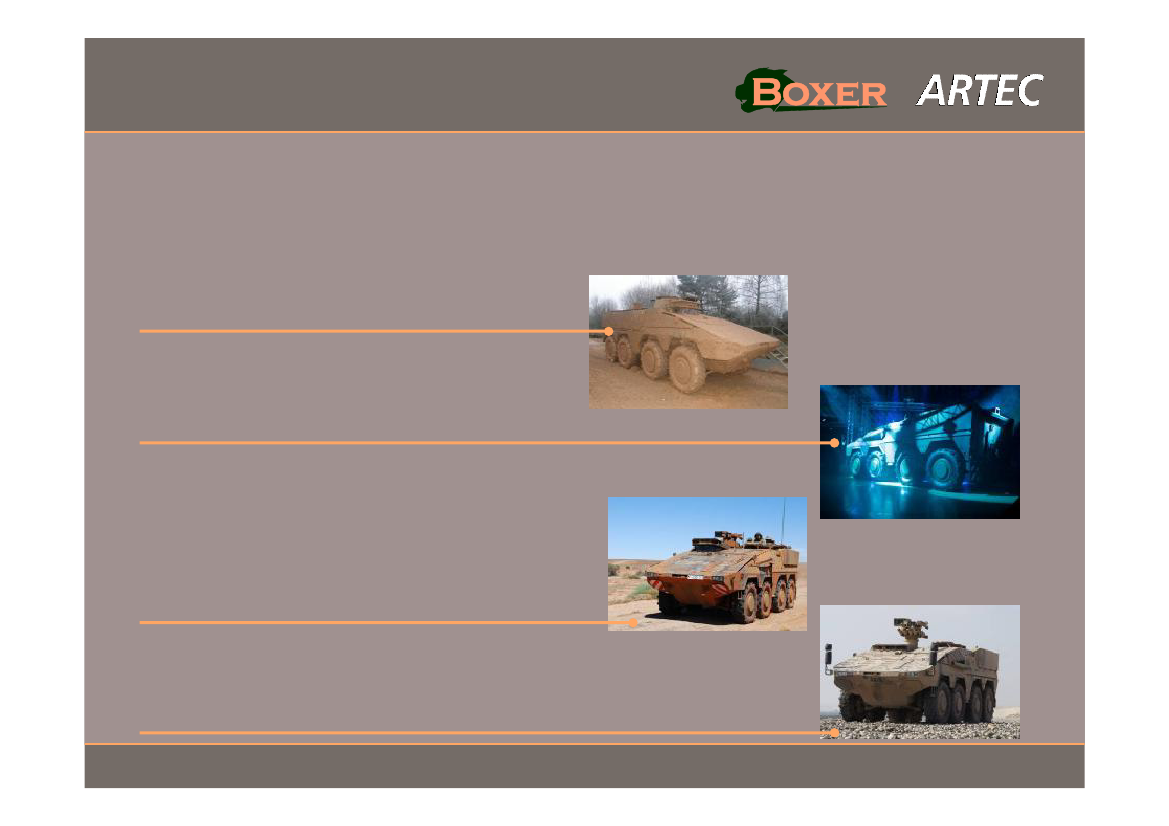

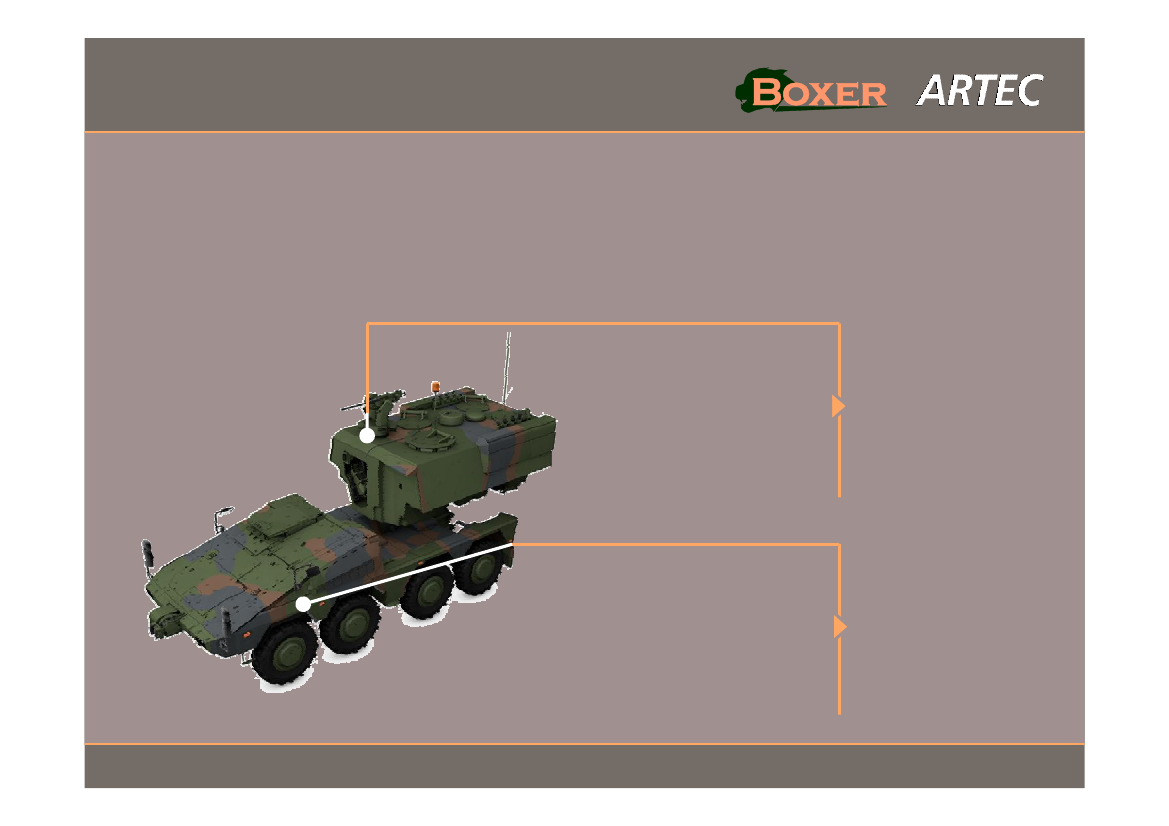

Flexibility – the mission changes, so does BOXER

• BOXER is basically defined by aDrive Moduleand aMission Module• The concept has been commonly chosen by theUK, Germany and the Netherlands• The modular principle enables efficientintroduction of diverse requirements – change ofmission modules <30 min• Flexibility also down to sub-systems: easytransportability and maintainability in theatre, e.g.exchange of power-pack <20 min

