Miljøudvalget 2011-12

MIU Alm.del Bilag 38

Offentligt

Meeuwenlaan 4-6office8011 BZ Zwolle (NL)P.O. Box 161postal8000 AD ZWOLLE (NL)+31 (0)38 -Phone00426 01+31 (0)38 -fax70 40423[email protected]e-mailwww.controlunion.comwebsitecci24274509NL12ABNA0468081410ibanbicABNANL2ANL806.327.789.B01vat

The use of Monocrotophos.Introduction.Control Union Certifications was instructed by the Danish Energy Agent to conduct an Evaluation ofinitiatives taken by United Plantations to phase out Monocrotophos.Executive summary.United Plantations operates in accordance with Good Agricultural Practice and hasdemonstrated best operational practices in accordance with the Round Table on SustainablePalm Oil principles and criteria.A review of medical records back to 1995 shows that United Plantations have not had a singlecase of pesticide poisoning or symptoms of pesticide poisoning.United Plantations are demonstrably putting more effort than any other oil palm company intothe phasing out of Monocrotophos and are complying with the FAO’s Code of Conduct.Monocrotophos is used for the effective control of Bagworm Caterpillars in oil palmplantations.Monocrotophos is approved for use by the Malaysian Palm Oil Board and currently there areno effective alternatives.The pesticide Imidacloprid is authorized for tall palms but has been proven to be non-effectiveand is not recommended for foliar application.United Plantations have been actively trying to source and to evaluate alternatives toMonocrotophos since 2006 and another trial project has been recently initiated by UnitedPlantations to find a natural biological control in co-operation with CABI (CommonwealthAgricultural Bureaux International).Whilst a number of other oil palm plantations have been actively looking for alternatives toMonocrotophos, there is no clear evidence of anyone being successful as not a single estatehas demonstrated the effective elimination of Monocrotophos. The use of integrated pestmanagement controls is the first line of control with the use of Monocrotophos as a final resort.The use of Monocrotophos has been demonstrably reduced over the past 4 years but a lack ofcontrol of Bagworm Caterpillars on neighbouring estates is resulting in increased numbers(and associated attacks) despite very sound control methods being implemented by UnitedPlantations.The use of Monocrotophos is only used as a last resort after all known biological controls havebeen exhausted.

Contents.

