Erhvervs-, Vækst- og Eksportudvalget 2011-12

ERU Alm.del Bilag 254

Offentligt

SiemensWind Power Division

Michael HannibalCEO Offshore, Business Unit EMEA

EKF2 May 2012� Siemens AG 2012� Siemens AG 2012. All rights reserved.

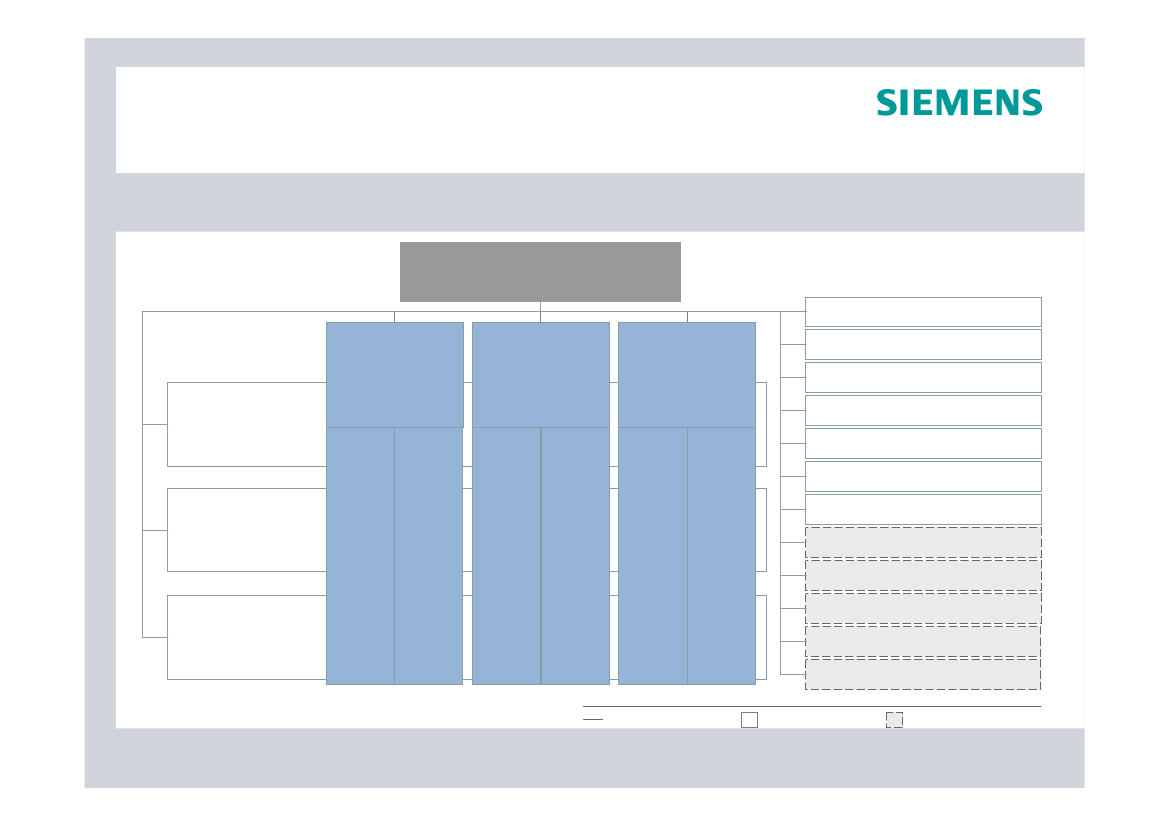

Siemens Global StructureSectorsIndustry

DivisionsIndustry automationDrive technologiesCustomer serviceOil & gasEnergy servicePower transmissionSolar and hydroClinical products

Energy

Fossil power generationWind powerImaging and therapy systemsCustomer solutionsDiagnosticsRail systemsMobility and logisticsLow and medium voltage

Healthcare

Infrastructure & Cities

Smart gridBuilding technologiesOSRAM� Siemens AG 2012. All rights reserved.

Siemens Energy SectorEnergy products and solutions – in 6 Divisions

Products and Systems in 6 DivisionsFossil PowerGenerationWindPowerSolar &HydroEnergyServicePowerTransmission

Oil & Gas

� Siemens AG 2012. All rights reserved.