� ARTEC 2012

14

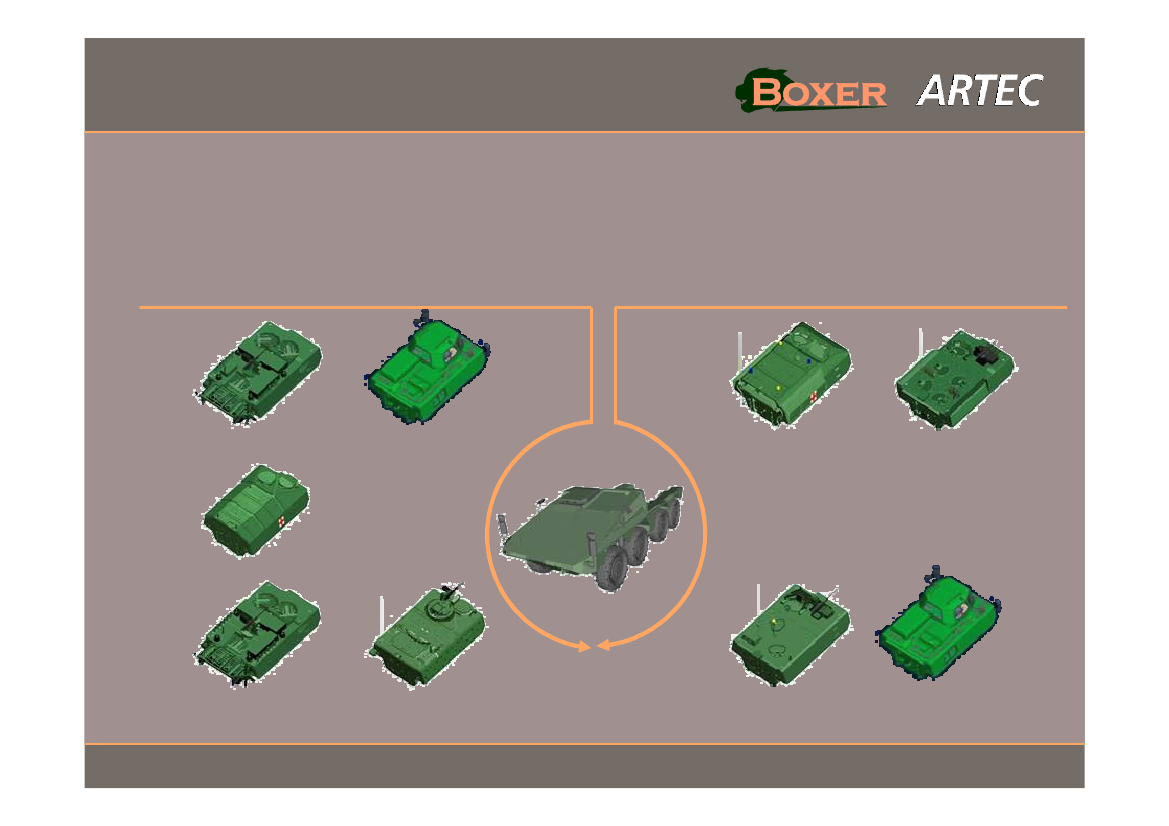

Flexibility in missions – with already eight of Modules,BOXER is capable of various missions in theatre …Current Missions ModulesNL-versionsGE-versions

Command PostNL

Driver Training

ArmouredMedicalTreatmentVehicle

APC

MedEvac

Engineer vehicle

Cargo� ARTEC 2012

Command PostDE

Driver Training15

… by relying on a common Drive Module for all nationalspecific versionsMain systems of common Drive ModuleMain Basic Vehicle Systems••••••••Power PackRunning GearHull Drive ModuleProtectionFuel SystemElectrics (CAN-System)Driver stationFire Extinguishing System

