Miljøudvalget 2011-12

MIU Alm.del

Offentligt

Executive SummaryCritical Review of Produced Water Sampling,Analysis and Reporting Procedures: DanishOffshore OperationsMaersk Oil DenmarkOur refABN1191601/002.001

LIFE MATTERS

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

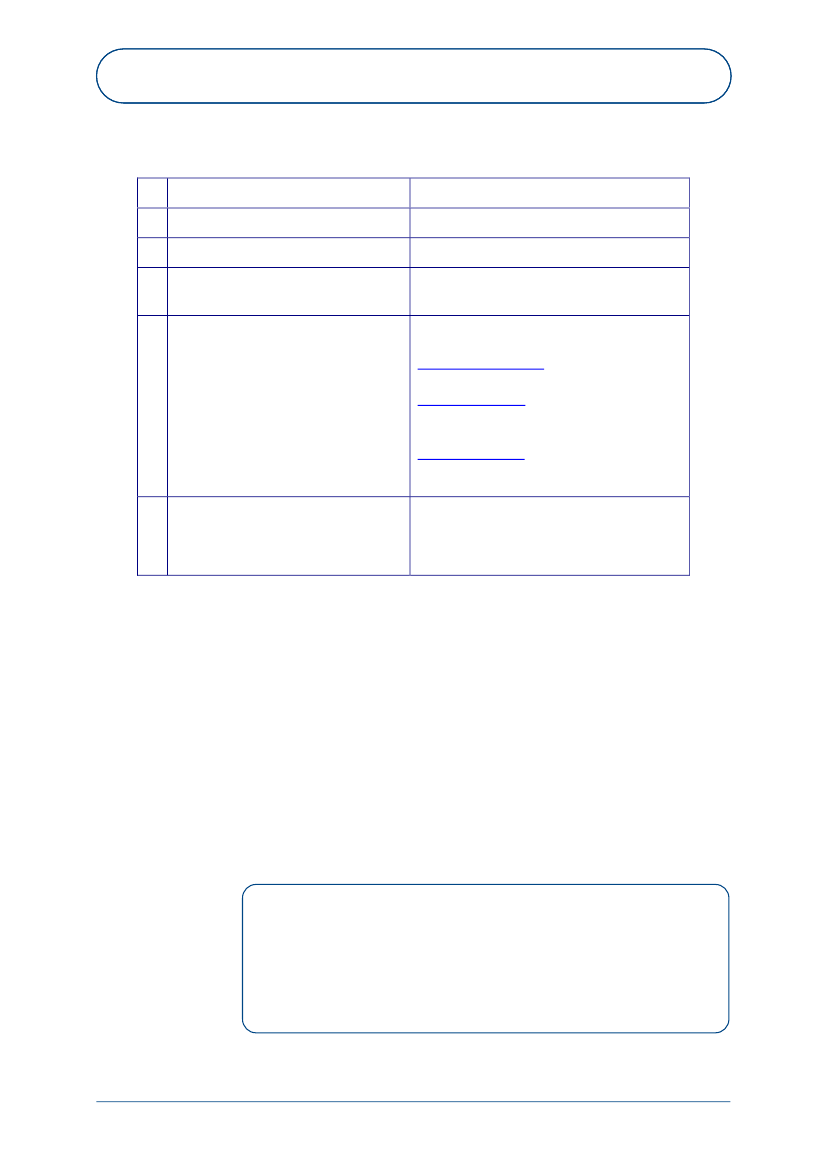

Contactsa)b)c)d)Registered nameRegistration numberRegistered addressAberdeen Office addressWritten by:Per Christofferson (Senior Consultant,Lloyd's Register Scandpower)Linda Murray (Consultant, ConsultingServices, Lloyd's Register EMEA)Amy Annand (Principal Consultant/TeamLeader, Consulting Services, Lloyd'sRegister EMEA)Lloyd’s Register EMEA29592R71 Fenchurch Street, London, EC3M 4BSDenburn House, 25 Union Terrace, Aberdeen,AB10 1NNMain Tel: + 44 (0)1224 267400[email protected]M +46 (0)708 690211[email protected]T+44 (0)1224 267872[email protected]M +44 (0)7770 958246T +44 (0)1224 267400F +44 (0)1224 267401M +44 (0)7768 214797

e)

f)

Approved by:Nick Jackson (Head of Consulting,Lloyd's Register EMEA)

