Sundheds- og Forebyggelsesudvalget 2011-12

SUU Alm.del Bilag 370

Offentligt

Addition of malodorants to lighter gas – a study of thephysical properties of mixtures of lighter gas and selectedsubstancesVasu Neela and Nicolas von Solms

Center for Phase Equilibria and Separation Processes (IVC-SEP)Department of Chemical and Biochemical EngineeringTechnical University of Denmark

i

Table of ContentsList of Tables -------------------------------------------------------------------------------------------- ivList of Figures ------------------------------------------------------------------------------------------- vi1234Introduction ---------------------------------------------------------------------------------------- 1Background----------------------------------------------------------------------------------------- 4Chemical ingredients in inhalants ------------------------------------------------------------- 6Effects of butane volatile substance abuse --------------------------------------------------- 74.14.2567Short term effect ....................................................................................................... 7Long term effect........................................................................................................ 7

Preventing volatile substance abuse ----------------------------------------------------------- 9The basic idea and its approach---------------------------------------------------------------10Theory and modeling ----------------------------------------------------------------------------127.17.27.37.3.17.3.27.3.37.3.47.3.57.3.67.3.77.3.87.3.97.3.107.3.117.3.127.3.137.3.147.3.157.3.16CPA (Cubic-plus-Association) Equation of State................................................... 12The COSMO-based thermodynamic model: .......................................................... 13Malodorants ............................................................................................................ 19Triethylamine --------------------------------------------------------------------------21Denatonium Benzoate (Bitrex) ------------------------------------------------------21Isobutyraldehyde-----------------------------------------------------------------------22Tetrahydrothiophene ------------------------------------------------------------------22Dimethylsulfide ------------------------------------------------------------------------232, 2, 4-Trimethyl pentane-------------------------------------------------------------24Picoline (2-methyl pyridine) ---------------------------------------------------------24Eucalyptol (1.8 Cineole)--------------------------------------------------------------25Nitrobenzene ---------------------------------------------------------------------------251-Pentanol-------------------------------------------------------------------------------26Sulfuryl chloride -----------------------------------------------------------------------27Cyanogen chloride---------------------------------------------------------------------27Bis-(2-chloroethyl) sulfide -----------------------------------------------------------28Bis-(2-chloroethyl) ethylamine ------------------------------------------------------28Ethyldichloroarsine--------------------------------------------------------------------29Bromobenzylcyanide------------------------------------------------------------------30ii

7.3.177.3.187.3.197.3.207.3.217.3.227.3.237.3.247.3.257.3.267.3.277.47.57.689

Chloropicrin ----------------------------------------------------------------------------30Diphenylcyanoarsine ------------------------------------------------------------------30Ethyl mercaptan------------------------------------------------------------------------31Bis(chloromethyl)ether ---------------------------------------------------------------322-Amino phenol------------------------------------------------------------------------32Propyleneglycol------------------------------------------------------------------------33s-Trioxane-------------------------------------------------------------------------------332-Chloroacetophenone ----------------------------------------------------------------34Indole ------------------------------------------------------------------------------------34Pyridine ---------------------------------------------------------------------------------35n-Butylamine---------------------------------------------------------------------------35

Estimation of pure compound parameters (CPA equation of state) ....................... 36Sigma Profiles ......................................................................................................... 38Vapor-liquid Equilibria........................................................................................... 57

Conclusion -----------------------------------------------------------------------------------------95References------------------------------------------------------------------------------------------96

iii

List of TablesTable 1: Death attributed to specific volatile substances in those under 18 from 1981-1990 .. 5Table 2: Chemical ingredients in inhalants............................................................................... 6Table 3 : Possible consequences from butane inhalant substances [9]..................................... 8Table 4: Malodorants .............................................................................................................. 19Table 5: Properties of Triethylamine ...................................................................................... 21Table 6: Properties of Denatonium benzoate (Bitrex) ............................................................ 22Table 7: Properties of Isobutyraldehyde ................................................................................. 22Table 8: Properties of Tetrahydrothiophene .......................................................................... 23Table 9: Properties of Dimethylsulfide................................................................................... 23Table 10: Properties of 2. 2. 4-Trimethyl pentane .................................................................. 24Table 11: Properties of Picoline.............................................................................................. 25Table 12: Properties of Eucalyptol ......................................................................................... 25Table 13: Properties of Nitrobenzene ..................................................................................... 26Table 14: Properties of 1-Pentanol ......................................................................................... 26Table 15: Properties of sulfuryl chloride ................................................................................ 27Table 16: Properties of cyanogen chloride ............................................................................. 28Table 17: Properties of Bis-(2-chloroethyl) sulfide ................................................................ 28Table 18: Properties of Bis-(2-chloroethyl) ethylamine ......................................................... 29Table 19: Properties of Ethyl dichloroarsine .......................................................................... 29Table 20: Properties of Bromobenzylvyanide ........................................................................ 30Table 21: Properties of Trichloronitromethane....................................................................... 30Table 22: Properties of Diphenylcyanoarsine......................................................................... 31Table 23: Properties of Ethylmercaptan ................................................................................. 31Table 24: Properties of Bis (chloromethyl) ether ................................................................... 32Table 25: Properties of 2-Aminophenol ................................................................................. 32Table 26: Properties of Propylene glycol................................................................................ 33Table 27: Properties of s-Trioxane ......................................................................................... 33Table 28: Properties of Chloroacetophenone.......................................................................... 34Table 29: Properties of Indole................................................................................................. 34

iv

Table 30: Properties of Pyridine ............................................................................................. 35Table 31: Properties of butylamine......................................................................................... 35Table 32: CPA Parameters for the compounds involved in this study ................................... 36

v

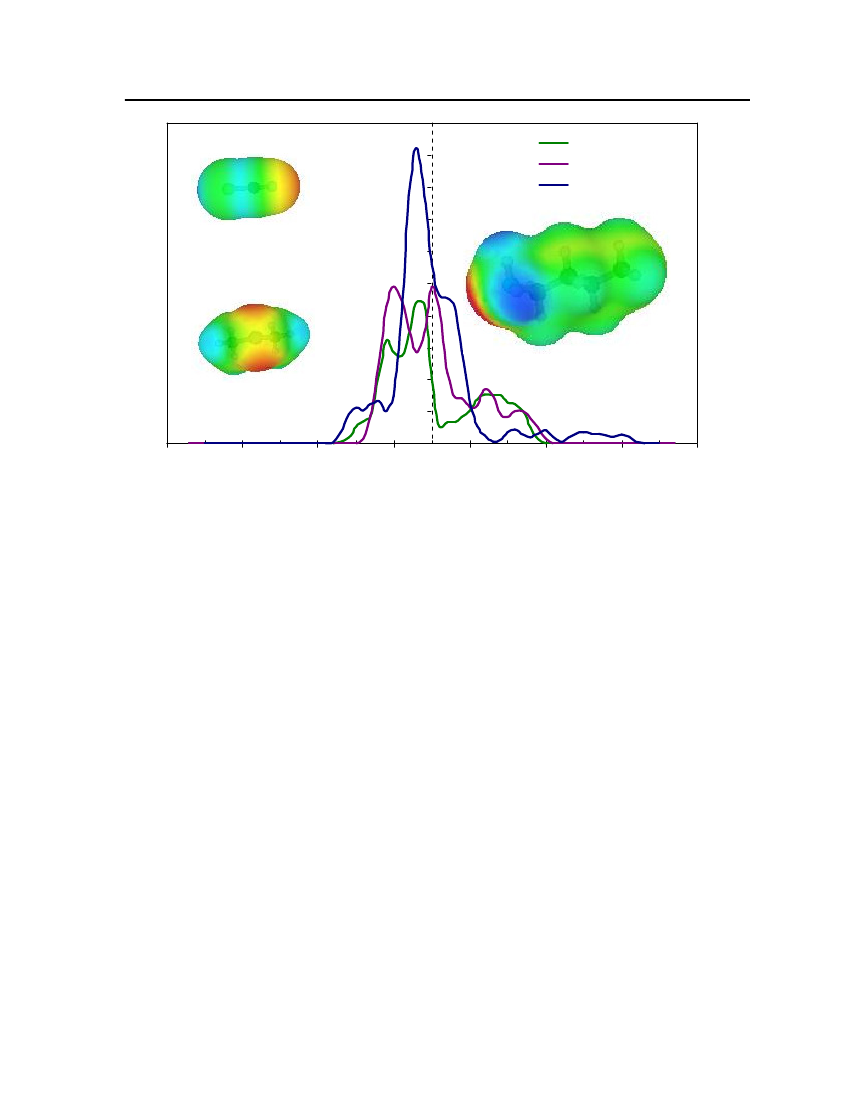

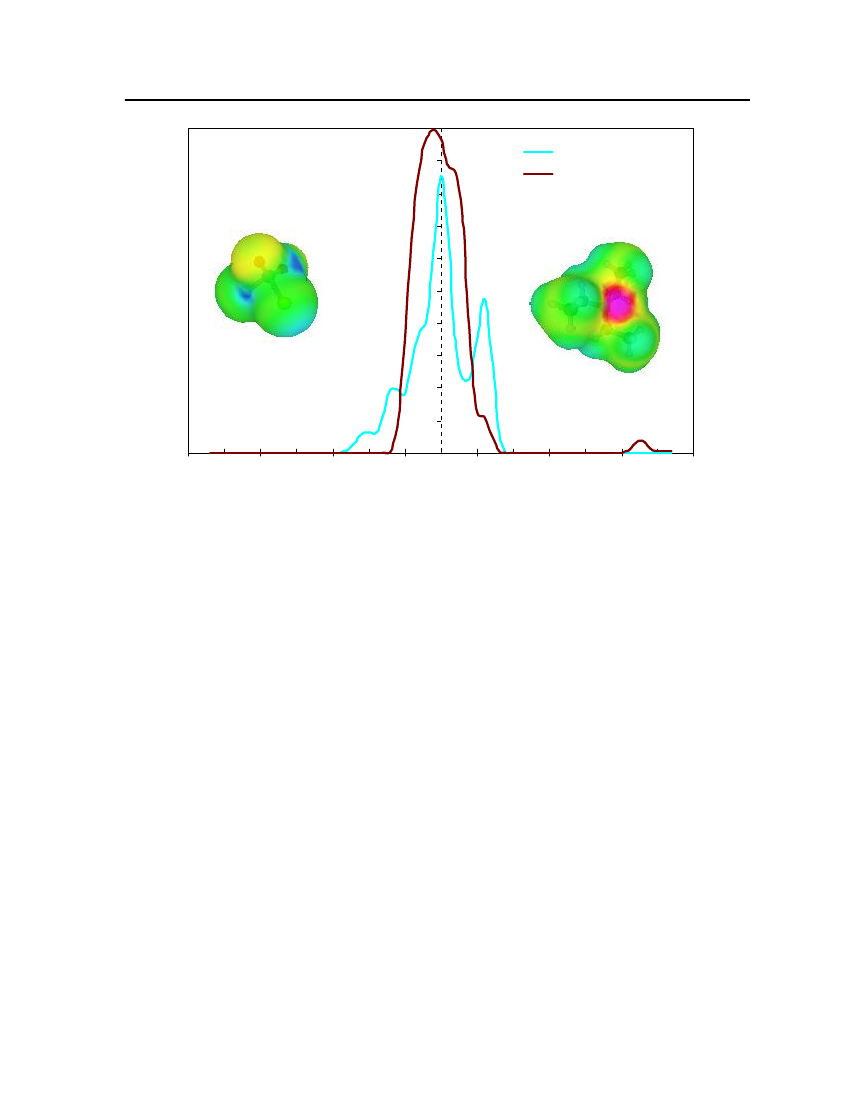

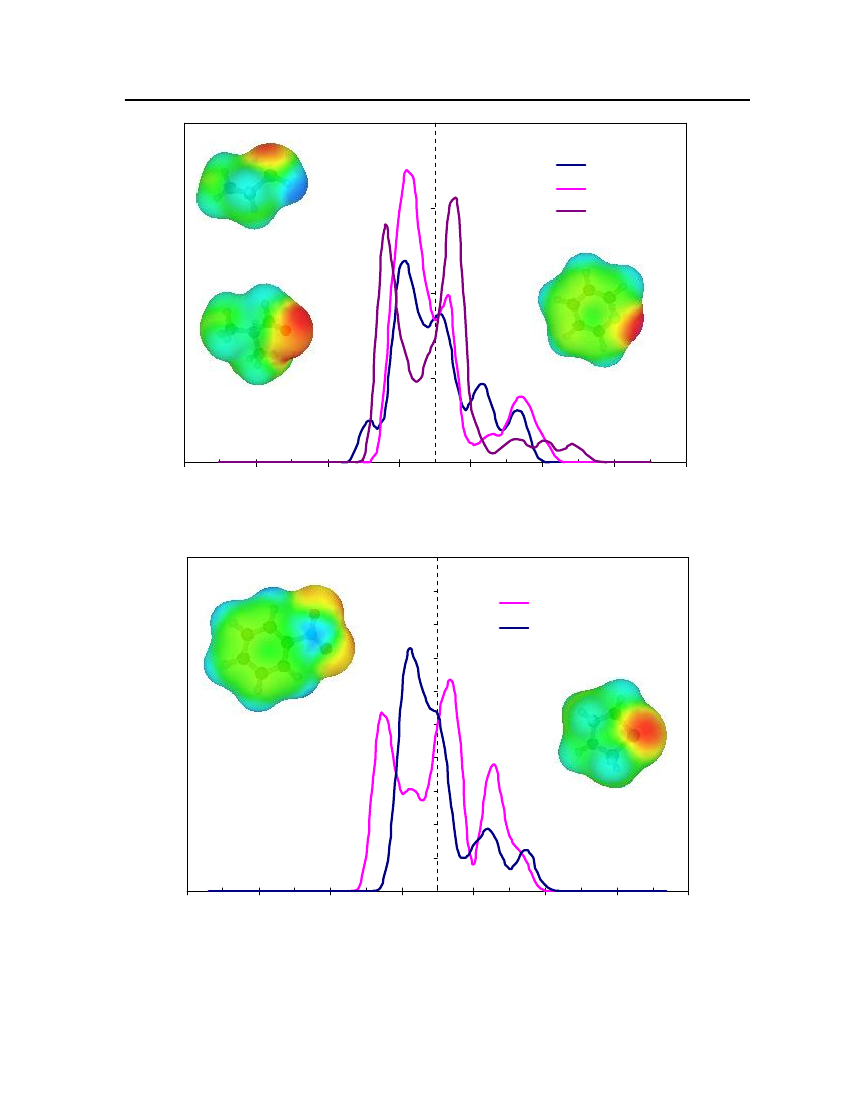

List of FiguresFigure 1: Ideal solvation process in COSMO-based models [18] .......................................... 13Figure 2: Schematic illustration of contacting molecular cavities and contact interactions[14].......................................................................................................................................... 15Figure 3: Comparison of Triethylamine Vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 38Figure 4: Comparison of Isobutyraldehyde Vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 39Figure 5: Comparison of Tetrahydrothiophene Vapor pressure between CPA, COSMOthermand DIPPR .............................................................................................................................. 39Figure 6: Comparison of DimethylsulfideVapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 40Figure 7: Comparison of 2,2,4 Trimethylpentane Vapor pressure between CPA,COSMOtherm and DIPPR...................................................................................................... 41Figure 8 Comparison of 2-MethylpyridineVapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 41Figure 9: Comparison of NitrobenzeneVapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 42Figure 10: Comparison of 1-Pentanol Vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 42Figure 11: Comparison of Sulfurylchloride Vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 43Figure 12: Comparison of CyanogenchlorideVapor pressure between CPA, COSMOthermand DIPPR .............................................................................................................................. 43Figure 13: Comparison of Ethylmercaptan Vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 44Figure 14: Comparison of Bis(chloromethyl)ether Vapor pressure between CPA,COSMOtherm and DIPPR...................................................................................................... 44Figure 15: Comparison of Propyleneglycol vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 45

vi

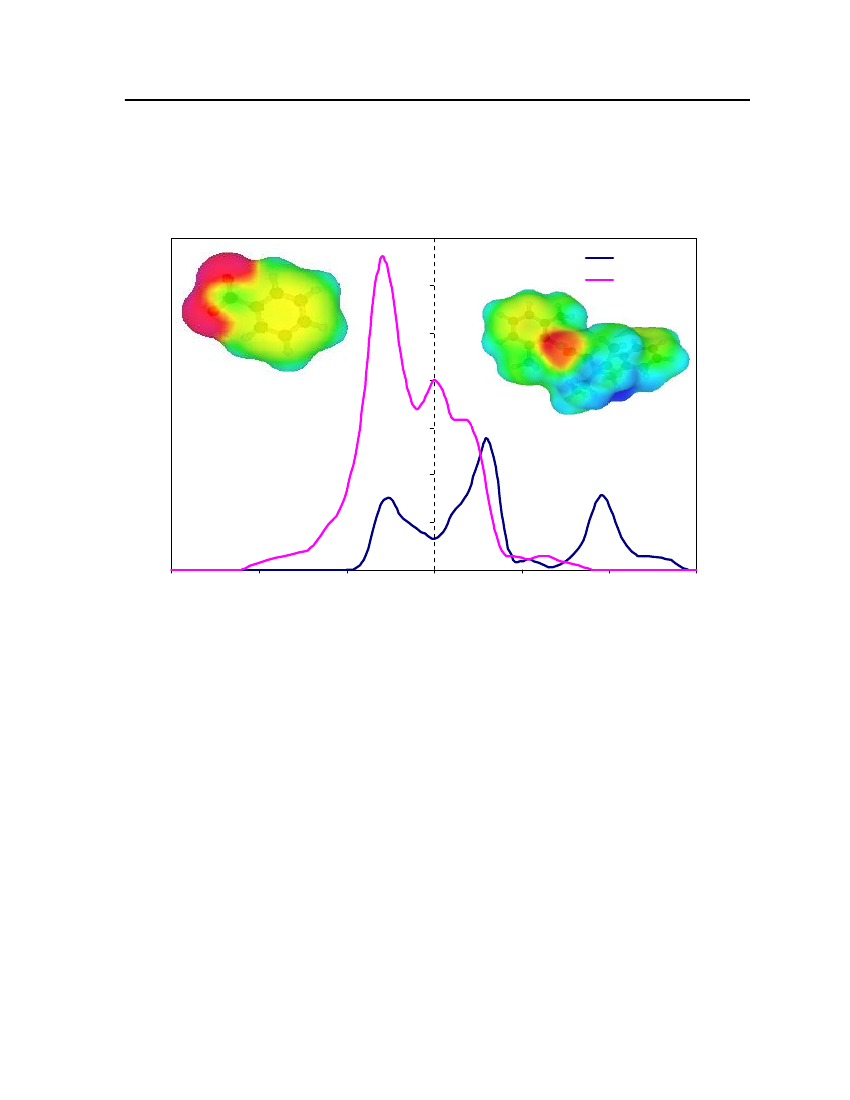

Figure 16: Comparison of s-Trioxane vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 45Figure 17: Comparison of Indole vapor pressure between CPA, COSMOtherm and DIPPR 46Figure 18: Comparison of Pyridine vapor pressure between CPA, COSMOtherm and DIPPR................................................................................................................................................. 46Figure 19: Comparison of Butylamine vapor pressure between CPA, COSMOtherm andDIPPR ..................................................................................................................................... 47Figure 20: Vapor-Liquid Equilibrium of Ethylmercaptan (1) /n-Butane(2) with CPA(Association scheme-2B) and COSMOtherm at 50oC............................................................ 49Figure 21: Vapor-Liquid Equilibrium of Ethylmercaptan (1) /n-Butane(2) with CPA (Nonassociation) and COSMOtherm at 50oC ................................................................................. 49Figure 22: Vapor-Liquid Equilibrium of Ethylmercaptan (1) /n-Butane(2) with CPA(Association scheme-2B) and COSMOtherm at 100oC.......................................................... 50Figure 23: Vapor-Liquid Equilibrium of Ethylmercaptan (1) /n-Butane(2) with CPA (NonAssociation) and COSMOtherm at 100oC .............................................................................. 50Figure 24: Sigma profiles for the lighter gas components (butane. isobutane and propane).. 51Figure 25: Sigma profiles of 1,8 cineole, 1-pentanol and 2-methylpyridine .......................... 52Figure 26: Sigma profiles of cyanogen chloride and dimethylsulfide .................................... 53Figure 27: Sigma profiles for the sulfurylchloride and triethylamine .................................... 54Figure 28: sigma profile for the ethyl mercaptan, Isobutanal and pyridine............................ 55Figure 29: sigma profile for the nitrobenzene and tetrahydrothiophene................................. 55Figure 30: sigma profile for the Bitrex anion and Bitrex cation............................................. 56Figure 31: Vapor-Liquid equilibrium for Triethylamine (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 58Figure 32: The X-Y diagram for Triethylamine (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 59Figure 33: Vapor-Liquid equilibrium for Isobutyraldehyde (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 60Figure 34: The X-Y diagram for Isobutyraldehyde (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 61

vii

Figure 35: Vapor-Liquid equilibrium for Tetrahydrothiophene (1) /n-Butane(2) / at 25oC.The solid curve shows the COSMOtherm predictions ........................................................... 62Figure 36: The X-Y diagram for Tetrahydrothiophene (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 62Figure 37: Vapor-Liquid equilibrium for Dimethylsulfide (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 63Figure 38: The X-Y diagram for Dimethylsulfide (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 64Figure 39: Vapor-Liquid equilibrium for 2, 2, 4Trimethyl-2-pentane (1) /n-Butane(2) at 25o

C. The solid curve shows the COSMOtherm predictions ..................................................... 65

Figure 40: The X-Y diagram for 2, 2, 4 Trimethyl-2-pentane (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 65Figure 41: Vapor-Liquid equilibrium for 2-methylpyridine (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 66Figure 42: The X-Y diagram for 2-methylpyridine (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 67Figure 43: Vapor-Liquid equilibrium for 1, 8 Cineole (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 68Figure 44: The X-Y diagram for 1, 8 Cineole (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 68Figure 45: Vapor-Liquid equilibrium for Nitrobenzene (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 69Figure 46: The X-Y diagram for Nitrobenzene (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 70Figure 47: Vapor-Liquid equilibrium for 1-Pentanol (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 71Figure 48: The X-Y diagram for 1-Pentanol (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 71Figure 49: Vapor-Liquid equilibrium for Sulfuryl chloride (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 72

viii

Figure 50: The X-Y diagram for Sulfuryl chloride (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 73Figure 51: Vapor-Liquid equilibrium for Cyanogen chloride (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 74Figure 52: The X-Y diagram for Cyanogen chloride (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 74Figure 53: Vapor-Liquid equilibrium for Bis(2-chloroethyl)sulfide (1) /n-Butane(2) at 25o

C.

The solid curve shows the COSMOtherm predictions .............................................. 75

Figure 54: The X-Y diagram for Bis(2-chloroethyl)sulfide (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 76Figure 55: Vapor-Liquid equilibrium for Bis(2-chloroethyl)ethylamine (1) /n-Butane(2) at25oC.25oC.The solid curve shows the COSMOtherm predictions ......................................... 77

Figure 56: Vapor-Liquid equilibrium for Bis(2-chloroethyl)ethylamine (1) /n-Butane(2) atThe solid curve shows the COSMOtherm predictions ......................................... 78Figure 57: Vapor-Liquid equilibrium for Dichloroethylarsine (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 79Figure 58: The X-Y diagram for Dichloroethylarsine (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 80Figure 59: Vapor-Liquid equilibrium for Bromobenzylcyanide (1) /n-Butane(2) at 25oC.The solid curve shows the COSMOtherm predictions ........................................................... 81Figure 60: The X-Y diagram for Bromobenzylcyanide (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 81Figure 61: Vapor-Liquid equilibrium for Chloropicrin (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 82Figure 62: The X-Y diagram for Chloropicrin (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 83Figure 63: Vapor-Liquid equilibrium for Chloropicrin (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 84Figure 64: Vapor-Liquid equilibrium for Ethylmercaptan (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 85

ix

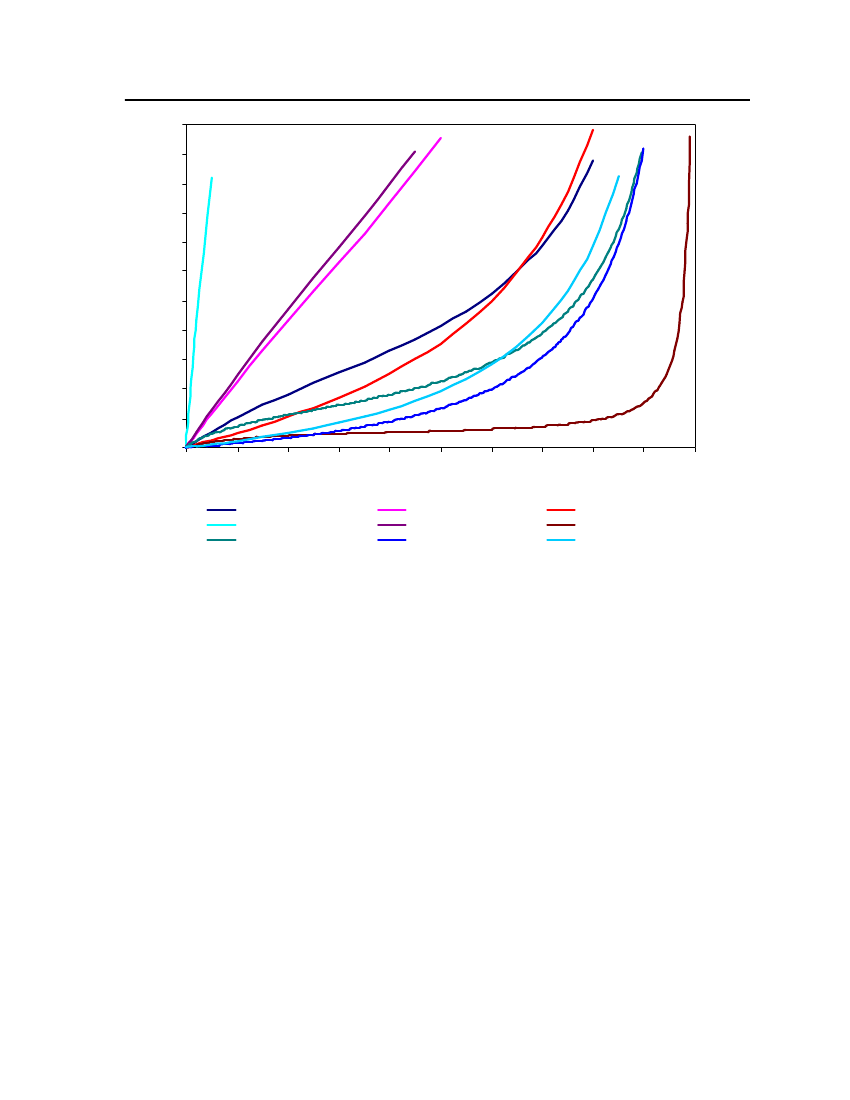

Figure 65: The X-Y diagram for Ethylmercaptan (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 85Figure 66: Vapor-Liquid equilibrium for Bis(chloromethyl)ether (1) /n-Butane(2) at 25oC.The solid curve shows the COSMOtherm predictions ........................................................... 86Figure 67: Vapor-Liquid equilibrium for 2-Amino phenol (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 87Figure 68: Vapor-Liquid equilibrium for Propylene glycol (1)/n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 88Figure 69: Vapor-Liquid equilibrium for 1, 3, 5 Trioxane (1) /n-Butane(2) at 25oC. Thesolid curve shows the COSMOtherm predictions................................................................... 89Figure 70: Vapor-Liquid equilibrium for Chloroacetophenone (1) /n-Butane(2) at 25oC.The solid curve shows the COSMOtherm predictions ........................................................... 89Figure 71: Vapor-Liquid equilibrium for Indole (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 90Figure 72: Vapor-Liquid equilibrium for Pyridine (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 91Figure 73: The X-Y diagram for Pyridine (1) /n-Butane(2) at 25oC. The solid curve showsthe COSMOtherm predictions ................................................................................................ 91Figure 74: Vapor-Liquid equilibrium for Butylamine (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 92Figure 75: The X-Y diagram for Butylamine (1) /n-Butane(2) at 25oC. The solid curveshows the COSMOtherm predictions ..................................................................................... 93Figure 76: The X-Y diagram for possible additives (1) /n-Butane(2) at 25oC. The solidcurve shows the COSMOtherm predictions ........................................................................... 94

x

1 IntroductionThis project involves studying some relevant physical properties of mixtures createdby adding agents to lighter gas which discourage its abuse. These additives are called“malodorants” here, although it is to be understood in a more general sense and includes anyeffect which discourages abuse (e.g. bittering agents, irritants, etc).In this work, the majority of the compounds considered have been selected based ontheir unpleasant odor. The aim is to find a substance that has not only the correctphysiological effect (discourages abuse) but also the correct physical behavior on addition tolighter gas (solubility, phase behavior). This means that the additive should not be toovolatile (so that it disappears quickly if the lighter gas canister is held open for a short while– a process know as “weathering”). Conversely, it should not be too heavy (i.e. have avolatility much less than lighter gas) since it would then be required to be added in largerquantities in the liquid in order for it to be present in the vapor in sufficient quantities to havethe required deterrent effect. This would also mean that in time the additive would be becomemore and more concentrated in the liquid and might finally affect the normal use of the gascanister. Finally, addition of the malodorants should not affect the normal use of lighter gas.The influence of physical factors such as temperature, pressure and concentration ofthe selected substances with lighter gas is studied in this work. It should be emphasized thatthis report represents only one component in a larger study examining the possibility ofadding malodorants to lighter gas and focuses on the physical chemistry or chemicalengineering aspects of the problem. Issues of toxicity, for example, have not been taken intoaccount although it may be mentioned that highly toxic substances such as mercaptans arealready added to natural gas as malodorants in very small amounts, so the toxicity of the puresubstance may not be the only factor that needs to be considered. Dosage and concentrationare of course also relevant.Lighter gas consists primarily ofn-butane(referred to in the remainder of the reportsimply as butane) isobutane and propane. Butane is a volatile substance and is a gas atatmospheric temperature and pressure. It is stored as a liquid in lighters and lighter-gas refillcans by increasing its pressure. Butane’s vapor pressure at room temperature (25oC) is 2.28atm which means that pure liquid butane in lighter gas containers is at a pressure of around

1

2.28 atm, depending on the temperature. The pressure of actual lighter gas is somewhatabove this value due to the presence of the lighter isobutane and propane.Cigarette lighter refill cans are the most commonly used butane product althoughbutane is also used as a propellant in aerosols. There are a wide range of butane productsincluding cigarette lighters and portable stoves. Butane is a colorless gas with a faintlydisagreeable odor and it is poorly soluble in water. The lower explosive limit of butane is1.9% and its toxicity is low. A typical lighter refill contains 54%n-butane,20% isobutane,and 26% propane. Refill cans for stoves contain 71%n-butane,28% isobutane, and 1%propane [2]. Butane is the main component of gas lighter refills and for the purposes of thisinvestigation it is assumed that lighter gas is pure butane. This assumption is not expected tohave an important influence on the results obtained here.In this investigation we have used two thermodynamic models - Cubic-Plus-Association (CPA) and COSMOtherm to predict the phase behaviour of the mixtures studied.The CPA equation of state combines the very widely used Soave-Redlich-Kwong (SRK)equation of state combined with an extra expression which accounts specifically forhydrogen-bonding substances, such as amines or alcohols. This equation is applicable tomulticomponent, multiphase equilibria for systems containing associating components. Inthis work, the CPA Equation of state is used to describe the vapor liquid equilibrium ofadditive (malodorants)-butane systems at different pressures and temperature is studied.The COSMOtherm software also used in this work, and is a commercially availablesoftware program. Predictions from this model are generally very good at pressures whichare not very elevated (for example the pressure of lighter gas at room temperature).COSMOtherm (Conductor like screening model) is a program that computes thermophysicaldata of fluid mixtures. COSMOtherm is developed based on COSMO-RS theory. COSMO-RS (Conductor like screening model for real solvents) is a theory of interacting molecularsurfaces as computed by quantum (QM) continuum solvation models (CSMs). Quantumchemical methods originally developed for isolated molecules i.e. for molecules in a vacuumor a gas. The basis of the COSMO model is the ‘‘solvent accessible surface’’ of a solutemolecule. COSMO places the molecule inside a cavity formed within a homogeneousmedium, taken to be the solvent. COSMO is a valuable tool for the chemical engineeringproblems to find out the activity coefficients and other thermo physical data of compounds in

2

fluid phase. A small number of adjustable and universal parameters, theσprofiles, surfaces,volume of the molecules and the molecule-specific charge distribution are required toperform the COSMO-RS calculations [14].COSMO-RS can be used for the prediction of vapor-liquid equilibria, liquid-liquidequilibria, solid-liquid equilibria, vapor pressures of pure compounds and mixtures, partitioncoefficients, heats of vaporization, activity coefficients, solubilities, excess Gibbs freeenergies, and excess enthalpies, etc. COSMO-RS has also been extended to ionic liquids. Theequilibrium behavior of mixtures of various additives in butane is studied in terms primarilyof their vapour-liquid equilibrium behaviour. This means that for a given composition of anadditive in the butane liquid we are interested in the composition in the vapour phase and theoverall pressure of the mixture. In some cases the additive is not soluble in butane and inthese cases liquid-liquid equilibrium behaviour is observed (i.e. two separate liquid phasesresult, although there will be a small degree of mutual solubility of each component in theother liquid phase).There is a very important difference between CPA and COSMOtherm which shouldbe borne in mind: In order to use CPA (or indeed any equation of state model)it is necessaryto have experimental data availablefor the pure components in the form of both liquiddensity and vapor pressure as a function of temperature. While this is usually not a problemfor commonly occurring substances, this data is lacking for ten of the twenty-sevenmalodorants considered in this study. Even when pure-component data is available, there isno guarantee that predictions of the behavior ofbinarysystems will be adequate.Experimental data for binary systems is even scarcer. Experimental data exists for only onebinary system studied here –n-butane– ethyl mercaptan, which enables an assessment of theperformance of the two models.COSMOtherm on the other hand requires no experimental data (pure or binary) and isbased solely on the chemical structure of the molecules combined with a quantum chemicalcalculation. This calculation only needs to be performed once to give a so-called chargesurface and charge profile for the molecule, after which thermodynamic calculations can bedone quickly and in a straightforward manner. Since no experimental data is required,COSMOtherm will not predict pure-component vapor pressures as accurately as CPAforsubstances for which experimental data exists,since the CPA parameters are fitted to the

3

experimental data. In general, however the uncertainty of prediction of pure-componentvapor pressures was deemed to be acceptable, and in particular, COSMOtherm performedvery well for the only binary system for which experimental data were available.

2 BackgroundLiquefied petroleum gas is used in cigarette lighter refills, small blow torches andcamping gas stoves. The liquefied petroleum gas usually consists of butane, isobutane andpropane in various proportions. Products other than cigarette lighter refills contain up to 40% of unsaturated hydrocarbons. Butane is odorless and heavier than air, with a flash point of-40oC and flammability limit of between 1.8 and 8.4% volume.n-butane,iso-butane andpropane vaporize at ordinary temperature and atmospheric pressure, the boiling points ofthese are -0.5, -11.7 and -42.1oC respectively.Volatile substances are generally separated into four groups, namely volatile solvents,aerosols, gases and nitrites. Volatile solvents are liquids or semi solids which vaporize atroom temperature. These products include paints, paint thinners and strippers, dry cleaningfluids, nail polish remover. Aerosols contain propellants and solvents. These include spraypaints, hair sprays and vegetable oil sprays. The aerosols contain substances such as butane,toluene, propane and acetate. Volatile substances classified as “gases” include gas lighters,fire extinguishers, fuel gas, and anesthetic gases. These products contain butane, isopropaneand nitrous oxide.These products are often available in inexpensive packs and are thus attractive tomisusers. Butane is most usually inhaled directly into the mouth from cigarette lighter refillcans. Cigarette lighter refills are misused by clenching the nozzle between teeth and pressingto release the gas. If the can is tilted then a jet of fluid cooled to at least -60oC by expansionmay be inhaled directly and there is also a risk of fire and explosion associated with themisuse of cigarette lighter refills. Butane gas affects the body about 5 minutes afterinhalation and its effect lasts for 15-45 minutes. After this, the inhaler may feel nausea up to9 to 12 hours. At the early stage of inhalation, the inhaler feels euphoria, a floating sensation,dizziness, slurred speech, sense of heightened power and hallucination. These symptoms mayresult in impulsive actions such as attacking other people [5].