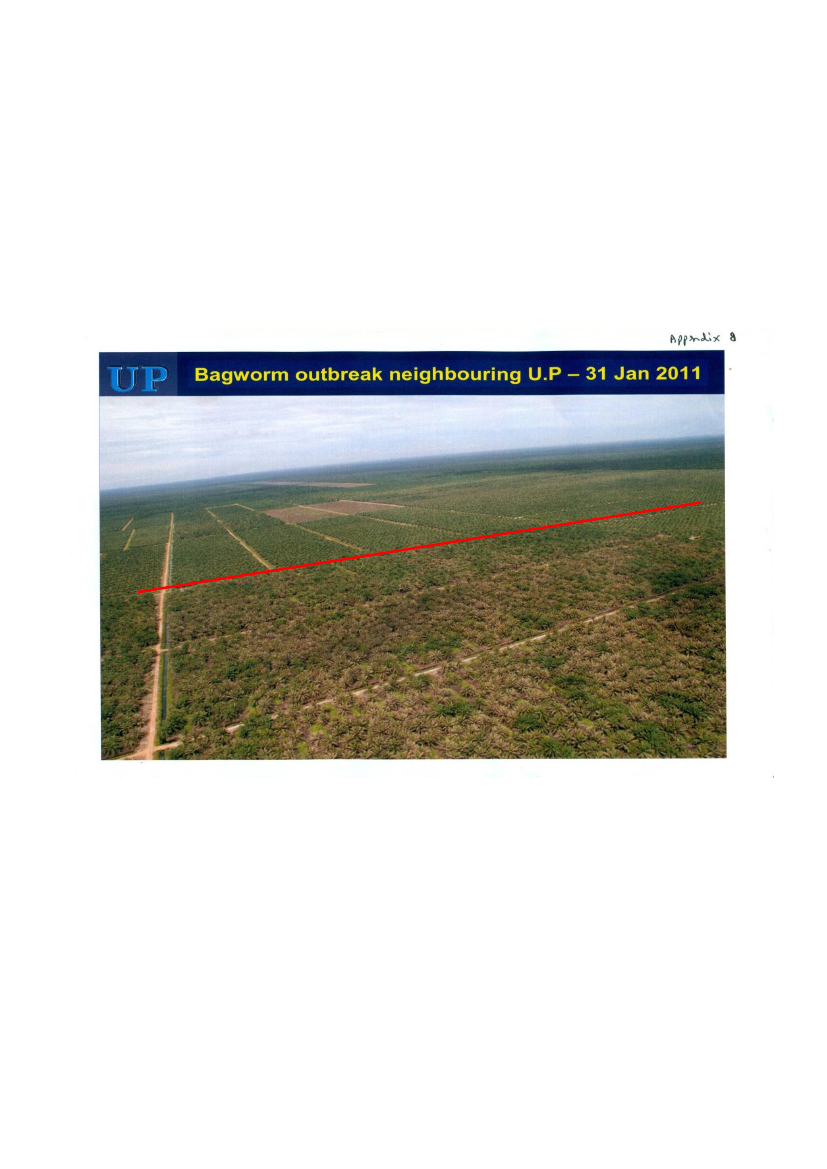

1. Terms of reference.2. Background.Map 1:The geographical distribution of bagworm outbreaks in Peninsular Malaysia.Map 2:Location of United Plantations oil palm estates in Lower Perak.Photograph 1:The outbreak of bagworm in estates adjoining United Plantations.3. Round Table on Sustainable Palm Oil.3.1FAO International Code of Conduct on the Distribution and Use of Pesticides.4. United Plantations Bhd. Good Agricultural Practice. (GAP).5. Research work to find an effective alternative to Monocrotophos for trunk injection.5.1 Internal trials.5.2 Other trial data.6. Active engagement of multi-national pesticide companies.7. Engaging CABI to conduct a two year project to research other effective bio-control methodsfor bagworm.8. Appendices.8.1Abbreviations applicable.8.2Economic loss slide.8.3Letter: 12/12/2007. System to curb bagworm threat.8.4Return of bagworm outbreak on oil palm estates for the month of October 2010.8.5Email: 19/01/2011. UP to BASF.8.6Letter: 01/03/2011. BASF to UP.8.7Letter: 17/01/2011. UP to BASF.8.8Email: 17/01/2011. BASF to UP.8.9Letter: 02/12/2010. UP to BASF.8.10Letter: 22/09/2010. BASF to UP.8.11Letter: 29/09/2010. Bayer Crop Science to UP.8.12Letter: 15/03/2010. Bayer Crop Science to UP.8.13Letter: 30/03/2011. Syngenta to UP.8.14Email: 03/11/2010. Cheminova to UP.8.15Email: 18/01/2011. UP to Cheminova and Cheminova to UP.8.16Letter: 13/04/2011. CABI to UP.8.17Proposal. CABI to UP.8.18Letter: 18/04/2011. Department of Agriculture to UP.8.19Letter: 29/10/2010. UP to Pest Control Dept.

1.

Terms of reference and methodology.The following terms of reference were given.Findings are included in the executive summary above and in the report below.Description of bagworm and nettle caterpillar problems in the region with special regards to the areas ofUP's plantationsDescription of GAP (Good Agricultural Practice) in neighboring regions/countries where monocrotophosis not authorizedDescription of possible financial losses due to caterpillars and documentation of economic damagethreshold.Description of current practices in order to avoid and/or contain a bagworm/nettle caterpillar infestation.Herein guidelines and recommendations on best practices (both national and international – such asMalaysian Palm Oil Board, CABI, FAO etc.).Description of UPs current practice in relation to competing plantations in the region. (If possible toobtain)Description of UPs current initiatives to phase out monocrotophos.IPM (biological and microbiological control initiatives)Test of alternative chemicals such as Acephate – incl. resultsCooperation with major chemical companies to develop and test new chemicals that could substitutemonocrotophosAn evaluation of UPs current initiatives to phase out monocrotophos compared to RSPO criteria andbest practices within the palm oil sector - including suggestions for possible improvements

www.controlunion.com

2.

