Erhvervs-, Vækst- og Eksportudvalget 2012-13

ERU Alm.del Bilag 204

Offentligt

Danish Parliament CommitteeFeb, 2013

Agenda

•BRASKEM overview•Innovation and Technology•Green chemicals and polymers

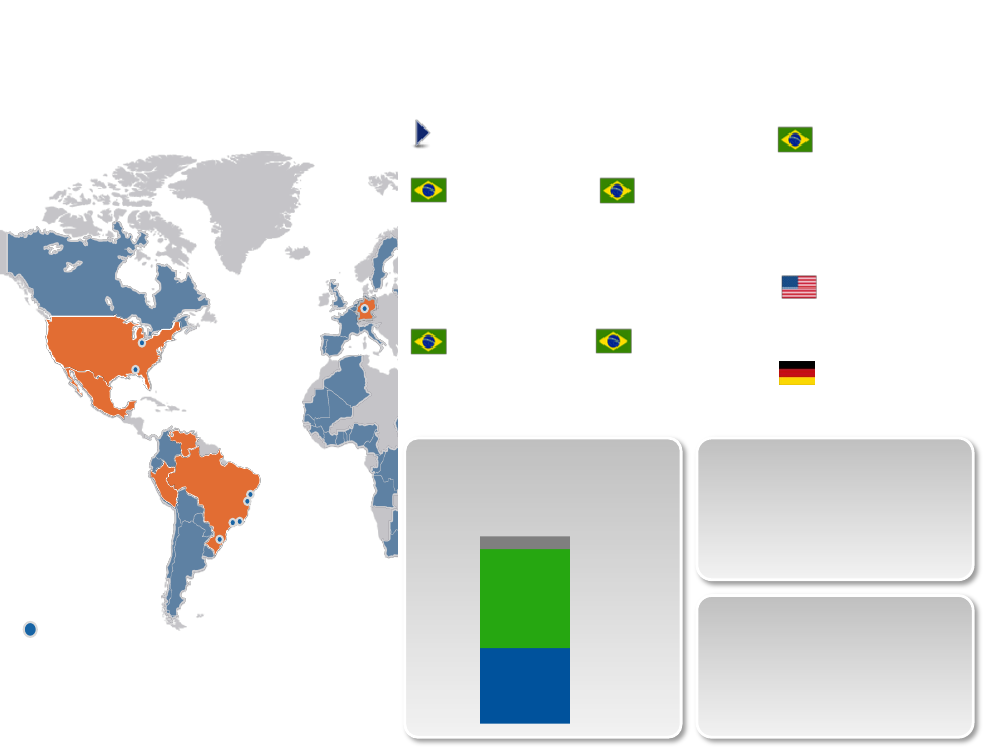

BRASKEM OVERVIEW35 Industrial sitesBahia14111Naphtha CrackerPEPPPVCChlorine Soda

Rio Grande doSul1521Naphta CrackerPEPPGreen Ethylene

Rio deJaneiro1 Gas Cracker1 PP1 PE

United Statesof America5 PP

Alagoas1 PVC1 Chlorine Soda

São Paulo1 Naphtha Cracker2 PP3 PE

Germany2 PP

CAPACITY(kt/p.a.)7.5105103965Industrial Presence3035Fonte: Braskem

2011 Net Earnings

PVCPP

US$19.9

billion

2011 EBITDAPE

US$2.2

billion

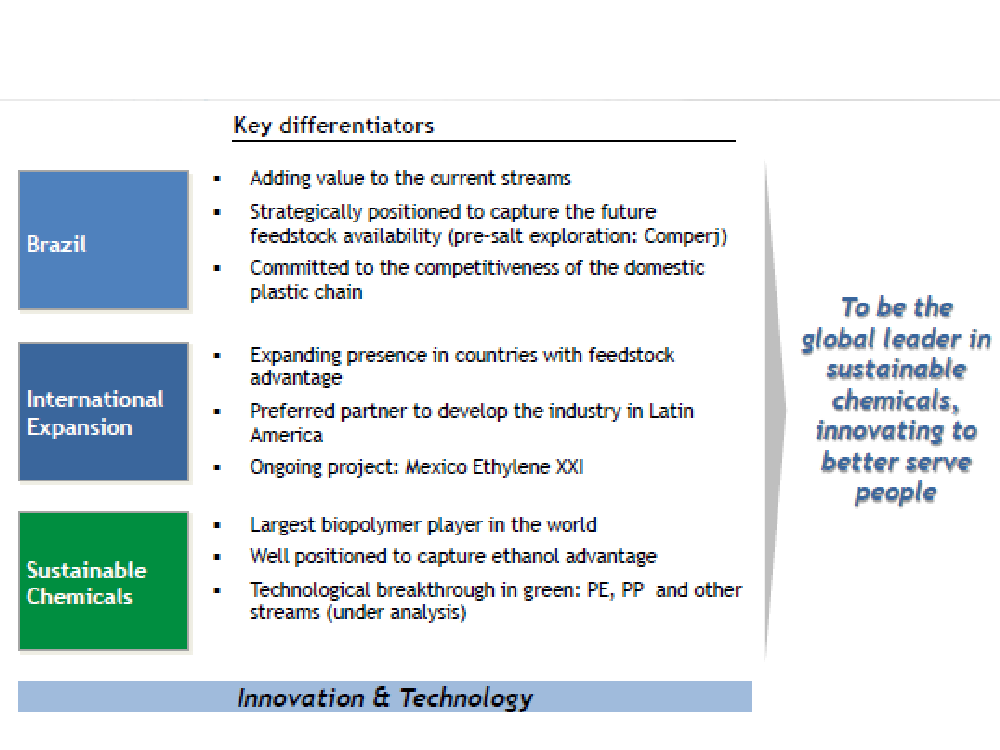

STRATEGY BASED ON 3 DRIVERS OF GROWTH

2020 Vision

BRASKEM BASES FOR GROWTHBrazilConsolidated Project PipelineBrownfield/Greenfield expansionprojects in Brazil: PE and PP assetsButadiene (100 kton/y)PVC Expansion(+ 200 kton/y)Comperj – integrated complex inRio de Janeiro (southeast Brazil)

Portfolio Expansion

Resin Capacity CAGR for 2010-2015: +4.3% p.y.

Diversification of raw materials and world-class assetsFiscal discipline and excellent track record of projects executionSource: Braskem

BRASKEM BASES FOR GROWTHInternationalization -Americas2015Ethylene XXI – Mexico•••1,000 kton/y ethylene and PEJV between Braskem (65%) and the Mexican groupIDESA (35%) for the purchase of ethane from PEMEXStrategic partnership with Ineos and Lyondell Basellfor PE plants technologies

Future projects over evaluationPeru•600 to 1,000 kton/y ethylene and PE

Venezuela•Under revaluation

USA•Shale gas opportunity, under evaluation

BRASKEM BASES FOR GROWTHSustainable ChemicalsBraskem: aglobal leader inbiopolymers

Development•Partnerships for thedevelopment of competitivetechnologies

Green PPGreen PEstarted up 4Q2010•Successful track record forimplementing projects: termand costs•Capture of 2.5t CO2/t PE•Innovation in bioplasticmarket•Production integrated withgreen propylene•Capture of 2.3t CO2/t PP•Development of other cracksstreams to sustainablechemicals•PE integrated project study•New biobased chemicalproducts studies