4

In the United Kingdom 605 people under the ago of 18 have died from volatilesubstance abuse in the period 1981-1990. Table 1 shows the deaths attributed to specificproducts in those under 18 from 1981-1990 in United Kingdom [6] and the largest number ofdeaths was attributed due to butane gas cigarette lighter fuel.Table 1: Death attributed to specific volatile substances in those under 18 from 1981-1990

ProductButane gas lighter fuelCalor gas (Propane)Butane gas cylinderPR sprayFire extinguisherAntiperspirantsOther spraysUnknown spray canisterEvostickOther gluesDry cleaning agentsOther cleaning agentsTypewriter correcting fluidChloroformPetrolUnknown gluesOther productsTotal

No of deaths20771026338815153522130673131511600

Frequency (%)34.51.21.74.35.514.74.52.55.83.70.25.011.20.52.20.81.8100

5

3 Chemical ingredients in inhalantsSolvents and volatile products contain many different chemicals. Table 2 shows theactive ingredients present in a sampling of products. These chemicals include both gases andliquids [13].Table 2: Chemical ingredients in inhalants

ProductAdhesivesAirplane glueRubber cement

Major volatile components

Toluene, ethyl acetateHexane, toluene, methyl chloride, acetone,methylethylketone, methylbutylketone

AerosolsSpray paintHair sprayAir freshenersFabric protection sprayComputer cleanerCleaning productsDegreaserSpot removerSolventsNail polish removerPaint thinnerCorrection fluidTolueneLighter fluidFood productswhippetsCanned whipped creamNitrous oxideNitrous oxideAcetone, ethyl acetate, tolueneToluene, methylene chloride, methanol, acetoneToluene, trichloroethylene, trichloroethaneMethylbenzeneButane, isopropaneTetrachloroethylene, trichloroethane, methanolXylene, petroleum distillates, trichloroethaneButane, fluorocarbons, toluene, hydrocarbonsButane, fluorocarbons, propaneButane, fluorocarbonsButane, trichloroethaneDimethylether, hydrofluorocarbons

6

4 Effects of butane volatile substance abuseVolatile substances such as butane gas produce can be inhaled to induce a psychoactive,or mind altering effect [9]. Butane vapors displace oxygen and can result in loss ofconsciousness and directly damage lung tissue. The vapors are easily absorbed through thelungs and carried to the brain where they act to depress the central nervous systems [9].4.1Short term effectThe short term effects are most rapid and relatively brief in duration. Immediateeffects may last only a minute or several minutes. These rapid effects are due to high lipidsolubility which allows for rapid absorption from the lungs to blood stream. Hydrocarbonspresent in volatile substances are easily absorbed into fatty tissues in the brain where they actas depressants [10]. Intensive use of inhalants may result in irregular heart rhythms andsudden death. The sudden sniffing death is particularly related to inhalation of butane andpropane fuels. Other inhalants, such as aerosols have been reported to induce sudden andfatal cardiac arrest, even in first time use. Recently, several deaths are associated with typecorrection fluid and lighter fluid [8]. Table 3 represents a range of possible consequences thatmay result from short term and long term chemical exposure [10].4.2Long term effectA long term effect may present itself after prolonged exposure. These effects dependon the amount which is inhaled over a period of time. Long term use is linked with muscleweakness, reduced bone density, leukemia and other cancer [9]. Long term chemicalexposure can cause damage to the liver, heart and lungs. A long term consequence ofinhalant use depends on four factors: the user, the substance used, the context of use andculture of use. Long term solvent abuse may lead to permanent neurological damage.

7

Table 3 : Possible consequences from butane inhalant substances [9]

Short term effectEuphoria/Feeling of well beingLoss of inhibitionDrowsiness/sedationSlurred speech/incoherenceWeaknessNauseaVomitingHeadachesLoss of short term memoryAggressionHallucinationsUncoordinated movements

Long term effectChronic headacheSinusitisTinnitusDiminished cognitive functionNosebleedsExtreme tirednessRed, watery eyesShortness of breathIndigestionDizzinessStomach ulcersChest pain or angina

8

5 Preventing volatile substance abuseThe following modifications have been proposed to prevent volatile substance abuse [10].••

Replacement of harmful or psycho- active components;Additions of deterrent chemicals such as odorants have been proposed to modifythe butane gas in lighter refill cans. Research by the CSIRO in Australia concludedthat adding mercaptans to butane gas at a level of 50 ppm would result in theproduct having unpleasant odor and emetic properties sufficient to deter misuse [1];

••

Package modification;Modifying the butane cigarette lighter refill container, where the product isdelivered from container to container (modification of nozzles of cans) ;

•

Replacement of the abusable or toxic elements of the product with a non abusablealternative;

••

Reformulation of products to remove or minimize abusable substances;Adding substances such as bittering agents (e.g. Bitrex) to make the product lessappealing to inhalers;

•

Ban on abusable chemicals (from legitimate products).

The purpose of this work is to consider a number of possible deterrent additives, andspecifically whether it is possible to add these to lighter gas, from a physicochemicalperspective.

9

6 The basic idea and its approachThe main objective of this work is to investigate compounds which are suitable formodifying the cigarette lighter fuel without affecting its performance. Compounds(malodorants) are selected based on physical and chemical properties such as compoundswhich are irritants, have an unpleasant odor or are bittering. The main volatile constituents ofcigarette lighter and butane fuel gases aren-butaneand isobutane. Butane is a straight chainaliphatic hydrocarbon gas at room temperature. The addition of mercaptans to butane gas hasbeen shown not to affect the short term performance of butane-burning devices such ascigarette lighters but further research is required to assess the long term effect [1]. The focusof this work is on compoundsotherthan those based on sulfur (such as hydrogen sulfide andmercaptans). However, a single comparison has been made for the system butane-ethylmercaptan, since some binary experimental data is available for this system. This has enabledthe theoretical approach used here to be verified.The physical properties of malodorants and their mixtures have been calculated using theCPA equation of state and the COSMOtherm program. If experimental data for the purecompounds is available (they are available for 17 out of 27 compounds), pure componentparameters can be found for the CPA equation of state by fitting the model to theexperimental data. The behaviour of the binary system (butane-malodorant) can then bepredicted. The COSMOtherm program can compute the physical properties of purecompounds and mixtures, without the need for experimental data. The results from the CPAmodel and the COSMOtherm program can then be compared with each other and withavailable experimental data (if available). Since there is only data for one binary system(butane – ethyl mercaptan) it is difficult to comment on which model is preferable. However,COSMOtherm performed very well for this system and our feeling is that the predictions ofbinary phase behaviour are reliable in nearly all cases studied here. CPA is probably asreliable, but can only be used if experimental data is available for the pure compounds.COSMOtherm is a program that computes thermophysical data of fluids. This programis based on the COSMO-RS theory and the computational procedure is takes place in threesteps. First, a molecule is “built” and a quantum chemistry calculation is performed in orderto calculate a sigma potential and a sigma profile by COSMO-RS. This calculation is time-

10

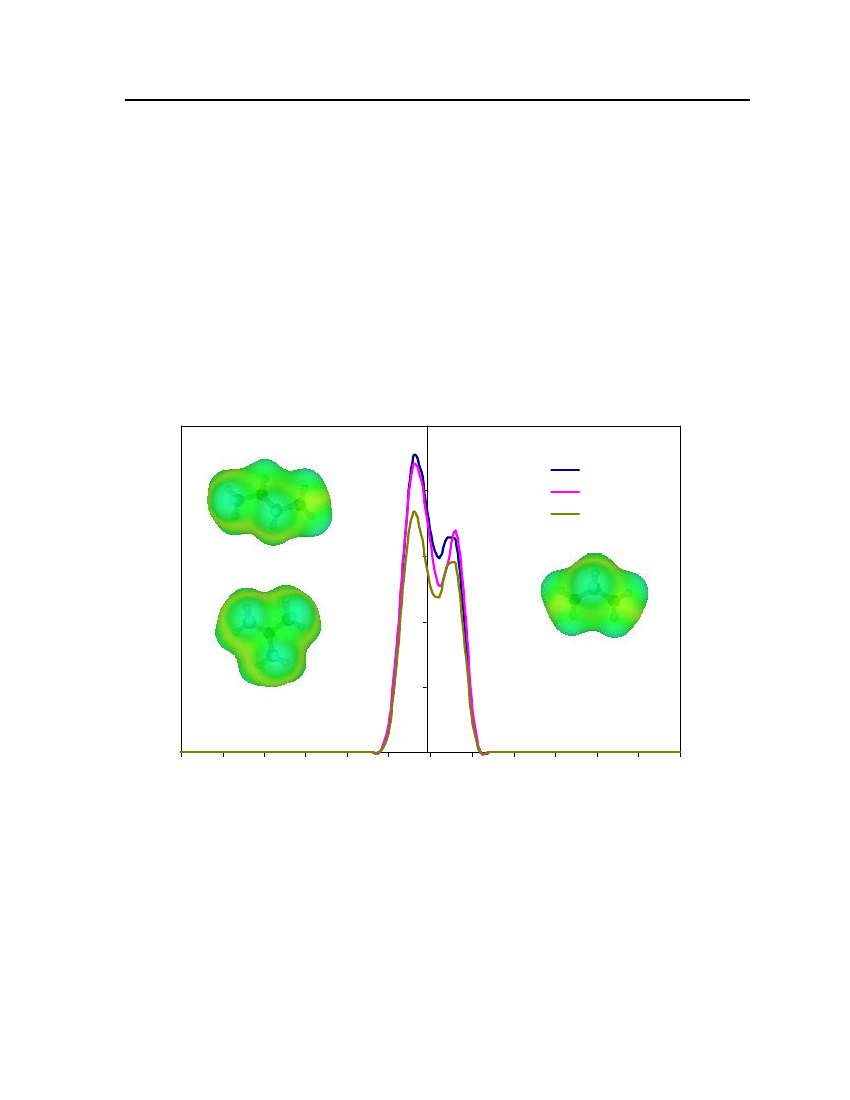

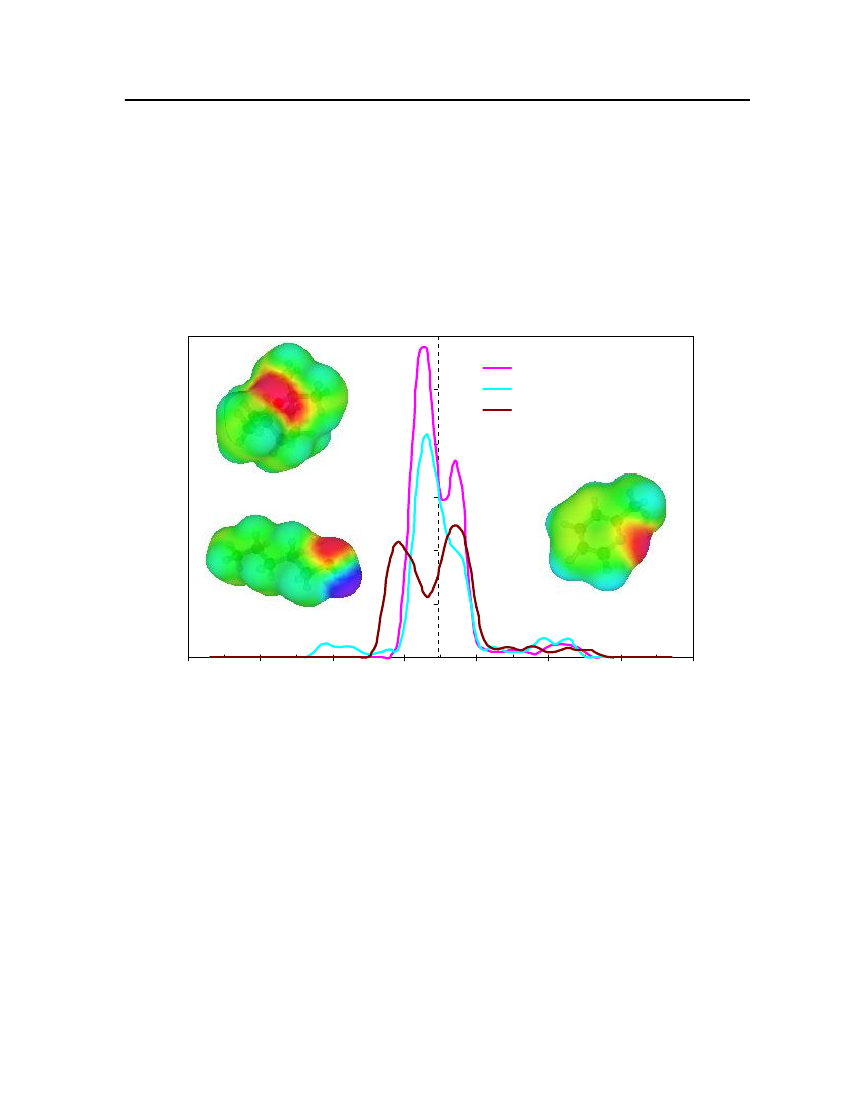

consuming but is performed only once for each compound and the profiles are then stored ina database. In fact the sigma profiles for most of the malodorants considered here had alreadybeen calculated and were already available in the program’s extensive database.Vapor pressures and vapor liquid equilibrium calculations can then be performed for thepure compounds and for mixtures. These calculations are relatively quick. Section 7.5discusses the sigma profiles and surfaces in detail.

11

7 Theory and modeling7.1CPA (Cubic-plus-Association) Equation of State

The CPA equation of state was developed by Kontogeorgis et al. [20,21]. This equation hasbeen applied to systems containing mainly hydrocarbons with associating compounds. Anassociating compound is one which exhibits hydrogen bonding (such as water, alcohols andamines). This equation combines a so-called “physical” interaction with an association termwhich accounts for hydrogen bonding. The physical interactions are accounted for using theSRK (Soave-Redlich-Kwong) equation of state. This equation of state (SRK) is very widelyused in the oil and gas industry and CPA was developed with this industry in mind – ratherthan develop a completely new equation of state, a term was simply added to the SRKequation to account for water, alcohols, etc. for which SRK was not performing adequately.In the absence of hydrogen bonding, CPA simply reduced to SRK. The result has been thatCPA has been adopted by the oil industry (traditionally a rather conservative industry)because it can be readily integrated into existing software. A detailed description of the CPAequation of state can be found in Kontogeorgis et al [20, 21].Without going into detail here, it is useful to know that the CPA equation of staterequires five parameters to describe a single pure associating compound - three for thephysical part, and two for the association part – an association energy (εAB) and anassociation volume(βAB). For a non-associating compound, such as butane, only threeparameters are required. These parameters are determined by fitting to experimental data(saturated vapor pressures and liquid density) for the pure compound. An extensivecollection of this data exists for many pure compounds (for example 17 of the 27 consideredhere). This compilation has been performed by the Design Institute for Physical Properties(DIPPR).

12

7.2

The COSMO-based thermodynamic model:The COSMO model has been covered extensively in the literature [14, 18, 19], so

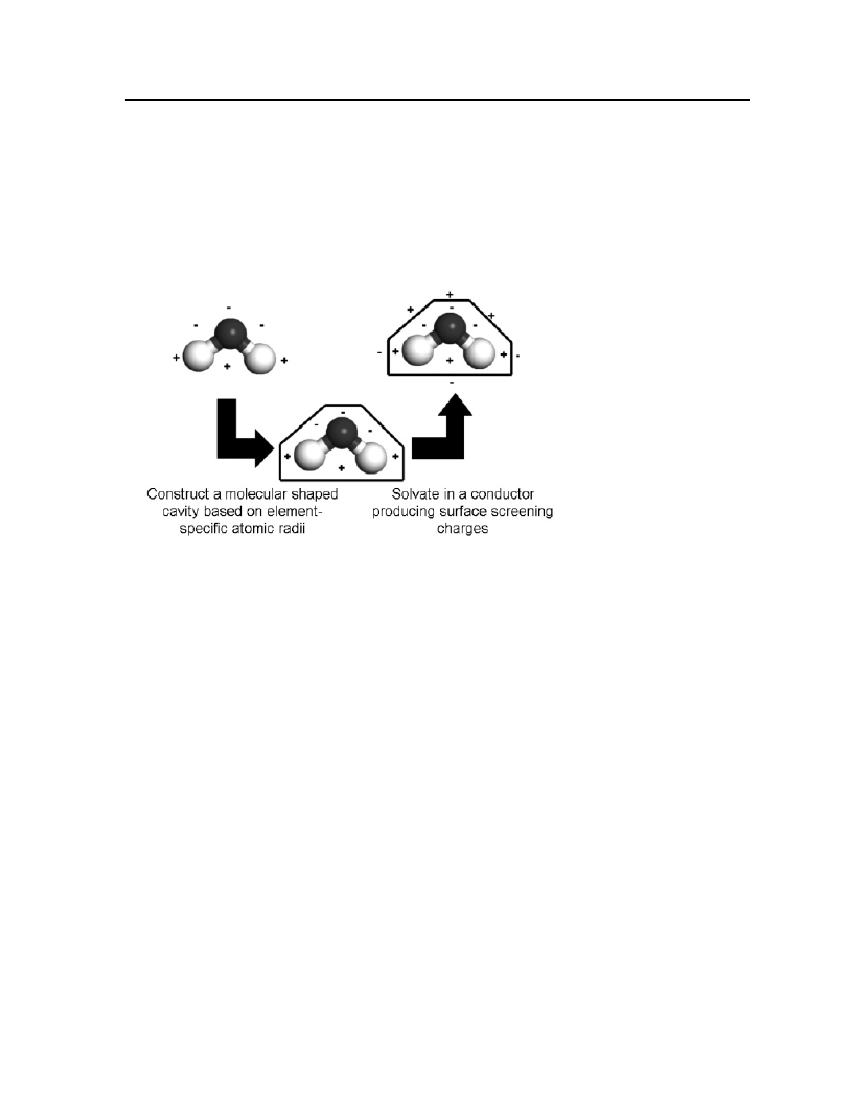

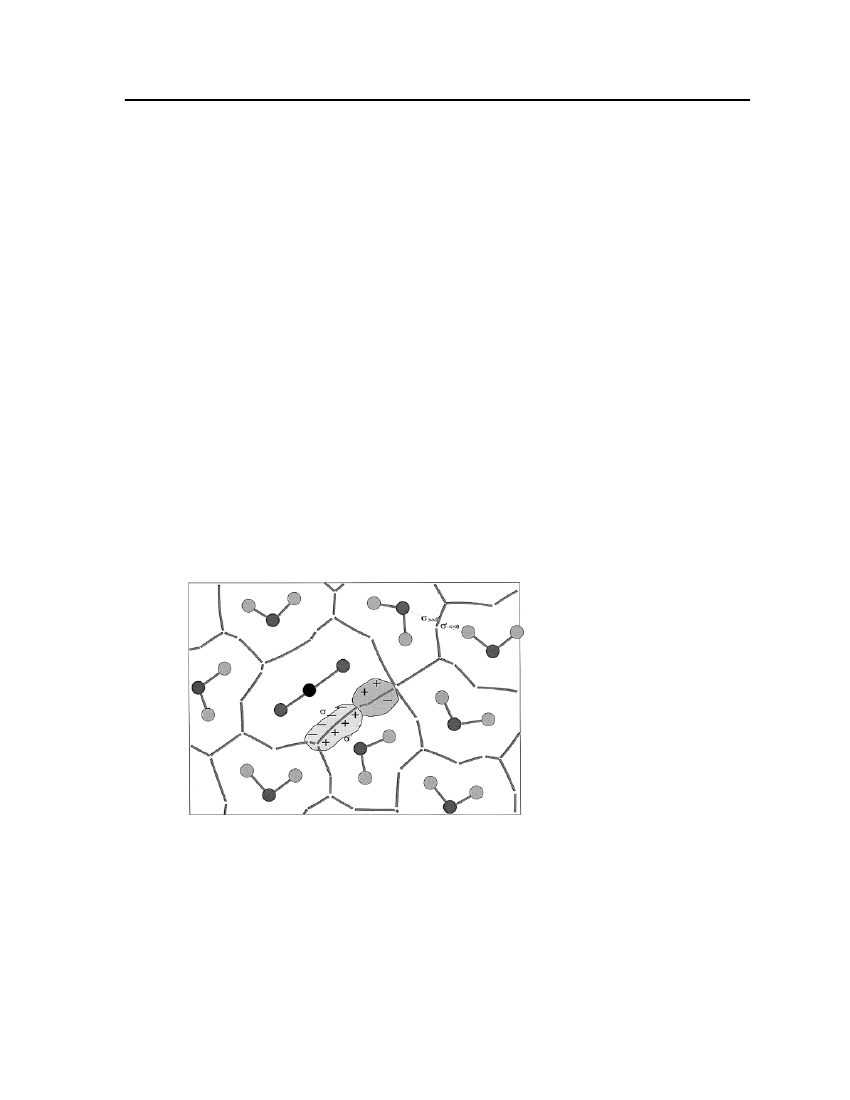

only a comparatively short discussion is given here. The basis of COSMO-based model is the“solvent-accessible surface” of a solute molecule. These COSMO-based models generate asurface charge distribution. Figure 1 shows the ideal solvation process in the COSMO-basedmodels [18].

Figure 1: Ideal solvation process in COSMO-based models[18]

COSMO-based models construct a molecular-shaped cavity within a perfectconductor according to a specific set of rules and atom-specific dimensions. Then themolecule’s dipole and higher moments draw charges from surrounding medium to thesurface of the cavity to cancel the electric field both inside the conductor and tangential to thesurface.The induced surface charges on the solute surface in discretized space is given by thefollowing equation(0)Φtot= Φi+ Φ(q∗)= Φi+Aq∗=0

(7.1)

Φtotis the total potential on the cavity surface,Φiis the potential due to the chargedistribution of solute moleculei,Φ(q∗) is the product of ideal screening chargeq*andcoulomb interaction matrixA. This coulomb interaction matrix describes the potentialinteractions between surface charges and is a function of cavity geometry [18].

13

For the calculation of sigma profiles, a construction of the molecular–shaped cavity inthe solvent continuum is required and surface segments need to be distributed over the cavitysurface. The charge density distribution (σprofile,pi(σ) ) is calculated from the averagedsurface charge densities. The charge distribution is represented as probability distribution ofa molecular surface segment having a specific charge density. This probability distribution iscalled the sigma profile (pi(σ) ). The sigma profile for a moleculeiis defined aspi(σ)=ni(σ)Ai(σ)=niAi

(7.2)

whereni(σ) is the number of segments with charge densityσin a single moleculeiandAi(σ) is the total surface area from all these segments.The probability of finding a segment with charge densityσin a mixture is theweighted sum of theσprofiles of all the components

∑x n p(σ)∑x A p(σ)p(σ)==xn∑∑x Ai iiiiiiisi iiiii

(7.3)

Theσprofile which ispi(σ) as a function ofσ, quantifies the electronic properties of afluid and is the most important characteristic of each species in the COSMO-RS model.The effective surface charge density can be calculated by using the following equation.22rn2ravdmn∑σnr2+r2exp−r2+r2nnavn avσm=22rn2ravdmnexp−2 22rn2+ravrn+rav*

(7.4)

whereσmis surface-charge density on segmentm,rnis the radius of the actual surfacesegment (assuming circular segments),ravis the averaging radius (adjustable parameter), anddmnis the distance between the two segments. The paired segmentsmandnhave segmentcharge densitiesσmandσnrespectively [16]. Sigma profiles and sigma surfaces are readilyvisualized – see section 7.5.

14

COSMO-RS theoryCOSMO-RS is a theory of interacting molecular surfaces as computed by quantumchemical methods (QM). Quantum chemical methods originally developed for isolatedmolecules i.e. for molecules in vacuum or in gas phase. The COSMO-RS is basis of COSMO(conductor-like screening model), which belongs to the class of QM continuum solvationmodels (CSMs). These CSMs are an extension of the basic QM methods towards thedescription of liquid phases. CSMs are describes the molecule in solution through a quantumchemical calculation of solute molecule with surrounding solvent as a continuum [14].COSMO theory of real solvents integrates concepts from quantum chemistry,dielectric continuum models, electrostatic surface interactions and statisticalthermodynamics. Basically QM-COSMO calculations provide a discrete surface around amolecule embedded in a virtual conductor. Figure 2 shows that each segmentiischaracterized by its areaaion the surface and the screening charge densityσion thissegment. A liquid is now considered to be an ensemble of closely packed ideally screenedmolecules as shown in Figure 2. The system has to be compressed in order to get closepacking and the molecules are slightly deformed from their original positions.

Figure 2: Schematic illustration of contacting molecular cavities and contact interactions [14].

Each piece of molecular surface is in close contact with another one. Assuming that eachmolecule is enclosed by virtual conductor and then the electrostatic interaction arises fromthe contact of two different screening charge densities (SCDs). The energy differencebetween the real situation of such contact and ideally screened situation is defined as a localinteraction energy, which results from the contact of molecules. The difference between the

15

screening charge densitiesσandσ'of a contact pair is a measure of the misfit of the SCDon both segments in the real system, compare to the situation inside the ideal conductor.Emisfit(σ,σ')=aeff

α'2

(σ+σ')2

(7.5)

whereaeffis the effective contact area between two surface segments andα'is an energyfactor.Hydrogen bonding can also described between two adjacent SCDs. Hydrogen bondingdonors having a strongly negative SCD and acceptors have strongly positive SCDs. If twopolar pieces of surface with opposite polarity are in contact with each other then hydrogenbonding occurs. This interaction energy is expressed asEHB=aeffcHBmin(0; min(0;σdonor+σHB) max(0;σdonor−σHB))

(7.6)

wherecHBandσHBare adjustable parameters. COSMO-RS can also counts the van derWaals interaction between segments by the following expressionEvdW=aeff(τvdW+τ'vdW)

(7.7)

whereτvdWandτ'vdWare element specific adjustable parameters. The van der Waals energydepends only on the element type of the atoms that are involved in surface contact. Statisticalthermodynamics provides the link between microscopic surface interaction energies andmacroscopic thermodynamic properties of a liquid. Since in COSMO-RS all molecularinteractions consist of local pair-wise interactions of surface segments, the statisticalaveraging can be done in the ensemble of interacting surface pieces. The composition of thesurface segment ensemble with respect to the interaction can be described by sigma profiles.The sigma profile of the whole system/mixture is just the sum of theσ-profiles of thecomponentsXiweighted with their mole fraction in the mixturexips(σ)=∑xipxi(σ)i∈S

(7.8)

The chemical potential of a surface segment with SCDσin an ensemble described bynormalized distribution functionps(σ) is given byaeffRT�s(σ)= −lnps(σ') exp(�s(σ')−Emisfit(σ,σ')−EHB(σ,σ'))dσ'aeff∫RT

(7.9)

16

�s(σ) is a measure of the affinity of the systemSto a surface of polarityσ. It is acharacteristic function of each system and is called “σpotential”. The COSMO-RSrepresentation of molecular interactions is namely theσprofiles andσpotentials ofcompounds and mixtures.COSMO-RS is also able to provide a reasonable estimate of a pure compoundschemical potential in the gas phaseXXXXX�Gas=EGas−ECOSMO−EvdW+ωRingnRing+ηGasRTiiiii

(7.10)

XiXiwhereEGasandECOSMOare the quantum chemical total energies of the molecule in the gasXiphase and in the COSMO conductor respectively.EvdWis the van der Waals energy ofXi.

The remaining contributions consist of a correction term for ring shaped molecule withXinRingbeing the number of ring atoms in the molecule.ωRingis an adjustable parameter and the

parameterηGasprovides the link between the reference states of the system’s free energy inthe gas phase and in the liquid [14].Once the chemical potential of pure compound has been computed in solution and in theideal gas phase, the vapor pressure of the pure compound can be calculated as:XXi�Xii−�GasP(T)=expkTXivap

(7.11)

XWherePvapiis the vapor pressure of pure compoundXi,kis the Boltzmann constant,Tis theXtemperature and�Xiiis the pseudo-chemical potential of pure compoundXiin a liquidXi.

After the vapor pressure of the pure compound has been calculated, COSMO-RS can predictvapor liquid equilibrium in mixtures using the standard thermodynamic relation:.

γSXi

X�SXi−�Xii=expRT

(7.12)(7.13)

Xiptotal=∑pvapxiγSXiiXipvapxiγSXi

yi=

ptot

(7.14)

17

In equation (7.12)γSXiis the activity coefficient of pure compoundXiin solution which isconsidered the continuum medium according to COSMO model,ptotalis the total vaporpressure of the mixture that is used to predict the vapor liquid equilibrium diagram,Xiis themole fraction of compounds in the liquid phase andYiis the mole fraction of compounds inthe gas phase. The vapor liquid equilibrium calculations in COSMO-RS are thus done basedon vapor pressure and the activity coefficients of the compounds in solution.

18

7.3

Malodorants

These compounds were initially chosen based on their deterrent effect (mainly odor) and thenchecked for suitability with respect to their physical properties (phase behavior andsolubility). The compounds selected for study are shown in Table 4.Table 4: MalodorantsS.NoMalodorants1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20.21.22.23.24.25.26.TriethylamineDenatonium benzoateIsobutyraldehydeTetrahydrothiopheneDimethylsulfide2,2,4 TrimethylpentanePicoline(2-Methylpyridine)Eucalyptol (1,8 Cineole)Nitrobenzene1-PentanolSulfurylchlorideCyanogenchlorideBis-(2-chloroethyl)sulfideCAS-number Chemicalformula121-44-83734-33-678-84-2110-01-075-18-3540-84-1109-06-8470-82-698-95-371-41-07791-25-5506-77-4505-60-2C6H15NDeterrent effectStrong fishyDIPPRdatabaseYesNoYesYesYesYes

C28H34N2O3Bitter tasteC4H8OC4H8SC2H6SC8H18C6H7NC10H180C6H5NO2C5H12OSO2Cl2CClNC4H8Cl2SC6H13Cl2NC2H5AsCl2C8H6BrNCCl3NO2C13H10AsNC2H6SC2CH4Cl2OC8H7NOC3H8O2C3H6O3C8H7ClOC8H7NC5H5NExtremely unpleasantStrong unpleasant odorUnpleasant odorGasoline/Petrol

Unpleasant (strong) odor YesStrong aromatic and spicy Nobitter (Almond-like odor) YesCharacteristic odor, stench YesBitter, Pungent odor,YesirritatingBitter, Pungent odor,YesirritatingGarlic or Horse radishFaint, Fishy, or mustyFruity but biting andirritatingSoured or rotting fruitStinging, pungent odorNoNoNoNoNo

Bis-(2-chloroethyl)ethylamine538-07-8EthyldichloroarsineBromobenzylcyanideChloropicrinDiphenylcyanoarsineEthylmercaptanBis(chloromethyl)ether2-AminophenolPropyleneglycols-Trioxane2-ChloroacetophenoneIndolePyridine598-14-116532-79-976-06-223525-22-675-08-1542-88-195-55-657-55-6110-88-3532-27-4120-72-9110-86-1

Garlic and bitter almonds NoGarlic odorStrong unpleasant odorPhenol-like (strongirritating)Mild odorIrritating odorEye, throat, skin irritantUnpleasant (strong)Characteristic fish likesmellYesYesNoYesYesNoYesYes

19

27.

Butylamine

109-73-9

C4H11N

Characteristic fish likesmell

Yes

A brief discussion of each component follows in sections 7.3.1 – 7.3.27.