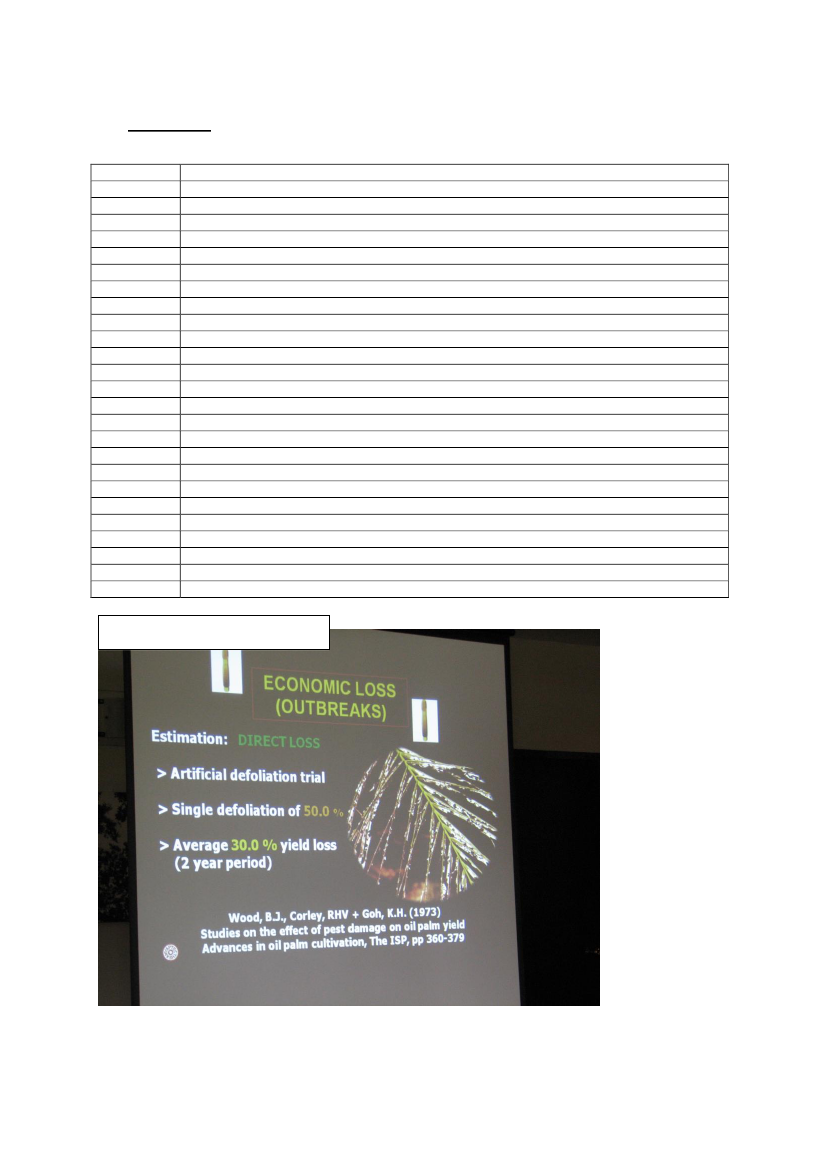

Background.Oil palm is a major agricultural crop with significant economic, environmental and social benefits forMalaysia. Like any agricultural crop, it is susceptible to attack by a wide range of pests and diseases someof which are of greater threat than others.Two leaf eating pests are the Bagworm and Nettle Caterpillars which can devastate significant areas of oilpalm if not detected and treated in the very early stages of an out-break. Of these two the BagwormCaterpillar (referred to as Bagworms) is the most damaging.Expected yield losses from oil palm plantations in which Bagworms are not effectively controlled can bebetween 40% and 50% - depending upon the extent of defoliation. This is supported in a paper written in1973 entitledStudies on the effect of pest damage on oil palm yieldsby BJ Wood, RHV Corley and KH Gohstates that a single defoliation of 50% results in an average loss in yield of 30% over a two year period.(See appendix 8.2)Responsible growers take a pro-active approach to controlling Bagworms by carrying out regular fieldinspections and by planting a range of beneficial plants. These plants encourage predators of the Bagwormsby providing nectar and shelter and represent an indirect bio-control system known as Integrated PestManagement (IPM).Fortunately Bagworms are not a wide spread problem for the oil palm industry but in 1988 the Palm OilResearch Institute of Malaysia (now known as the Malaysian Palm Oil Board – MPOB) conducted a surveyand identified the lower areas of Perak State to contain endemic levels of Bagworms.

KeyBagworm outbreak areas

Map 1. The geographical distribution of bagwormoutbreaks in Peninsular Malaysia.

Map 2. Location of United Plantations oil palm estates inLower Perak

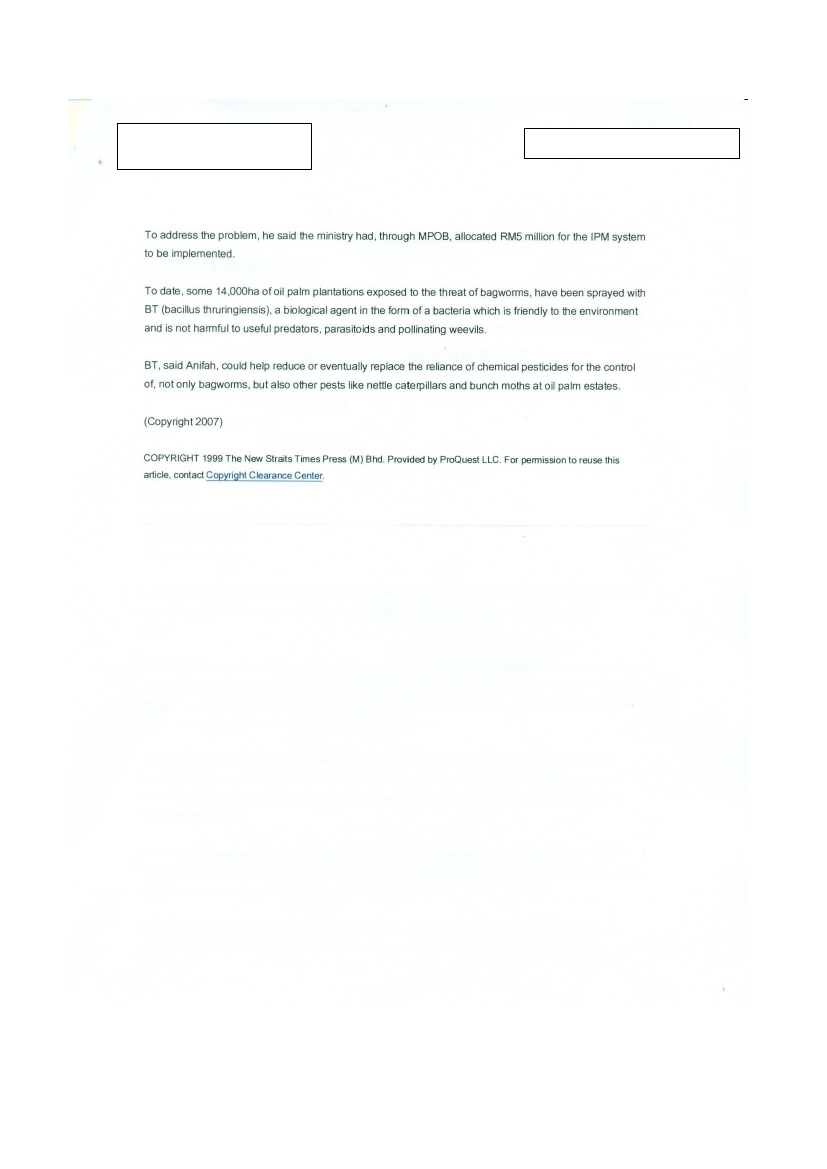

In the survey, 29 out of 113 respondents reported Bagworm outbreaks. This represents 26% of the oil palmestates in Perak State and is double the national average of 13.5%. Members of the MPOB report monthlyon the total area of oil palm infested and the return for October 2010 show that out of 58,185ha, 13,847 hawere infested in the Perak State.In 2007, the Deputy Plantation Industries and Commodities Minister reported that 33,475ha of oil palm inlower Perak State were seriously affected by Bagworm outbreaks. As a result, a Government subsidisedaerial spraying program was initiated but the number of Bagworms is again on the increase in part due to thelack of control by some estates and many smallholders. (See appendix 8.3)

www.controlunion.com

United Plantations manage about 35,791 ha of oil palm in lower Perak State and an aerial survey taken onst31 January 2011shows that the infestation of Bagworms in neighbouring properties is of significant threat toUnited Plantations. It is noted that airborne Bagworm larvae can spread over several kilometres over-timeand that one male and one female can become 843,000 bagworm within 6 months – assuming no naturalmortality.United Plantations are not unique in having pressure of bagworm attack originating from neighbouringplantations. It is a problem faced throughout Lower Perak where Sime Darby (Sugei Samak Estate), TaipingOil Palms, Palm World, Soon Seng, Ganda, Southern Perak, Old Samak, Kelapa Bali, Felda (Besout Estate)and MHC Plantations examples of others who face similar problems. (See appendix 8.4)

Photograph 1This photograph shows the outbreak of bagworm in estates that adjoin United Plantations and illustrates thedefoliation that can take place.