•Partnership with Customers

BRASKEM GREEN POLYETHYLENE: A RUNNING BUSINESS

StartupSept 24, 2010Capacity200 ktyInvestmentUS$ 290 MM

Braskem is the leading globalsupplier of biopolymers

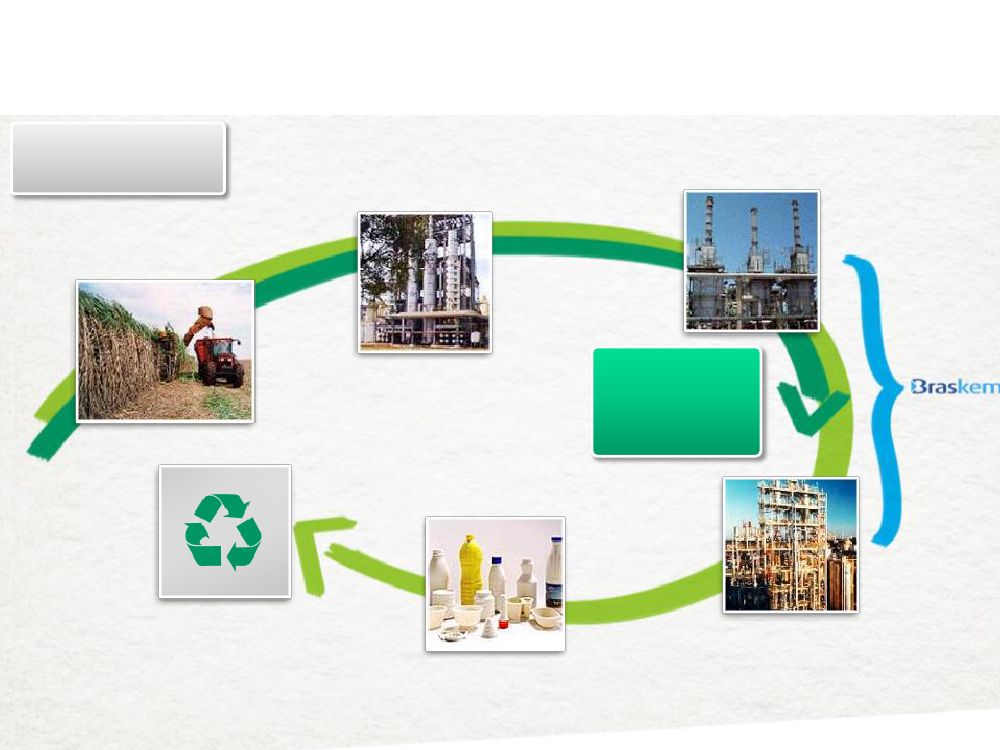

GREEN POLYETHYLENE CYCLEFROM CRADLETO CRADLESugarcaneThe sugarcane crop metabolizesthe CO2to produce sucrose

Ethanol CH3-CH2OH

Ethylene CH2=CH2Through the dehydration, theethanol is transformed in ethylene

At the distillery, the sugarjuice is fermented anddistillated to produce ethanol

Very FavorableEcoprofile*Captures and Fixes2,5 t CO2/t PE

RecyclingThe green polyethyleneis 100% recyclable(Mechanical / Incineration)* Preliminary Ecoeficiency Analysis (From cradle to Braskemgate)– Funda§ão Espa§o Eco 2007/2008

Green PE [CH2=CH2]Carbon captureThe green polyethylene istransformed in final products inthe same unities already existentsThe ethylene is polymerizedin polyethylene productionunities

Green PE/PP has the same technical and recyclability properties than petrochemical PE/PP.

GREEN POLYETHYLENESugarcane

Oil

Fully identicalproperties

Green PE/PPcan berecycled in the samestream alreadyestablished for thepetrochemical PE/PPGreen PE/PP regrindcan also beincorporated in theconverter’s productionsystems

PetrochemicalPE/PP

GreenPE/PP

GREEN POLYETHYLENEPartnerships with Leading Global Companies reinforce sustainability strategy

Agenda

•BRASKEM overview•Innovation and Technology•Green chemicals and polymers

MANAGING INNOVATIONR&D Structure

INNOVATION AND TECHNOLOGYEXPENDITURES, TEAM LEVEL, INFRASTRUCTURE,…I&T Expenditure: 2011 – 93 MM USD; 2010 – 40 MM USD; 2009 – 30 MM USD.298 People; Areas of Qualification: Chemical and Materials Engineering,Chemistry, Biochemistry and Biology; 16% of PhDs, 30% of researchers MScand Post – Graduate.