Siemens Wind PowerFacts at a glanceSiemens Wind Power facts

One of the world’s leading suppliers of wind power solutionsAcquired Danish wind turbine manufacturer Bonus Energy A/S in 2004Installed Base: > 10,600 turbines with > 15,800 MW capacity1)Installed: > 2,900 MW in 2011More than 8,000 employees globallyRecord order backlog of ~ € 12 billion incl. serviceRevenue in 2011: ~ € 3,9 billion2)1) Dec 20112) consolidated on Renewable Energy Division level

� Siemens AG 2012. All rights reserved.

Siemens Wind Power is on track for further growth

Clear No. 1 in Offshore

Major German orders (Borkum Riffgrund II, Meerwind)Alliance with Scottish Southern Energy for UK round 3

Enel Green Power onshore order of 1.2 GW frame contractNew direct drive turbines with 50% less moving parts andsignificant weight reduction

SWT 6.0 next generation offshore turbine prototype installed in Høvsøre, DenmarkSWT 2.3-113 for low to medium wind speeds

> DKK 1 billion investment initiated in Denmark

� Siemens AG 2012. All rights reserved.

Division structure reflects importance ofthree Business Units and Global FunctionsOrganizational structure for E WWind Power (E W)

Felix Ferlemann (CEO)Wolfgang Hermann (CFO)Americas (AM)Europe, MiddleEast, & Africa(EMEA)Jan Kjaersgaard (CEO)Gerlinde Sturm (CFO)

Chief Technology OfficerCTO – Henrik Stiesdal

Asia Pacific(APAC)Kay Weber (CEO)Bruno Nicol (CFO)

StrategyST – Moritz IngerfeldBusiness ExcellenceEnv. Prot., Health Mgmt & SafetyHuman ResourcesPerformance ControllingRisk & Internal ControlCorporate CommunicationsExport Control and CustomsGeneral Counsel, Legal & Compliance

Engineering (EN)

Mark Albenze (CEO)Karen Lane (CFO)

ONM. Revak

OFT. Mousten

ONH. Reuter

OFJ. M.Hannibal

ON

OF

B. Mueller M.V.Gerhardt

Supply ChainManagement (SCM)

ProjectManagement (PM)

IT & SAPSEC & CR

Line Management

E W organization

E Sector organization

� Siemens AG 2012. All rights reserved.

Siemens Wind Power – a global player

In 2011 alone, we have createdmore than 1000 jobs inDenmarkBut Denmark is still the hotspot of theglobal wind industry.150 new positions are stillscheduled to be created thisyear1 billion DKK investments inR&D test facilities in Denmarkare under way

� Siemens AG 2012. All rights reserved.