Lloyd's Register EMEA, its affiliates and subsidiaries and their respective officers, employees oragents are, individually and collectively, referred to in this clause as the ‘Lloyd's RegisterGroup’. The Lloyd's Register Group assumes no responsibility and shall not be liable to anyperson for any loss, damage or expense caused by reliance on the information or advice in thisdocument or howsoever provided, unless that person has signed a contract with the relevantLloyd's Register Group entity for the provision of this information or advice and in that caseany responsibility or liability is exclusively on the terms and conditions set out in that contract.� Lloyd’s Register EMEA 2011

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

ContentsExecutive Summary1.1 Introduction1.2 Scope of Work1.3 Findings1.4 Conclusions and Recommendations22226

Lloyd's Register EMEA

Page 1

28/02/2011

Maersk Oil Denmark

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Executive Summary1.1

Introduction

During December 2010, Maersk Oil Denmark was subject to allegations published in the Danishnewspaper,Politiken, regarding the integrity of their produced water management processes,including Oil-in-Water (OiW) analysis and reporting. Maersk Oil Denmark engaged Lloyd'sRegister EMEA to conduct an independent review of the associated environmental processesand procedures (including implementation). Initial reviews of the Tyra production unit wereconducted by Nick Jackson and Amy Annand of Lloyd's Register EMEA, and Stig Stangeland ofLloyd's Register Scandpower. Subsequent reviews of the DUC operations were conducted byPer Christofferson of Lloyd's Register Scandpower and Linda Murray of Lloyd's Register EMEA;they were also supported onshore (Esbjerg) by Amy Annand and Nick Jackson.

Scope of Work

Lloyd's Register EMEA reviewed and determined the degree to which Maersk Oil Denmark’sproduced water sampling, analysis and reporting (i.e. specifically Oil-in-Water/OiW) processestruly reflected accepted industry practice. The review evaluated existing documented processesand procedures, and compared their implementation onshore and offshore to recognisedindustry practice, best laboratory practice, and also compliance with the current OiW dischargepermits for operating in the Danish sector of the North Sea. The review also included a series ofinterviews with workforce representatives who developed and used these processes andprocedures. Additionally, the review verified a number of samples of reported concentrations,following the path along data transfer points.The LR EMEA review teams visited:•••••••Tyra West.Tyra East.Dan.Halfdan.Gorm (including Skjold).Harald.Esbjerg offices.Findings

Commendations•Maersk Oil Denmark has established appropriate procedures (specifically OPM 2B Part 3Rev 9) and associated guidance documents and initiatives which enable operations tomeet expectations of the discharge permits associated with the Danish production units.It is noted that in response to the recent changes to the discharge permit, Maersk OilDenmark has already commenced a review and revision of the OiW procedures andpractices.Lloyd's Register EMEA

Page 2

28/02/2011

Maersk Oil Denmark

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•

Processes are established for employee engagement in procedural change (i.e. theupdated Rev 9 of the OiW procedure and Rev 10 that is a work in progress).Feedback indicated that the response and reporting culture relating to dischargeconcentrations greater than 20 mg/l appears to be supportive and reflective of goodpractice.The action level for OiW is 20 mg/l, although the permit defines average monthlydischarge limit of 30mg/l. This means that corrective action is often applied before apermit breach occurs. It is also noted that Maersk Oil Denmark has stipulated variousinternal KPIs, some as low as 5 mg/l for specified discharge points.As part of their continual improvement processes, Maersk Oil Denmark hasimplemented a number of initiatives to improve the efficiency of produced watertreatment on board. These have included increasing heating capacity in order toimprove separation efficiency, improving flow and skimming properties of the de-gasser,relocating the injection points for the water clarifier, and reducing flow throughputfluctuations.Evidence indicated that further improvements to the produced water treatmentprocesses will be introduced. These include exploring the use of online OiW monitoringand investigating the accuracy of overboard flow metering systems.Daily production checks are conducted on individual produced water process trains.These checks include levels, pressures and temperatures of specific treatmentequipment and processes. This data is then used to troubleshoot and define correctiveactions if the 20 mg/l limit is exceeded. Some platforms have also implemented in-linecontinuous OiW monitoring processes to enhance process control and troubleshooting.Evidence obtained from offshore conversations confirmed that employees (e.g. the CCR)are empowered to shut down wells/operations and have done so when necessary.Communication with regard to OiW appears to be open and honest, and the workforceis actively encouraged to report on any observed undesired emissions and processdeviations. The "eyes and ears" of the workforce were seen to be an important tool inmonitoring OiW treatment.It is clear that some sound practices have been established and individuals know how torespond and troubleshoot when OiW KPIs are exceeded.It is clear that the overwhelming majority of the workforce has great pride in workingfor Maersk Oil Denmark and cares deeply about their responsibilities. People reportedthat they did not understand what prompted the newspaper allegations, which theybelieved did not represent the Maersk Oil organisation that they work for, or the realityof OiW management.