Over US$ 200 million in R&D assets: 2 Tech Centers,8 pilot plants, 24 labs.

445 patents filed until 2011Joint technology programs; Partnership with universitiesand R&D centers in Brazil and USA14

TECHNOLOGY CENTERS AND LABORATORIESTECHNOLOGY CENTERPittsburgh in United StatesPolymer development3 laboratories37 qualified staff

EUROPE LABORATORY- Wesseling inGermanyPolymer development

HMPE LABORATORY -Cama§ari/BAHMPE Fiber development1 pilot plant14 qualified staff

BIOTECNOLOGY LABORATORYTECHNOLOGY CENTER -Triunfo/RSPolymer development17 laboratories + 7 pilot plants (6 pilot plantsin Triunfo/RS and 1 in Cama§ari/BA)158 qualified staffCampinas/SPBiopolymers development: Partnership withLNBio2 Laboratory31 qualified staff

PETROCHEMICAL PROCESSLABORATORYABC/SPLaboratoryTechnology CenterFuture LaboratoryFonte: Braskem

3 qualified staff

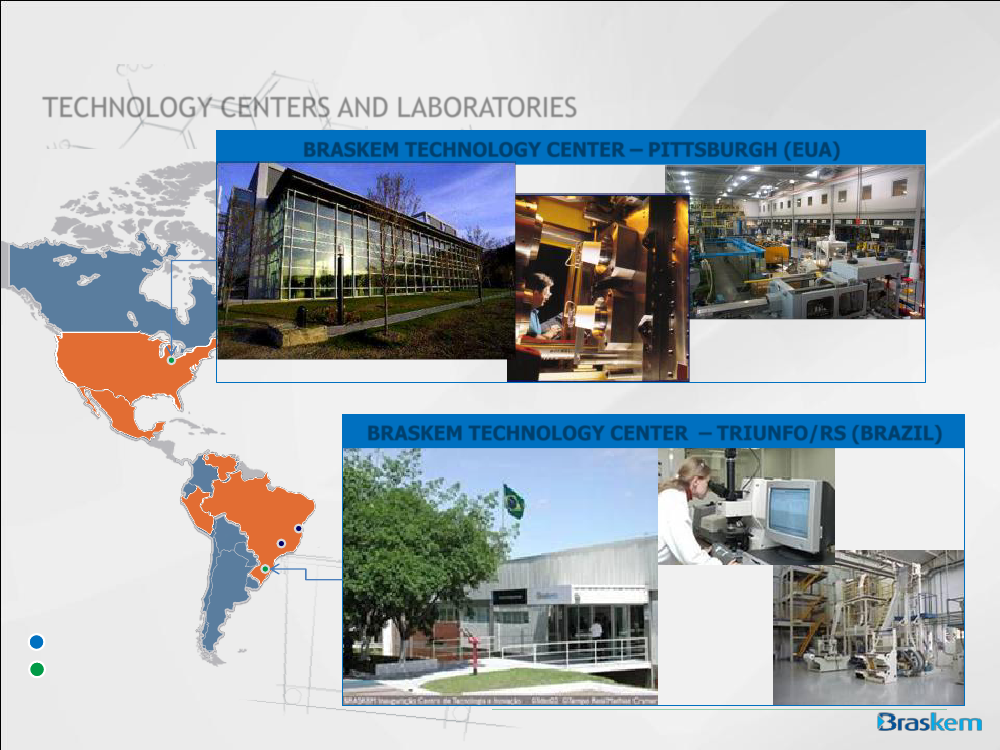

INNOVATION AND TECHNOLOGYTECHNOLOGY CENTERS AND LABORATORIESBRASKEM TECHNOLOGY CENTER – PITTSBURGH (EUA)