UP Plantations

Neighbouring Estates infected withbagworms

Following this reconnaissance, a second aerial reconnaissance was arranged for 13 managers ofneighbouring estates to United Plantations. It is noted that several of these managers were surprised tonote the extent of the bagworm outbreak on their respective properties.United Plantations subsequently arranged for training in bagworm monitoring and control techniques forthe neighbouring estates who clearly have an obligation to control bagworm.

www.controlunion.com

3.

Round Table on Sustainable Palm Oil. (RSPO).The RSPO is a global, multi-stakeholder initiative on sustainable palm oil. Members of RSPO andparticipants in its activities come from many different backgrounds, including plantation companies,manufacturers and retailers of palm oil products, environmental NGOs and social NGOs and from manycountries that produce or use palm oil.The principal objective of RSPO is “to promote the growth and use of sustainable palm oil through co-operation within the supply chain and open dialogue between its stakeholders”.The RSPO Principles and Criteria for Sustainable Palm Oil Production were adopted in November 2005.Malaysia prepared a National Interpretation of these Principles and Criteria and this was endorsed by theRSPO Executive Board in 2008. There are 8 principles, 39 Criteria and 125 indicators used to evaluatewhether an oil palm plantation and associated palm oil mill is operating in accordance with the RSPO beforea certificate of compliance can be awarded.On the 5 July 2011, there were 865,563 ha of certified oil palm across the globe producing 4,244,543 mt ofCPO. This represented about 10% of the supply base.There are 2 principles and some associated criteria that are related to the scope of this audit:Principle 4: The use of appropriate best practice by growers and mills.‘Criterion 4.5: Pests, diseases, weeds and invasive introduced species are effectively managed usingappropriate integrated Pest Management (IPM) techniques’.4.1.1: Documented Standard Operating Procedures (SOP) for estates and mills.4.1.2: Records of monitoring and the actions taken are maintained and kept for a minimumof 12 months.‘Criterion 4.6 Agrochemicals are used in such a way that does not endanger health or the environment.There is no prophylactic use, and where agrochemicals are used that are categorised as World HealthOrganisation Type 1A or 1B, or are listed by the Stockholm or Rotterdam Conventions, growers areactively seeking to identify alternatives, and this is documented’.4.6.1: Written justification in Standard Operating Procedures of all agrochemical use.4.6.2: Pesticides selected for use are those officially registered under the Pesticides Act 1974 (Act149) and the relevant provision (Section 53A); and in accordance with USECHH Regulations(2000).4.6.3: Pesticides shall be stored in accordance to the Occupational Safety and Health Act 1994 (Act514) and Regulations and Orders and Pesticides Act 1974 (Act 149) and Regulations.4.6.4: All information regarding the chemicals and its usage, hazards, trade and generic names mustbe available in language understood by workers or explained carefully to them by a plantationmanagement official at operating unit level.4.6.5: Annual medical surveillance as per CHRA for plantation pesticide operators.4.6.6: No work with pesticides for confirmed pregnant and breast-feeding women.4.6.8: Documented justification of any aerial application of agrochemicals.‘Criterion 4.7: An occupational health and safety plan is documented; effectively communicated andimplemented’.4.7.1: Evidence of documented Occupational Safety Health (OSH) plan which is in compliance withOSH Act 1994 and Factory and Machinery Act 1967(Act 139).‘Criterion 4.8 All staff, workers, smallholders and contractors are appropriately trained’.4.8.1: A training programme (appropriate to the scale of the organization) that includes regularassessment of training needs and documentation, including records of training for employeesare kept.Principle 8: Commitment to continual improvement in key areas of activity.‘Criterion 8.1: Growers and millers regularly monitor and review their activities and develop andimplement action plans that allow demonstrable continual improvement in key operations’.8.1.1: Minimise use of certain pesticides.th

www.controlunion.com

3.1 FAO International Code of Conduct on the Distribution and Use of Pesticides.The RSPO International Principles and Criteria specifically refer to the Food and AgriculturalOrganisation of the United Nations (FAO) International Code of Conduct on the Distribution and Useof Pesticides. It is an inherent requirement that any company certified in accordance with the RSPOprinciples and criteria is aware of and is implementing practices that comply.United Plantations demonstrated compliance as laid out in section 4 below.3.1.1Introduction to the code of practice.TheInternational Code of Conduct on the Distribution and Use of Pesticideswas one ofthe first voluntary Codes of Conduct in support of increased food security, while at thesame time protecting human health and the environment. It was adopted in 1985 by theFAO Conference at its Twenty-third Session, and was subsequently amended to includeprovisions for the Prior Informed Consent (PIC) procedure at the Twenty-fifth Session ofthe FAO Conference in 1989. The Code established voluntary standards of conduct for allpublic and private entities engaged in, or associated with, the distribution and use ofpesticides, and since its adoption has served as the globally accepted standard forpesticide management.ROME, 4 November 2002 -- A revised 'International Code of Conduct on the Distributionand Use of Pesticides' should significantly reduce the threats posed by agro-chemicals indeveloping countries. The Code was adopted by the FAO Council.3.1.2Summary of the code.Sets standards for governments, the pesticide, food and equipment industry,traders, environmental and consumer groups, trade unions and internationalorganizations and strengthens the monitoring and observance of these standards.Governments, the pesticide industry and international organizations recognize thevoluntary Code.Compliance with the Code is obligatory for the members of Crop LifeInternational, the international association of pesticide manufacturers.Several governments have incorporated the Code, or parts of it, into their nationalpesticide legislation.The revised Code promotes practices that minimize potential health andenvironmental risks associated with pesticides.It addresses the life-cycle of pesticides: from their development, regulation,production, management, packaging and labelling, to their distribution,application, use and control and disposal.It calls upon industry "to supply only pesticides of adequate quality, and to payspecial attention to the choice of pesticide formulations and to the presentation,packaging and labelling in order to reduce risks to users and minimize adverseeffects on the environment."Manufacturers should recall pesticides that pose an unacceptable risk to people,animals and the environment.It promotes Integrated Pest Management (IPM) strategies that reduce thereliance on pesticides.IPM emphasises the growth of healthy crops and encourages natural pest controlsystems.It urges countries to prevent the accumulation of obsolete pesticides and usedpesticide containers.The pesticide industry should assist in the disposal of toxic pesticide waste in anenvironmentally sound manner.(According to FAO estimates, more than 500,000tonnes of old and unused pesticides that have been banned or have expired areseriously threatening the health of millions of people and the environment innearly all developing countries and countries in transition).

www.controlunion.com

4.