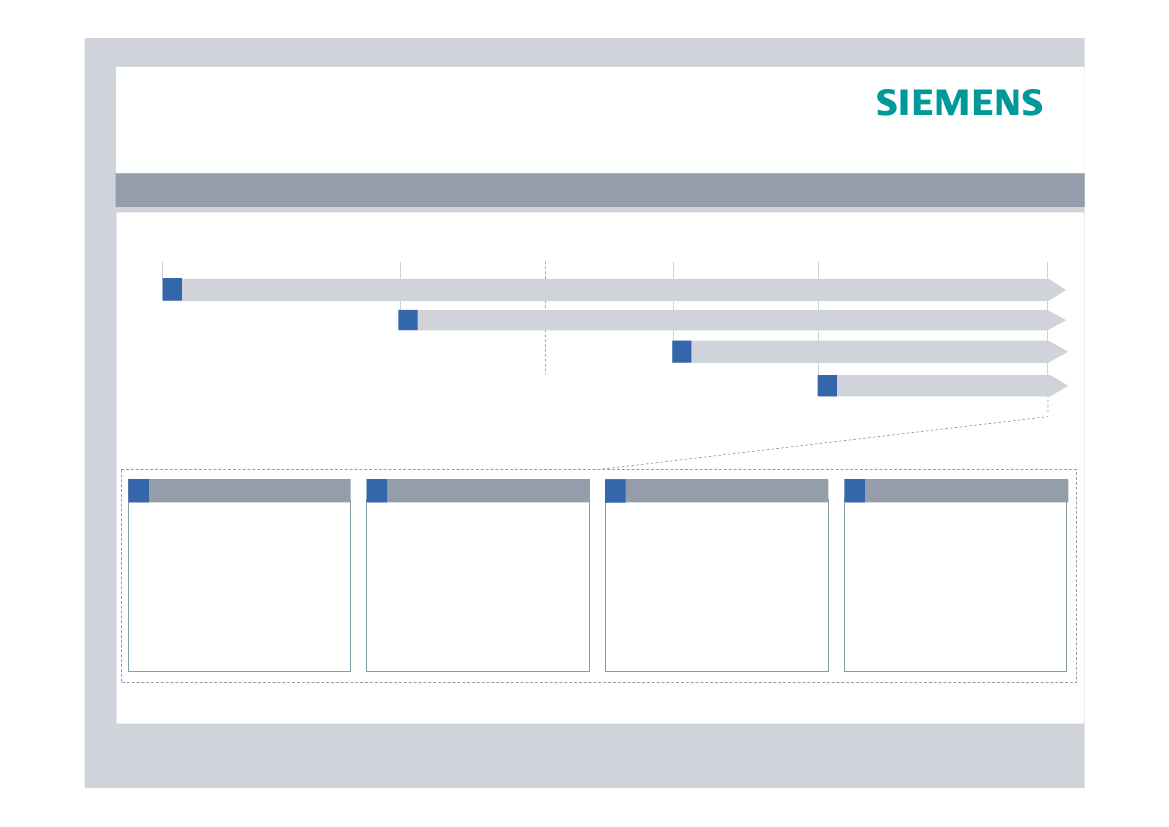

Continuous investment in DenmarkDevelopment of Siemens Denmark facilities19801Brande2Aalborg3Engesvang

2002

2004

2006

2008

2011

(continuous extensions since 2004)

Acquisitionof Bonus

4Ølgod

1

Brande

2

Aalborg

3

Engesvang

4

Ølgod

Nacelle production,R&D, headquarters3,700 employees86,000 m2under roof,460,000 m2land

Blade production1,100 employees71,000 m2under roof,350,000 m2land

Blade production300 employees16,000 m2under roof,140,000 m2land

Hub production100 employees7,500 m2under roof,34,500 m2land

� Siemens AG 2012. All rights reserved.

Groundbreaking of new test center, March 6th2012

CTO Henrik Stiesdal broke the ground for the newR&D test center in Brande on March 6th.The 8,000 sqm. building is expected to be finishedby summer.The facility, with a height of 22 m, will houseprototype production, component testing,laboratories and warehousing

� Siemens AG 2012. All rights reserved.

We continue with our strategy4 I strategy

InnovationKey success factor to bring down costsand differentiate Siemens fromits competitorsMakingWind Power competitivewith conventional energysourcesMaintaining leadingposition in windSecuring technologyleadership

IndustrializationKey lever to make wind power affordableand position Siemens as key enabler forenergy change

InternationalizationDrives local accessibility, strengthensregional commitment and gets Siemensclose to its customer

Intensifiedcustomer tiesEnables progress in projectsand technology while deepeningcustomer relations

� Siemens AG 2012. All rights reserved.