BRASKEM TECHNOLOGY CENTER – TRIUNFO/RS (BRAZIL)

LaboratoryTechnology CenterSource: Braskem

16

INNOVATION AND TECHNOLOGYTECHNOLOGY CENTERS AND LABORATORIESHPME FIBER LABORATORY BRASKEM– CAMAÇARI/BAHIA(BRAZIL)

BIOTECNOLOGY LABORATORY BRASKEM – CAMPINAS/SP(BRAZIL)

LaboratoryTechnology CenterSource: Braskem

17

BRASKEM BIOTECHNOLOGY LABORATORYAvailable resourcesLaboratório de biotecnologiaBRASKEMbioinformática

shakersHTS

biofreezer

Cromatógrafos

Sistema de gera§ão deimagens molecuaresFermentadores

BRASKEM´s OPEN INNOVATION VIEWpartnerships with universities and research centers

BRASKEM´s OPEN INNOVATION VIEW

December 2009

Braskem and Novozymes established a newpartnership based on Novozymes’ fermentationtechnology and Braskem’s expertise in chemical

technology and thermoplastics to develop a greenalternative to polypropylene derived from oil.

BRASKEM IS AWARDED BY FINEPFINEP – “Financier of Studies and Projects”

BraskemwinsFINEP2011Innovation Award in the LargeBusiness category;

Braskem wins FINEP 2012 awardonSustainableInnovationcathegory for Green PE case;

http://www.braskem.com.br/site.aspx/Releases-Details-USA/Braskem-wins-FINEP-Innovation-Award-in-the-Large-Business-category/FINEP website

POLYMERSInnovation throughout the production chain

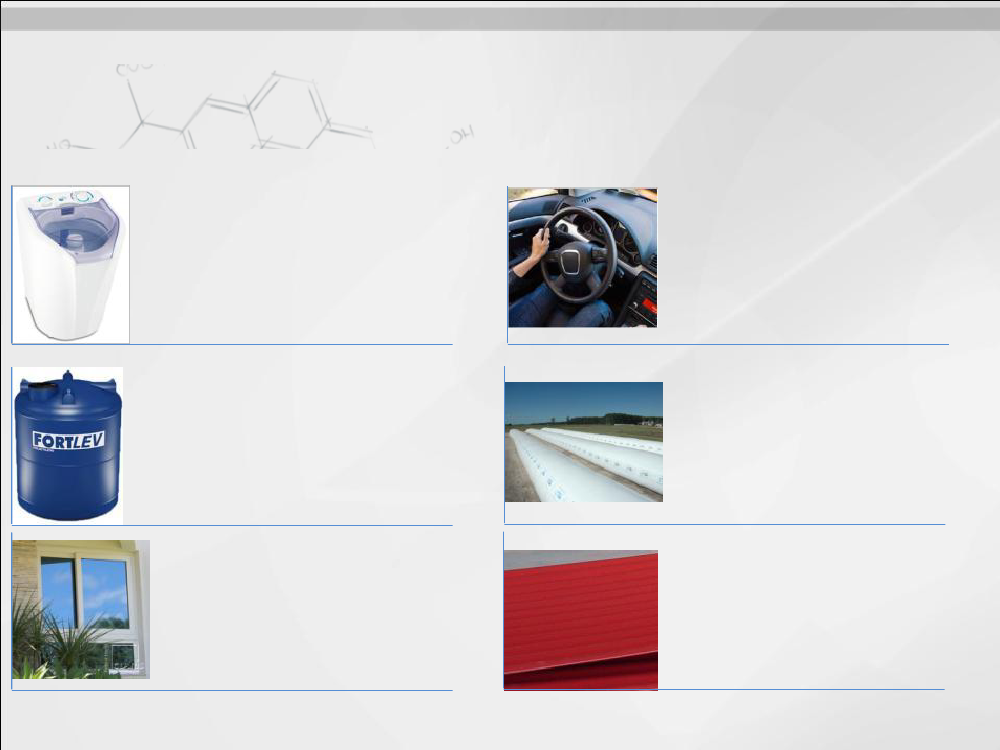

Partners: Electrolux and ColormaqReplace steel and PET in parts of thewashing machine, reducing the cost andweight.