United Plantations Bhd. Good Agricultural Practice (GAP).In 2008, United Plantations became the first plantation company in the world to be awarded the prestigiousRSPO certification for all their operations in the Perak State. The process included 2 pre-assessments and afull main assessment conducted by an audit team from Control Union Certifications.Subsequently annual surveillance audits have been conducted to confirm that the company continues tooperate in accordance with the RSPO principles and criteria and both Principles 4 and 8 were included in theannual surveillance audits.Principle 4: The use of appropriate best practice by growers and mills.4.1.1: Documented Standard Operating Procedures.United Plantations has a full set of Standard Operating Procedures covering all oil palm operations.The SOP for Bagworm identification and control comprises a 5 step preventative program:1. IPM.Planting of beneficial plants to enhance the natural parasitic and predator activities against bagworm.To date more than 98,000 beneficial broadleaved flowering plants have been planted.Census gangs deployed on each estate who take random frond samples in a pre-determined pattern.These fronds are subjected to insect counts and damage assessments by trained personnel.Regular aerial reconnaissance is carried out to better detect, pre-empt and treat potential outbreaks.For example:Bacillus Thuringiensisas the first line of treatment against an outbreak.As a final resort and only when the above steps have proven to be futile.

2.3.4.5.

Monitoring and census.

Aerial surveillance.Use of biological control agents.Chemical intervention.

4.1.2: Records of monitoring.Monitoring records of the use of Monocrotophos include:Monitoring census.Date of application.Field of application.Quantity of pesticide used and quantity of active ingredient per ha.Name of operator.4.6.1: Written justification for all agrochemical use.Justification for use is laid out in Field Management Manual supplements section 3.1.4.1.The use of Monocrotophos is justified as follows:It is the only effective pesticide available for the effective control of Bagworm in oil palmplantations with tall palms (3 metre total height).It is included in the Malaysian Palm Oil Board (MPOB) list of approved Pesticide for use in oilpalm plantations in Malaysia.4.6.2: Pesticides are those officially registered under the Pesticides Act 1974.Monocrotophos is registered under the Pesticides Act 1974. See also appendices.4.6.3: Pesticides shall be stored in accordance to the Occupational Safety and Health Act 1994 etc.All the United Plantation chemical stores are inspected as part of the RSPO certification procedure and itis noted that they all comply with the relevant act as well as best practice.All stores are secured under lock and key with restricted access.Pesticides are separated by class and class 1 and II chemicals are further stored underseparate lock and key within the main store.Store keeper is fully trained in the handling of all pesticides.4.6.4: All information regarding the chemicals and its usage, hazards, trade and generic names must beavailable in language understood by workers or explained carefully to them by a plantation managementofficial at operating unit level.MSDS leaflets are available in all pesticide stores. (Material Safety Data Sheet)Workers applying Monocrotophos are fully trained and aware of the hazards.

www.controlunion.com

4.6.5: Annual medical surveillance as per CHRA for plantation pesticide operators.All pesticide operators have a monthly medical check-up.All pesticide operators undergo a comprehensive annual medical check-up which includesblood analysis.It is noted that there have been no documented cases of any operators suffering from anysymptoms of pesticide poisoning over the past 16 years.Furthermore It is noted that immediately after the allegation arose in the Danish press, aninterim and additional full medical check-up was conducted and blood analysis showneither exposure nor symptoms of Monocrotophos poisoning.4.6.6: No work with pesticides for confirmed pregnant and breast-feeding women.No women are employed for agrochemical application purposes. This includes both pesticides andherbicides.4.6.8: Documented justification of any aerial application of agrochemicals.No aerial application of any agrochemicals on any United Plantation estates.4.7.1: Evidence of documented Occupational Safety Health (OSH) plan which is in compliance with OSH Act1994 and Factory and Machinery Act 1967(Act 139).United Plantations have a comprehensive generic OSH plan which includes:A list and classification of all hazards – including the application of pesticides.A risk assessment for each hazard.Action to be taken to eliminate the risk associated with each hazard.Personal Protective Equipment (PPE) to be worn for all operations.Management responsible for ensuring implementation of action.Training required for each operation that is linked to the hazard and risk assessment.Regular meetings of OSH committees for each estate.Daily safety briefings for all workers applicable to their duties.Records of distribution and maintenance of all PPE distributed.4.8.1: A training programme (appropriate to the scale of the organization) that includes regular assessmentof training needs and documentation, including records of training for employees are kept.Training programs are prepared based upon the hazard and risk assessments and full training recordsare available that include:Date.Purpose.Details of the training.List of all participants.Photographic evidence.It is noted that for the application of Monocrotophos, dedicated and trained teams (comprising 3persons to a team) are deployed.The audit team note that the training records are comprehensive and linked to the OSH(Occupational Safety and Health) policy procedures. Interviews of workers confirmedthat the training was carried out and was effective.Principle 8: Commitment to continual improvement in key areas of activity.8.1.1: Minimise use of certain pesticides.United Plantations were awarded RSPO certification in July 2008 and since then have under-gone 2annual surveillance audits. During these audits, their progress to reduce certain pesticides was auditedand the following findings noted with particular reference to Monocrotophos:IPM is implemented throughout all estates.The number of beneficial plants on all estates is being increased on an annual basis.In 2007 the average number of plants per ha was 1.11. There has been an increase of about260% to 2.92 plants per ha.The use of pheromone traps has increased.Across the entire United Plantations oil palm estates, the quantity of Monocrotophos hasdecreased from 0.35 kg/ha in 2006 to 0.20kg in 2009 and a slight increase in 2010 to 0.245kg/ha due to a rise in bagworm numbers on neighbouring estates which have spread into UnitedPlantations Estates.It is also noted that the use of paraquat was eliminated entirely as from October 2010 as aconsequence of a voluntary effort which commenced in February 2008.

www.controlunion.com

5.