20

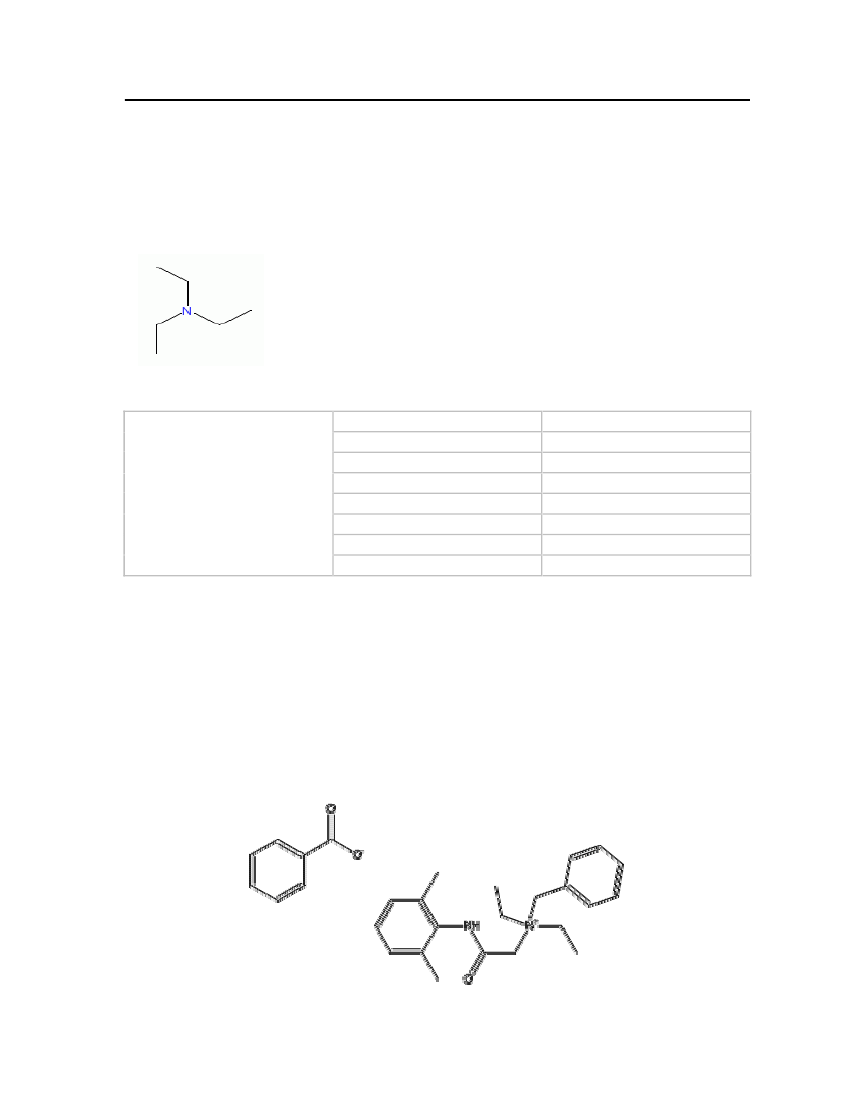

7.3.1 TriethylamineTriethylamine occurs as a colorless flammable liquid and it is soluble in water and otherorganic solvents. It has been selected based on its strong fishy ammonia-like odor. Theproperties of triethylamine are shown in Table 5.Molecular Structure:

Table 5: Properties of Triethylamine

Triethylamine

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Strong fishy101.19 kg/kmol535.15 K30.4 bar0.39 m�/kmol158.45 K361.92 K0.139672 m�/kmol

7.3.2 Denatonium Benzoate (Bitrex)Denatonium Benzoate has an extremely bitter taste. It is easily soluble in water, alcohol andother solvents. Bitrex is not a very toxic substance and has been added to a wide range ofchemicals to deter ingestion. Addition of Bitrex to alcohol makes it unfit for consumption. Itis also added to all kinds of harmful liquids including solvents, paints, varnishes, toiletriesand other household products. The physical and chemical properties are shown in Table 6.Molecular Structure:

21

Table 6: Properties of Denatonium benzoate (Bitrex)

Denatonium benzoate

OdorMolecular WeightFreezing/Melting Point

Bitter taste446.581 kg/kmol163-170oC

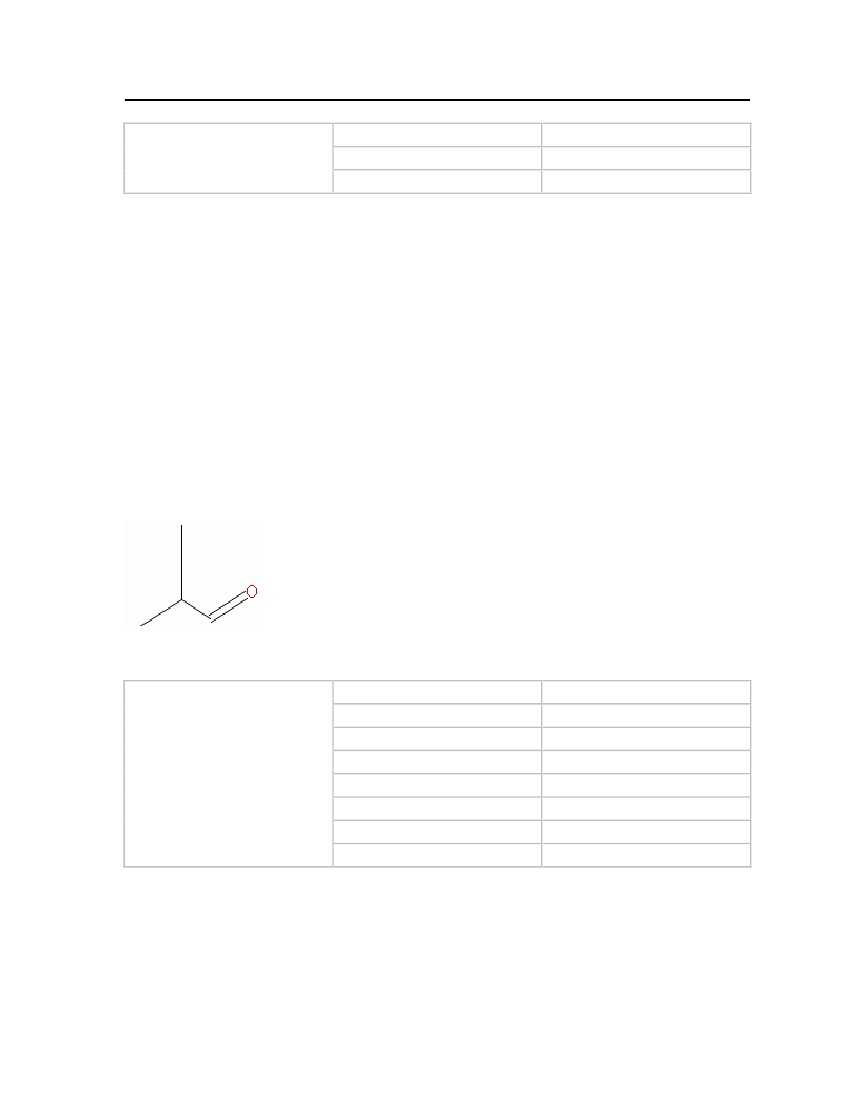

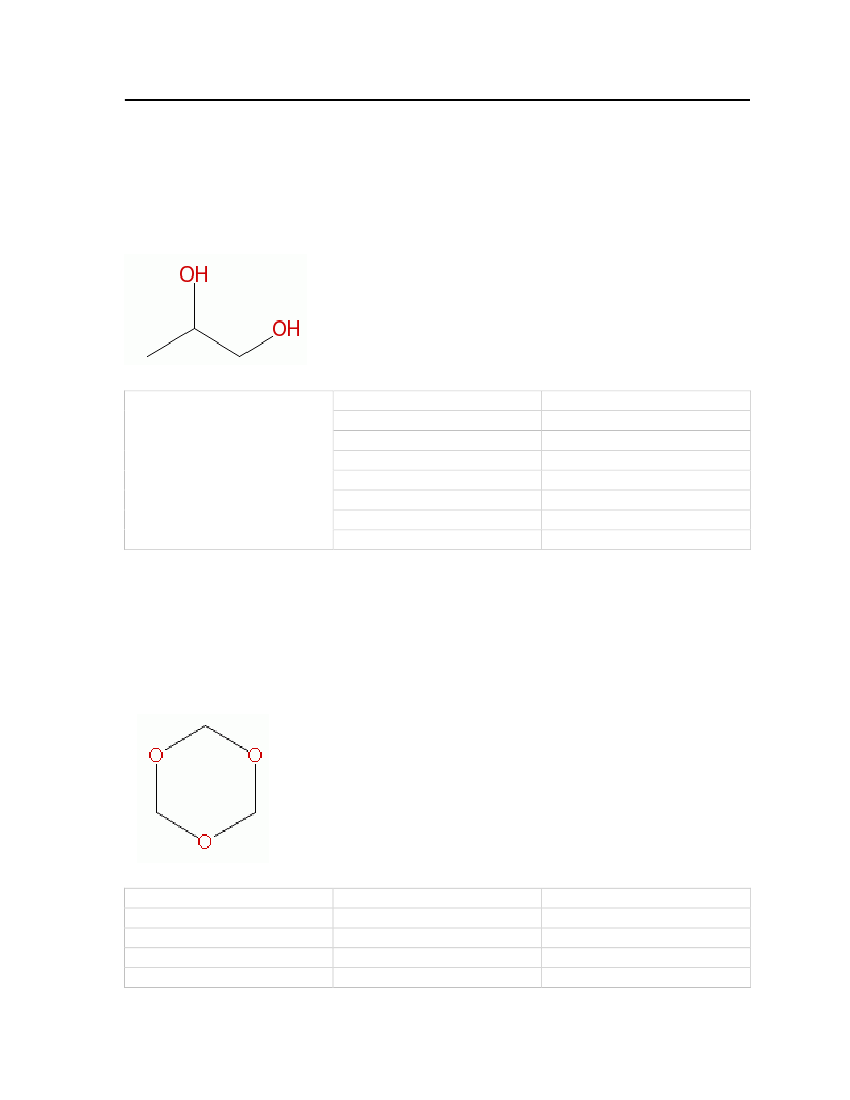

It is considered that this comparatively large molecule would not be a suitable deterrentadditive to butane because of its low vapor pressure. However it is included here forcompleteness since it is one of the few examples of deterrents which is actually added tocommercial products.7.3.3 IsobutyraldehydeIsobutyraldehyde (isobutanal) is a liquid at ambient temperatures and is soluble in water. It isconsidered a highly flammable liquid which can easily be ignited by heat, spark or flame.Isobutanal is selected based on its unpleasant smell. The physical and chemical properties areshown in Table 7.Molecular Structure:

Table 7: Properties of Isobutyraldehyde

Isobutyraldehyde

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeFreezing/Melting PointNormal Boiling PointLiquid Molar Volume

Extremely unpleasant smell72.10572 kg/kmol507 K41.0 bar0.263 m�/kmol208.15 K337.25 K0.0920264 m�/kmol

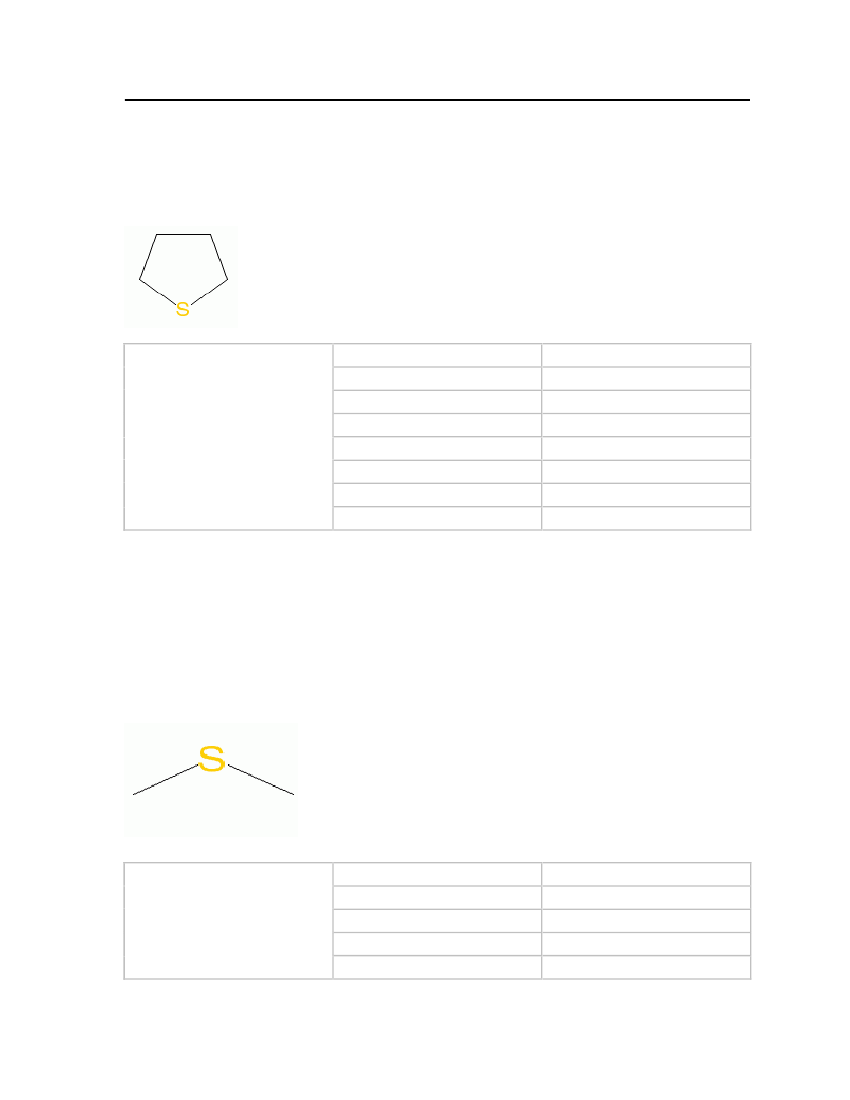

7.3.4 TetrahydrothiopheneTetrahydrothiophene (thiolane) is a heterocyclic organic compound. It consists of a five-membered ring containing four carbon atoms and one sulfur atom. It has a strong unpleasant

22

odor and is used as an odorant in natural gas. Thiolane is easily soluble in water but isinsoluble in other solvents such as ether and ethanol.

Molecular Structure:

Table 8: Properties of Tetrahydrothiophene

Tetrahydrothiophene

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Strong unpleasant odor88.17132 kg/kmol631.95 K51.6 bar0.249 m�/kmol176.99 K394.267 K0.0887032 m�/kmol

7.3.5 DimethylsulfideDimethyl sulfide is a low molecular weight organosulfur compound with a garlic-like odor. Itis stable and incompatible with strong oxidizing agents. This compound is slightly soluble inwater. It is used as a flavor in other products. The physical and chemical properties areshown in Table 9.Molecular Structure:

Table 9: Properties of Dimethylsulfide

Dimethylsulfide

OdorMolecular WeightCritical TemperatureCritical PressureCritical Volume

Garlic like odor62.13404 kg/kmol503.04 K55.3 bar0.201 m�/kmol

23

Melting PointNormal Boiling PointLiquid Molar Volume7.3.6 2, 2, 4-Trimethyl pentane

174.88 K310.48 K0.0737373 m�/kmol

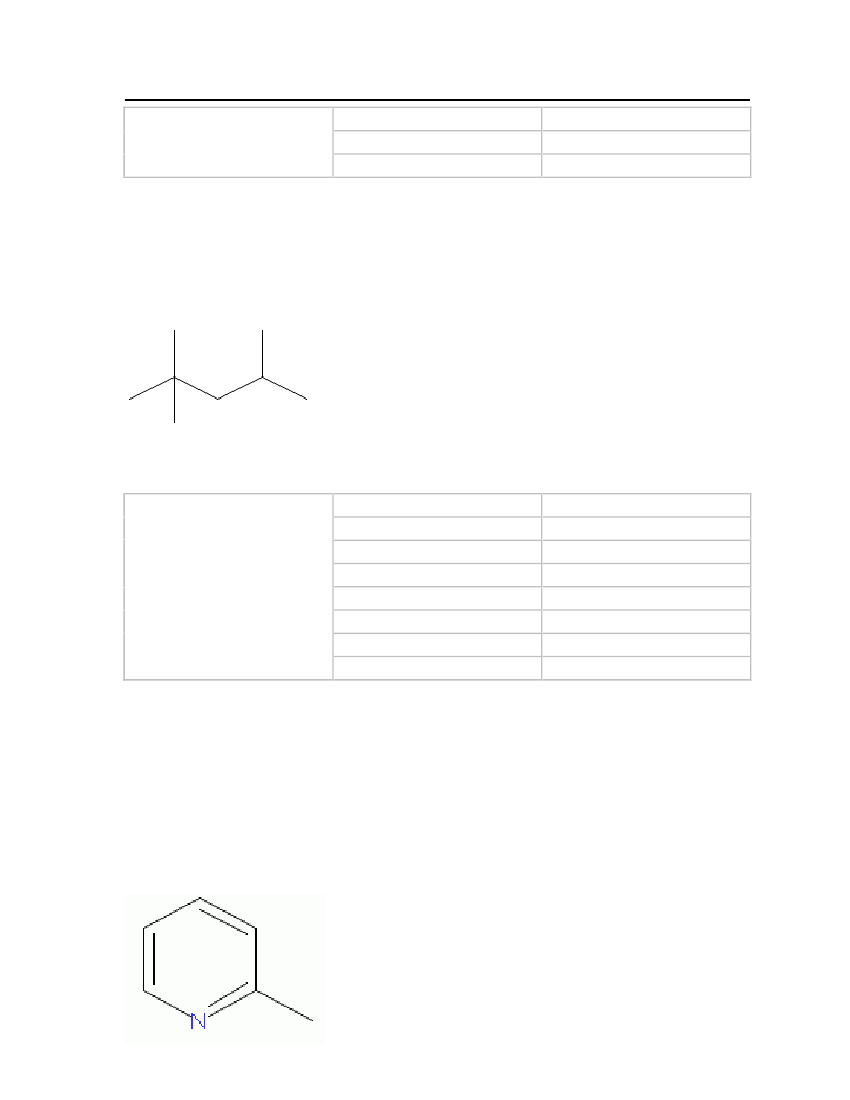

Isooctane is clear, colorless liquid which smells like gasoline. It is used as a solvent and todetermine the octane number of fuels.Molecular Structure:

Table 10: Properties of 2. 2. 4-Trimethyl pentane

2,2,4 Trimethylpentane

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeFreezing/Melting PointNormal Boiling PointLiquid Molar Volume

Gasoline smell114.22852 kg/kmol543.8 K25.7 bar0.468 m�/kmol165.777 K372.388 K0.165478 m�/kmol

7.3.7

Picoline (2-methyl pyridine)

Picoline is a colorless liquid at room temperature and pressure. It is obtained from coal tarand has a putrid fish-like odor. Picoline is useful as a solvent and as a raw material forvarious chemical products used in polymers, textiles, fuels and pharmaceuticals. Theproperties are shown in Table 10.Molecular Structure:

24

Table 11: Properties of Picoline

2-Methylpyridine (Picoline)

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Unpleasant (Strong)93.12648 kg/kmol621 K46.0 bar0.335 m�/kmol206.44 K402.55 K0.0990828 m�/kmol

7.3.8

Eucalyptol (1.8 Cineole)

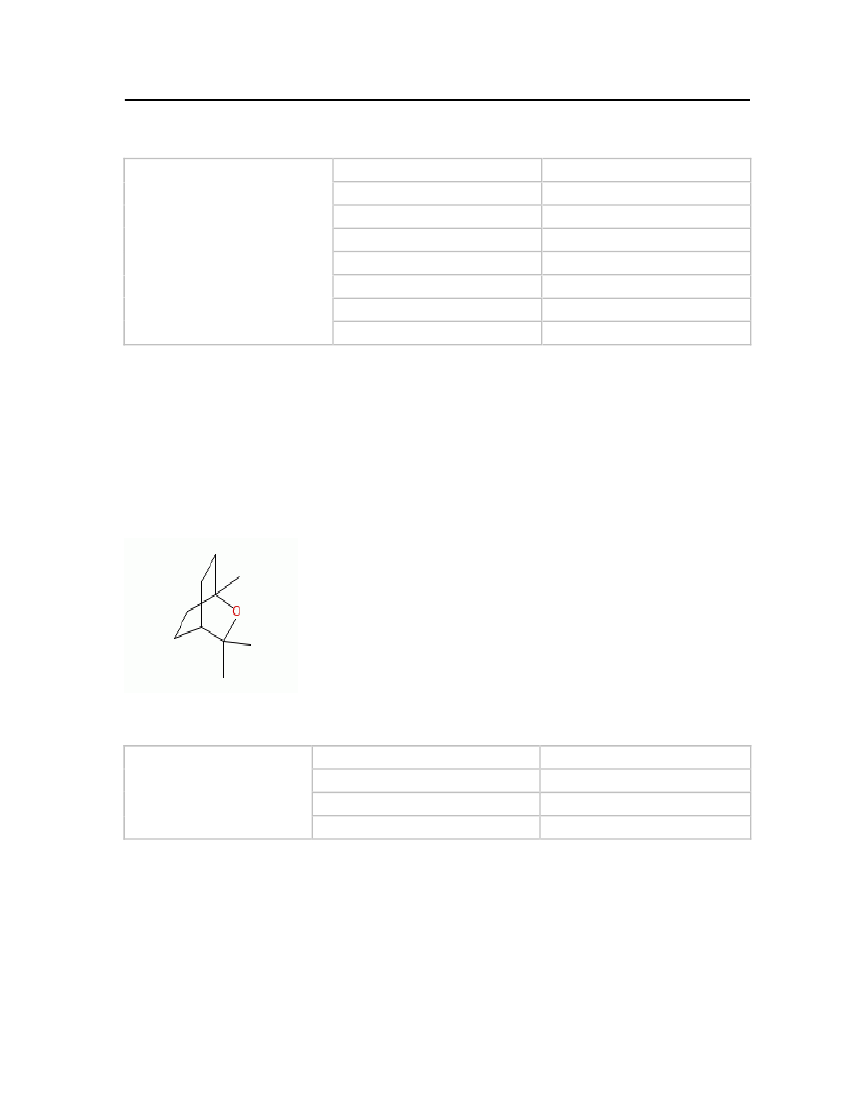

Eucalyptol is obtained from oil of eucalyptus and it is natural organic compound. It is acolorless liquid and having strong aromatic odor. It is used in flavoring, fragrances andcosmetics. It is also ingredient in many brands of mouthwash and cough suppressant. Theproperties are shown in Table 12.Molecular Structure:

Table 12: Properties of Eucalyptol

Eucalyptol (1, 8 Cineole)

OdorMolecular WeightFreezing/Melting PointNormal Boiling Point

Strong aromatic odor and spicy154.2491.5oC176-177oC

7.3.9

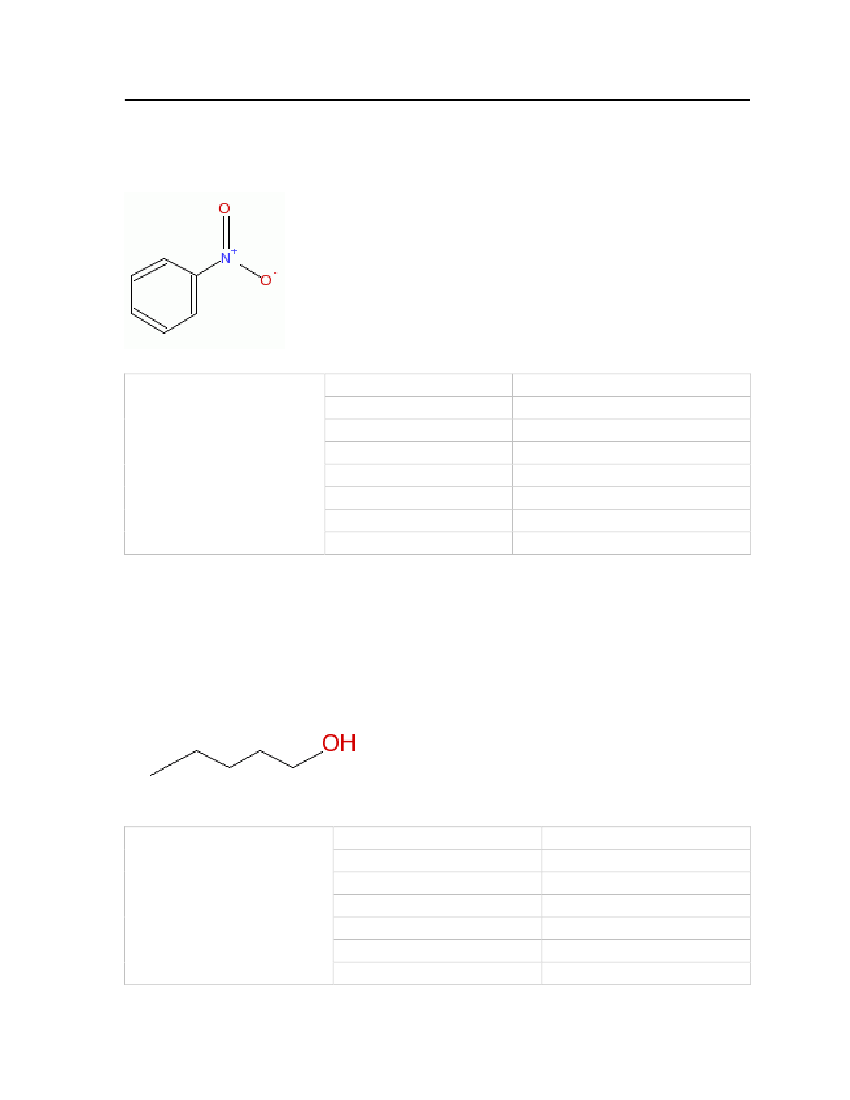

Nitrobenzene

Nitrobenzene is an aromatic nitro compound with an odor resembling that of bitter almonds.It is colorless to pale yellow, oily liquid or as greenish yellow crystals. Mostly nitrobenzeneis used in the manufacturing of aniline. Nitrobenzene is used in pesticides, rubber chemicals,

25

pharmaceuticals and dyes. It is also used as solvent in petroleum refining and synthesis ofother organic compounds. The properties are shown in Table 13.Molecular Structure:

Table 13: Properties of Nitrobenzene

Nitrobenzene

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Strong bitter (Almond-like odor)123.11 kg/kmol719.00 K44.0 bar0.35 m�/kmol278.91 K483.95 K0.10 m�/kmol

7.3.10 1-Pentanol1-Pentanol is clear, colorless liquid with characteristic choking odor. It is obtained by thefermentation of starches and from the distillation of petroleum. The physical and chemicalproperties are shown in Table 14.Molecular Structure:

Table 14: Properties of 1-Pentanol

1-Pentanol

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling Point

Characteristic odor. stench88.1482 kg/kmol588.1 K38.97 bar0.326 m�/kmol195.56 K410.9 K

26

Liquid Molar Volume7.3.11 Sulfuryl chloride

0.10854 m�/kmol

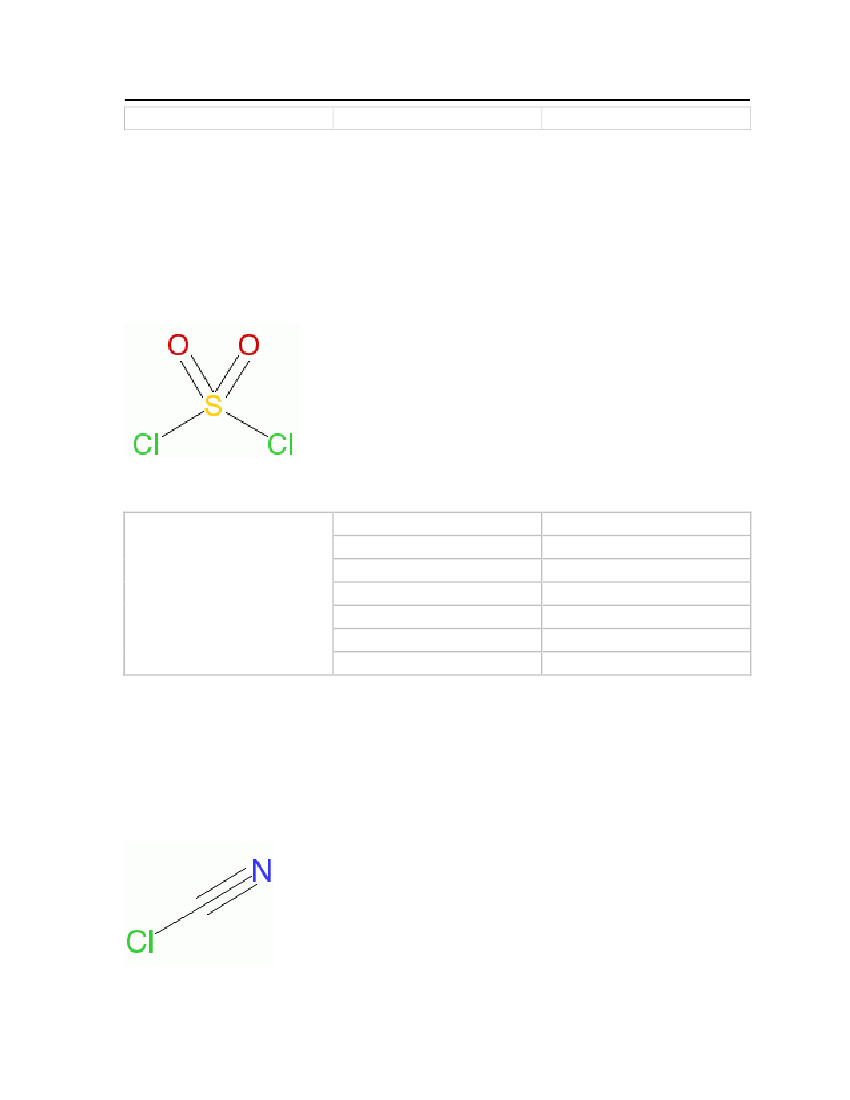

Sulfuryl chloride is colorless liquid and having a pungent odor. It is used as chlorinating anddehydrating agent and boils at 69oC. It is decomposed by hot water and alkaline substances.It is soluble in most organic solvents like benzene, chloroform, carbon tetrachloride andacetic acid. The chemical and physical properties are shown in Table 15.Molecular Structure:

Table 15: Properties of sulfuryl chloride

Sulfurylchloride

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling Point

Bitter, Pungent odor, irritating134.9698 kg/kmol545 K46.1 bar0.234 m�/kmol219 K342.55 K

7.3.12 Cyanogen chlorideCyanogen chloride is a colorless, highly volatile liquid with a pungent, biting odor. Thiscompound is selected because of its tearing and irritating properties. Normally cyanogenchloride is non-persistent and is used as a quick-acting casualty agent.Molecular Structure:

27

Table 16: Properties of cyanogen chloride

Cyanogenchloride

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Pungent, biting and irritating61.4704 kg/kmol449 K59.9 bar0.163 m�/kmol266.65 K286 K0.0524536 m�/kmol

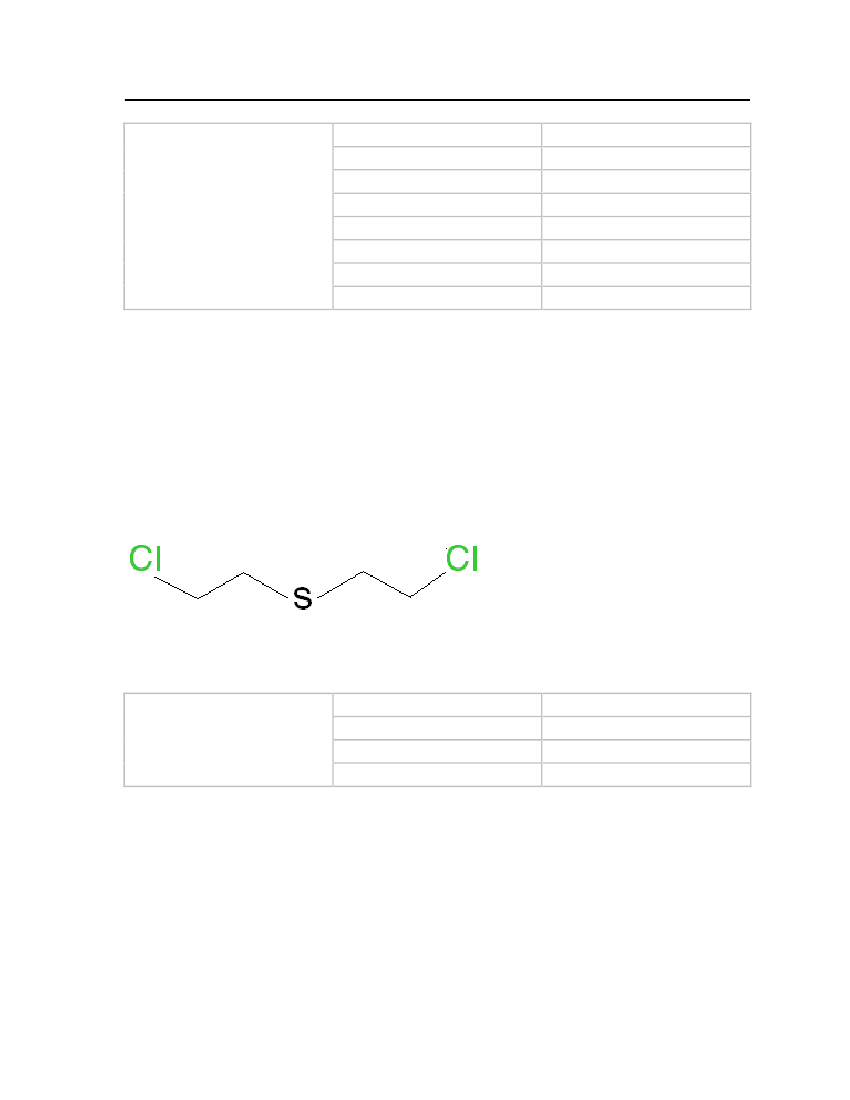

7.3.13 Bis-(2-chloroethyl) sulfideBis-(2-chloroethyl) sulfide is a colorless to amber-colored liquid with garlic like odor and itis more stable in storage. This compound is lighter than water and small droplets will float onwater surfaces and present a hazard. It was selected because of its garlic like odor. Theeffects from this compound are vomiting, fever and skin reddening. The physical andchemical properties are shown in Table 17.Molecular Structure:

Table 17: Properties of Bis-(2-chloroethyl) sulfide

Bis-(2-chloroethyl) sulfide

OdorMolecular WeightFreezing/Melting PointNormal Boiling Point

Garlic or horse radish159.0814.45oC227.8oC

7.3.14 Bis-(2-chloroethyl) ethylamineBis-(2-chloroethyl) ethylamine is more volatile, colorless liquid with a fishy or musty odor. Itwas selected because of its fishy odor and it is easily soluble in organic solvents. Severevapor exposure will result in redness of the skin, causing irritation and itching.

28

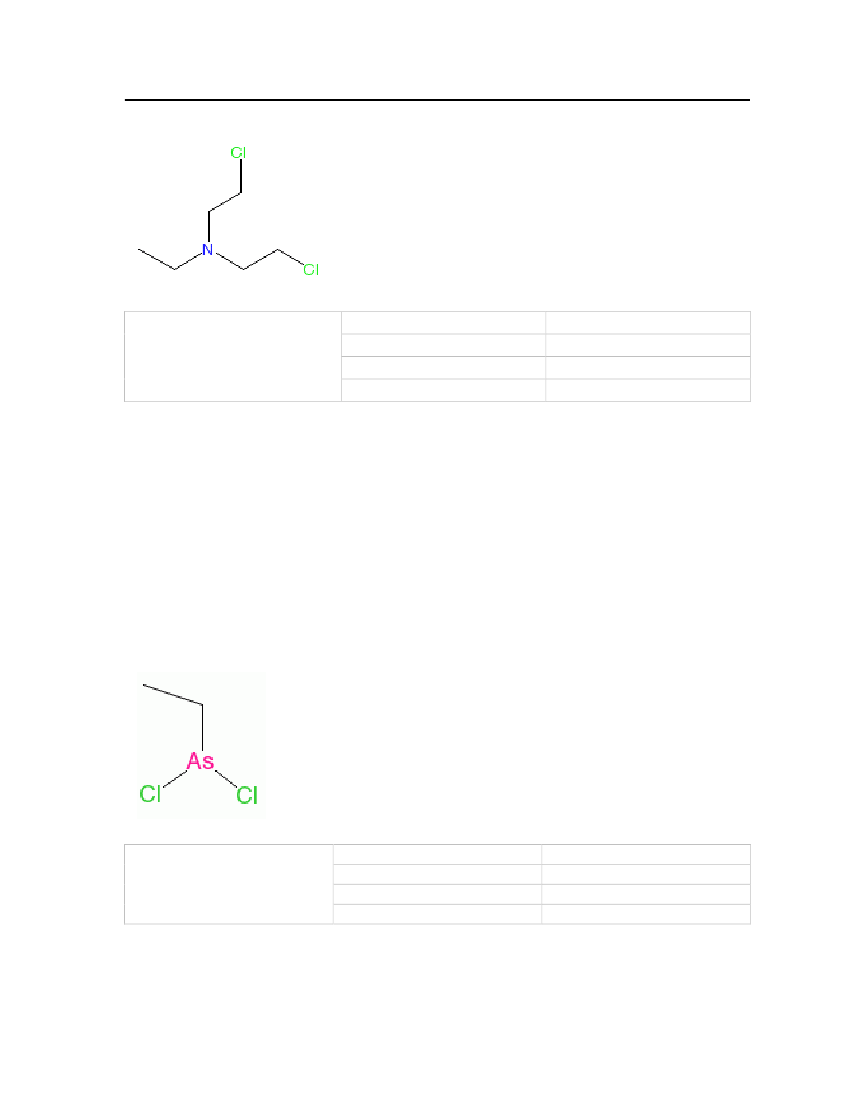

Molecular Structure:

Table 18: Properties of Bis-(2-chloroethyl) ethylamine

Bis-(2-chloroethyl) ethylamine OdorMolecular WeightFreezing/Melting PointNormal Boiling Point

Faint, fishy, or musty170.08-34oC194oC

It is considered that this comparatively large molecule with a high boiling point would not bea suitable deterrent additive to butane.7.3.15 EthyldichloroarsineTable 19 shows the physical and chemical properties of ethyldichloroarsine and it is a liquidwith a fruity but biting and irritating odor. It is selected due to its biting and irritating odor. Itis easily soluble in alcohol and acetone. Arsine-containing agents irritate the eyes and theliquid may produce severe eye injury.Molecular Structure:

Table 19: Properties of Ethyl dichloroarsine

Ethyldichloroarsine

OdorMolecular WeightMelting PointNormal Boiling Point

Fruity but biting and irritating174.88 kg/kmolLess than -65oC156oC

29

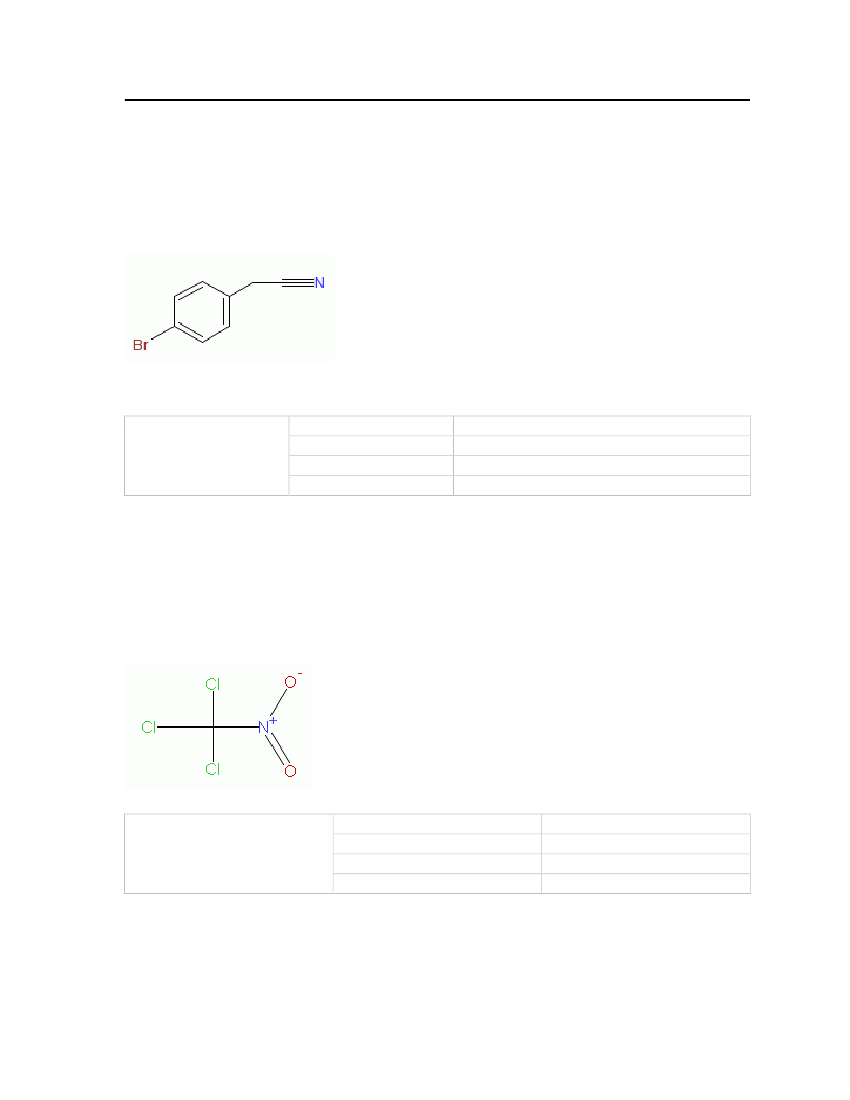

7.3.16 BromobenzylcyanideBromobenzylcyanide was the first tearing agent used and it produces irritation and tearing ofthe eyes with pain in the forehead. It is mainly considered based on the fact that it is anirritant. The physical and chemical properties are shown in Table 20.Molecular Structure:

Table 20: Properties of Bromobenzylvyanide

Ethyldichloroarsine

OdorMolecular WeightMelting PointNormal Boiling Point

Soured or rotting fruit. Irritant, tearing agent196 kg/kmol25.5oC242oC

7.3.17 ChloropicrinChloropicrin is a pungent. Colorless, oily liquid and it was shown in Table 21. It is veryvolatile and a powerful irritant. The vapors cause irritation, coughing and vomiting. It isconsidered based on odor and its solubility in organic solvents.Molecular Structure:

Table 21: Properties of Trichloronitromethane

Chloropicrin

OdorMolecular WeightFreezing/Melting PointNormal Boiling Point

Stinging. Pungent odor164.375 kg/kmol-69oC112oC

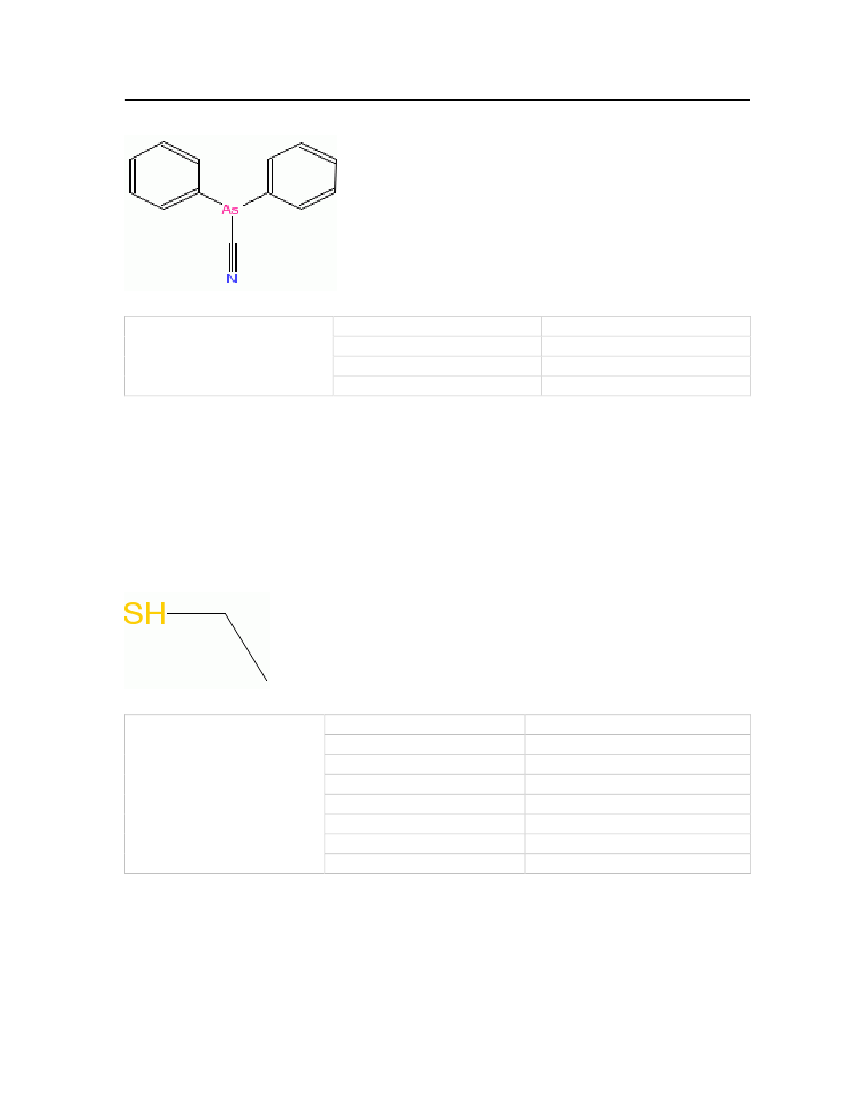

7.3.18 DiphenylcyanoarsineThe properties of diphenylcyanoarsine are shown in Table 22. This compound producesstrong irritation, vomiting and it is selected based on its odor of garlic and bitter almonds.

30

Molecular Structure:

Table 22: Properties of Diphenylcyanoarsine

Diphenylcyanoarsine

OdorMolecular WeightFreezing/Melting PointNormal Boiling Point

Garlic and bitter almonds255.147 kg/kmol-31.5oC350oC

7.3.19 Ethyl mercaptanEthyl mercaptan is a colorless liquid and it has a strong garlic odor. Mercaptans are added tofuel at the refinery and local distribution centers. Addition of mercaptans to petrol increasessulfur levels. It is included here partly because some experimental data for the binary systemethyl mercaptan – butane exists.Molecular Structure:

Table 23: Properties of Ethylmercaptan

Ethylmercaptan

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Garlic odor62.13404 kg/kmol499.15 K54.9 bar0.207 m�/kmol125.26 K308.153 K0.0746133 m�/kmol

31

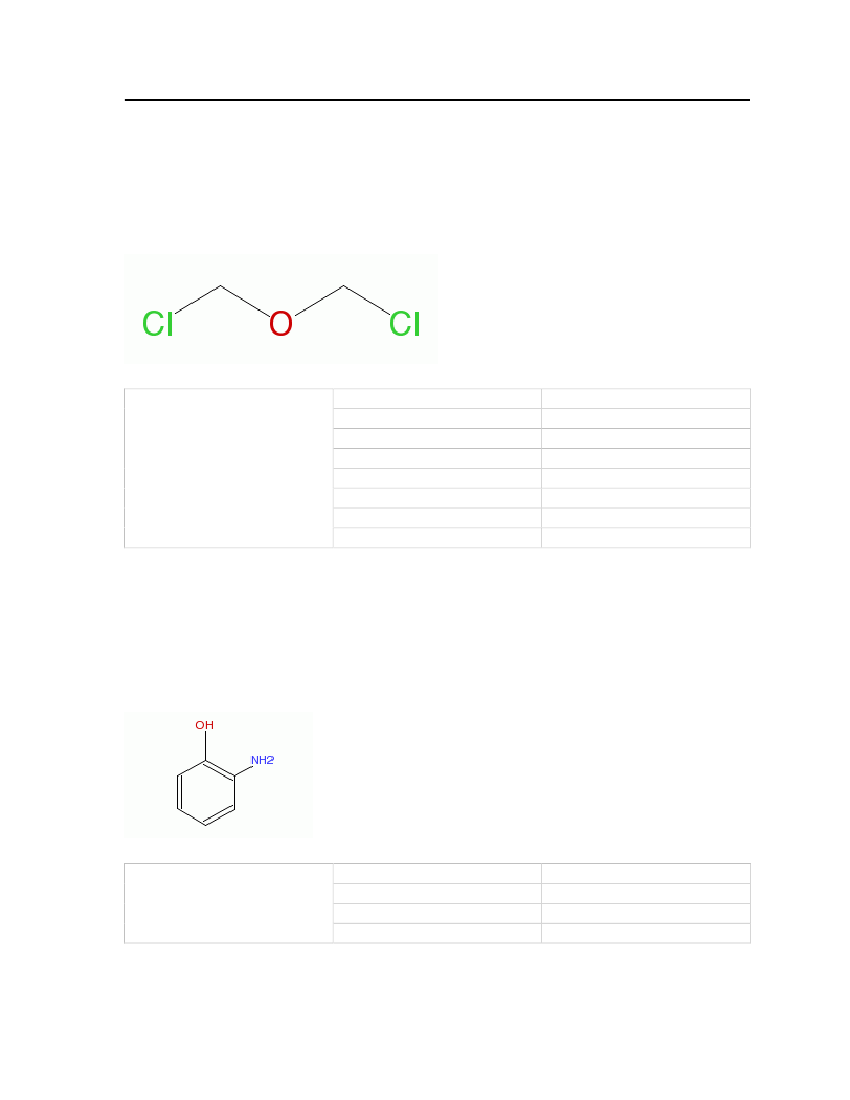

7.3.20 Bis(chloromethyl)etherBis(chloromethyl)ether is a chemical with a strong unpleasant odor. It is clear liquid at roomtemperature, but readily evaporates into air. Table 24 shows the physical and chemicalproperties of Bis(chloromethyl)ether.Molecular Structure:

Table 24: Properties of Bis (chloromethyl) ether

Bis(chloromethyl)ether

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Strong unpleasant odor114.95856 kg/kmol579 K45.8 bar0.258 m�/kmol231.65 K378 K0.0876502 m�/kmol

7.3.21 2-Amino phenol2-Amino phenol is used as an intermediate for azo and sulfur dyes. It is off-white in colorand has a strong irritating odor. This compound is selected based on odor and solubilityproperties. The physical and chemical properties are shown in Table 25.Molecular Structure:

Table 25: Properties of 2-Aminophenol

2-Aminophenol

OdorMolecular WeightMelting PointNormal Boiling Point

Phenol-like (strong irritating)109.13 kg/kmol172oC164oC

32

7.3.22 PropyleneglycolPropyleneglycol is a colorless, viscous and hydroscopic liquid and it is used in anti freezingsolutions, hydraulic fluids, and as a solvent. The physical and chemical properties are shownin Table 26.Molecular Structure:

Table 26: Properties of Propylene glycol

Propyleneglycol

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting PointNormal Boiling PointLiquid Molar Volume

Mildodor76.09442 kg/kmol626 K61 bar0.239 m�/kmol213.15 K460.75 K0.0736939 m�/kmol

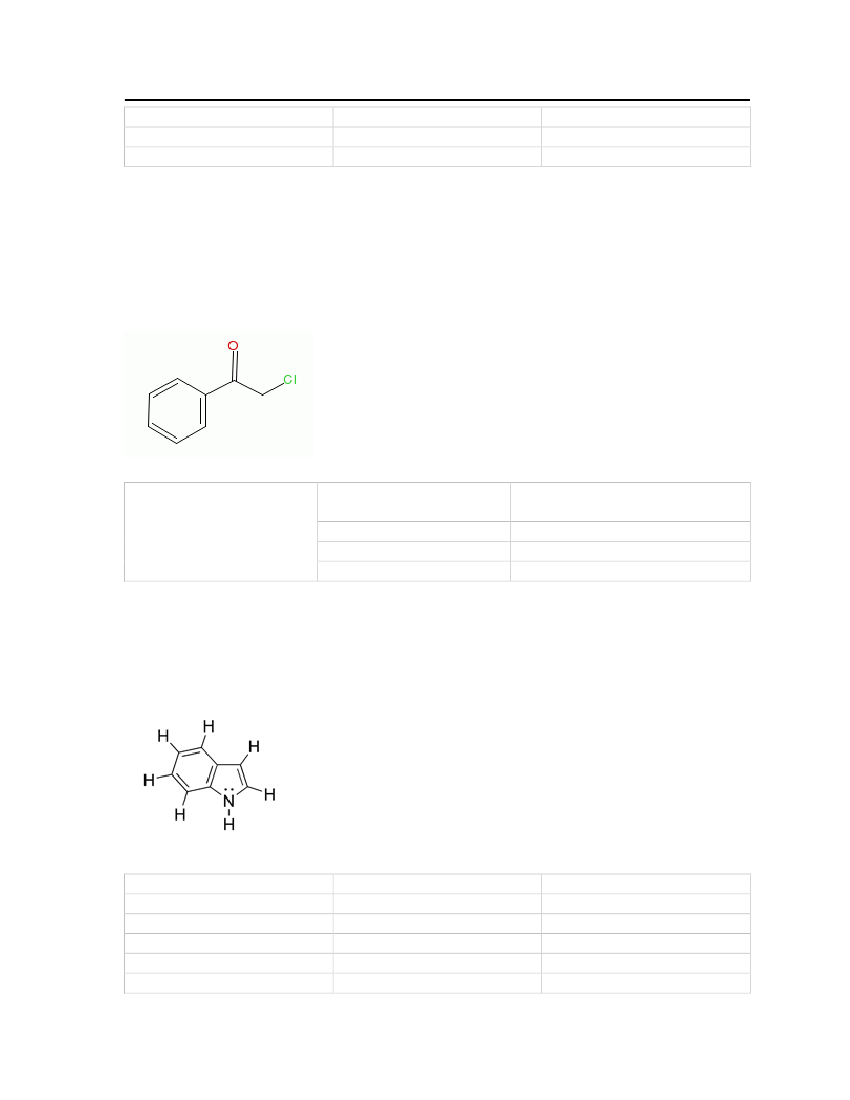

7.3.23 s-Trioxanes-Trioxane is a stable cyclic trimer of formaldehyde with a chloroform odor. It is a colorless,crystalline solid. It is easily soluble in water at room temperature and the physical andchemical properties are shown in Table 27.Molecular Structure:

Table 27: Properties of s-Trioxane

s-Trioxane

OdorMolecular WeightCritical TemperatureCritical PressureCritical Volume

Irritating odor90.07794 kg/kmol604 K58.2 bar0.224 m�/kmol

33

Melting PointNormal Boiling PointLiquid Molar Volume7.3.24 2-Chloroacetophenone

334.65 K387.65 K0.0766816 m�/kmol

Chloroacetophenone has is easily soluble in organic solvents. In higher concentrations itcauses a tingling sensation, irritation, burning and pain of the nose and throat. Is used in teargas and chemical mace. The physical and chemical properties are shown in Table 28.Molecular Structure:

Table 28: Properties of Chloroacetophenone

ChloroacetophenoneOdorMolecular WeightMelting PointNormal Boiling Point

Fragrant: similar to apple blossoms.Irritant to nose and throat154.59 kg/kmol54oC248oC

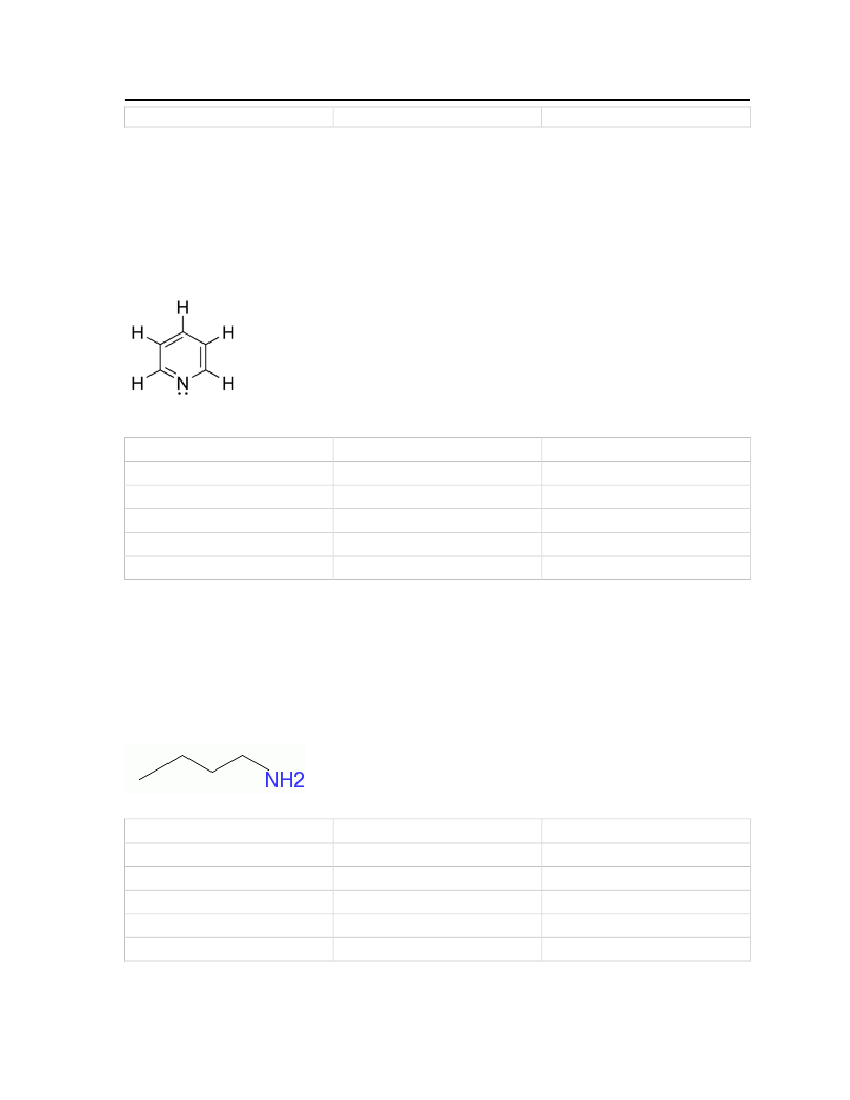

7.3.25 IndoleIndole is colorless and has an unpleasant odor. It occurs naturally in human feces and has anintense fecal odor. The physical and chemical properties are shown in Table 28.Molecular Structure:

Table 29: Properties of Indole

Indole

OdorMolecular WeightCritical TemperatureCritical PressureCritical VolumeMelting Point

Unpleasant (strong)117,14788 kg/kmol790 K43 bar0,431 m�/kmol326,15 K

34

Normal Boiling Point7.3.26 Pyridine

526,15 K

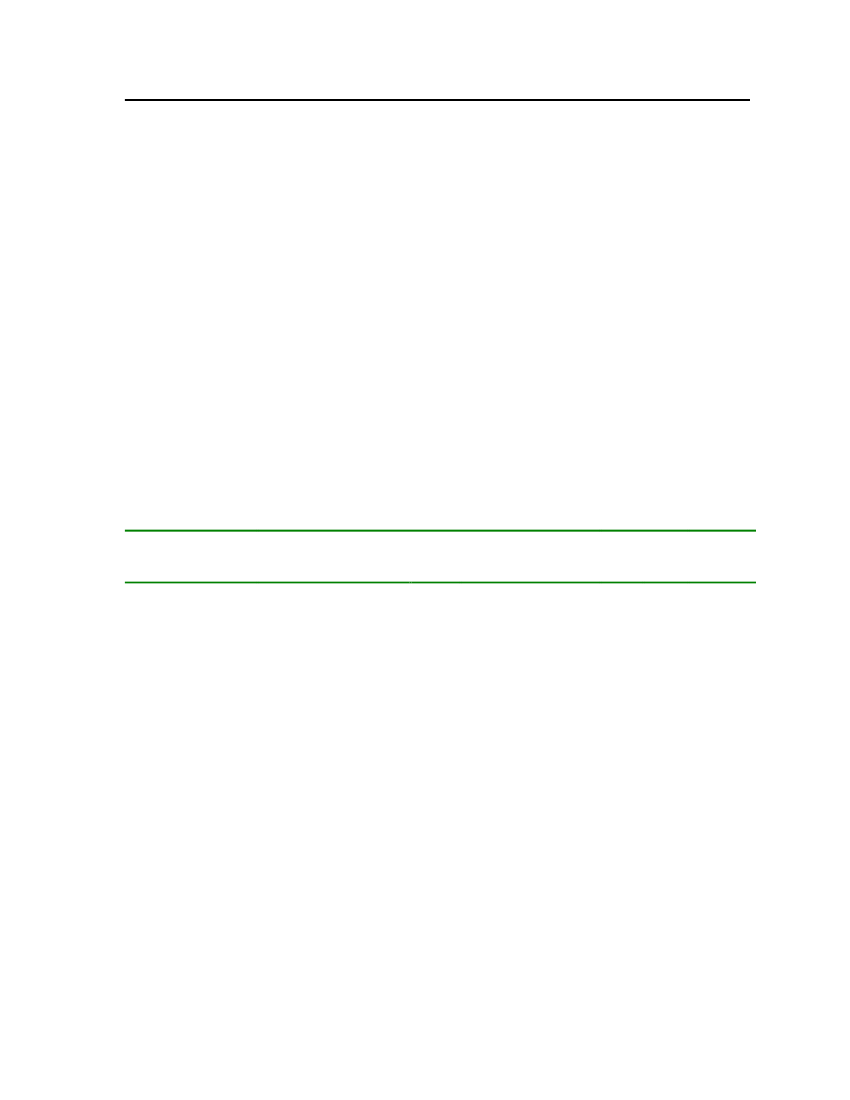

Pyridine is a liquid with a fish-like odor. It is used as intermediate in making dyes, foodflavorings, pharmaceuticals, rubber chemicals and adhesives. The physical and chemicalproperties are shown in Table 30.Molecular Structure:

Table 30: Properties of Pyridine

Pyridine

OdorMolecular WeightCritical TemperatureCritical PressureMelting PointNormal Boiling Point

Characteristic fish like smell79.0999 kg/kmol619.95 K56.3 bar231.53 K388.41 K

7.3.27n-ButylamineButylamine is a liquid having a fishy, ammonia-like odor common to amines. It is used as aningredient in the manufacture of pesticides, pharmaceuticals, and emulsifiers. The physicaland chemical properties are shown in Table 31.Molecular Structure:

Table 31: Properties of butylamine

Butylamine

OdorMolecular WeightCritical TemperatureCritical PressureMelting PointNormal Boiling Point

Characteristic fish like smell73.13684 kg/kmol531.9 K42 bar224.05 K350.55 K

35

7.4

Estimation of pure compound parameters (CPA equation of state)

The CPA equation of state has up to five adjustable pure compound parameters. The fiveparameters for pure associating compounds are, three for the physical part,a0,C1andb; andtwo for the association part - association energy (εAB) and association volume(βAB).These parameters are determined by regression of saturated vapor pressures and liquiddensity data over a wide temperature range, usually ranging from (close to) the triple point to(close to) critical point. The vapor pressure and liquid density of pure compounds are takenfrom the DIPPR database (which is a collection of experimental data). However, only 17 outof 27 malodorants are available in the DIPPR database. CPA parameters for these 17compounds are shown in table 32. Of these, 9 are considered to be associating. Mostassociating compounds are considered to have two association sites (known as the 2Bscheme) but some, such as water are considered to have 4 associating sites. Of the substancesconsidered in this study, only propylene glycol has 4 associating sitesTable 32: CPA Parameters for the compounds involved in this studyCPA ParametersRMSPEABABCompounda0bc1εβ*1000 ERR. P ERR. D Association6-23-13-1[bar cm mol ] [cm mol ][bar cm mol ]SchemeTriethylamineButylaminePyridineIsobutyraldehydeEthylmercaptan195025311683228118845285168903669330709115.9584.0971.5876.9759.11139.0658.9968.4141.4197.2977.976.7767.6787.7498.38101.8265.420.78212 131495.60.75803 117612.30.77061 133372.10.91279 109697.90.58262 112655.50.87691 -0.70002 -0.75793 -0.76412 -0.92138 215043.20.58312 1223420.88853 -0.74271 197598.10.86376 -0.8447 -0.9411 -0.87733 110119.177.2426 0.0018 0.0059 2B33.8039 0.0014 0.0049 2B0.69330 0.0012 0.0059 2B0.509004 0.0028 0.0069 2B97.924----0.0013 0.0042B

2,2,4 Trimethylpentane32142567DimethylsulfideSulfurylchlorideCyanogenchloride1-PentanolTetrahydrothiophene127184421597221584380402317912118801411

0.0052 0.0111 -0.0088 0.0131 -0.020.06--

0.0236 0.009

2.64607 0.0008 0.0081 2B46.51-11.953---2.0480.0005 0.0042 2B0.0076 0.0078 -0.0261 0.0186 4C0.0059 0.0059 -0.0167 0.021-

Bis(chloromethyl)ether19260947Propyleneglycol2-MethylpyridineNitrobenzeneIndoles-Trioxane1379820623246503326054403561413716960394