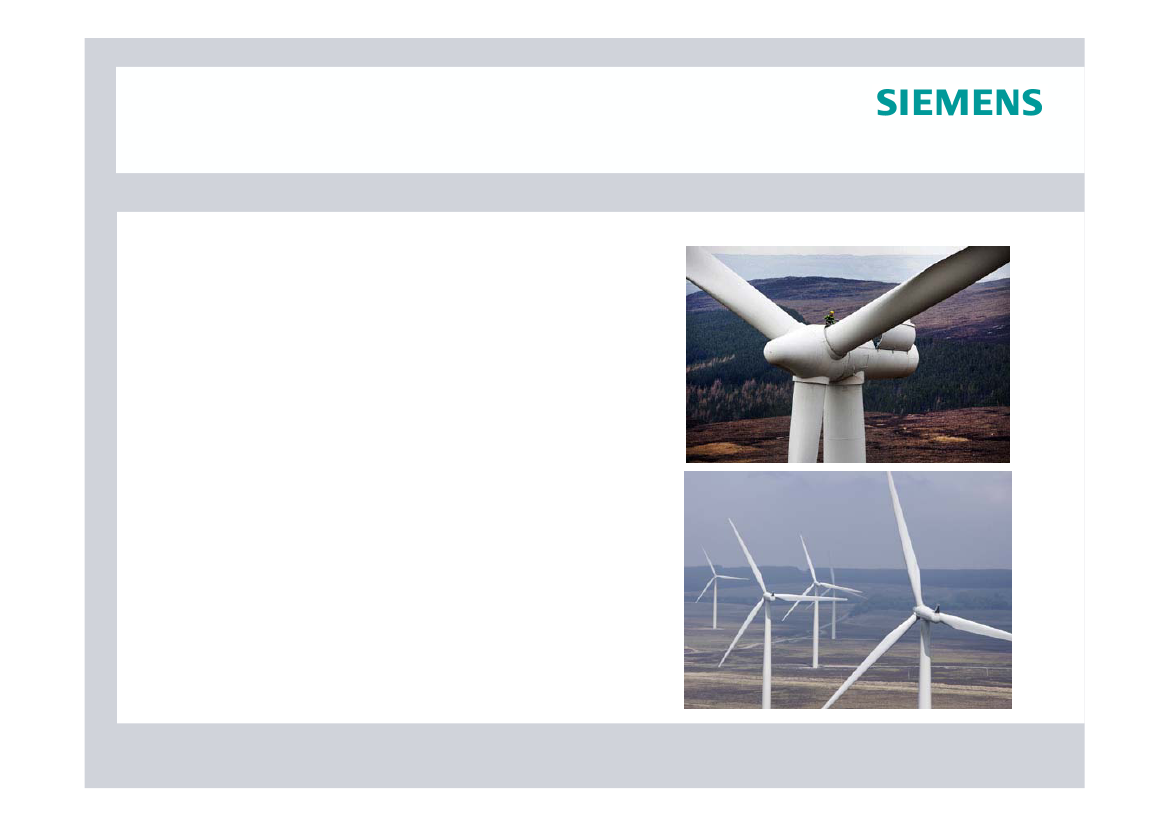

Continuous investment into new technologyresulted in groundbreaking direct drive turbinesInnovation - Siemens direct drive technology

Introduction of new SWT-3.0-101 direct drive windturbine in April 2010 and the SWT-2.3-113 directdrive wind turbine in March 2011Direct drive technology with no gearboxSimplified design with 50% less parts than inequivalent geared designMore power with compact designMinimizes the cost of energy

� Siemens AG 2012. All rights reserved.

Siemens SWT-6.0-154: The next generation offshorewind turbineInnovation - SWT-6.0-154

Direct drive technology with permanent magnetgenerator and a 154 m rotor offers superiorperformance and efficiency.Optimized nacelle layout for excellent serviceability; withthe highest degree of safety and quality in mind.Proven technology, redundancy in critical componentsand rigorous testing for maximized reliability.New low-weight standard for offshore wind turbinesoffering significant cost benefits throughout the entirevalue chain.Industrialization in manufacturing, quality assurance andinstallation, significantly shortening commissioning timefor faster project hand-over.

Prototype installed in Høvsøre Denmark: SWT-6.0-120

� Siemens AG 2012. All rights reserved.