• NBC/AC-System• Rear ramp

� ARTEC 2012

16

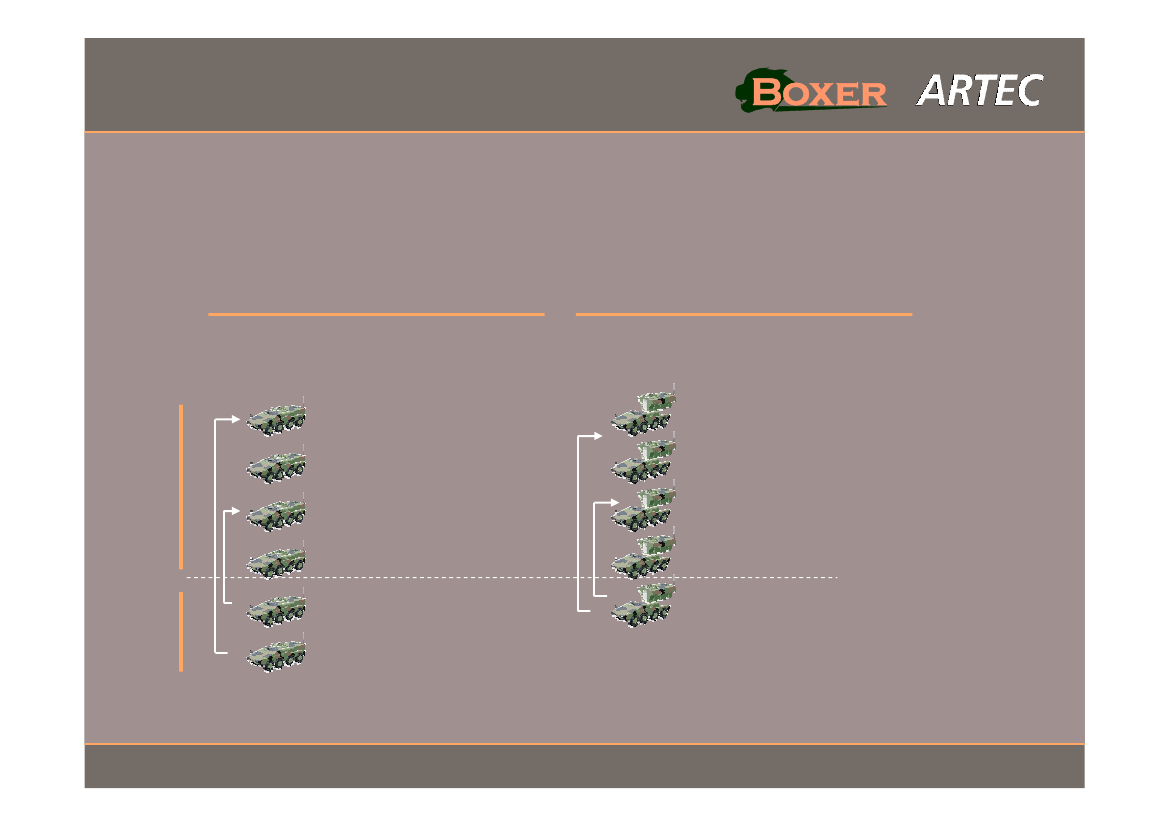

The inherent flexibility of BOXER provides an unique portfolioof advantages compared to all other vehiclesProcurement•Less DriveModules–Procurement of lessDrive than MissionModules possible•Specific MissionModules– Procure-ment of specificMission Modulesonly possible•Efficient use–Drive Modules arebeing used veryefficient as they arecapable to carry allMission Modules

Adaptation and growth•National specific MM– whilerelying on common DriveModule, national specific MissionModules only to developed•Partner Nations– minimizingdevelopment efforts by relying onalready existing Mission Modulesfrom allied nations with onlyadd-on development as far asnecessary•Adaptation of Mission Module– for major changes in specific(e.g. communication) onlyMission Module to be adapted•Adaptation of Drive Moduleindependently– for majorchanges only the Drive Modulehas to be redesigned� ARTEC 2012

Operation in theatre•Tailored to Mission– Vehiclestailored on daily basis to the mission•Severe puncture– in case of severepuncture, Mission Module can betaken off and used further•Lowering costs of transport– incase of overhaul in Denmark, onlyDrive or Mission Module are to betransported•Smaller technical reserve intheatre– modular design allows fora lower number of complete vehicleson standby•Easing maintenance– easedaccess to components (saving time)•Stationary situations– someMission Modules (e.g. AMB) could beused also in stationary situations17