0.0108 0.0094 -0.0031 0.0059 2B

36

n-ButanePropaneIsobutane

13447507915469512935743

74.6458.6975.1

0.72748 -0.66653 -0.71322 -

---

0.0027 0.0111 -0.003 0.0131 -0.0083 0.0173 -

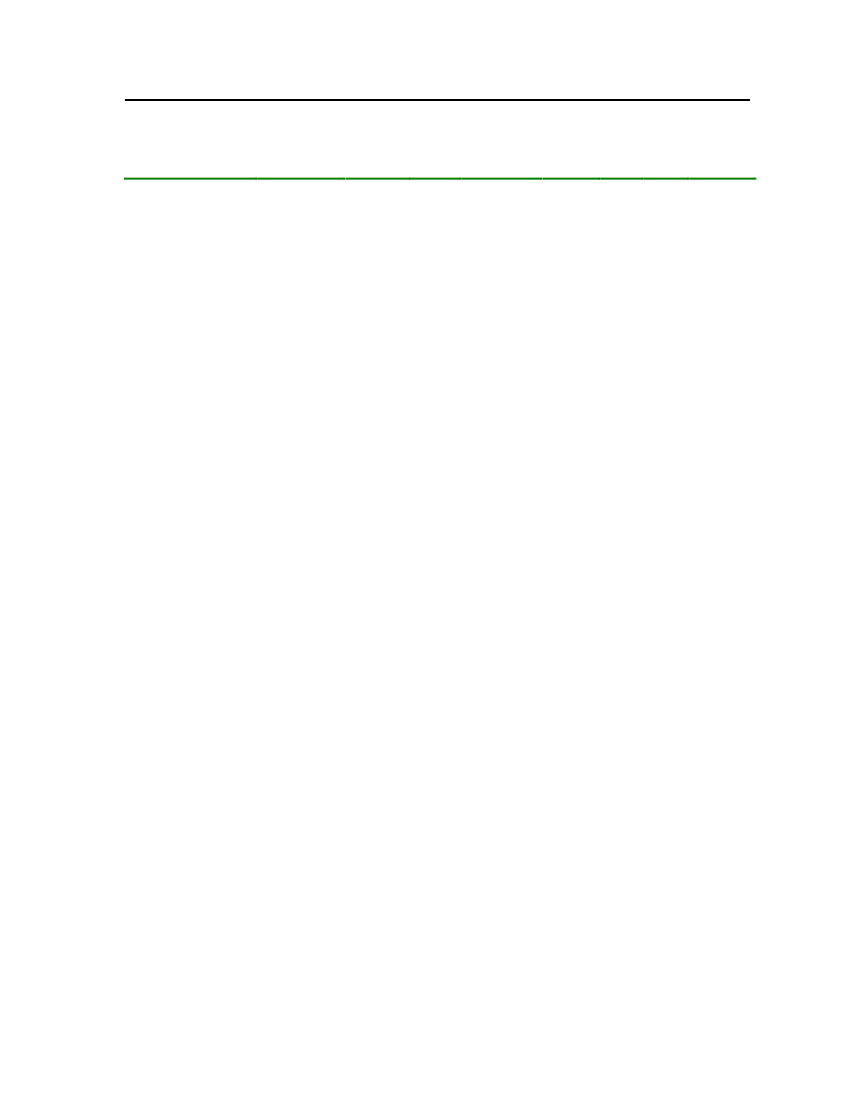

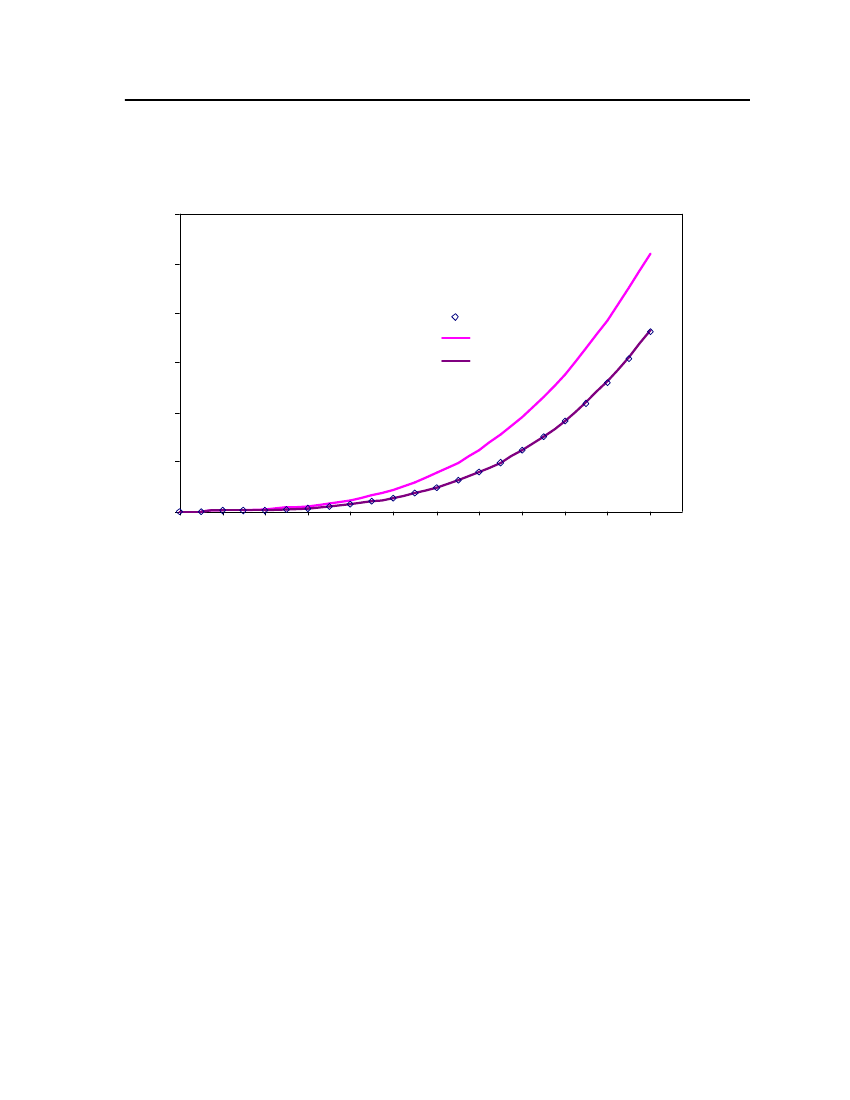

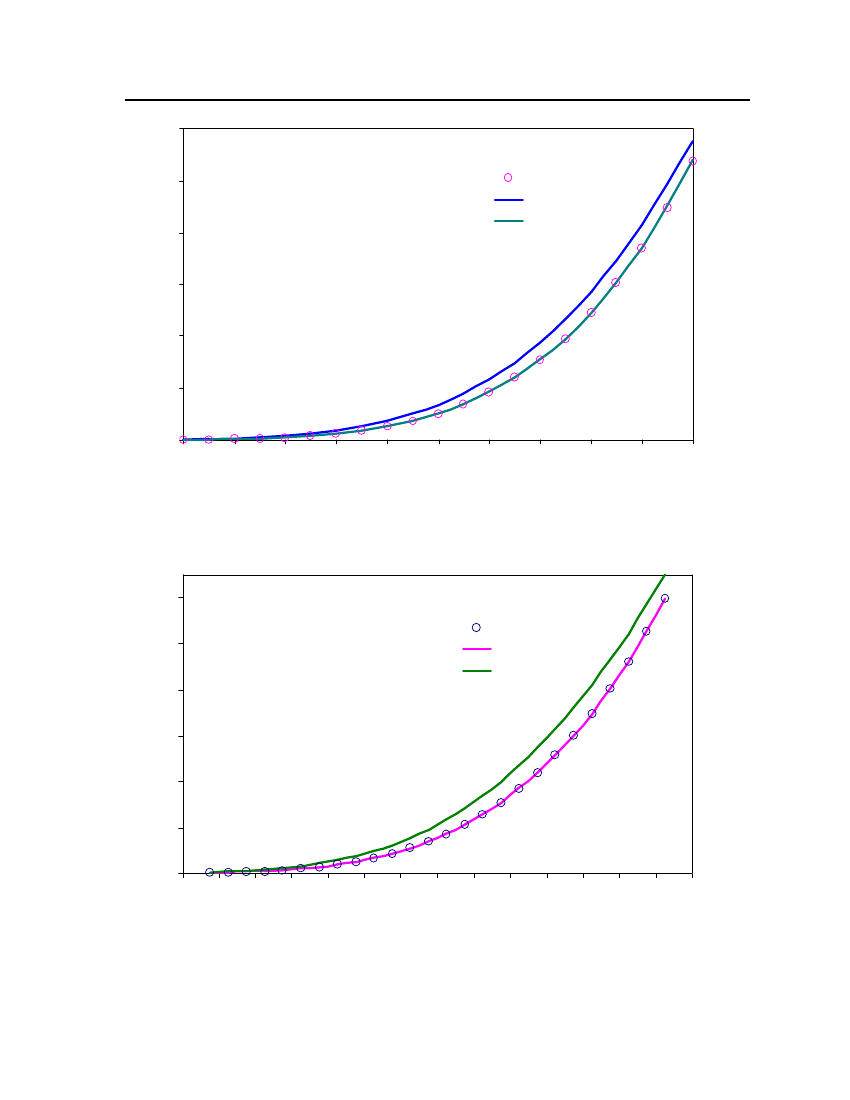

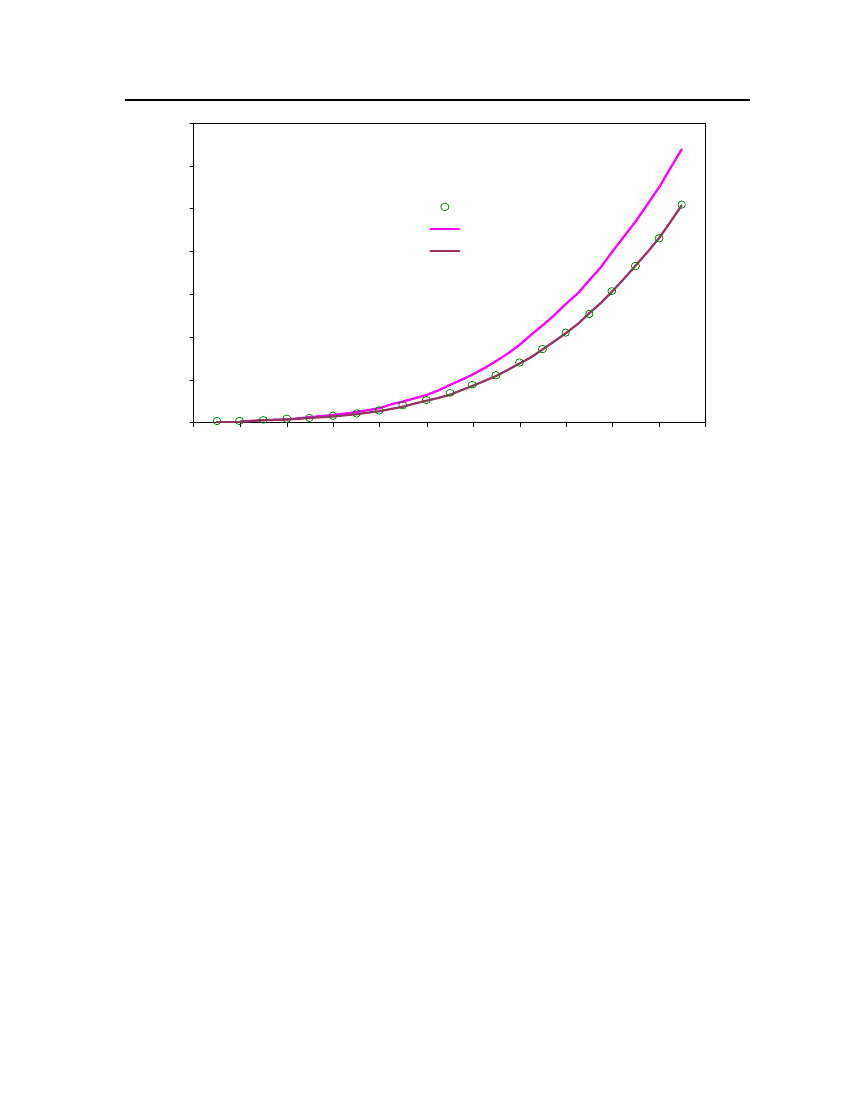

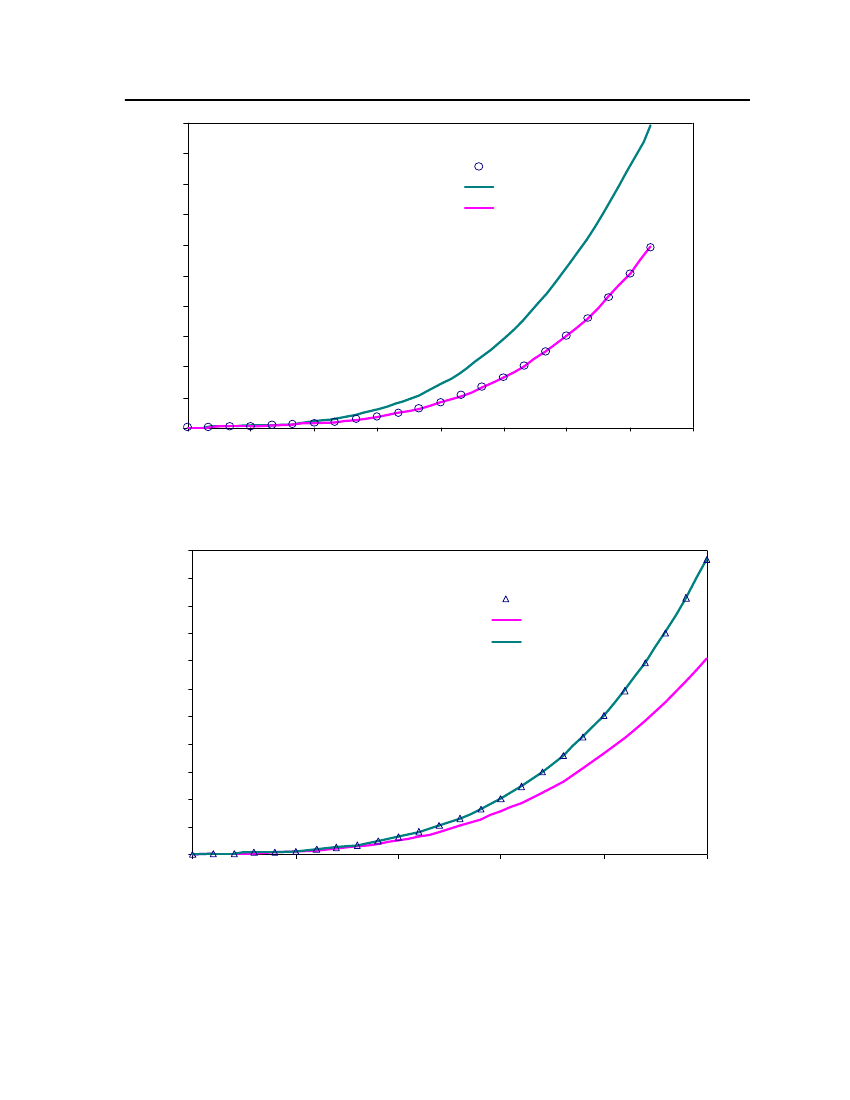

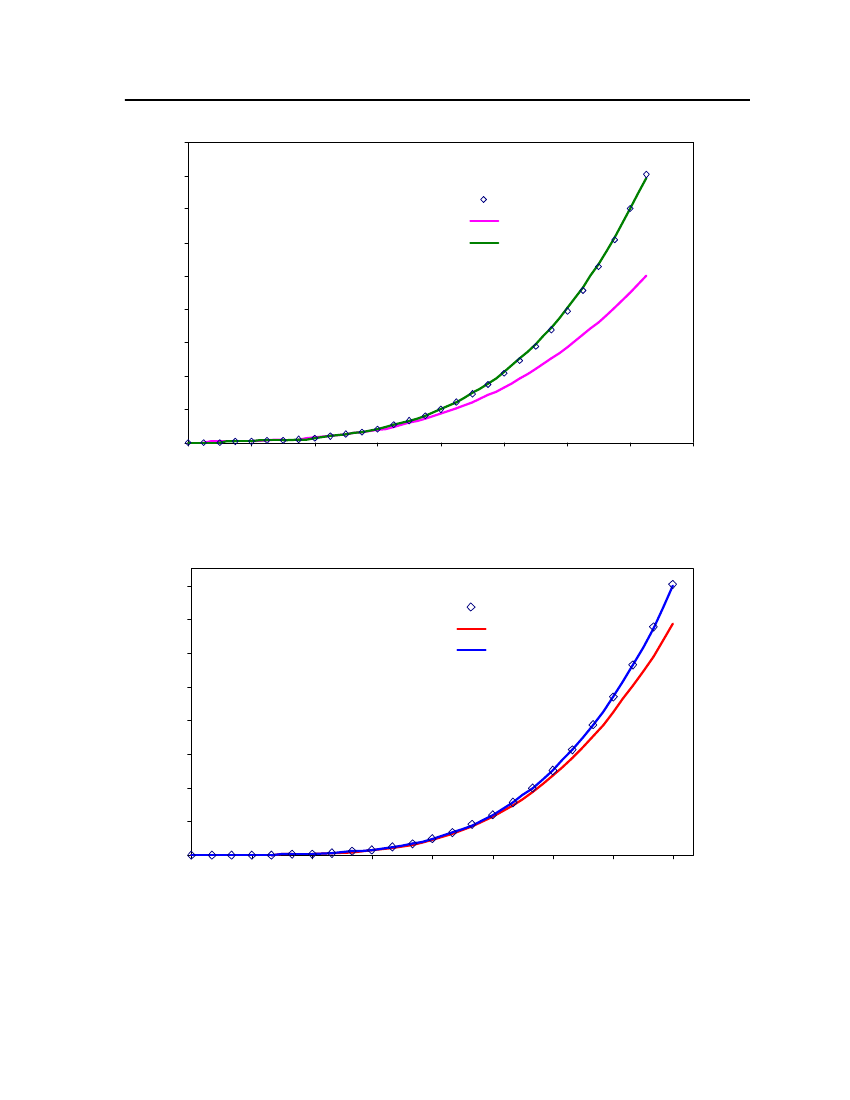

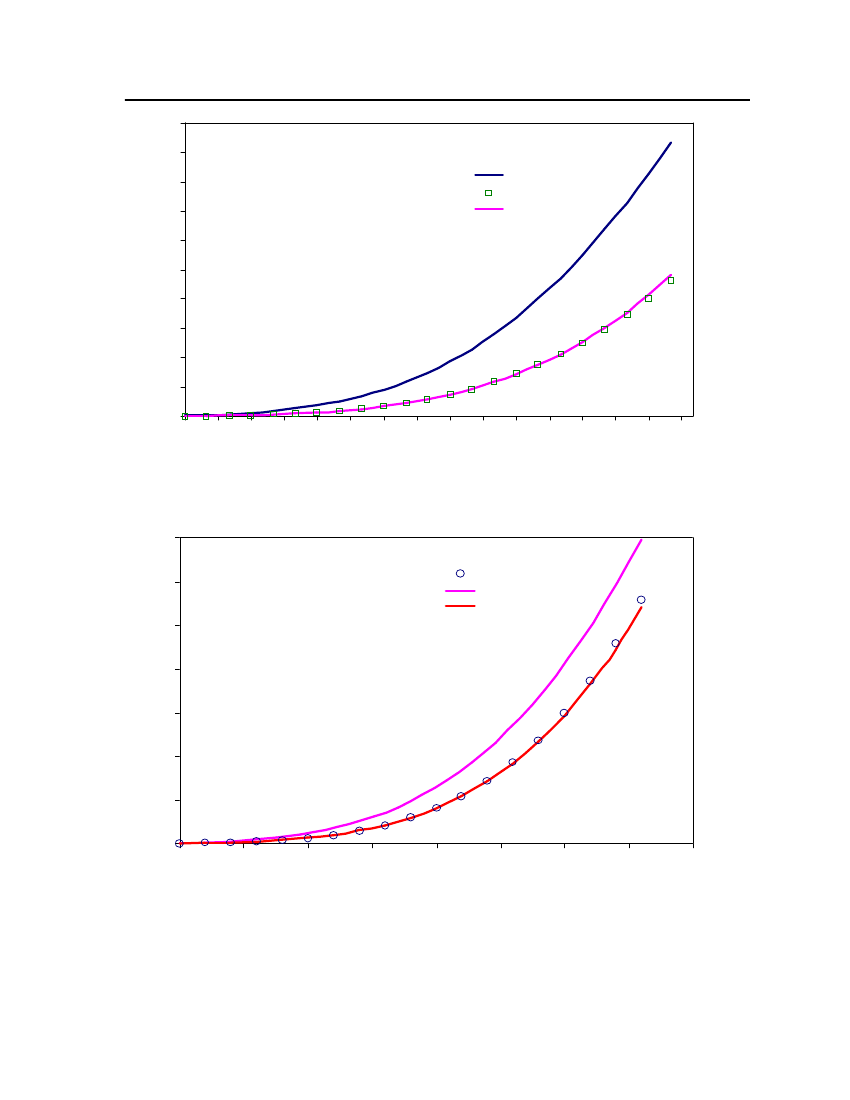

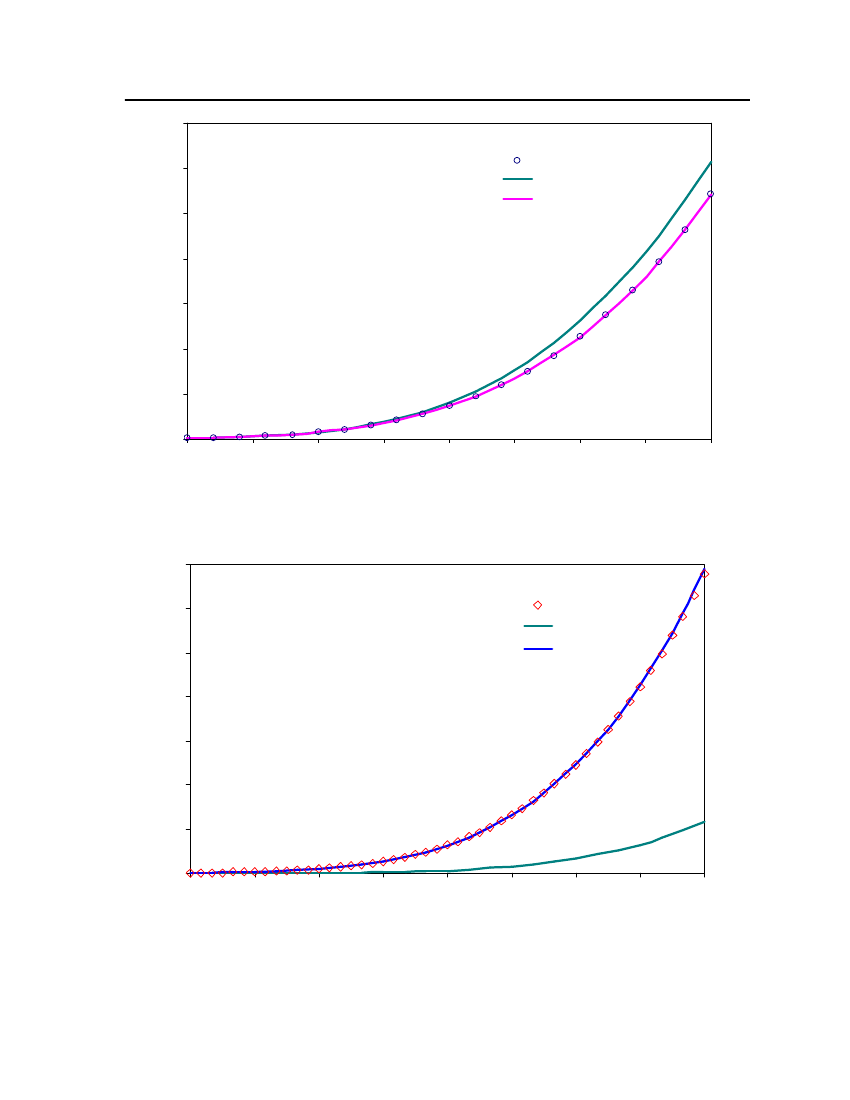

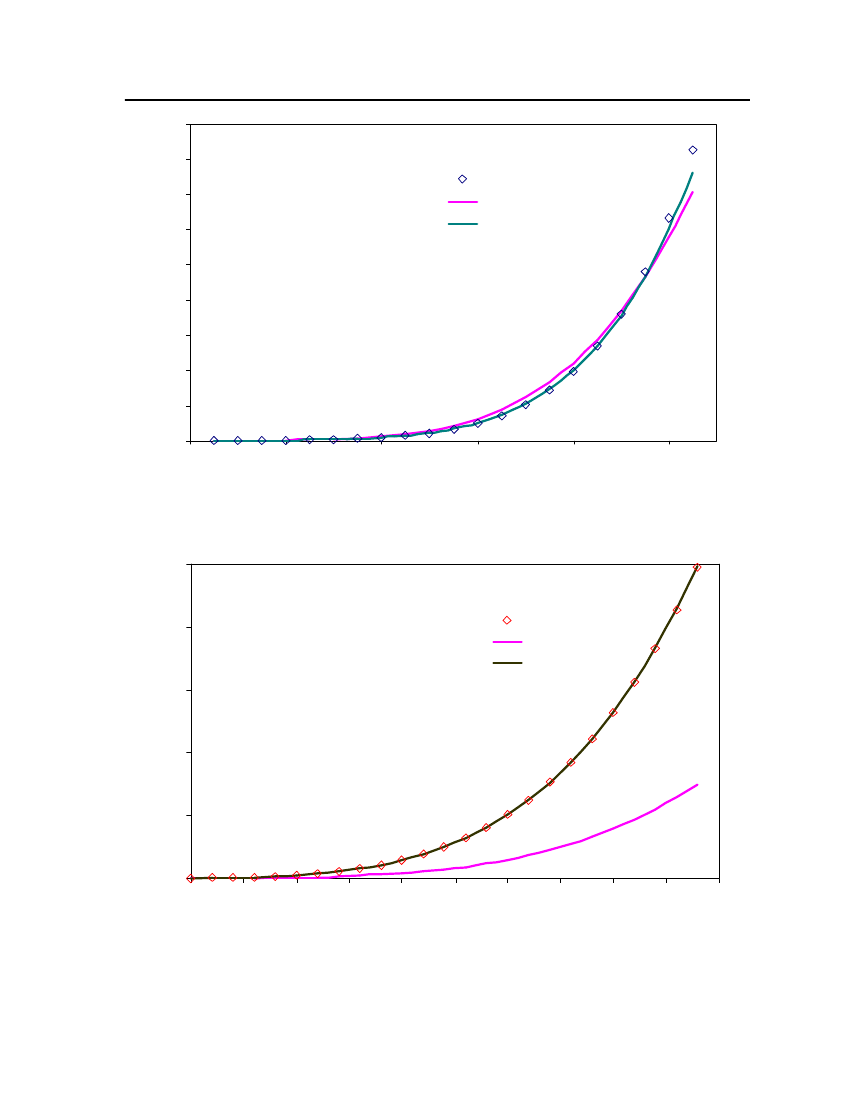

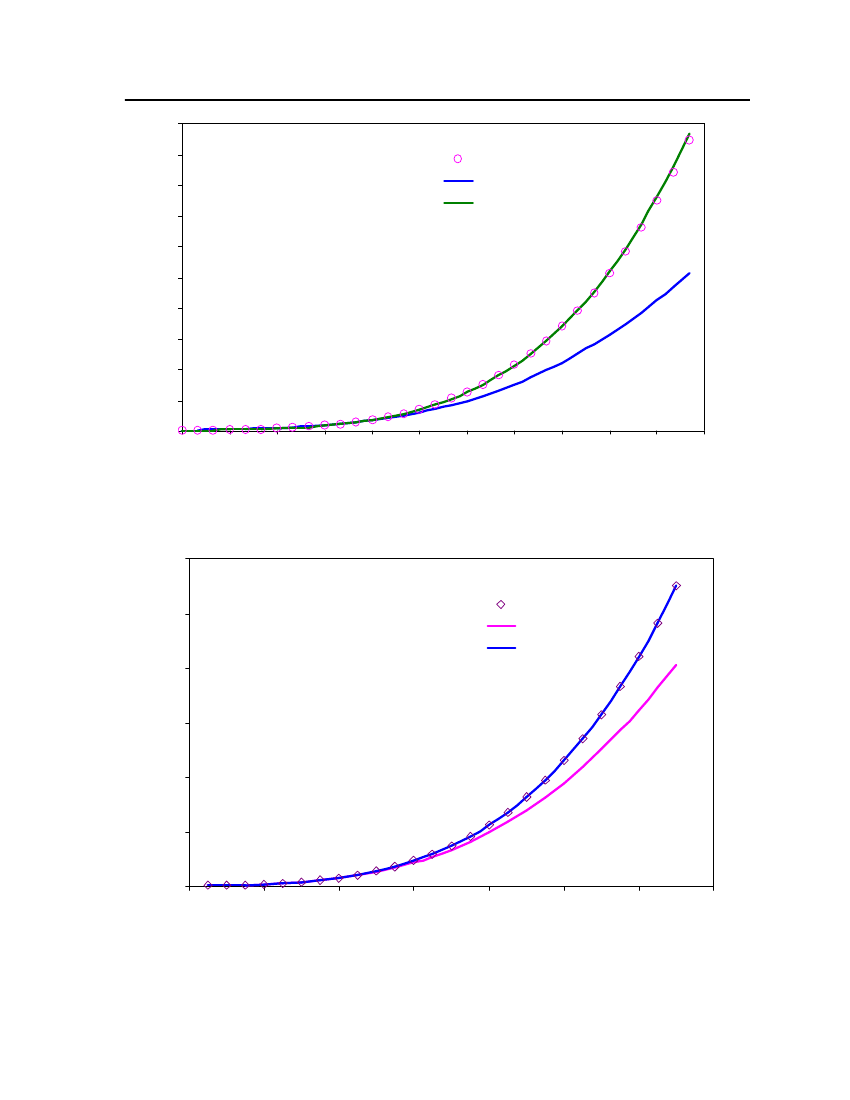

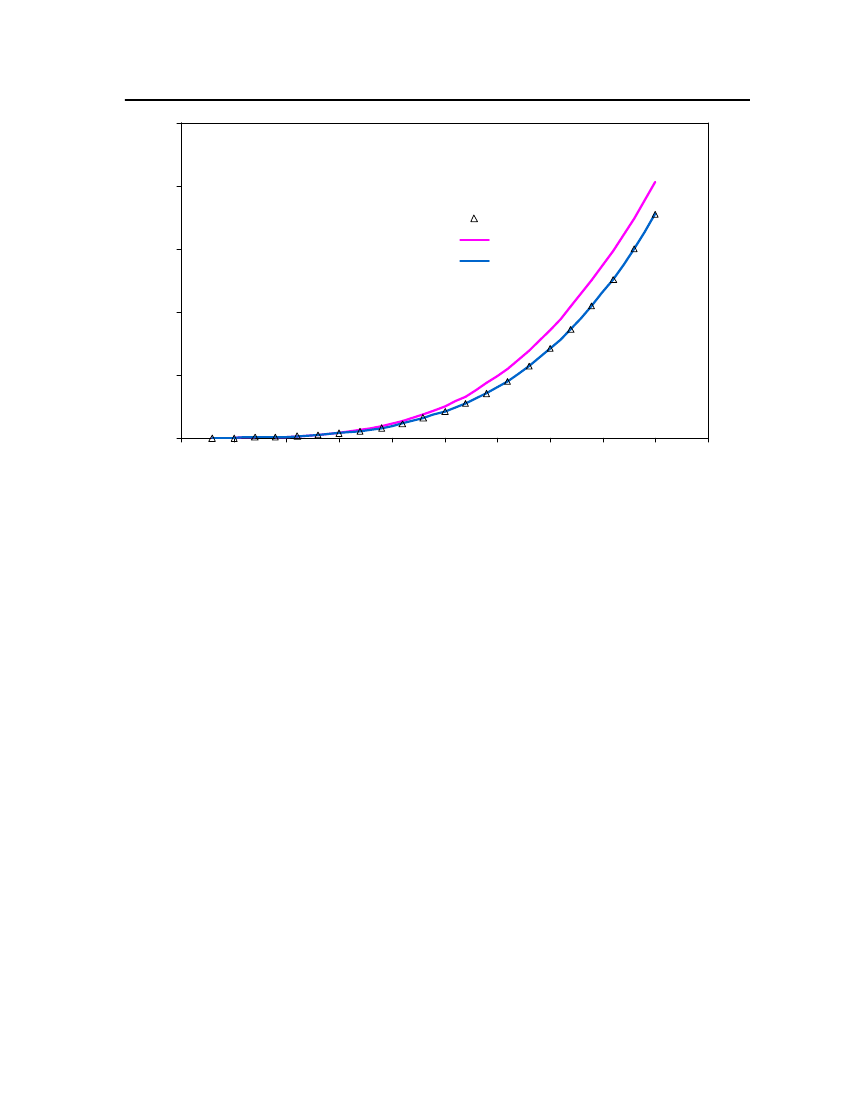

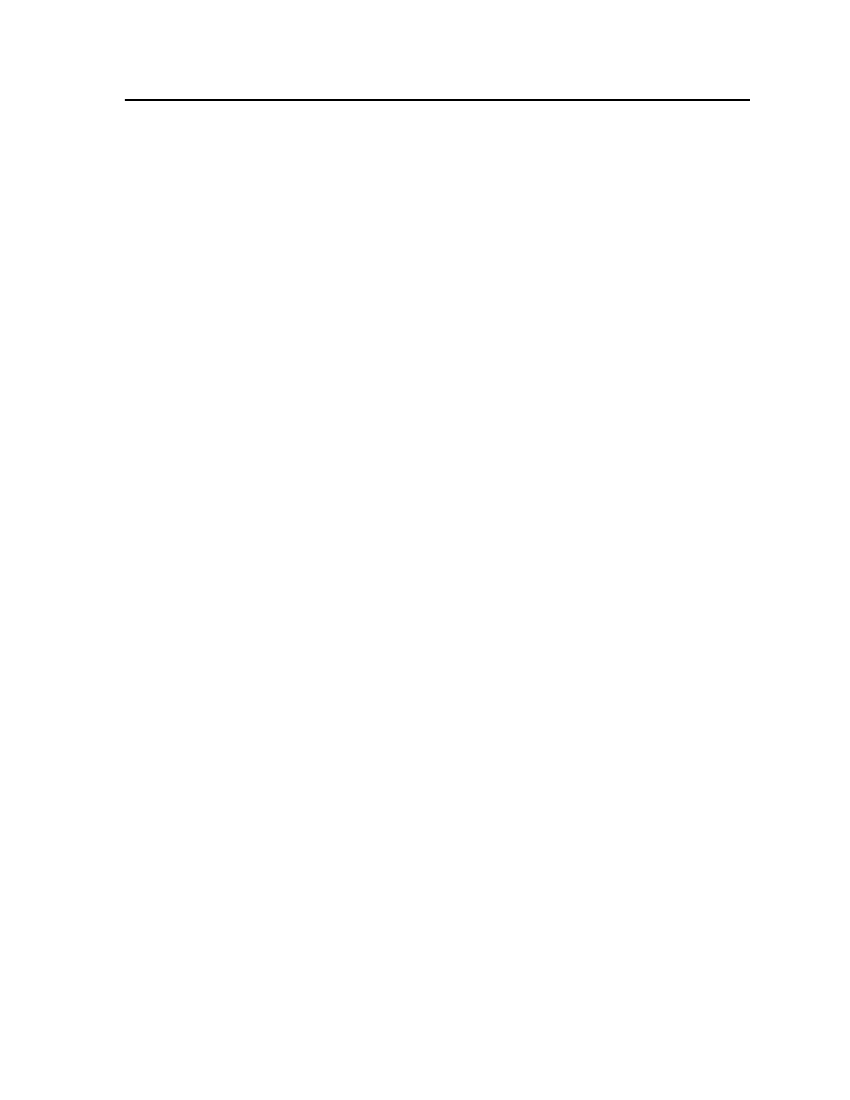

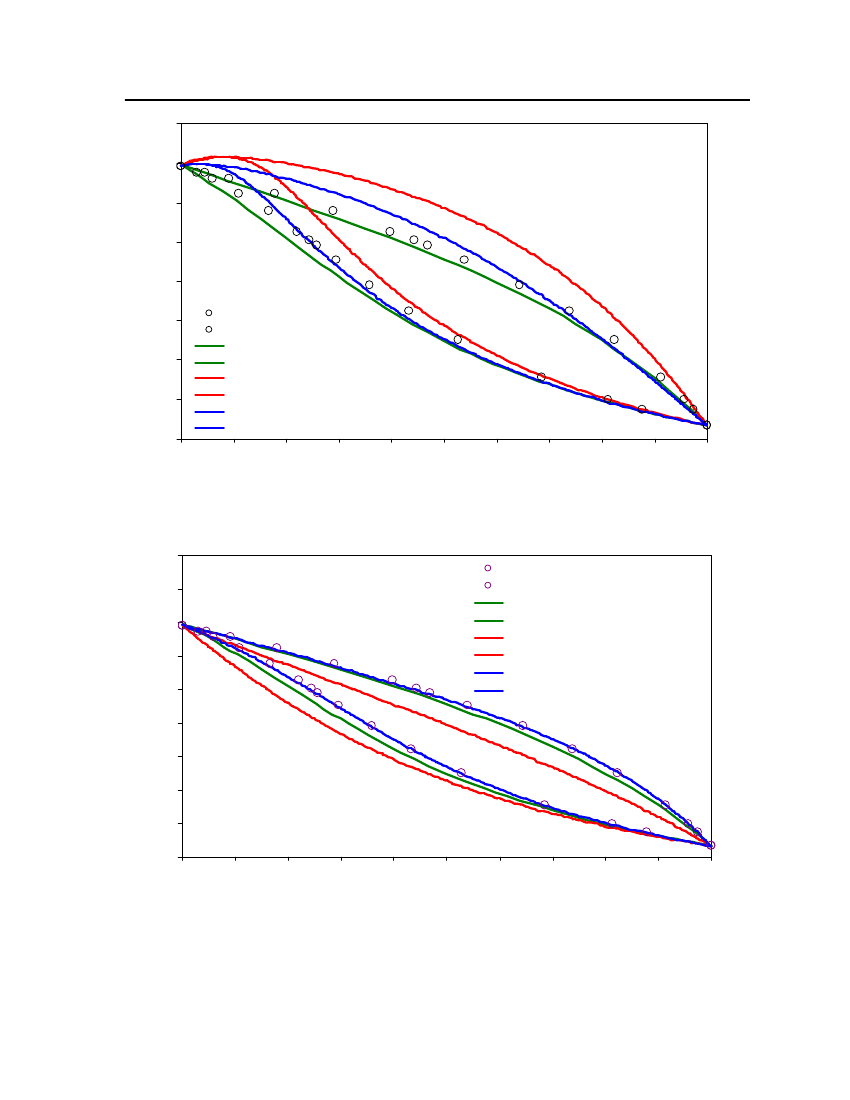

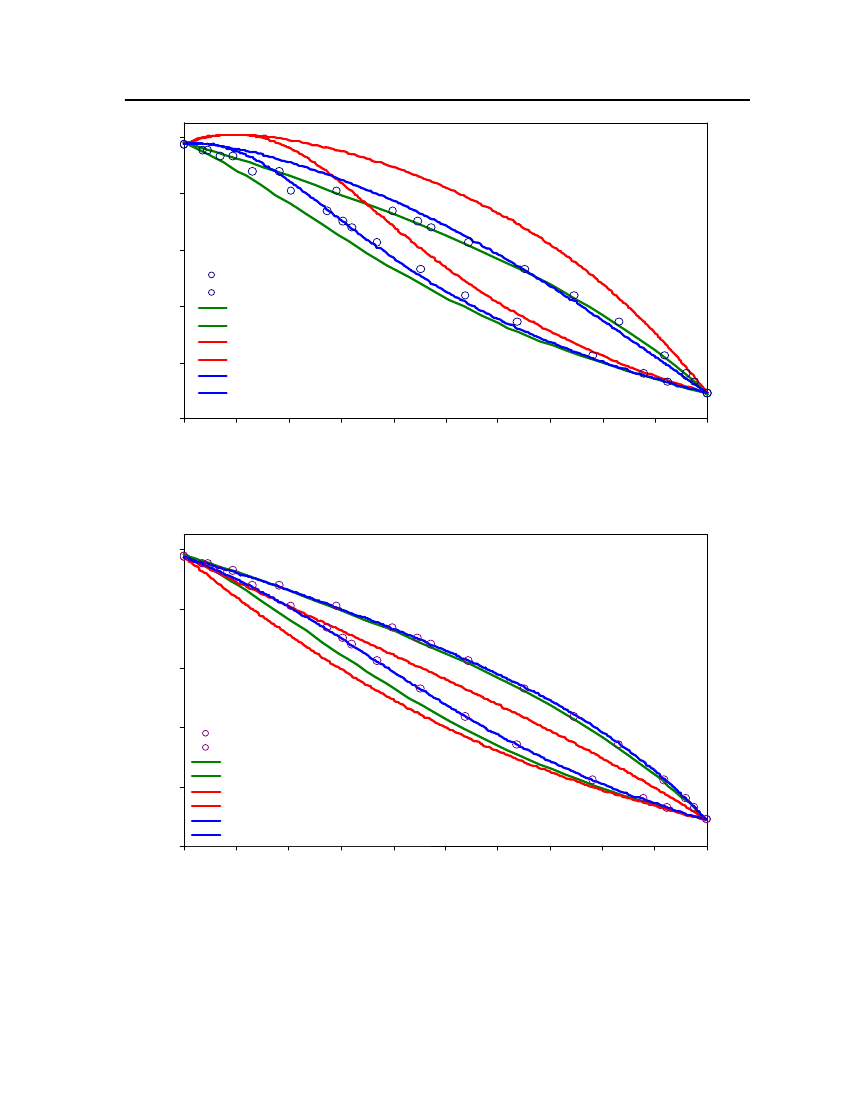

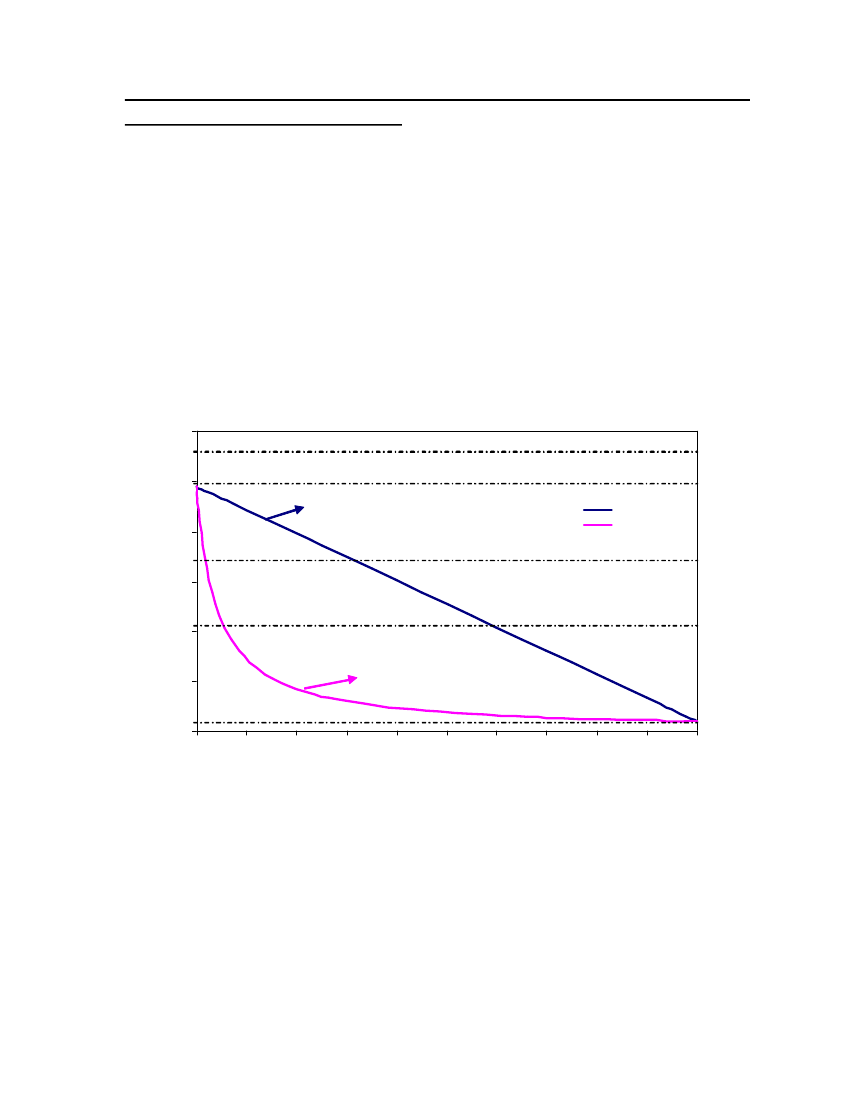

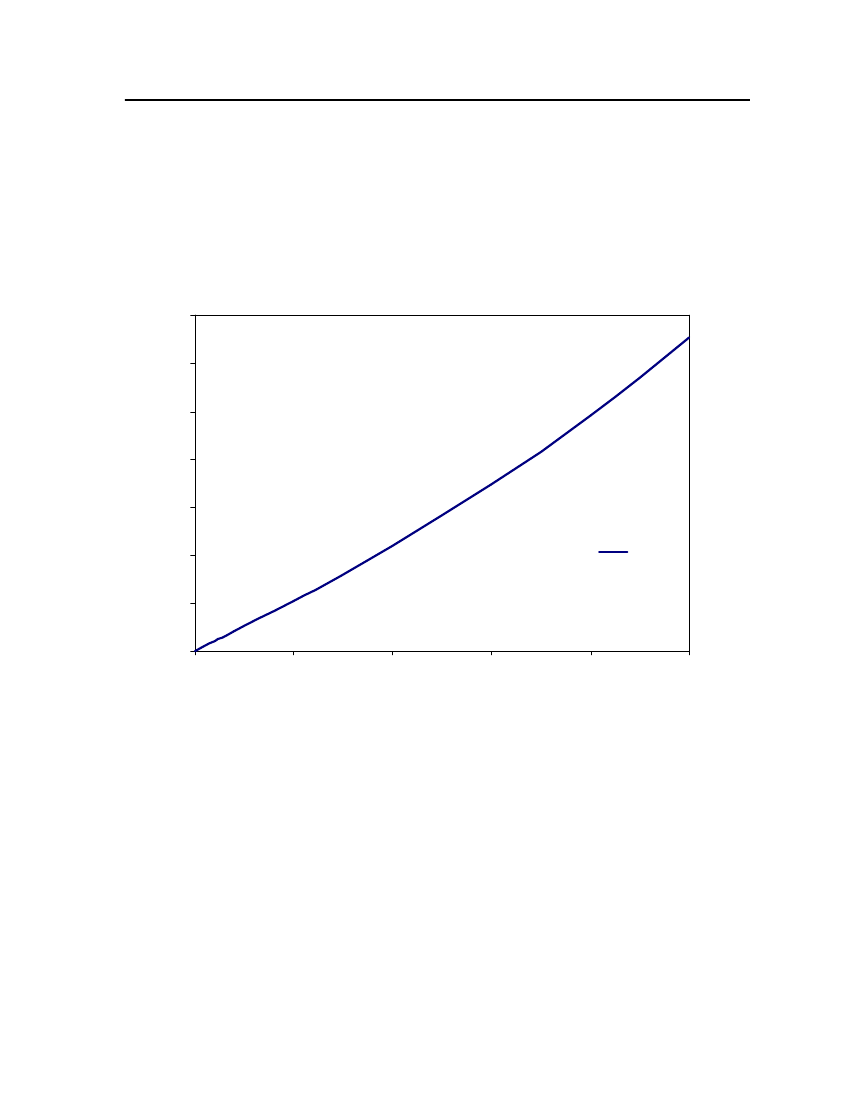

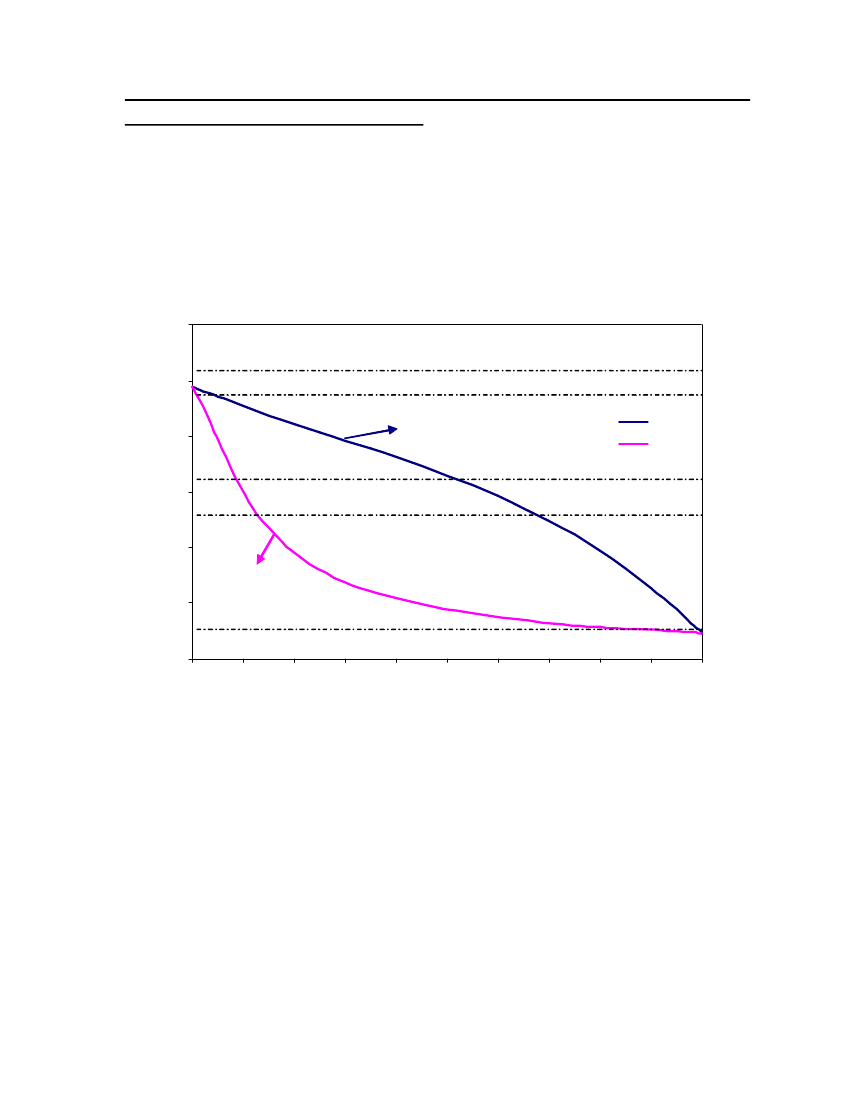

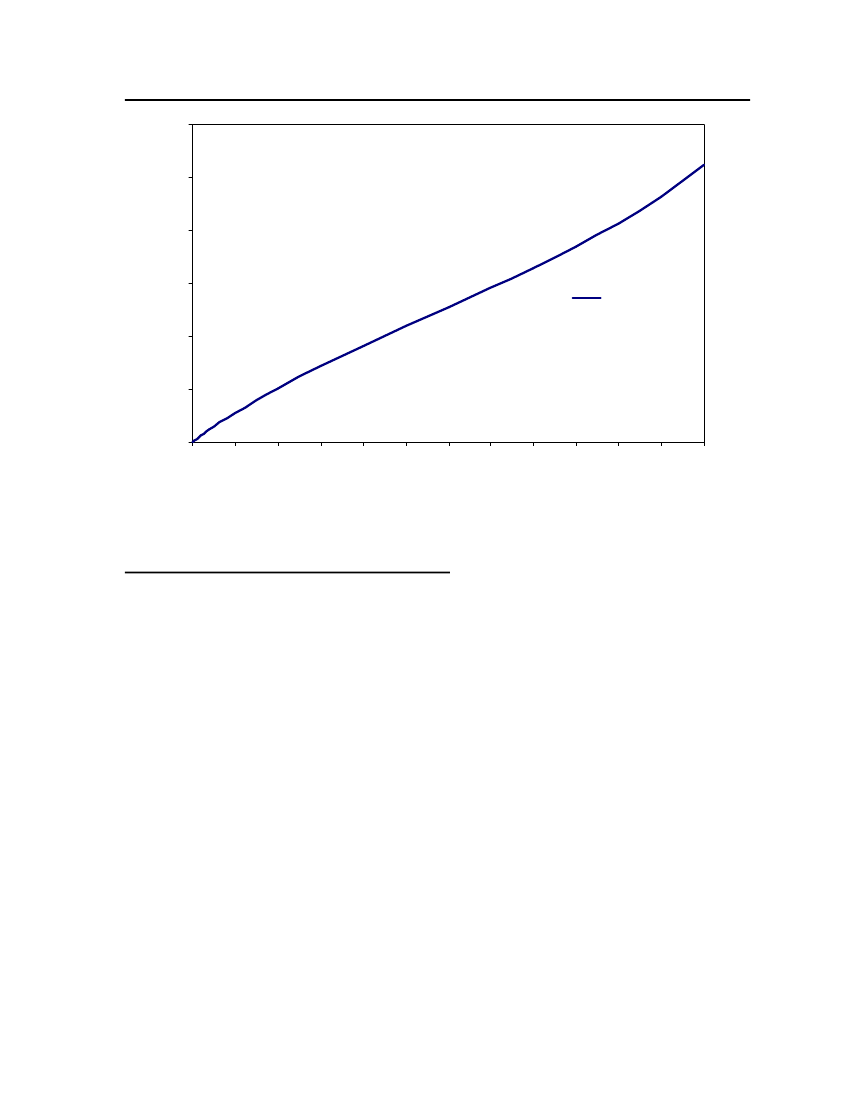

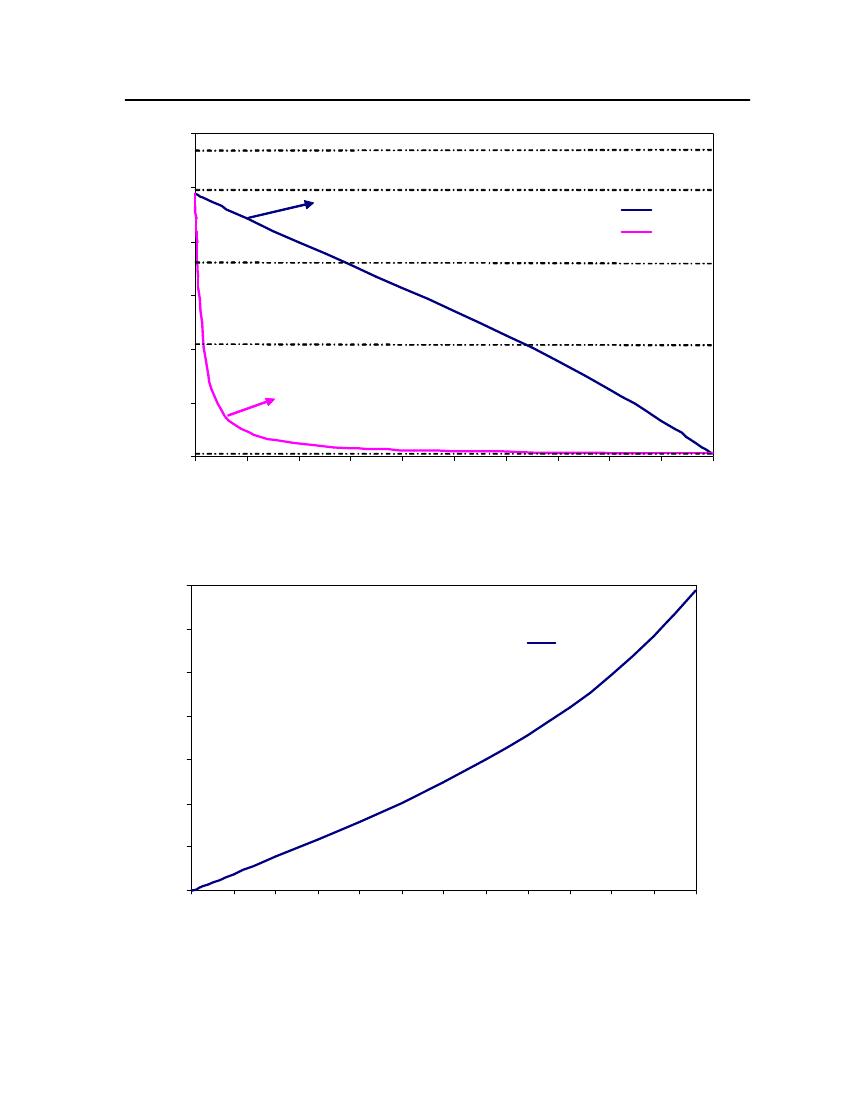

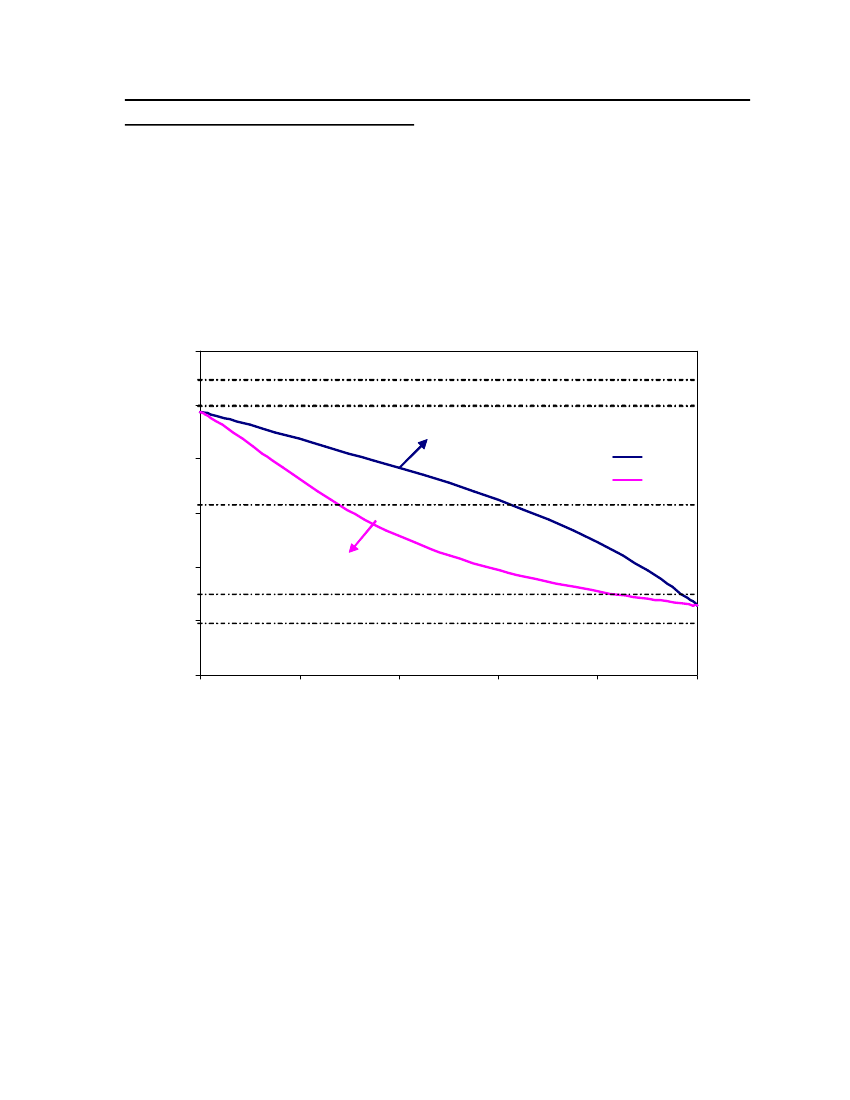

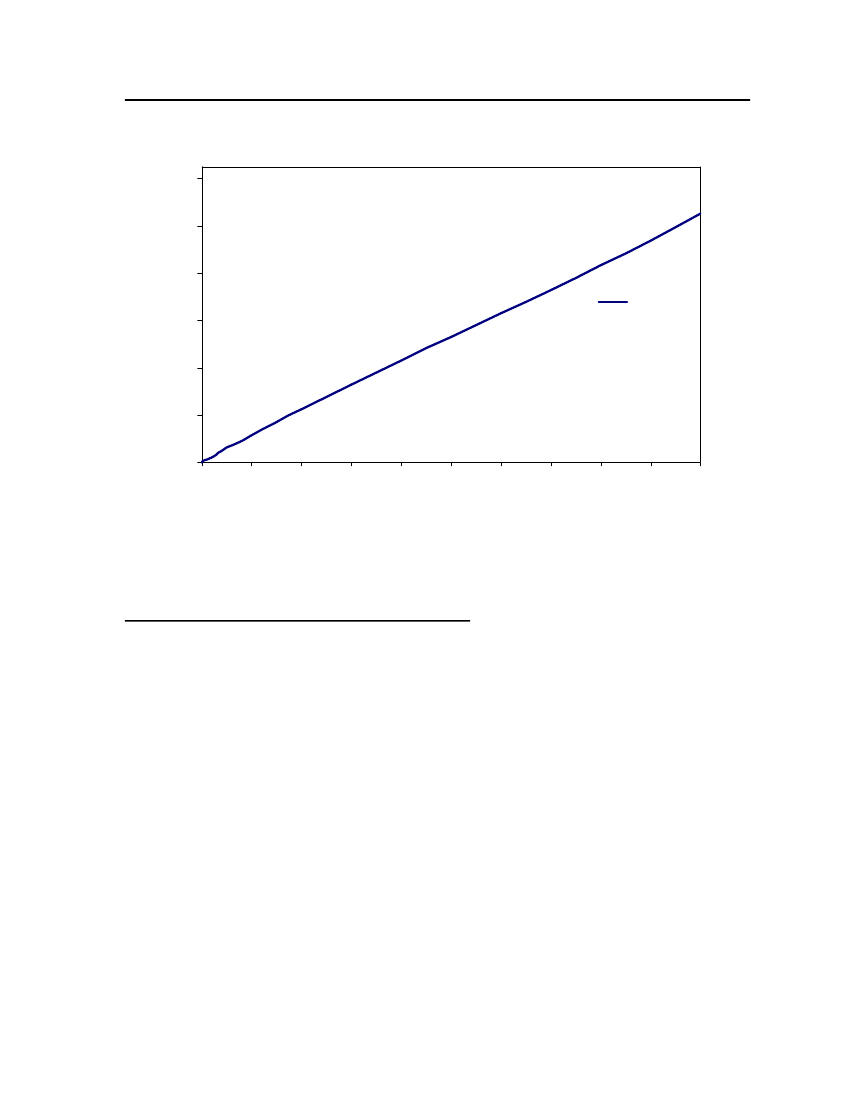

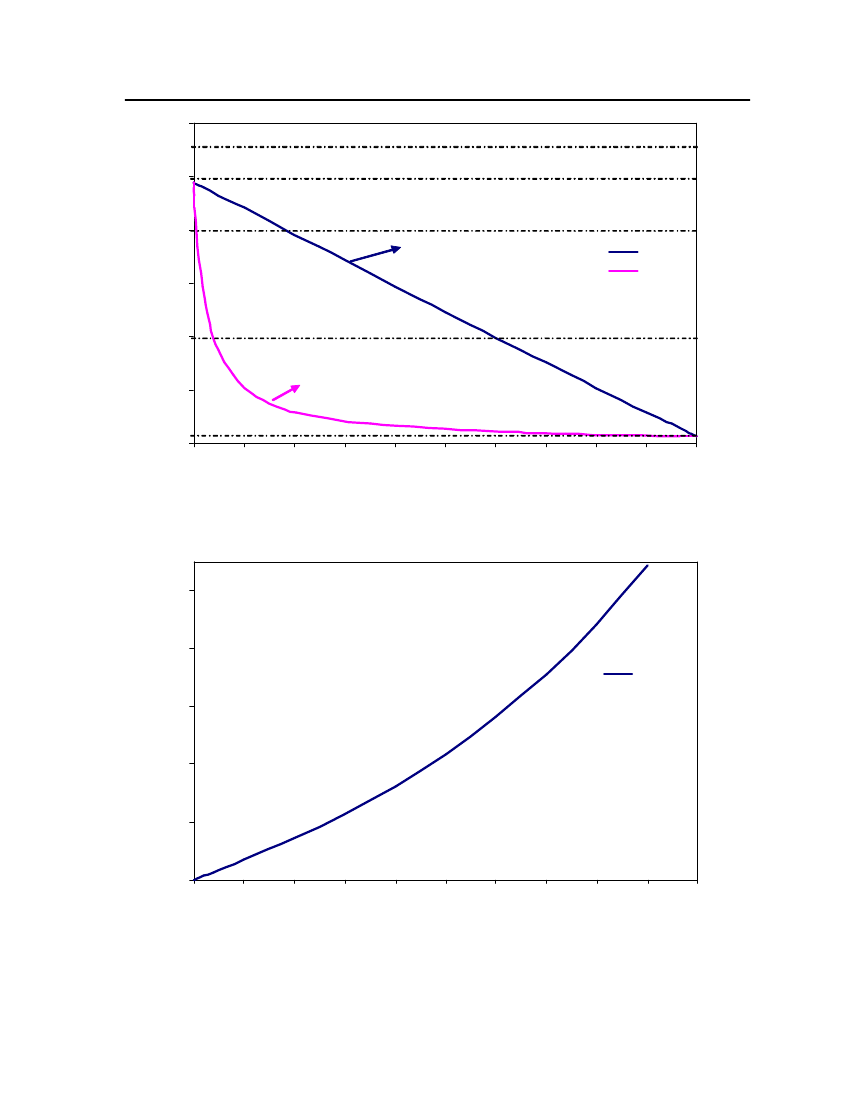

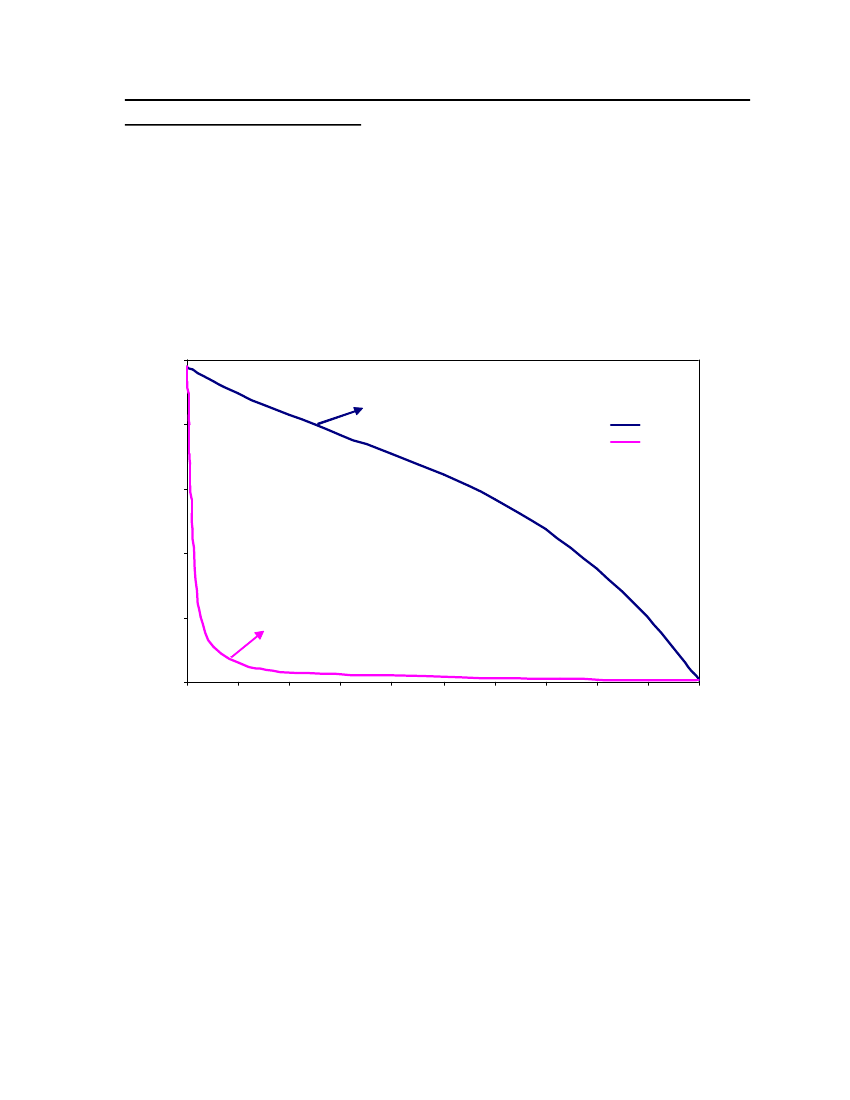

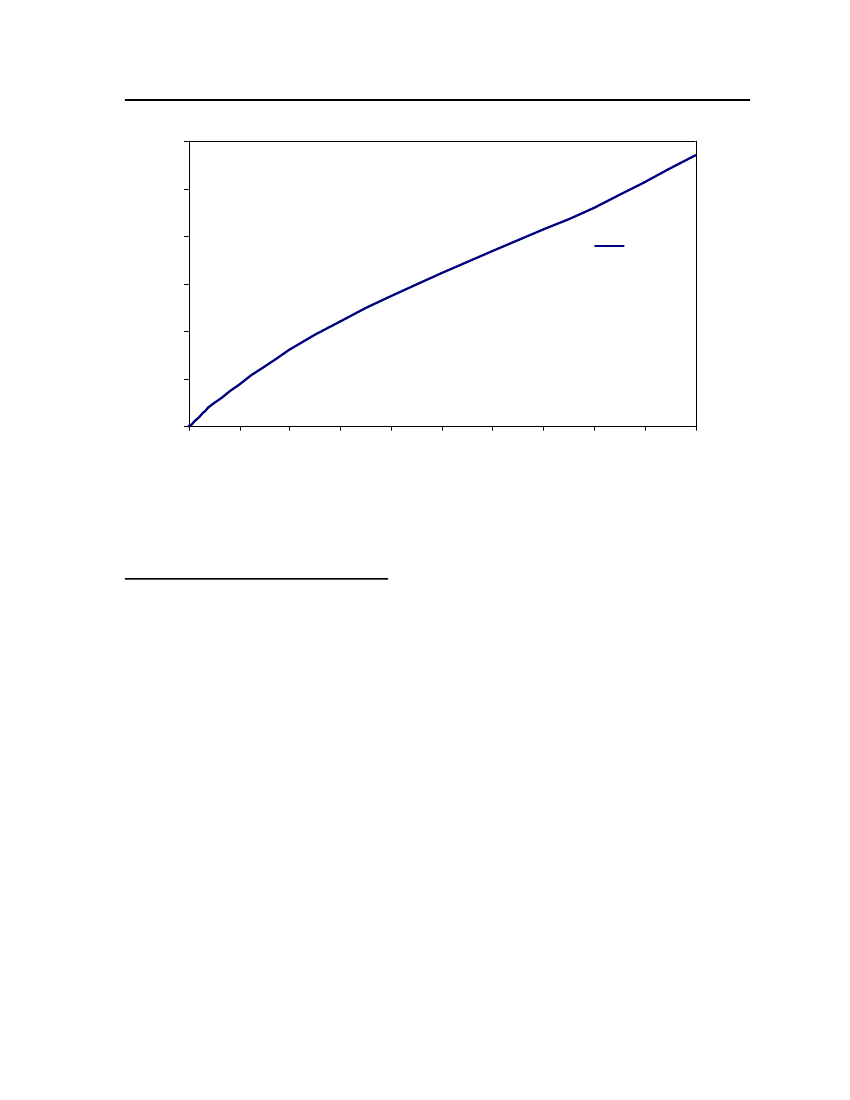

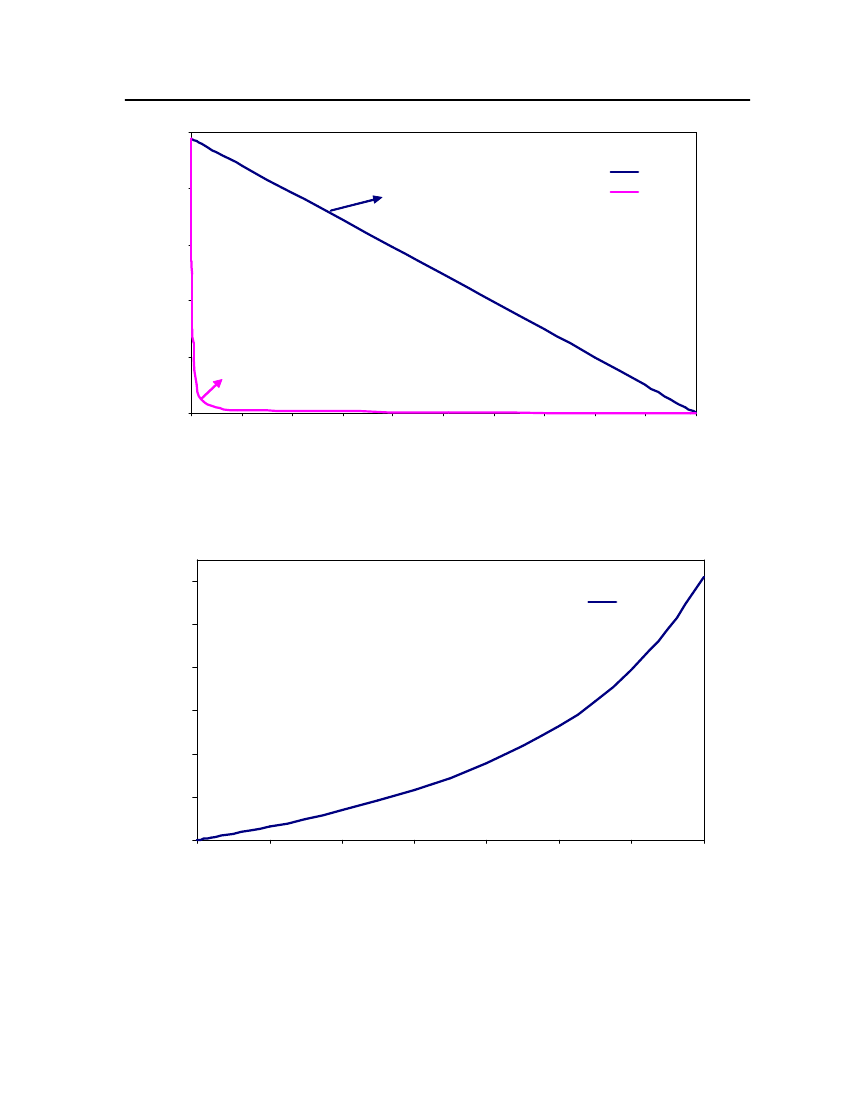

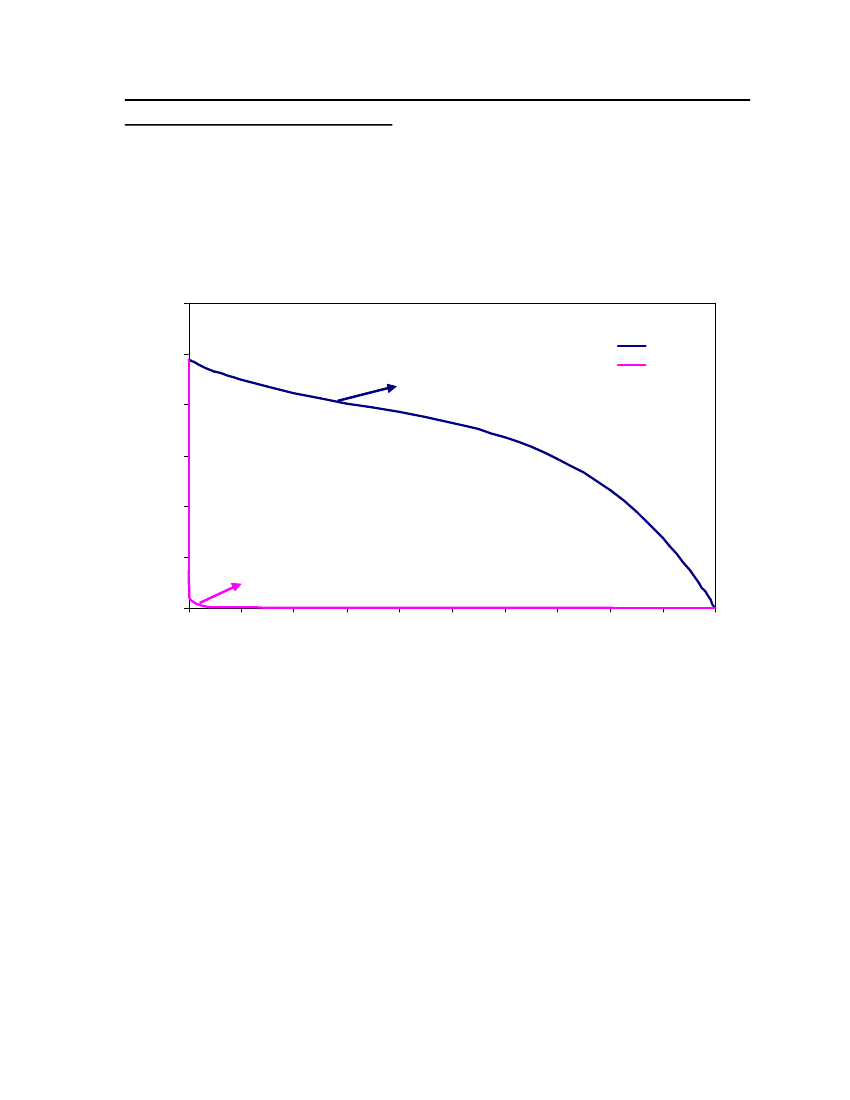

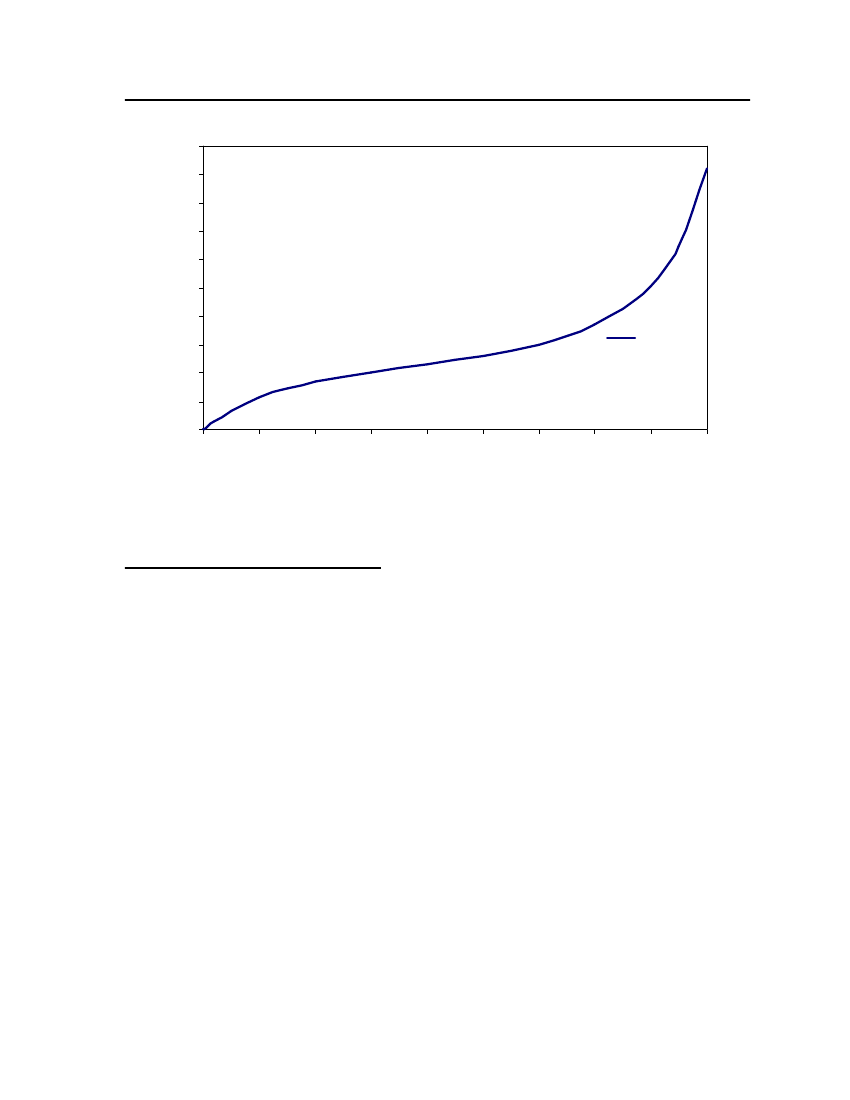

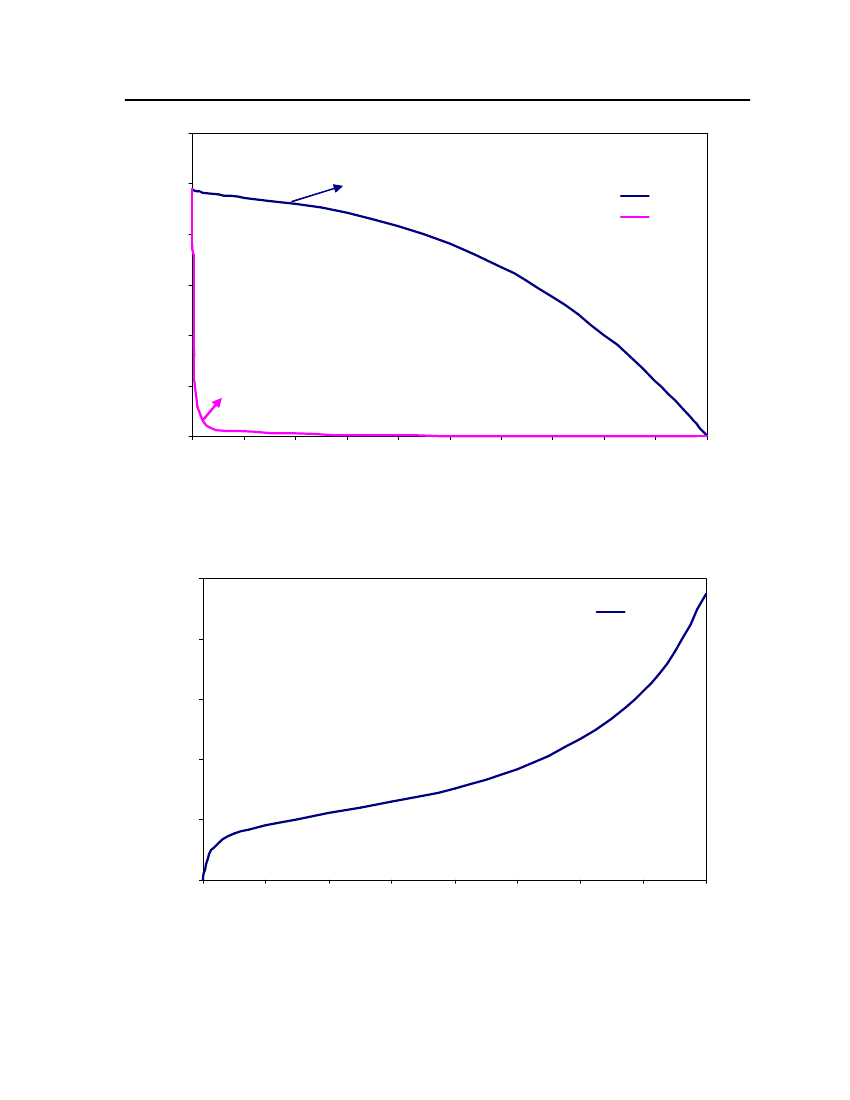

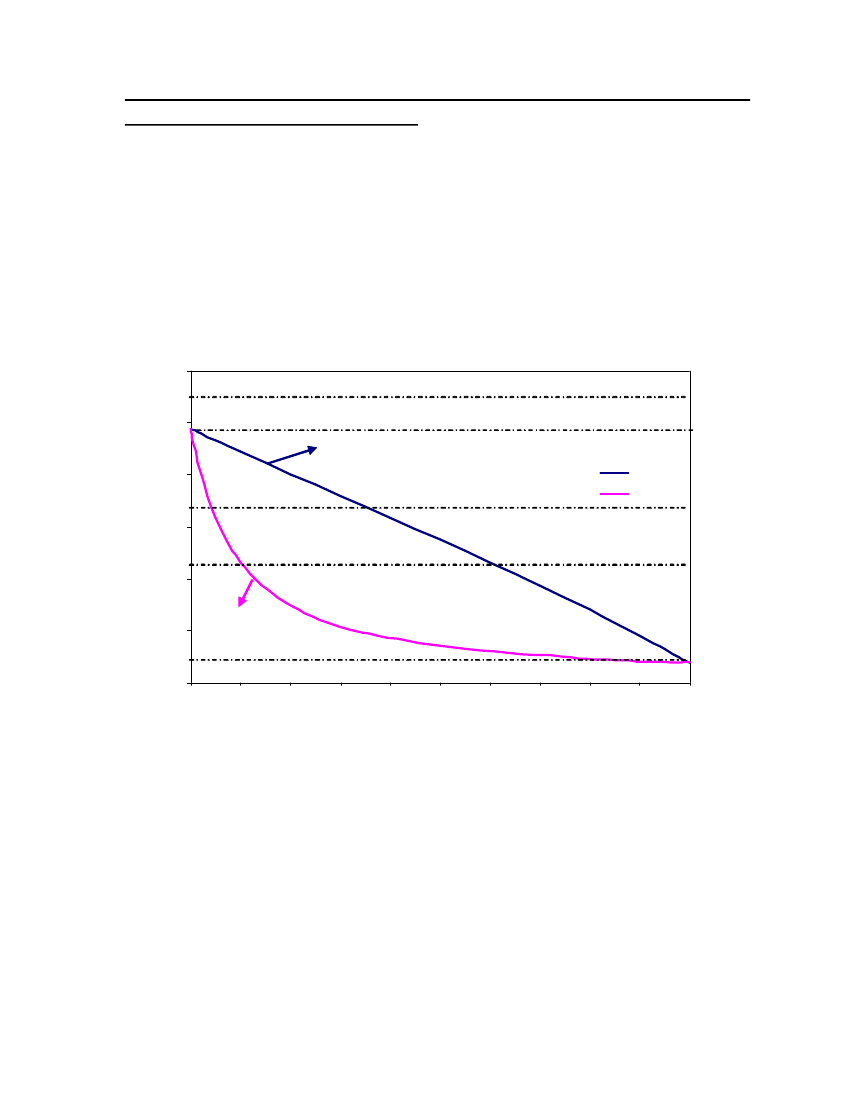

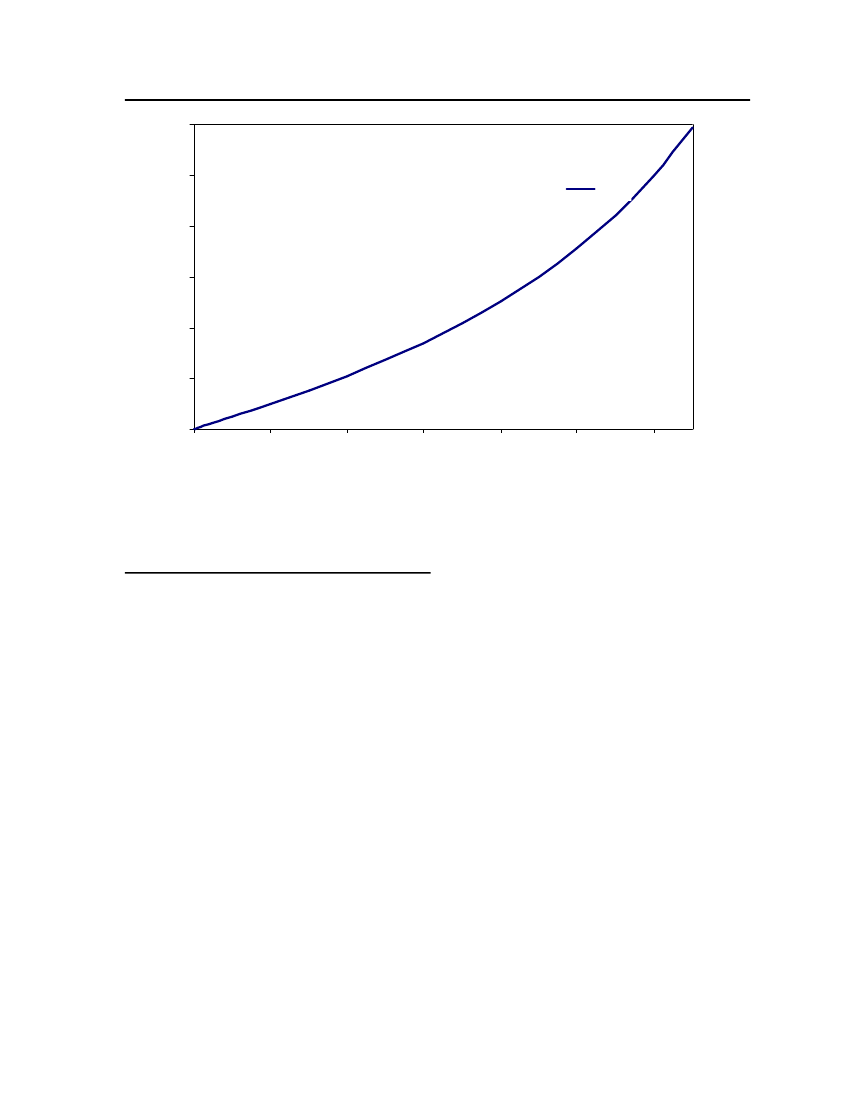

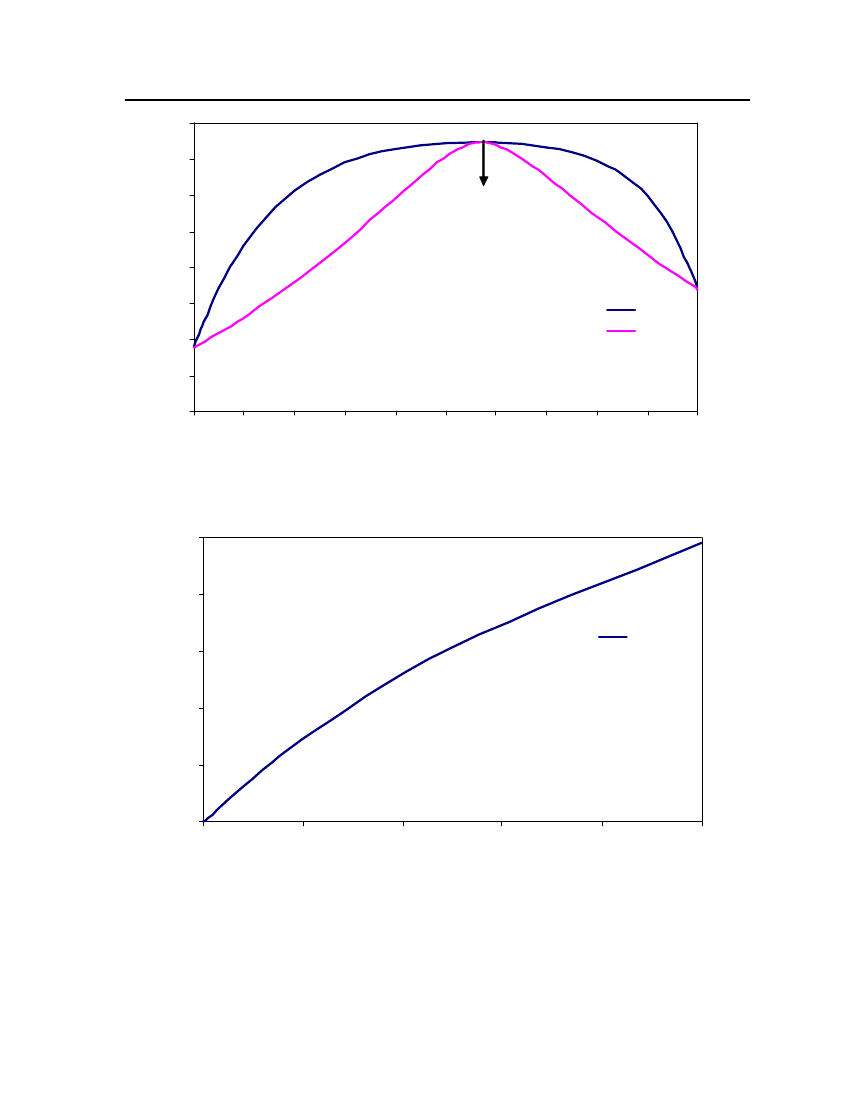

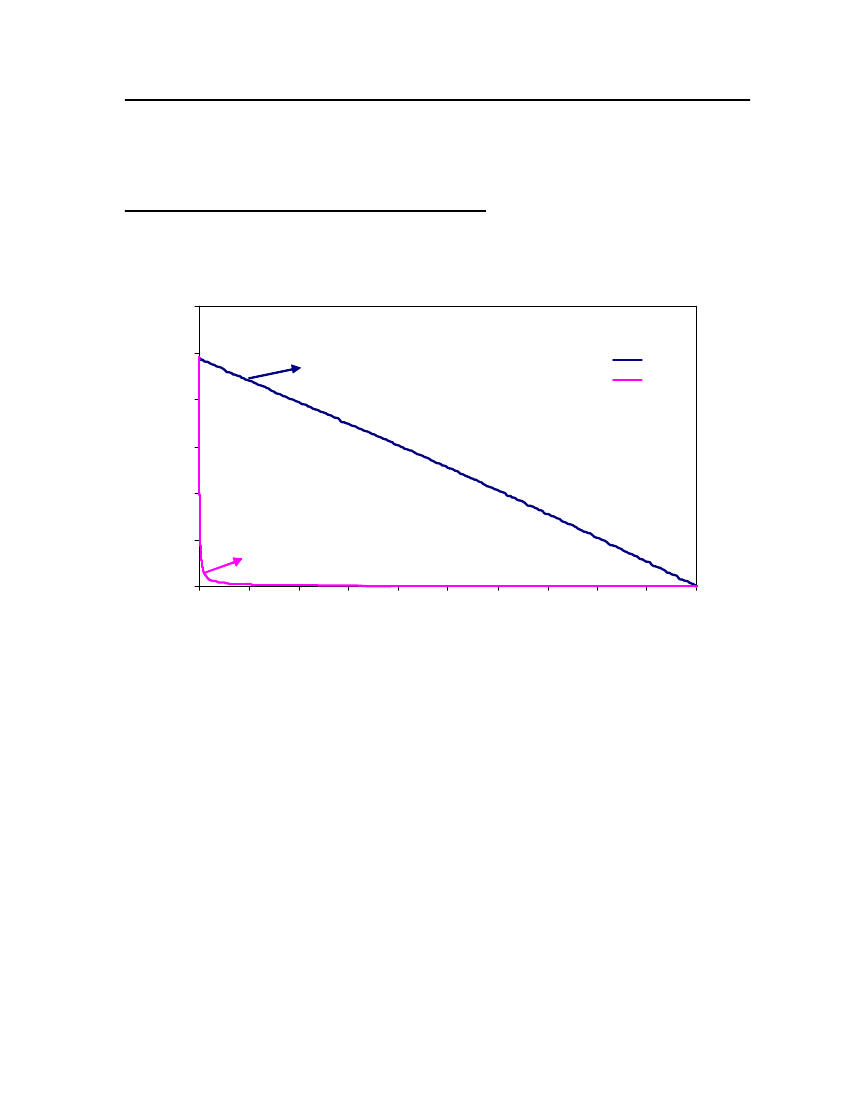

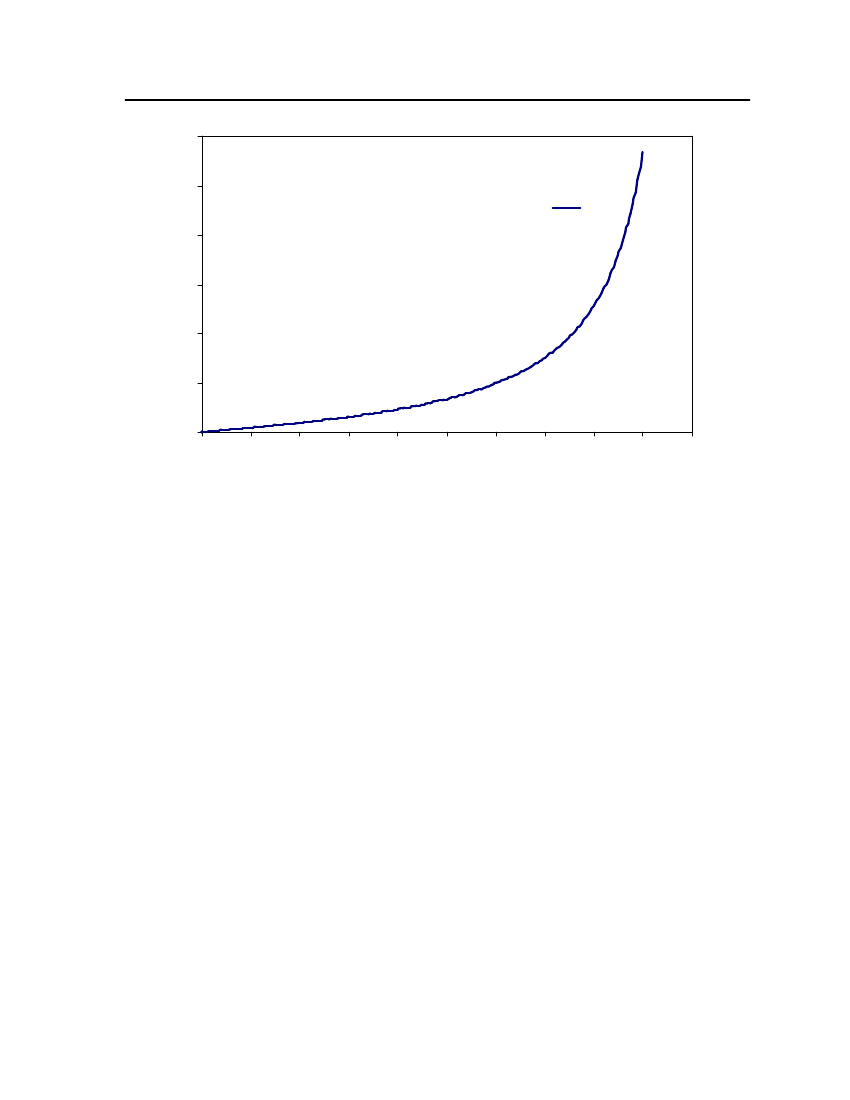

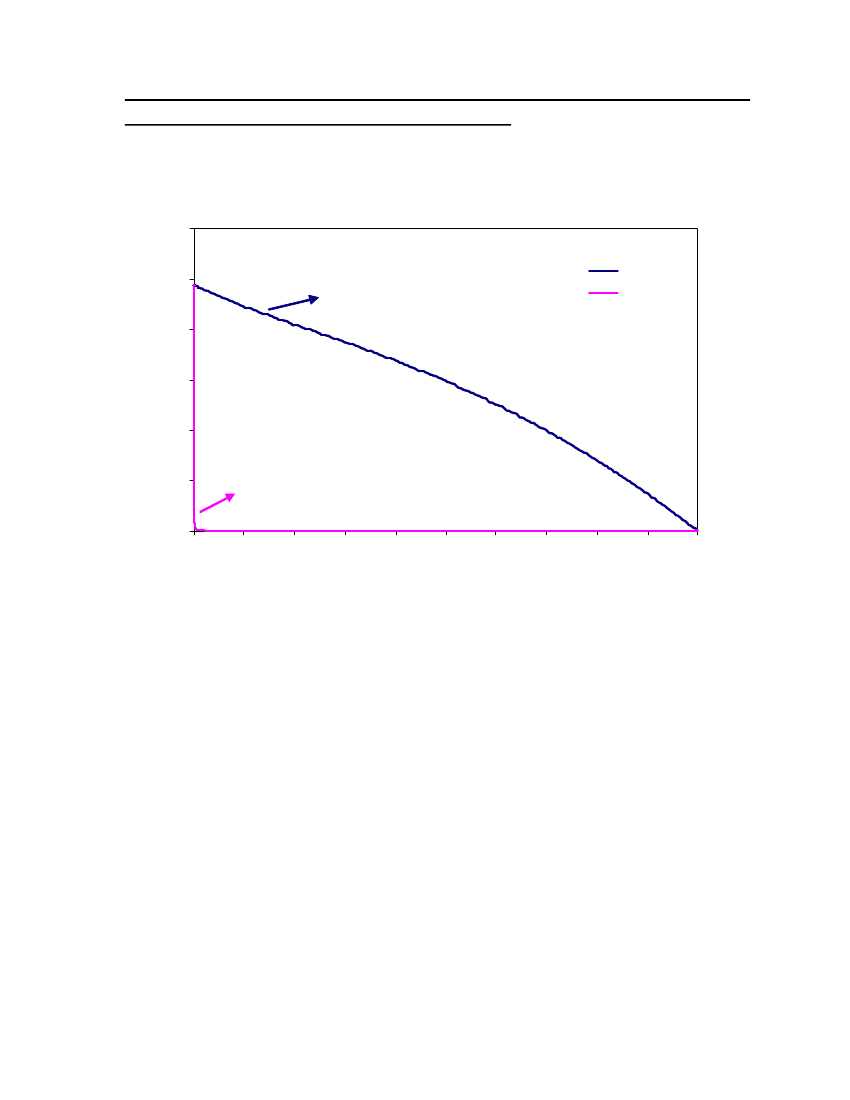

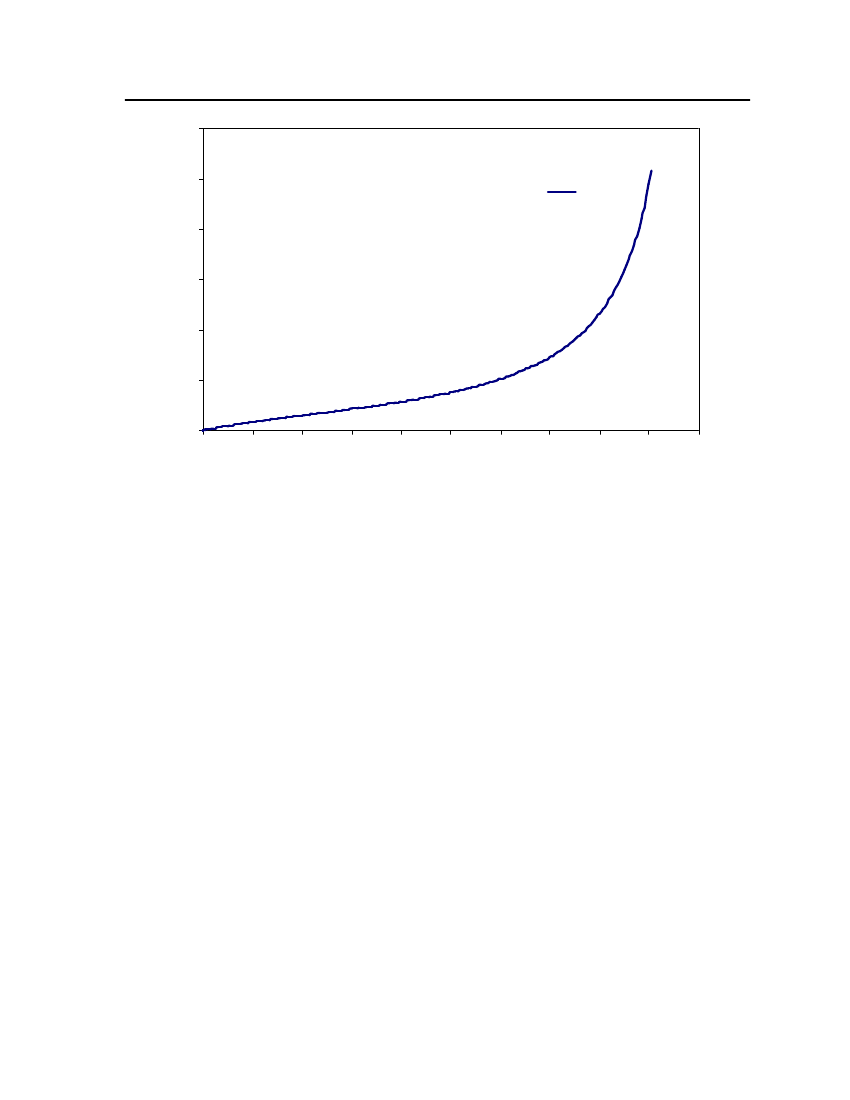

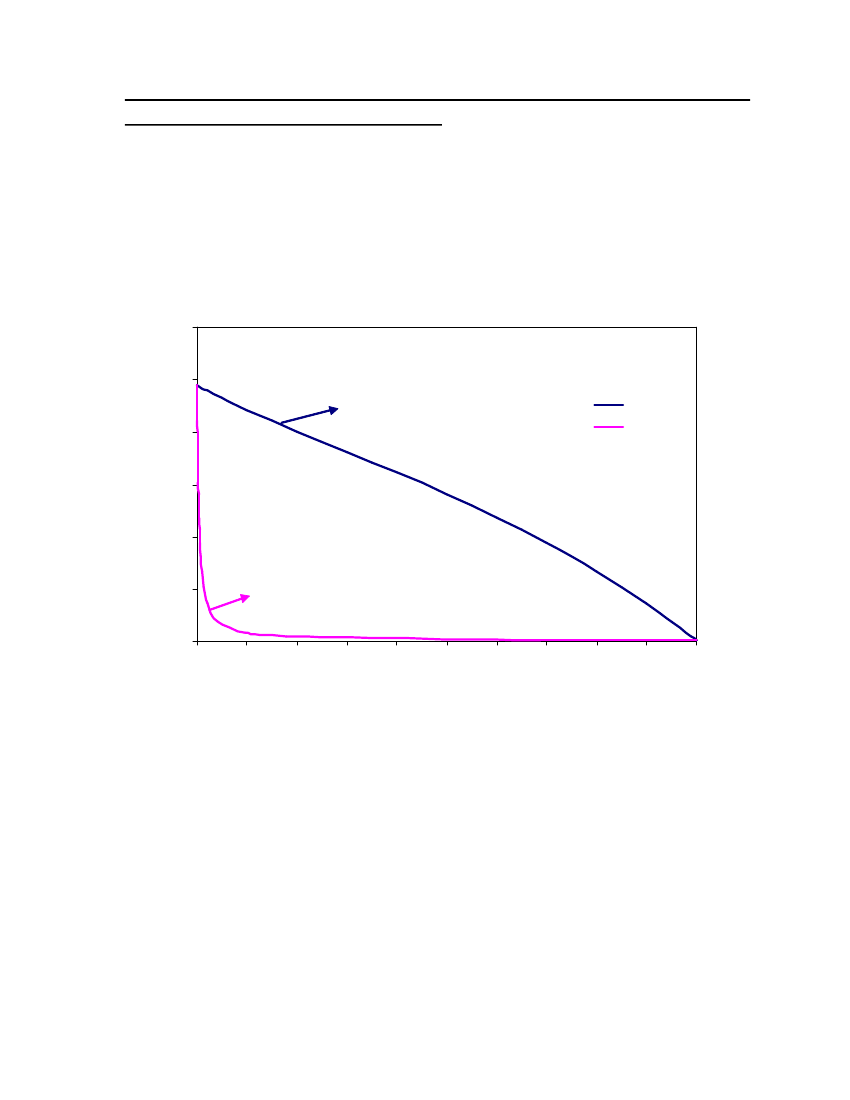

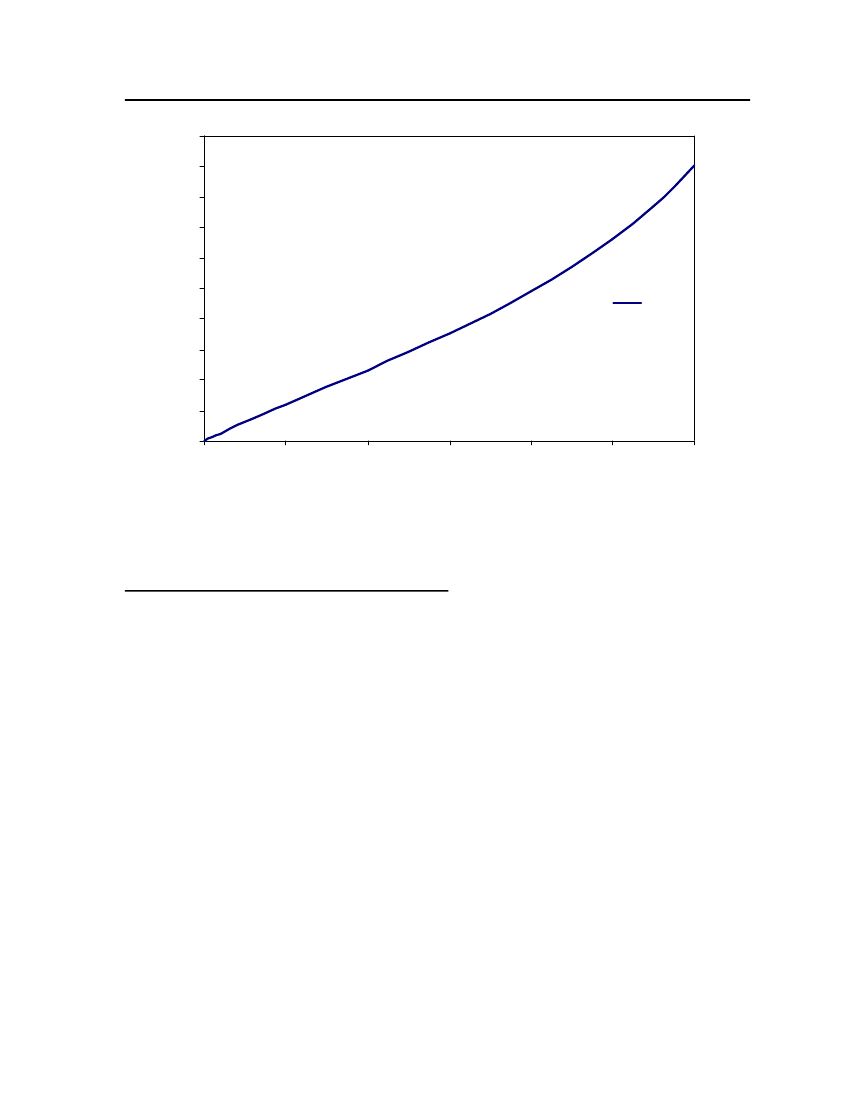

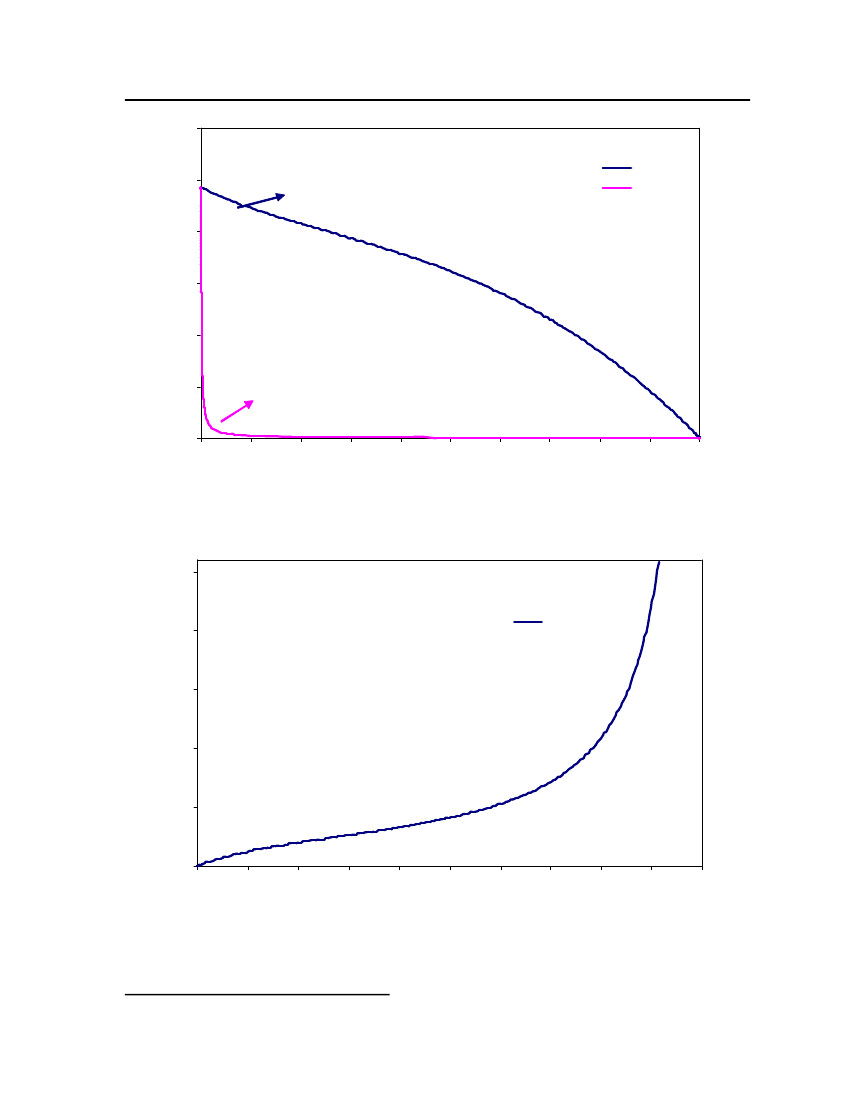

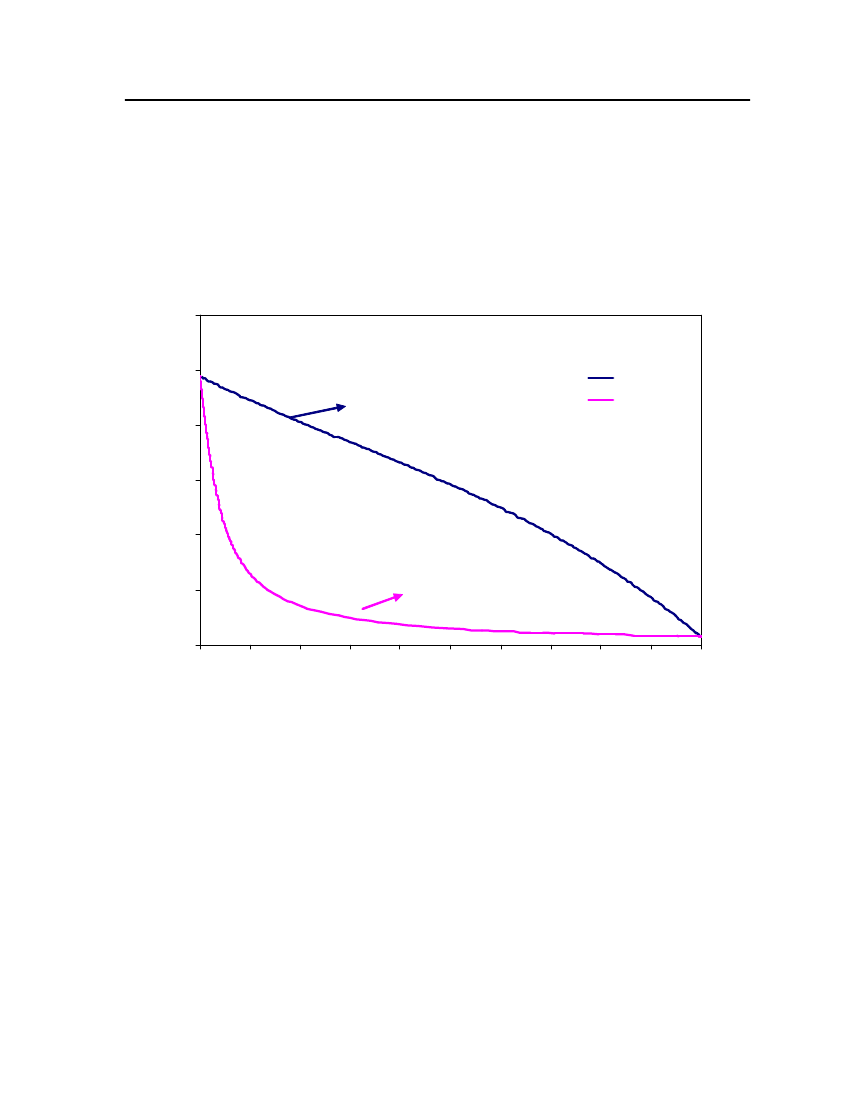

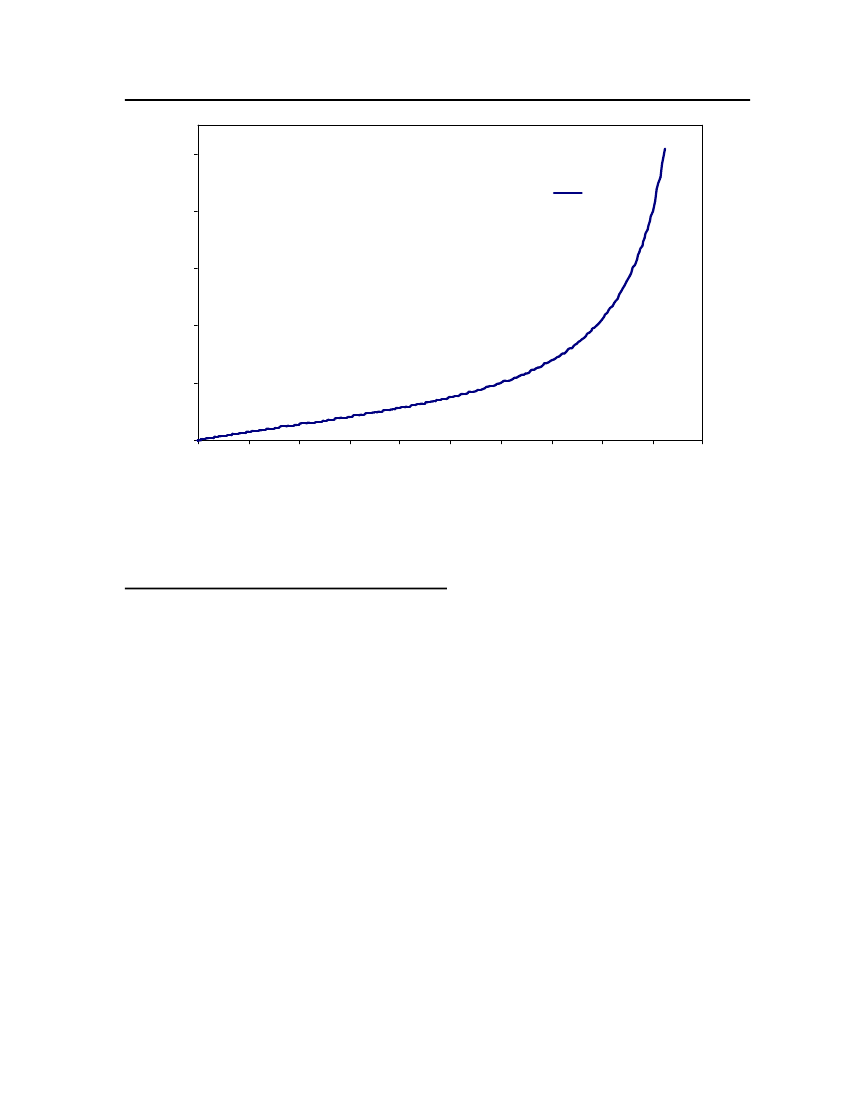