POLYPROPYLENE (PP)Washing Machines

Partners: Lyondell-Basell BrazilHigh-performance plastics in automotiveitems

POLYPROPYLENE (PP)automotive

POLYETHYLENE (PE)Water tanksPartners: FortlevReplacement fiberglass.

Partners: PacifilFlexible silos for grain storage, facilitatinginstallation and reducing costs.

POLYETHYLENE (PE)Bags of Grain

Partners: Claris, First Line, Veka andWeikuIncreased use of PVC in building.

PVCframes

PP

Partners: Precon IndustrialReplacement of cement and tile.

PVCtiles

22

BRASKEM INNOVATION AND TECHNOLOGYAreas of interest•Sustainability(performance improvement, post-consuption destination)•Polymers– new molecules (PEF, PLA, PA, PPC, PPE, others)•Catalysis(Phthalate Free for PP and PE; ionic liquid; nanocatalysis)•RenewableSources for chemicals and new monomers (furans, C2, C3,C4, C5 and C6)

•GMO•PerformanceMaterials (Composites, thermosets, PEEK, othes)•CO2chemistry•UHMWPE23Source: Braskem

Agenda

•BRASKEM overview•Innovation and Technology•Green chemicals and polymers

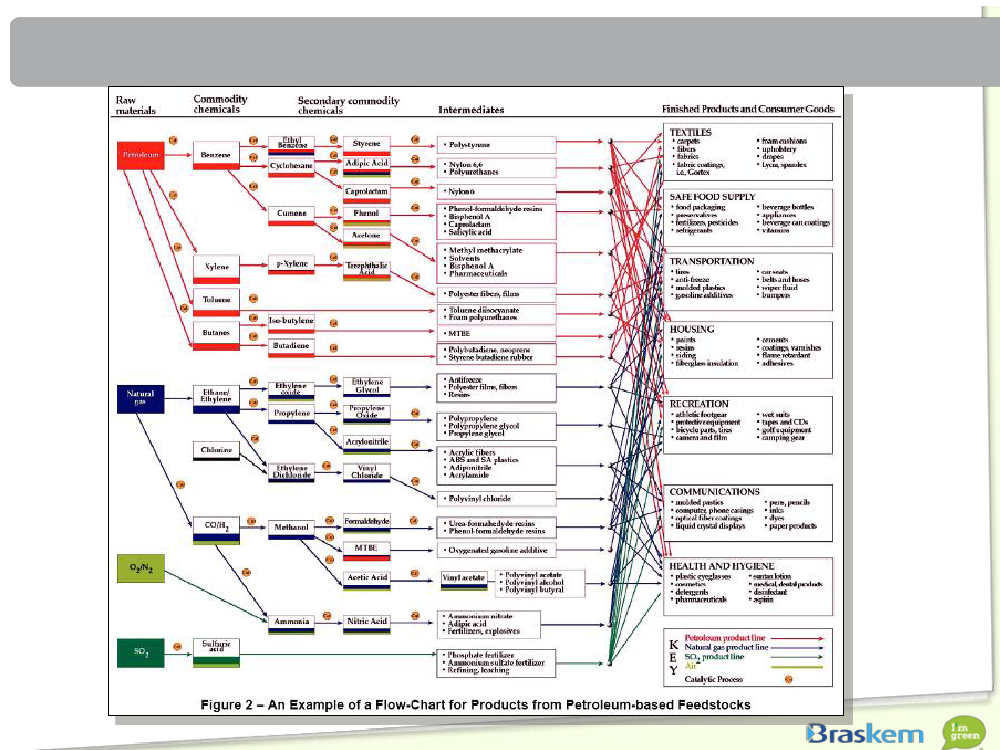

Product chain based on fossil source

Source:

US DOE–Top Value Added Chemicals from Biomass–Volume I - 2004

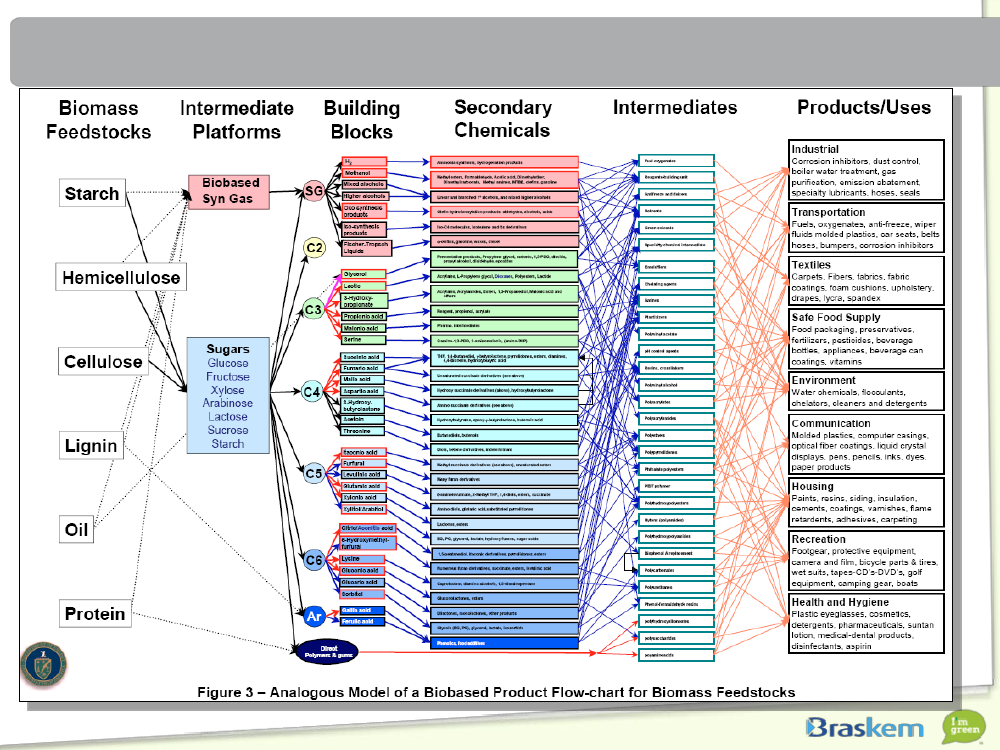

Possible product chain based on renewable source

Source:

US DOE–Top Value Added Chemicals from Biomass–Volume I - 2004PEP–Advanced Biorefinaries 2005Patrick R. Gruber, Michael Kamm, Biorefineries–Industrial Processes and Products, Vol 1, cap 1

Roadmapping for biobased chemicals and polymersDRIVERSMercadoCrisePerformance

PRODUTOSBiocombustíveisQuímicosBiopolímeros

TECNOLOGIASGaseifica§ão/PiróliseHidróliseácida/EnzimáticaCatálise/Polimeriza§ãoFermenta§ãoGenéticaPre-Tratamento

ProcessosdeSepara§ão

2

Green Plataform developmentFocus will be on “familiarity”Complexity and riskExisting••••Chemicals we participate intoday– “Drop-in” productsWell known applicationsWell known markets andcustomersLittle to no market acceptancerisk••••AdjacentChemicals we do not currentlyparticipate in today, butadjacent to our core capabilitiesWell known applicationsNeeds market and customerdevelopmentLittle to no market acceptancerisk•NewChemicals we do not participatetoday and far from our corecapabilities OR chemicals that donot exist today

•

Well known applications forexisting chemicals and not welldefined for new chemicalsNeed market and customerdevelopmentLittle to no market acceptancerisk for existing chemicals, butlarge risk for new chemicals