BACKUP

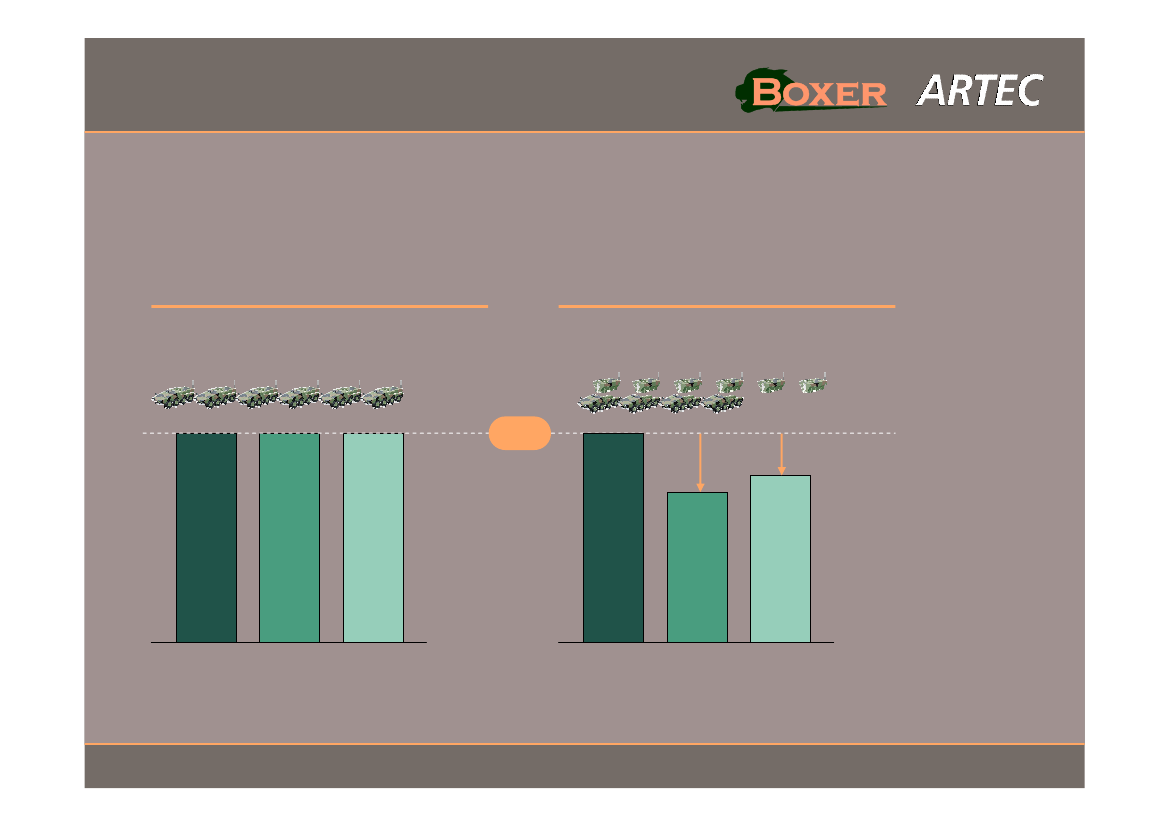

Less Drive Modules – procuring less Drive Modules thanMission Modules is feasible and provides unique advantagesAdvantages of using less Drive than Mission Modules – genericAPC procurement “standard”• Using standard vehicles• No use of modular concept

APC procurement “optional”• Use of modular concept• Flexible use

100%

Procurement Costs

Procurement Costs

Operational Costs

System Capability

• Same system capability possible• Reduced procurement costs• Reduced operational costs� ARTEC 201218

System Capability

Operational Costs

BACKUP

Smaller technical reserve in theatre – modular design allowsfor a lower number of complete vehicles on standbyAdvantages of lower number of complete vehicles for reserve in theatreAPC in mission “standard”• Using standard vehicles or• No use of modular conceptengine fault

APC in mission “optional”• Use of modular concept• Flexible useengine fault Drive Module