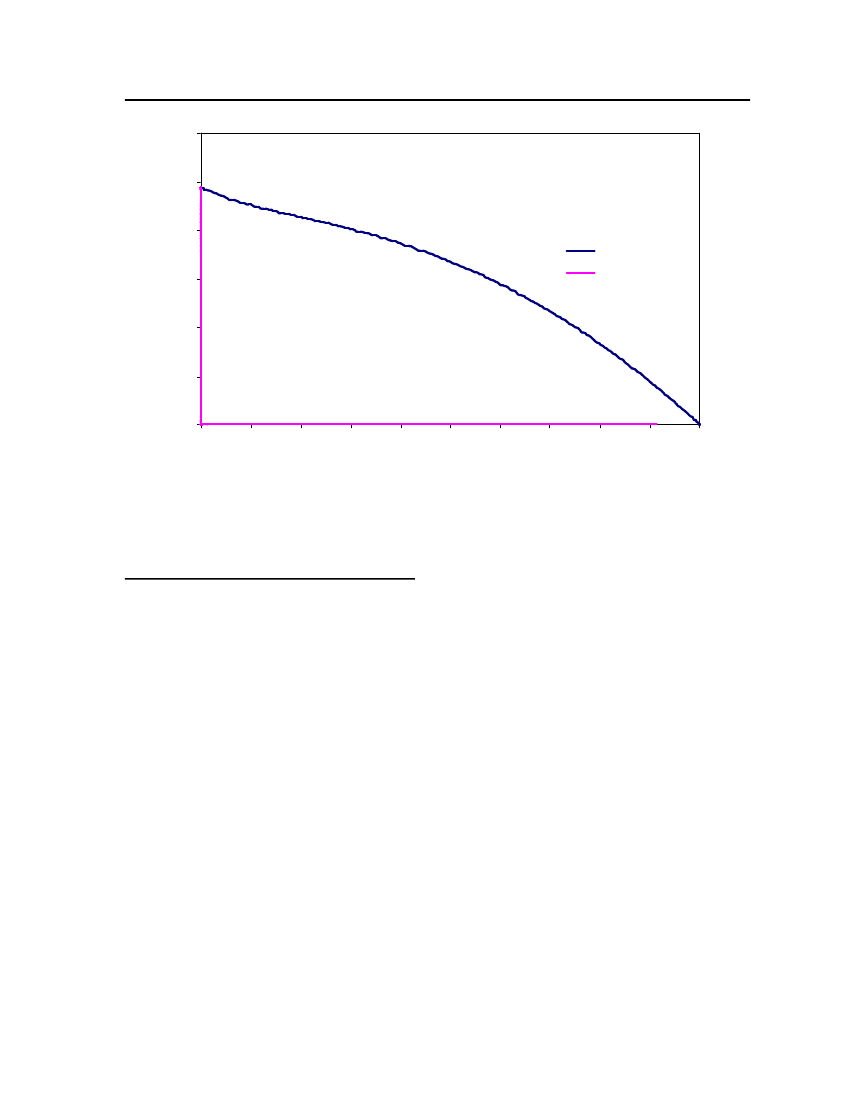

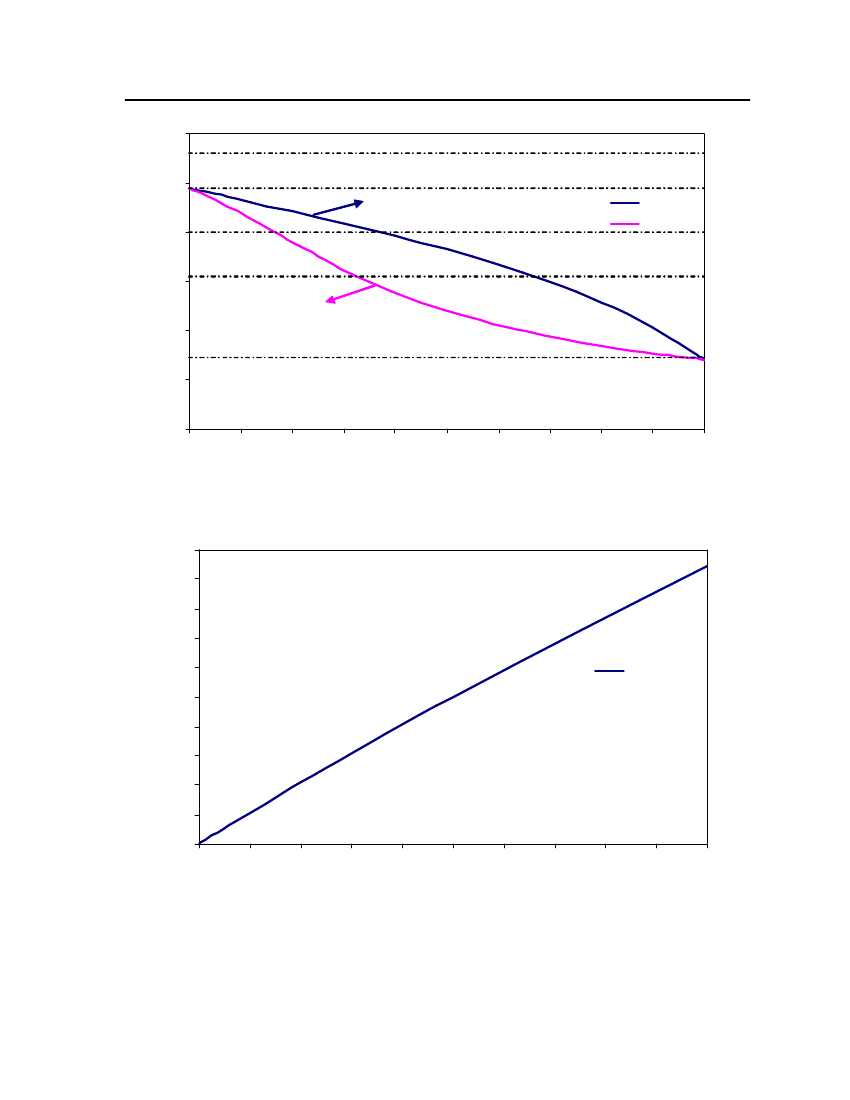

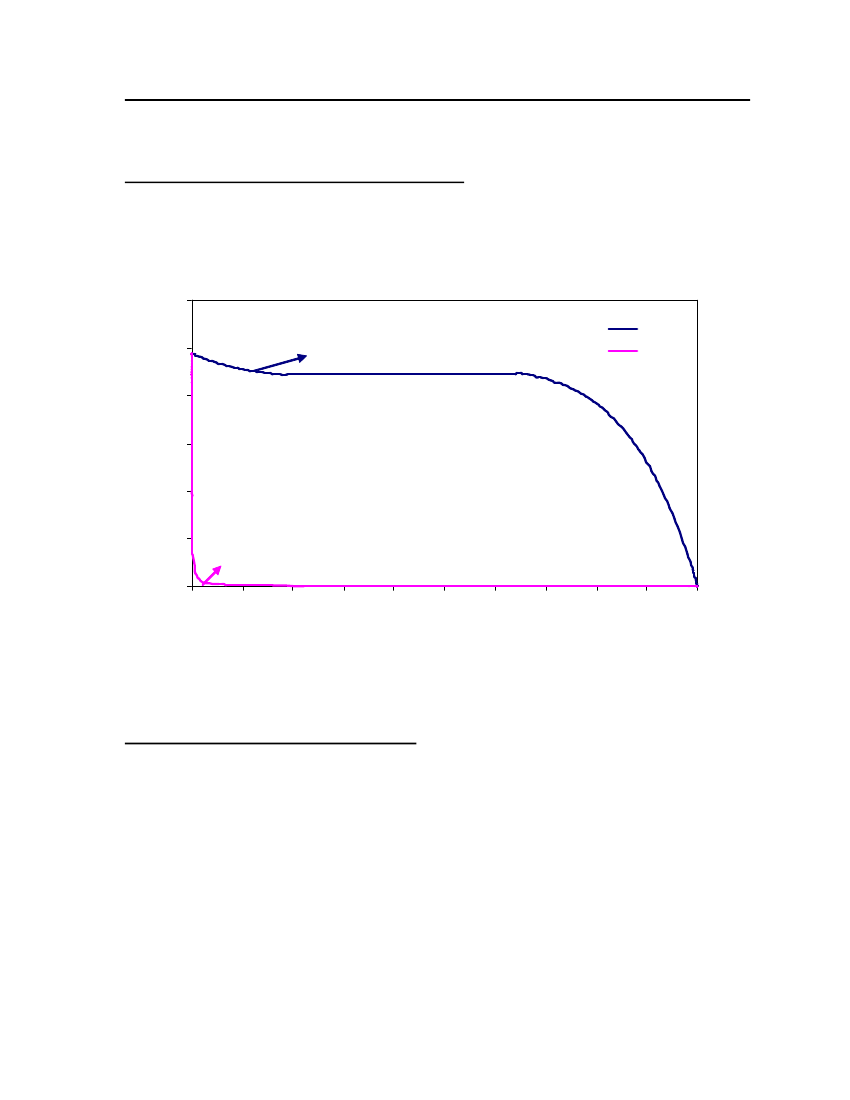

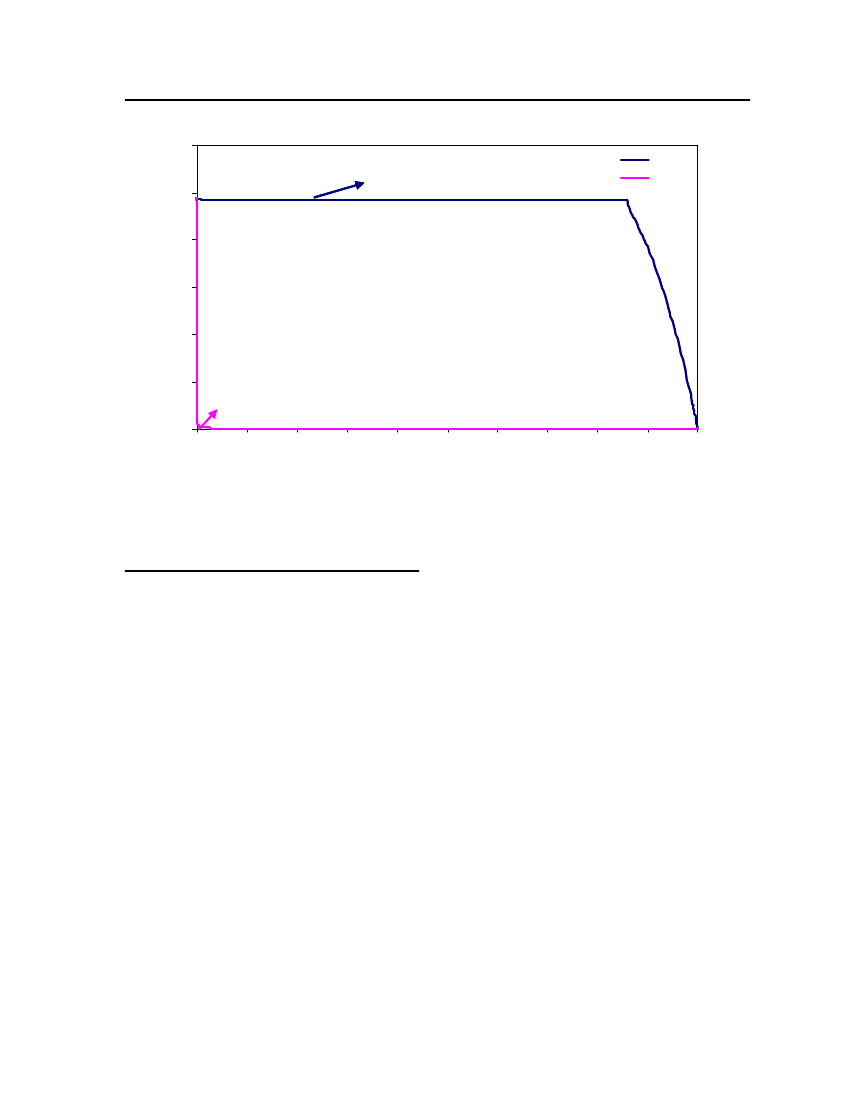

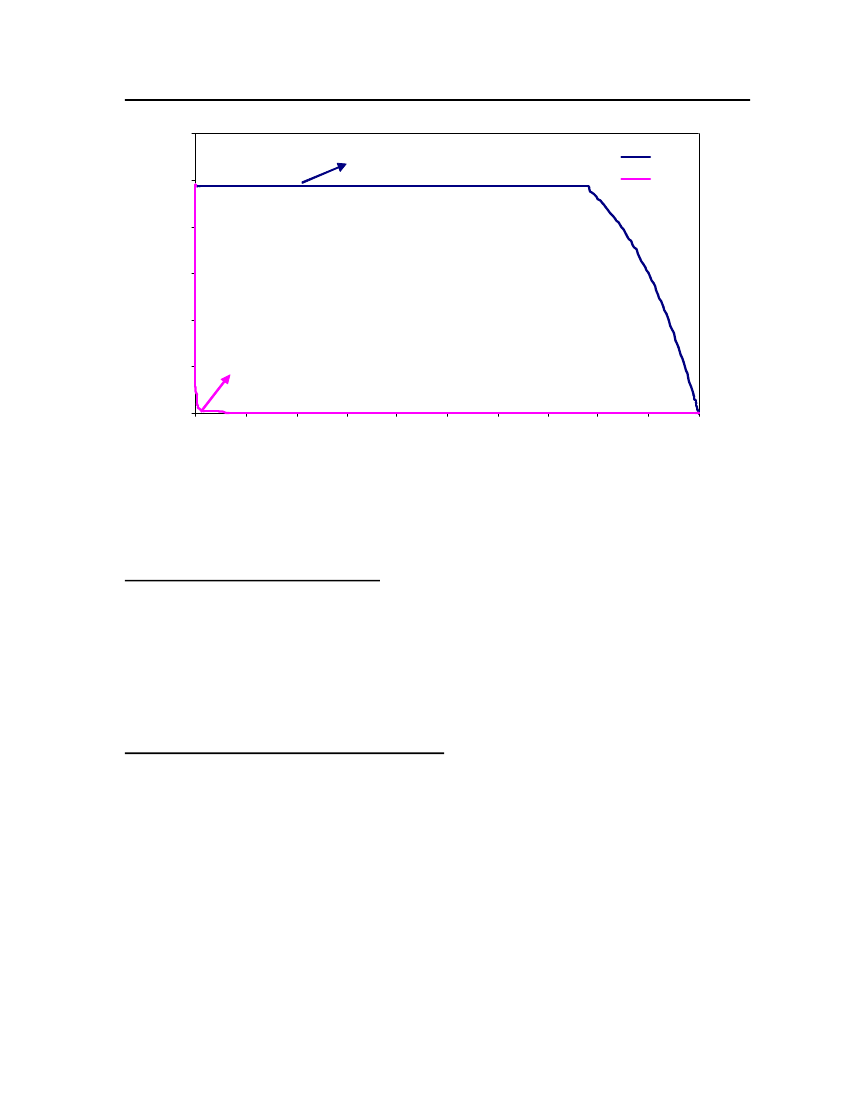

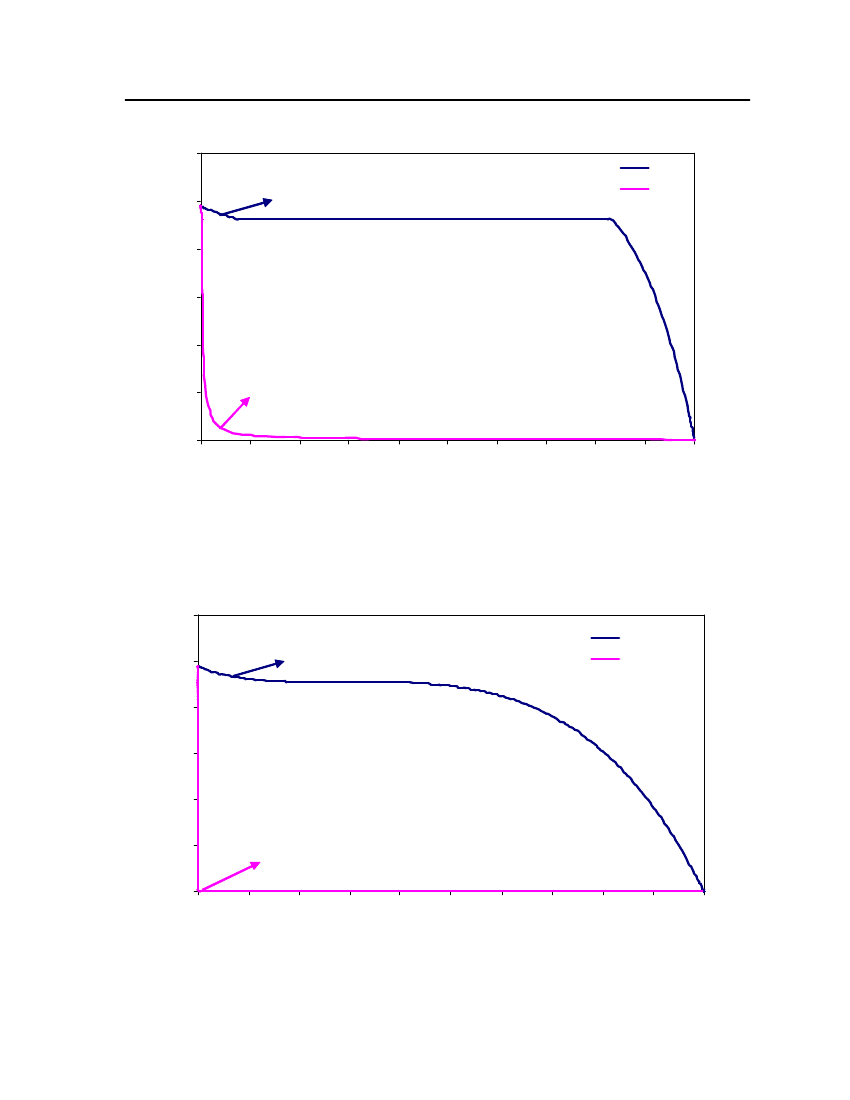

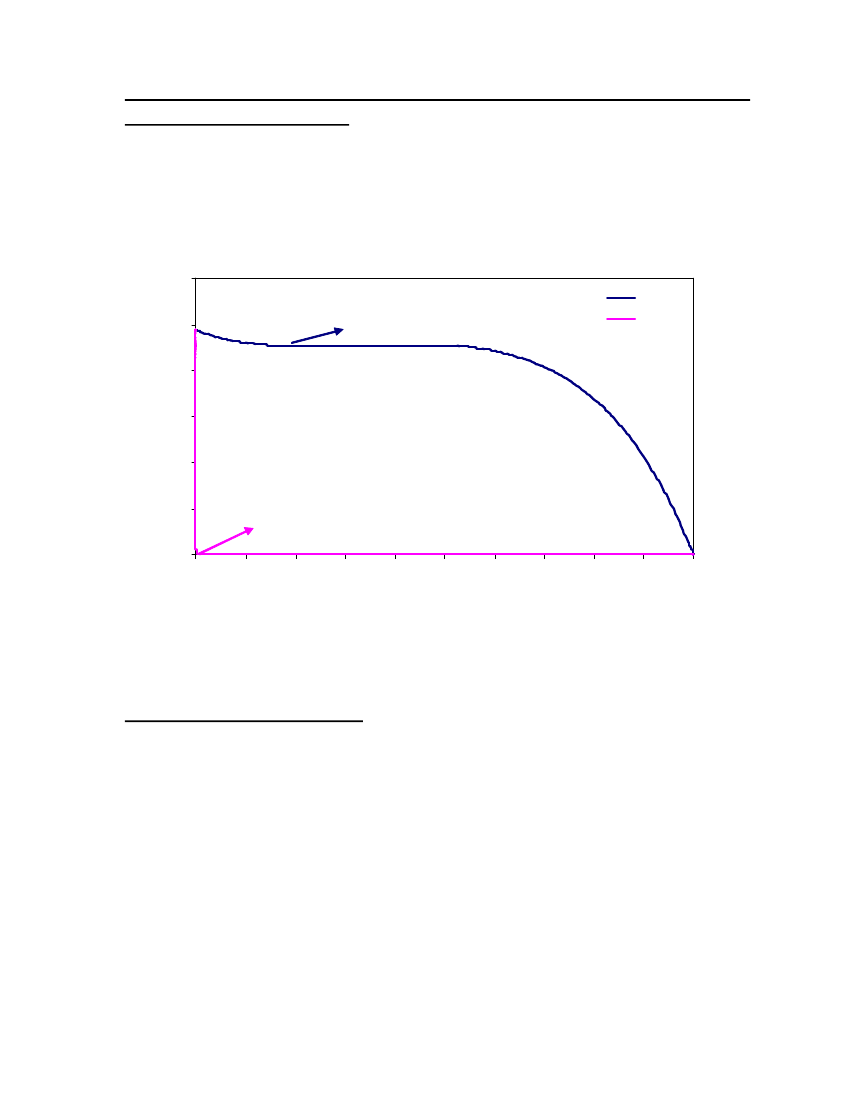

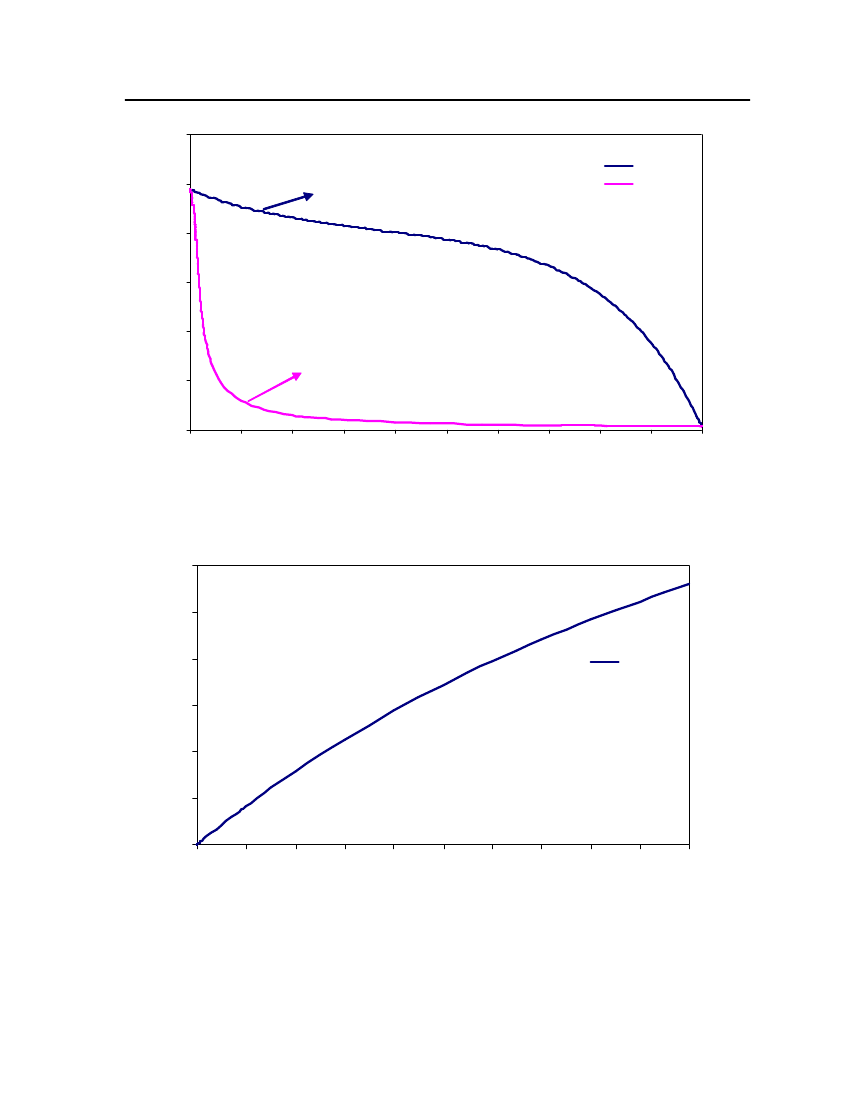

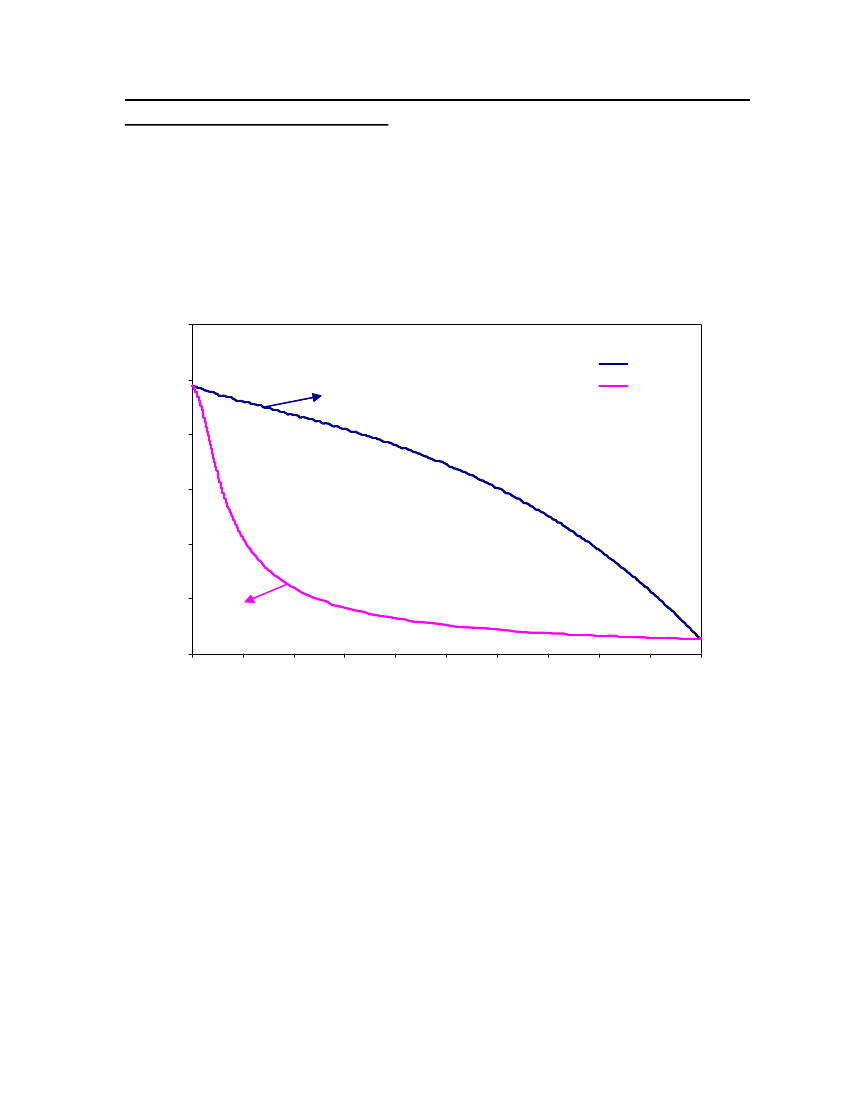

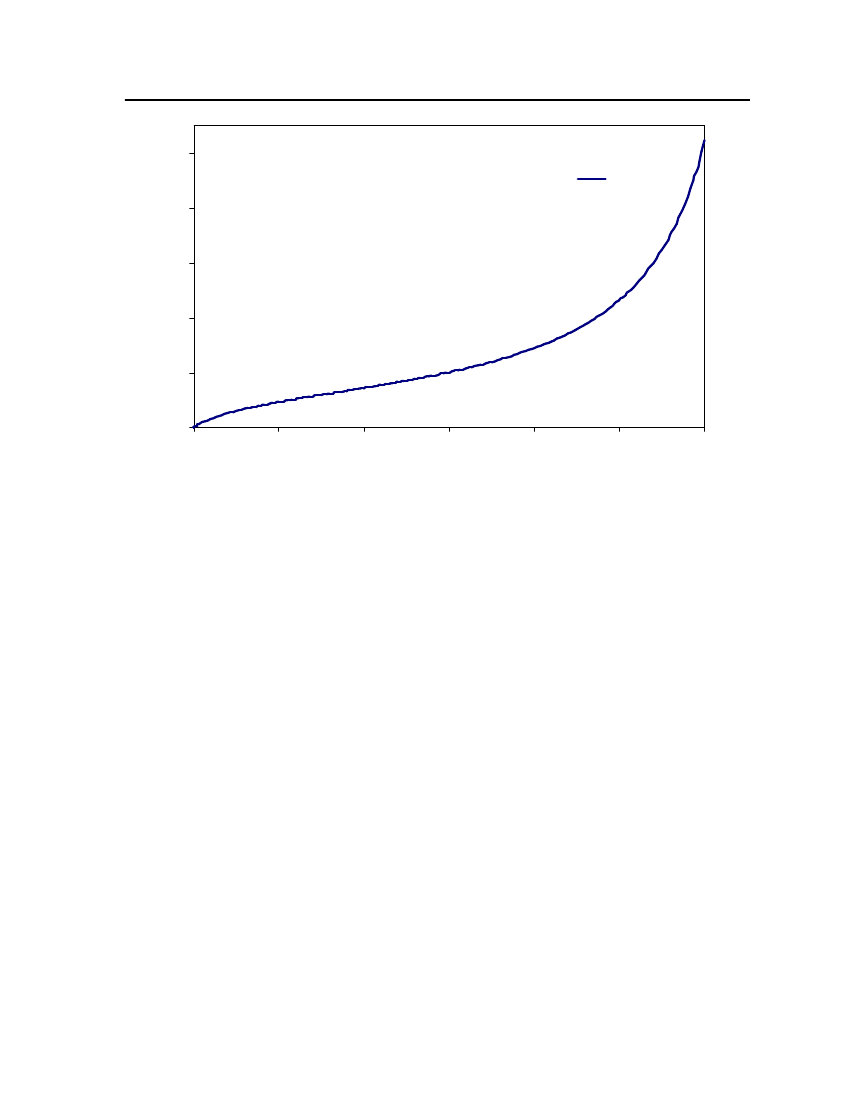

Comparison of the CPA and COSMOtherm performance with Experimental data:The malodorants’ pure-component parameters for the CPA model are found by fitting tovapor pressure and liquid density data. The parameters are shown in the table 32. Theproperty that is of interest to us is vapor pressure, so we compare the performance of themodels on this property. Figures 3-19 show the vapor pressure as a function of temperaturefor the 17 compounds where we have experimental data. In all cases, the vapor pressure fromCPA is in excellent agreement with experiment. This is to be expected, since the parameterswere obtained in order toensuregood agreement for this property. However, in the absenceof experimental data, CPA cannot be used. From the comparisons with COSMOtherm, wecan see that in most cases, the prediction (based only on the chemical structure of thecompound) is acceptable. This gives us some confidence that the pure-component vaporpressures for the ten compounds for which no experimental data exists, should besatisfactorily predicted by COSMOtherm.Figure 3 shows the vapor pressure of triethylamine at different temperatures for CPA(with 2B association scheme for triethylamine) and COSMOtherm. These results arecompared with the DIPPR correlations (based on experiment). As expected, the CPAequation of state is able to represent correctly the pure triethylamine vapor pressure fortriethylamine. COSMOtherm tends to overpredict the vapor pressure