••

Examples of opportunities to beevaluated (not exhausted list):Biopolymers•PE•PP•PVCGreen chemicals•Isoprene•Benzene•Toluene•Xylene•Butadiene•Butene•Ethylene•Propylene

Examples of opportunities to beevaluated (not exhausted list):Biopolymers•PET•PA•PC•PLA•StarchGreen chemicals•Acrylic Acid•Surfactants•Solvents•Acetic Acid•Methanol•DMC•Succinic Acid•Butanediol•PTA

Examples of opportunities to beevaluated (not exhausted list):Biopolymers•PHA•PEFGreen chemicals•FDCA•1,3 HPA•New Solvents

Aggressively pursueSOURCE: Braskem

Pursue

Opportunistic

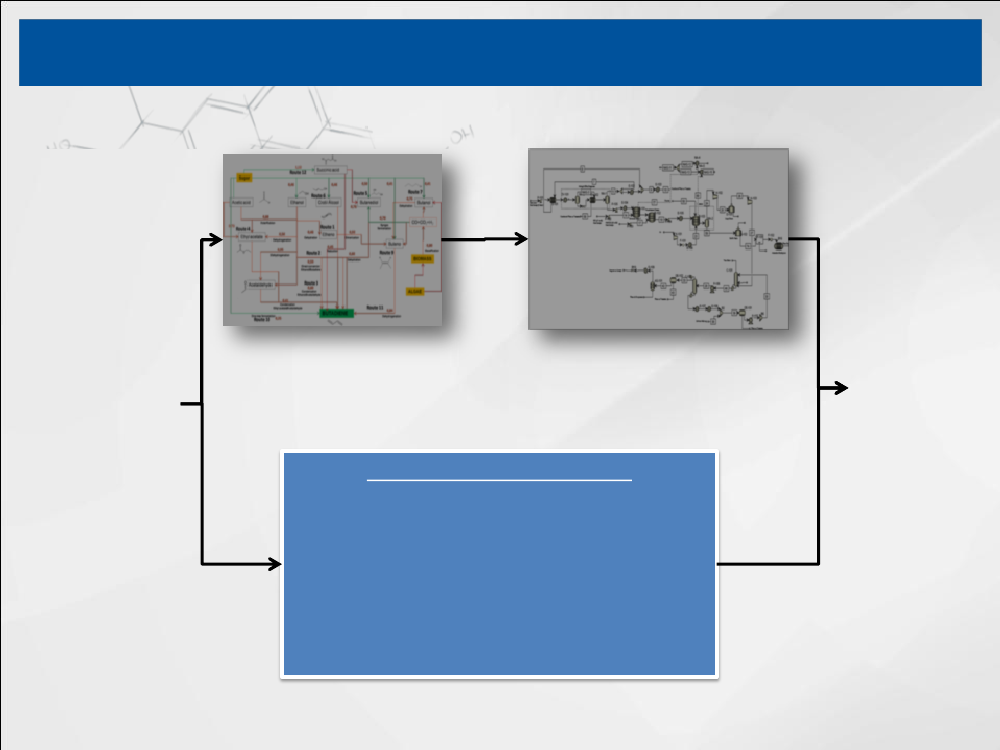

Green Plataform developmentHow to choose the best opportunity?

Polymers unitdecides whichproduct shouldbe analysed(marketdriven)

Possible routesCorporate IT + RenewableTechnologies

CAPEX (FEL 1), OPEXCorporate IT + RenewableTechnologies

EVTE

Market analysis & forecastingPriceDemand and productionCompetitorsValue chain, etc(UNIB + Corporate IT + Renewable Chemicals)

BRASKEM´s OPEN INNOVATION VIEWHow could we increase our partnership?

Current...

- Current discussion of metabolic

engineering projects;

- Metabolic Engineering Course ( 4

days in course in Brazil - Jens

Nielsen; Jochen Förster; Andreas

Gombert

In discussion...

... Other opportunities ?