•

•

•

•

•

•

•

•

•

Lloyd's Register EMEA

Page 3

28/02/2011

Maersk Oil Denmark

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

1.3.2

Areas for ImprovementThe critical OiW review identified six areas of potential improvement, which are summarisedbelow.

1.3.2.1

OiW procedureThe OiW Sampling, Analysis and Reporting procedure (OPM 2B, Part 3, Rev 9) enablesoperations to meet the expectations of the discharge permits. However, the clarity andstructure of the procedure can be strengthened. Visibility and understanding of the overall OiWsample collection, analysis and reporting process within the procedure could be improvedthrough the use of Process Mapping.It is noted that the OiW procedure differs slightly from the reference (OSPAR) method, withexamples highlighted below:•••••Sample and reagent volumes.Sample gas release.Sample clean-up.Emulsification of sample.Blank samples.

The review of the OiW procedure also identified an inconsistent approach to the level of detailcontained within the asset specific sections of the procedure. There should be a standardisedminimum amount of platform specific data included in all asset specific sections of theprocedure. Additionally, there is a lack of platform specific information relating to (whereapplicable):••Expectations relating to communication, and how knowledge or data is transferred.Details related to the use of in-line and/or continuous monitoring equipment tosupplement OiW management.Sampling (including when samples should and should not be taken), labelling,packaging, protection, storage and transporting (i.e. sample custody and integrity).Determining total volume of re-injected produced water and total volume of overboardproduced water.Post analysis reporting (i.e. cross-referencing workbooks, production logs and OiWdatabase).

•

•

•

1.3.2.2

Integrity of dataThe Lloyd's Register EMEA reviews could find no evidence that the OiW data had been falsified.However, the lack of robust and transparent sample and data management means that MaerskOil Denmark is exposed to the potential for error and misconduct. Identified examples of theseexposures include the following:

Lloyd's Register EMEA

Page 4

28/02/2011

Maersk Oil Denmark

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•••••••

Existing sample custody practices introduce the potential for samples to be tamperedwith or to be misplaced; however, there was no evidence that this had taken place.Critical data is sometimes verbally transferred.There is a lack of written Laboratory Logbooks (denoting sample times, analyticalresults, anomalies, changes, errors, comments etc.).There is a lack of security of data contained within platform specific Excel workbooks.When changes are made to data contained within the workbook, there is no record ofthe original data or documented reason for the change.Sense checks (conducted onshore) of reported concentrations did not consistentlycapture noted data anomalies.The first point of verification (using existing practices) is the Excel spreadsheetworkbook. This is an issue because the spreadsheet is populated at an advanced stageof the OiW sampling, analytical and reporting process.

1.3.2.3

Lack of robust verificationThe overall process for OiW management should be underpinned by robust verification andQuality Assurance. The review revealed a number of areas where Maersk Oil Denmark did notdemonstrate structured processes to assure data quality and compliance with best practice.Examples of these areas include:•••••Lack of structured supervisory Quality Assurance.Lack of robust verification of On-the-Job training.No QC samples analysed to provide assurance of accuracy of results. NB: this is notaligned with good laboratory practice.Lack of robust internal audits in order to scrutinise OiW processes.The limit of the scope of the Force Technology Audits (i.e. only sampling andlaboratory practices and OSPAR correlation) did not enable complete verification ofOiW processes.

1.3.2.4

Degree of variability of reported concentrationsThe uncertainty (standard deviation) of reported concentrations and overboard oil volumes isnot fully quantified. Variability levels will be associated with:•••••The sensitivity of Wilkes Analyzer at lower concentrations (NB: Maersk Oil Denmark hasdetermined the Limit of Detection to be approximately 4mg/l).Individual pieces of laboratory equipment (e.g. balances, volumetric flasks, measuringcylinders etc.).Differing approaches by individuals with regard to sample collection, storage,extraction and clean-up.The OSPAR correlation method.Accuracy of overboard flow meters.