at higher temperatures.However at the temperature of relevance (around a room temperature of 293 K) theprediction is satisfactory. The vapor pressures of the remaining 16 malodorants for which wehave experimental data are shown in Figure 4 to Figure 19. Predictions from COSMOthermare generally very good, especially at around room temperature. Compounds for whichCOSMOtherm performs less well are 2,2,4-trimethyl pentane (figure 7), sulfuryl chloride(figure 11), bis(chloromethyl)ether (figure 14), s-trioxane (figure 16) and indole (figure 17).The vapor pressure of bis(chloromethyl)ether (figure 14) is particularly poorly represented.The reason for this is not clear. However, in general COSMOtherm does a good job ofrepresenting the vapor pressure of the pure substances, which leads us to believe that we can37

accept the vapor pressure predicted for the other ten compounds where we have noexperimental data.

24

20Vapor Pressure (bar)

16

Exp (DIPPR)COSMOthermCPA

12

8

4

0265285305325345365385405425445465485Temperature (K)

Figure 3: Comparison of Triethylamine Vapor pressure between CPA, COSMOtherm and DIPPR

38

18

15Vapor Pressure (bar)

Exp (DIPPR)COSMOthermCPA

12

9

6

3

0250270290310330350370390410430450Temperature (K)

Figure 4: Comparison of Isobutyraldehyde Vapor pressure between CPA, COSMOtherm and DIPPR

24Exp. (DIPPR)20Vapor pressure (bar)CPACOSMOtherm16128

4

0300

320

340

360

380

400

420

440

460

480

500

520

540

560

580

Temperature (K)

Figure 5: Comparison of Tetrahydrothiophene Vapor pressure between CPA, COSMOtherm and DIPPR

39

35302520151050240260280300320340360Temperature (K)380400420440460Exp (DIPPR)COSMOthermCPA

Figure 6: Comparison of DimethylsulfideVapor pressure between CPA, COSMOtherm and DIPPR

Vapor Pressure (bar)

40

201816Vapor pressure (bar)14121086420270300330360390420Temperature (K)450480510DIPPRCOSM OthermCPA