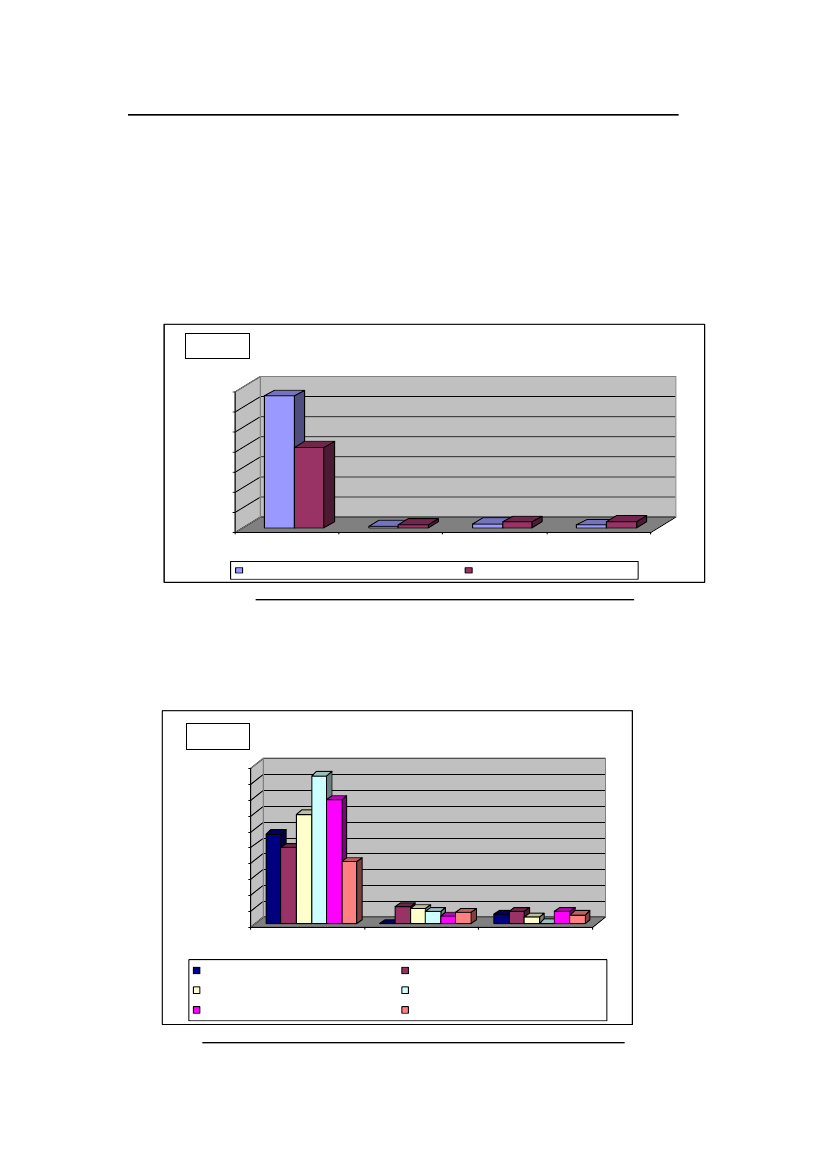

Research work to find an effective alternative to Monocrotophos for trunk injection.The Research Department of United Plantations has been taking a pro-active approach to source andevaluate alternatives Class 1B to Monocrotophos since 2006 and this work includes the following:1.Internal trials of 2 formulations of acephate and imacloprid.2.Active engagement of multi-national pesticide companies to source viable alternatives tomonocrotophos for trunk injection.3.Engaging CABI (Commonwealth Agricultural Bureaux International) to conduct a two year project toresearch other effective bio control methods of bagworm.5.1 Internal trials.Two trials were carried out in February 2011 in areas where 4-10 larvae per frond were present. Thisis less than optimal levels of pest numbers.5.1.1 Trial 1showed that monocrotophos was more effective than acephate with the acephatetreated palms having slightly higher pest numbers / frond at week 4.Trial 1Trunk Injection for Bagworm ControlLSE 35A Treated 17.2.2011 P. pendula/M. plana

7

Av Live Larvae/Frond

6543210Pre-TmtWeek 1Week 2Week 4

Monocrotophos (Phoskill 10ml/palm)

Acephate (Lipat 4.4g/palm)