The cumulative variability with the aforementioned elements creates an unknown level ofuncertainty for the method. Understanding the lower limits of detection is particularlyLloyd's Register EMEAPage 528/02/2011Maersk Oil Denmark

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

important for reporting lower concentrations, especially those concentrations related to OiWKPIs.1.3.2.5Competency assurance processesMaersk Oil Denmark is currently establishing a structure for offshore workforce trainingprogrammes which includes: training needs analysis, job descriptions, technical trainingprogrammes, On-the-Job training programmes etc. This is documented and managed onshorevia the Learning Management System (LMS). This framework is still under development andtherefore is not fully implemented.The offshore workforce’s individual training programmes are documented in the LMS. It is theexpectation that employees will be trained by experienced team members based on tailored rolespecific training programmes.1.3.2.6Tyra East specific improvementsSome participants on board Tyra East described strong feelings of mistrust towardsmanagement both on and offshore. This was supported by perceptions of exclusion and lack ofinvolvement, which are further compounded by stated beliefs that communications betweenoffshore and onshore are ineffective.

Conclusions and Recommendations

OiW procedureIn line with our findings, the OiW procedure (OPM 2B, Part 3, Rev 9) requires a significantupdate to meet the requirements of the new discharge permit. This upgrade should alsoaddress the expectations of OSPAR and strengthen the clarity and structure of the procedure.The platform specific information (e.g. platforms without laboratory facilities, platforms that re-inject produced water etc.) should also undergo a critical review to ensure adequacy. This willenable consistent understanding and application of the overall OiW sample collection, analysisand reporting process.1.4.2

Integrity of dataThe findings indicate that there is a lack of robust and transparent sample and datamanagement meaning that Maersk Oil Denmark is exposed to the potential for error andmisconduct. It is therefore recommended that Maersk Oil Denmark implements a number ofdata integrity control measures in order to reduce the risks associated with inaccurate OiWreporting. These measures include:•••••The platform specific instructions should be developed to include a documentedsampling plan and procedure.Formally document and log verbal transfer of critical information.Establish ‘Good Laboratory Practice’ with the use of written Laboratory Logbooks.Introduce data security controls within platform specific workbooks.Formalise onshore based sense checks to capture noted data anomalies.

Lloyd's Register EMEA

Page 6

28/02/2011

Maersk Oil Denmark

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•1.4.3

Introduce robust verification processes that would verify the data trail from samplecollection to reporting.

Lack of robust verificationThe overall process for OiW management should be underpinned by robust verification andQuality Assurance. The review revealed a number of areas where Maersk Oil Denmark did notdemonstrate structured processes to assure data quality and compliance with best practice.These processes should include:••••••Structured supervisory Quality Assurance.Robust verification of On-the-Job training.Analyse QC samples to provide assurance of accuracy of results.Robust internal audits.Third party audits.Update procedures: ensure that the verification processes add value, and are alignedwith revised OiW procedures.

1.4.4

Degree of variability of reported concentrationsInevitably sample collection, custody, analysis and reporting processes will introduce somedegree of variability in reported OiW concentrations. The Limit of Detection is likely to beimportant when the data is utilised for the setting and achieving of internal KPIs, where theseare at levels lower than those that can be reasonably detected. It is therefore recommendedMaersk Oil Denmark attempts to quantify the lower Limit of Detection for the OiW method andrecognises it when setting internal OiW KPIs.

1.4.5

Competency assurance processesMaersk Oil Denmark is currently establishing a structure for offshore workforce trainingprogrammes. They must formalise arrangements to ensure that:•Existing and new Laboratory Technicians should either complete the newly developedOiW training programme, or verify competency levels of existing Laboratory Techniciansagainst the programme requirements.All relevant job descriptions are cohesive and complete. They must accurately reflectproduced water management tasks and responsibilities.Training programmes are implemented as per identified needs.On-the-Job training is formalised, including verification.

•••1.4.6

Tyra East specific improvementsCritical review findings relating to the Tyra East installation differ from the other DUC assets.Specific recommendations pertaining to this asset are:•Maersk Oil Denmark has processes to enable individuals to report concerns. It isimportant that these processes are not only established, but are fully supported andPage 728/02/2011Maersk Oil Denmark

Lloyd's Register EMEA

EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED W ATER S AMPLING, AN ALYSISAND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

people are encouraged to use them. While recognising that this process is supportedby Maersk Oil Denmark, it is clear that some individuals on Tyra East elected to choosea different vehicle to communicate concerns. In support of this recommendation, aculture of openness in reporting and communicating should be further nurtured andembraced within the organisation.•Maersk Oil Denmark should carefully consider the internal communication andmanagement actions to be taken in the aftermath of these events. This would includecommunication (i.e. internal/external announcements, lessons learned, and individualresponse actions) to the workforce and relevant stakeholders. This should clearly definethe expectations of onshore and offshore management, and those actively involved inthe OiW processes.

Lloyd's Register EMEA

Page 8

28/02/2011

Maersk Oil Denmark