Figure 7: Comparison of 2,2,4 Trimethylpentane Vapor pressure between CPA, COSMOtherm andDIPPR22201816Vapor Presure (bar)14121086420310360410460510560Temperature (K)Exp (DIPPR)COSMOthermCPA

Figure 8 Comparison of 2-MethylpyridineVapor pressure between CPA, COSMOtherm and DIPPR

41

18,016,014,0Vapor Pressure (bar)12,010,08,06,04,02,00,0355395435475515555Temperature (K)595635675Exp (DIPPR)COSMOthermCPA

Figure 9: Comparison of NitrobenzeneVapor pressure between CPA, COSMOtherm and DIPPR

16,014,0Vapor Pressure (bar)12,010,08,06,04,02,00,0290320350380410440Temperature (K)470500530

Exp (DIPPR)COSMOthermCPA

Figure 10: Comparison of 1-Pentanol Vapor pressure between CPA, COSMOtherm and DIPPR

42

504540Vapor pressure (bar)35302520151050270285300315330345360 375 390 405Temperature (K)420435450465480495

COSMOthermExp (DIPPR)CPA

Figure 11: Comparison of Sulfurylchloride Vapor pressure between CPA, COSMOtherm and DIPPR

35302520151050225250275300325350Temperature (K)375400425Exp(DIPPR)COSMOthermCPA

Figure 12: Comparison of CyanogenchlorideVapor pressure between CPA, COSMOtherm and DIPPR

Vapour Pressure (bar)

43

35Exp (DIPPR)COSM OthermCPA25Vapor Pressure (bar)

30

20

15

10

5

0250275300325350375Temperature (K)400425450

Figure 13: Comparison of Ethylmercaptan Vapor pressure between CPA, COSMOtherm and DIPPR

211815129630280310340370400Temperature (K)430460490520Exp (DIPPR)COSMOthermCPAVapor Pressure (bar)

Figure 14: Comparison of Bis(chloromethyl)ether Vapor pressure between CPA, COSMOtherm andDIPPR

44

4,54,0

Exp (DIPPR)3,5Vapor Pressure (bar)3,02,52,01,51,00,50,0300340380420Temperature (K)460500

COSMOthermCPA

Figure 15: Comparison of Propyleneglycol vapor pressure between CPA, COSMOtherm and DIPPR

25

20Vapor Pressure (bar)

Exp (DIPPR)COSMOthermCPA

15

10

5

0300325350375400425450Temperature (K)475500525550