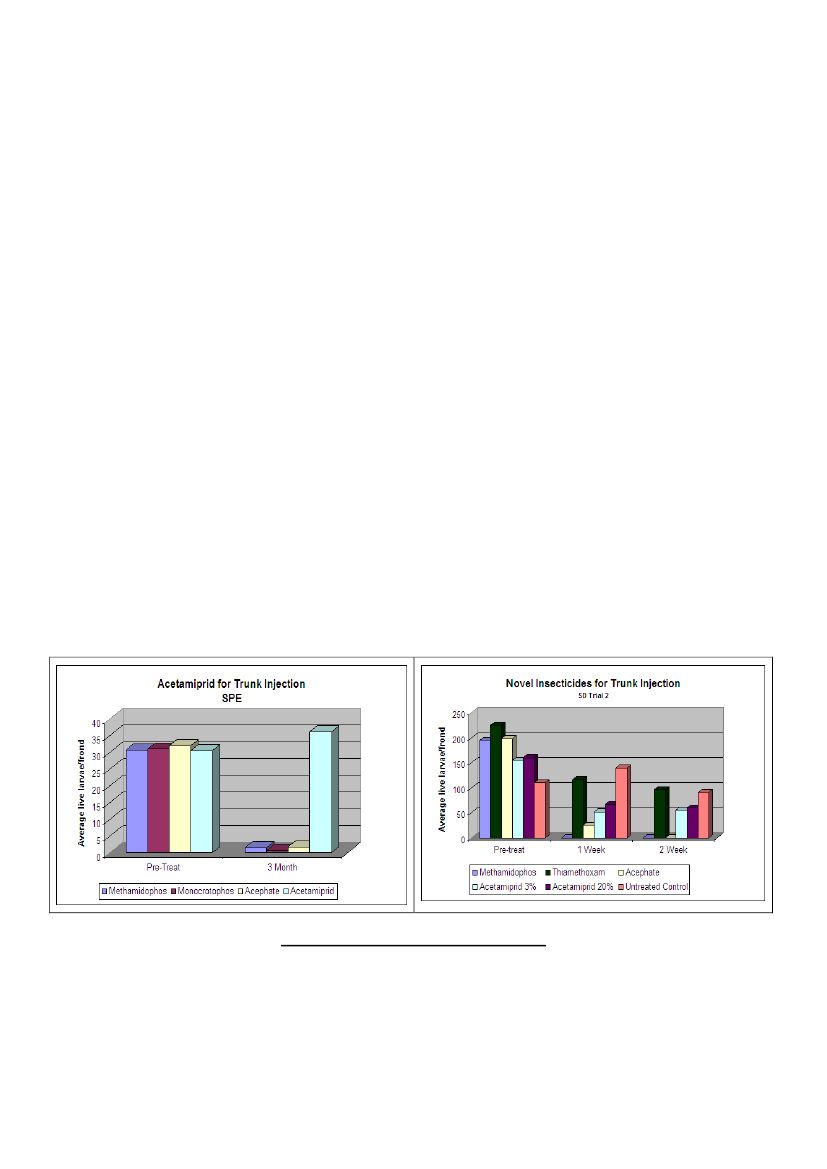

Table 1 showing trial result with monocrotophos and acephate.5.1.2 Trial 2showed that acephate as Duo Man Lo and imidacloprid gave inferior control comparedto monocrotophos.Acephate as Lipat at 20ml/palm appeared to give good control even up to 4 weeks but this is atdouble the dosage as the usual rate being used commercially in the past. Acephate isdisallowed to be used for trunk injection in Malaysia.

Trial 210.009.008.007.006.005.004.003.002.001.000.00

Trunk Injection For Bagworm Control Trial 2LSE 35A Treated 26-28.2.2011 P.pendula/M. plana

Average live larvae/frond

Pre-Tmt

Wk 1

Wk 2Acephate ( Duo Man Lo 10ml/palm)Acephate (Lipat 20ml/palm)Untreated

Monocrotophos (Phoskill 10ml/palm)Acephate (DML 20ml/palm)Imidacloprid ( Confidor 20ml/palm)

Table 2 showing second trial result with monocrotophos and acephate.