MISSION

readyCommander’s station faultready

readyCommander’s station faultMission Moduleready

RESERVE

� ARTEC 2012

19

BACKUP

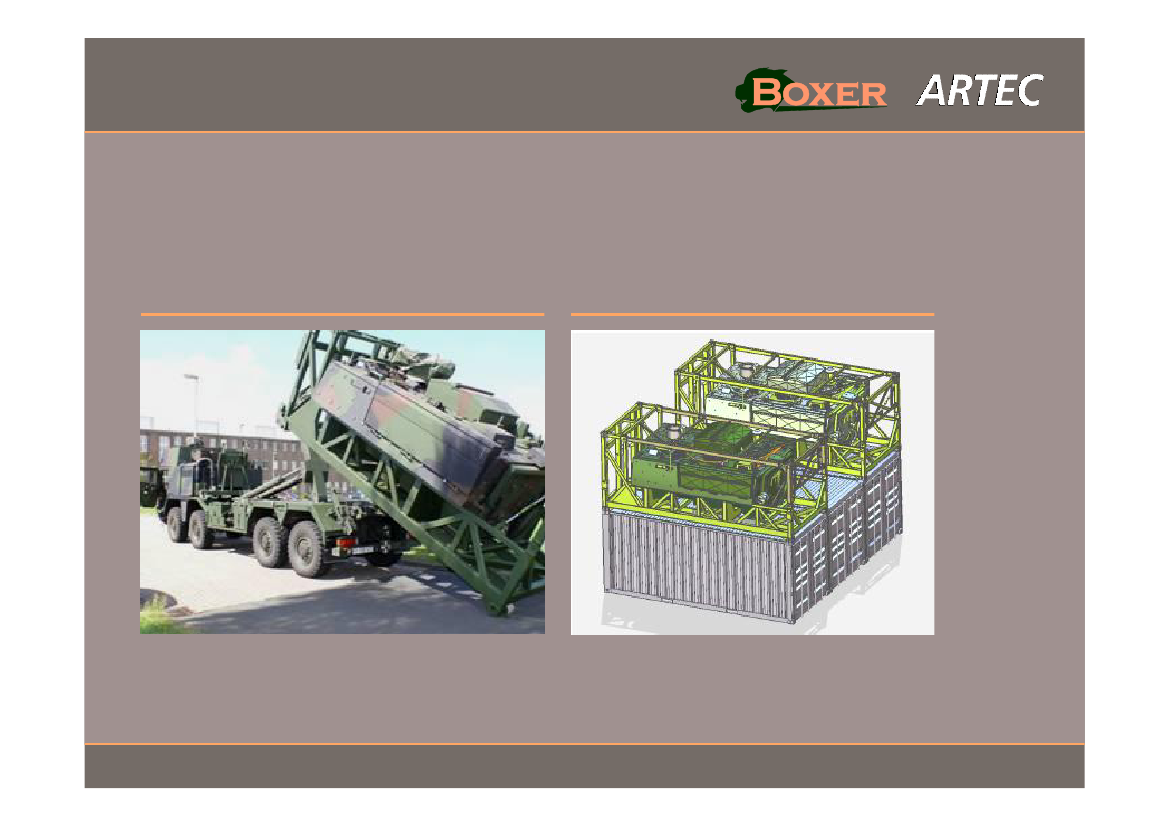

Lowering costs of transport – In case of overhaul in homecountry, only the Drive or Mission Module is be transportedExemplary possibilities of transporting Mission Modules without a Drive ModuleTransport on a Container-truckTransport as a container

� ARTEC 2012

20

3.

BOXER as an interesting solution also for the DanishIndustry

� ARTEC 2012

21

Danish industry could benefit from advantages of BOXER andcooperation with leading German defence companiesAdvantages of BOXER for industrial cooperation with Danish industry•Unique modular conceptprovides a one-time opportunityfor an industrial footprint with a wide range ofparticipation of Danish industry

•State-of-the-art technologyfor land vehicles –esp. electrical system, welding, protection, drive train

•Proven solution• Manifold experience in production and developmentdue to current German/Netherlands-Programme• Successfully operated by German Army in theatre

•Access to business opportunitiesofKrauss-Maffei Wegmann Rheinmetall and MAN

� ARTEC 2012

22

The modularity of BOXER provides for unique opportunitiesfor industrial cooperation …Modular sub-systems of BOXERMission Module• One common hull floorand currently only 2different hulls• Rear ramp• NBC-unit• Hatches• Part of electricsDrive Module•••••Power PackRunning GearHull Drive ModuleDriver stationPneumatic/hydraulicpower unitStep-by-stepapproach inproduction –starting withcomponents viasub-systems tocomplete assembly23

R&D and/orproductioncompletely byDanish Industryfrom beginonwards

� ARTEC 2012

… as the Drive and the Mission Module can be handledseparately in terms of development, production and servicePossibilities of BOXER for an industrial conceptUnique to BOXER

Step of valuechainDevelopment

DriveModule

MissionModule

üDepending on capa-bilities and experience

Production incl.• Procurement• Assembly• Integration• DeliveryServices

1) Documentation/Manuals, Spares, Special T ool, Training equipment, Training� ARTEC 201224

Besides BOXER, ARTEC’s shareholders are an ideal partnerfor Danish industry, offering a complete defence portfolio• Offering acomplete Land SystemsPortfolio…– 4x4, 6x6, 8x8, tracked vehicles– Weapon stations– C4I-Systems, Air Defence– Soldier Systems …• …via thecomplete value chain…– R&D, Production, Service (incl. training,training equipment, spares supply,maintenance, in-theatre support, specialtools, documentation)• …sincedecades– Rheinmetall: established 1889– KMW: established 1838� ARTEC 201225

ARTEC and its shareholders are open to enter into anycooperation scenario with Danish Industry

• Acooperationwith Danish industry couldencompass:– Adaptation of specific Mission Modules– Series Production- Components, sub-systems- Drive and/or Mission Module- Assembly and Integration– Logistic Support, Maintenance – alsoPerformance Based Logistics• The BOXER Modular concept specifically allowsfor development and production of the MissionModules byDanish Industrybased onDanishArmy’s requirementssimilar to the Netherlandsentrance into the Programme in 2004� ARTEC 201226