www.controlunion.com

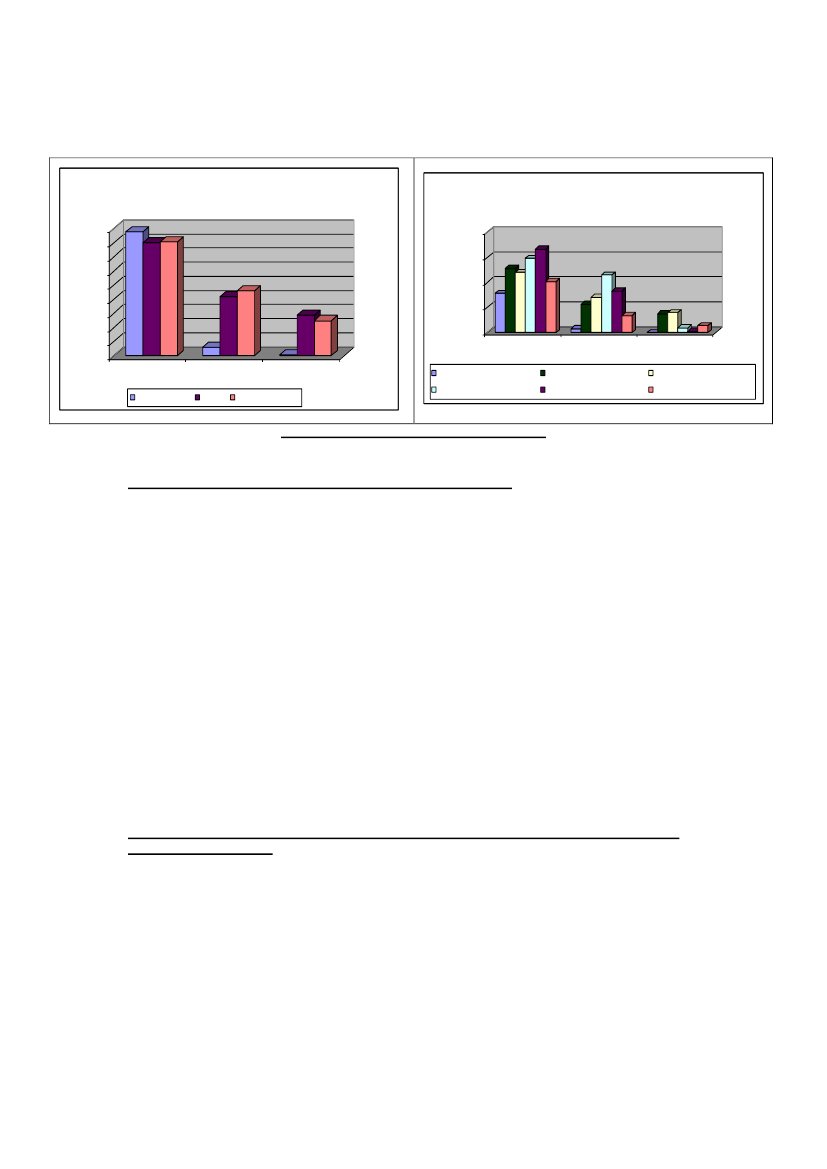

5.1.3 Control plot.Pests in the control plots can also fluctuate due to their life cycle stage at the time of the trial aswell as other natural factors active in the field.United Plantations used 4 plots containing 20 palms each in order to minimise plot variations.Early results from trials 1 and 2show that monocrotophosis more effective in controlling bagworm.Acephate treated palms show re-infection after 4 weeks.5.1.4 Longer term trial.An area has been identified to carry out more formal trials over a period from February 2011 tofirst quarter of 2013. The trials include the following treatments of trial plots covering 4 rows of 5palms replicated 3 to 4 times:a. Acephate at 3.7g a.i. per palm.(5ml/palm).b. Acephate at 7.5g a.i. per palm.(10ml/palm).c. Acephate at 11.25g a.i. per palm.(15ml/palm).d. Acephate at 15g a.i. per palm.(20ml/palm).e. Imidacloprid at 10ml product per palm.f. Imidacloprid at 20ml product per palm.g. Monocrotophos at 10 ml product per palm.h. Untreated.Palm census is carried out by well trained and experience staff assisted by workers to checkthe trial results. The census is carried out at each week for 4 weeks from the treatment day.The 10 most infested palms in each plot is marked and results monitored. Census includes therecording the live larvae, dead larvae, live pupae, empty pupae and dead pupae.5.2 Other trial data.In September 2010, trial data from both United Plantation and from other trials were presented to theDanish Energy Aency.In summary these trials indicated that:Monocrotophos and metamidophos gave the most consistent and effective control through trunkinjection for leaf eating pestsAcephate is not as consistent in performance, being slower acting and not reducing the pestpopulation to the same extant as the products in (a)Acetamiprid, thiamethoxam, fipronil, chlorantraniliprole, and ememectin were also tested andfound to be not effective or slower acting the the standard monocrotophos or metamidophostreatments.

Table 4. Graphic results of these other trials.

www.controlunion.com

Novel Insecticides for Trunk InjectionSD Trial 4

Novel Insecticides for Trunk InjectionSD Trial 6

90Average live larvae/frond

200Average livelarvae/frond

80706050403020100Pre-treatMethamidophos1 WeekFipronil2 WeekUntreated Control

150100500Pre-treat1 WeekChlorantraniliproleEmemectin 5ml/5ml w ater2 WeekImidaclopridUntreated Control

MonocrotophosEmemectin 2.5ml/7.5ml w ater

Table 5. Graphic results of these other trials.

6.

Active engagement of multi-national pesticide companies.See also appendices for communications with the following companies.6.1 BASF.After several meetings between United Plantations and their R &D personnel, BASF indicated they areyet to formulate an alternative to replace monocrotophos. (See appendices 8.5 to 8.10).6.2 Bayer Crop Science.Active discussions are on-going between United Plantations and Bayer Crop Science to test a range ofexisting and novel Bayer products for their efficacy in trunk injection for bagworm control. Bayer is stillworking on the technical stability of their products before commencing the trial.(See appendices 8.11 and 8.12).6.3 Syngenta.Several discussions have been held between United Plantations and Syngenta to seek for alternativeinsecticides to replace monocrotophos. Whilst Syngenta indicated they have some experimentalcompounds that can be tested for trunk injection, they have written to request for more time before thesamples are available for testing. (See appendix 8.13)6.4 Cheminova.Having met with Cheminova’s Business Manager for Asia and their Malaysia Head we had enquired ifthey have any alternatives to monocrotophos. To-date United Plantations have not received anyindications from them on this subject. (See appendices 8.14 and 8.15).

7.

Engaging CABI to conduct a two year project to research other effective bio controlmethods of bagworm.It is anticipated that an agreement will be entered into with CABI for a collaborative trial to breed and releasepredators as biological control agents for bagworm.This project is expected to last for a period of 2 years and interim results are not expected until the thirdquarter of 2012. (See appendices 8.16 and 8.17).

www.controlunion.com

8.

Appendices.8.1 Abbreviations applicable.Chemical Health Risk AssessmentCommonwealth Agricultural Bureaux InternationalCrude Palm OilCorporate Social ResponsibilityControl UnionControl Union CertificationDepartment of Occupational Safety and HealthFood and Agriculture Organization of the United NationsFresh Fruit BunchGood Agriculture PracticeHazard Analysis and Critical Control PointHazard Identification, Risk Assessment and Risk ControlIntegrated Pest ManagementMaterial Safety Data SheetNon Governmental OrganisationNational Institute of Occupational Safety and HealthOccupational Safety and HealthOccupational Safety and Health Assessment SchemePersonal Protective EquipmentResearch and DevelopmentRoundtable on Sustainable Palm OilStandard Operating ProcedureUnited PlantationRegulation2000-Use And Standard of Exposure of Chemicals Hazardous to Health,Visiting Medical OfficerWorld Health Organizations

CHRACABICPOCSRCUCUCDOSHFAOFFBGAPHACCPHIRARCIPMMSDSNGONIOSHOSHOSHASPPER&DRSPOSOPUPUSECHHVMOWHO

Appendix 8.2

www.controlunion.com

Appendix 8.3.

www.controlunion.com

Appendix 8.3 continued.

.

www.controlunion.com

Appendix 8.4

www.controlunion.com

Appendix 8.5

www.controlunion.com

Appendix 8.6

www.controlunion.com

Appendix 8.7

www.controlunion.com

Appendix 8.8

www.controlunion.com

Appendix 8.9

www.controlunion.com

Appendix 8.10

www.controlunion.com

Appendix 8.11

www.controlunion.com

Appendix 8.12

www.controlunion.com

Appendix 8.13

www.controlunion.com

Appendix 8.14

www.controlunion.com

Appendix 8.15

www.controlunion.com

Appendix 8.16

www.controlunion.com

Appendix 8.17

www.controlunion.com

Appendix 8.18

www.controlunion.com

Appendix 8.19

www.controlunion.com