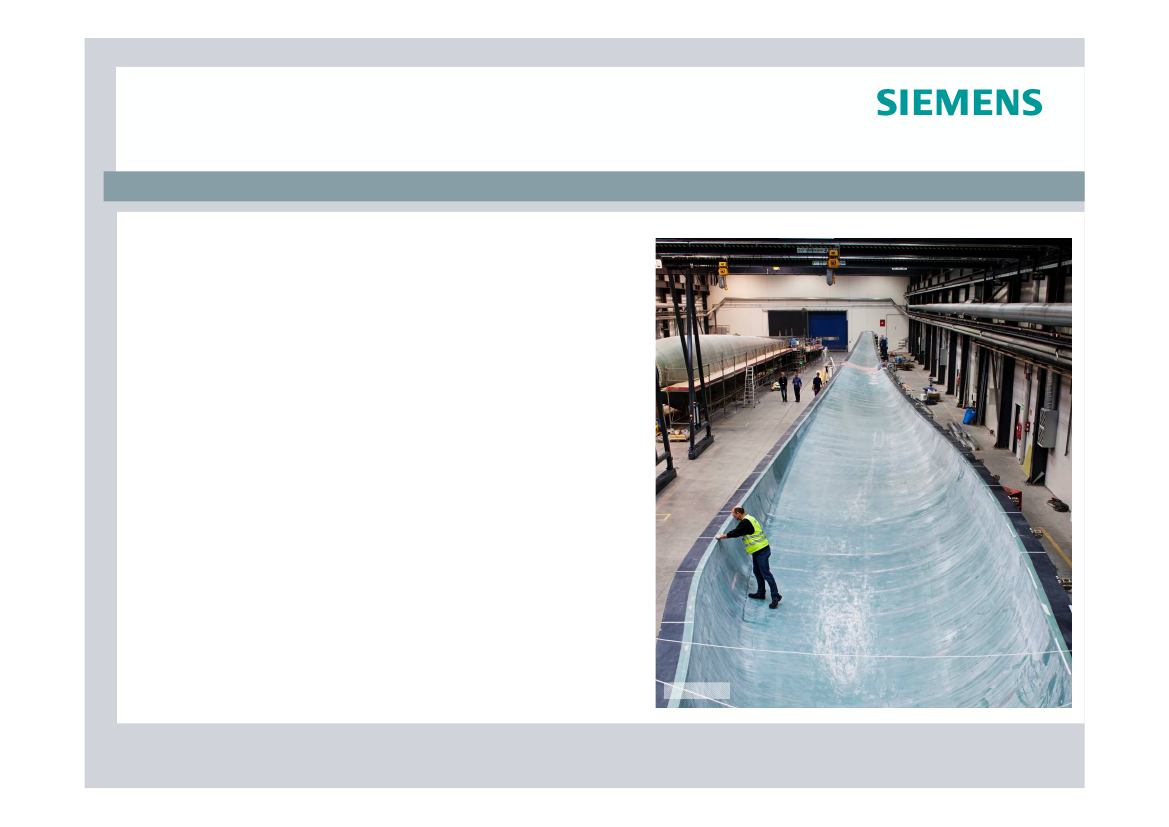

Proven IntegralBlade�technology eliminates gluejoints and ensures blade strengthTechnology: IntegralBlade�

IntegralBlade�technology is a closedmanufacturing process invented bySiemens offering high quality in anoptimal working environment.One-shot manufacturing processeliminating the presence of glue joints inthe blade for a robust design.The IntegralBlade�process is based onvacuum-assisted resin transfer molding.The blade is not gel coated as part of themanufacturing process, making itpossible to visually inspect the blade toensure high quality.

B75 Mould

� Siemens AG 2012. All rights reserved.

From Bonus to the new assembly lineIndustrialization - Brande facilities and 2.3 nacelle production

2004Production:3 x 2.3 MW nacelles per week36 h per turbine

2011Production Capacity:40 x 2.3 MW nacelles per week17.5 h per turbine

� Siemens AG 2012. All rights reserved.

Market leader in offshore with > 2 GW installed*Burbo Banks, UK25 x SWT-3.6-107 (2007)Lynn / Inner Dowsing, UK54 x SWT-3.6-107 (2008)Gunfleet Sands, UK48 x SWT-3.6-107 (2009)Rhyl Flats, UK25 x SWT-3.6-107 (2009)Walney, UK51 x SWT-3.6-10751 x SWT-3.6-120Pori, FIN1 x SWT-2.3-101 (2010)Baltic I, DE21 x SWT-2.3-93 (2010)Rudong Intertidal, CHN21 x SWT-2.3-101Vindeby, DK11 x 0.45 MW (1991)Middelgrunden, DK20 x SWT-2.0-76 (2000)Samsø, DK10 x SWT-2.3-82 (2002)Rønland, DK4 x SWT-2.3-93 (2002)Rødsand/Nysted, DK72 x SWT-2.3-82 (2003)Frederikshavn, DK1 x SWT-2.3-82 (2003)Horns Rev II, DK91 x SWT-2.3-93 (2009)Rødsand II, DK90 x SWT-2.3-93 (2010)Lillgrund, SE48 x SWT-2.3-93 (2007)Hywind, NO1 x SWT-2.3-82 (2009)*commissioned

� Siemens AG 2012. All rights reserved.

Many projects under installation and to come…Greater Gabbard, UK140 x SWT-3.6-107Sheringham Shoal, UK88 x SWT-3.6-107London Array, UK175 SWT-3.6-120Lincs, UK75 x SWT-3.6-120Gwynt Y Mor, UK160 x SWT-3.6-107West of Duddon Sands, UK108 x SWT-3.6-120Teesside, UK27 x SWT-2.3-93Anholt, DK111 x SWT-3.6-120Baltic 2, DE80 x SWT-3.6-120Borkum Riffgat, DE30 x SWT-3.6-107DanTysk, DE80 x SWT-3.6-120Borkum Riffgrund 1+2, DE178 x SWT-3.6-120Meerwind Süd Ost, DE80 x SWT-3.6-120Amrumbank West, DE80 x SWT-3.6-120

� Siemens AG 2012. All rights reserved.

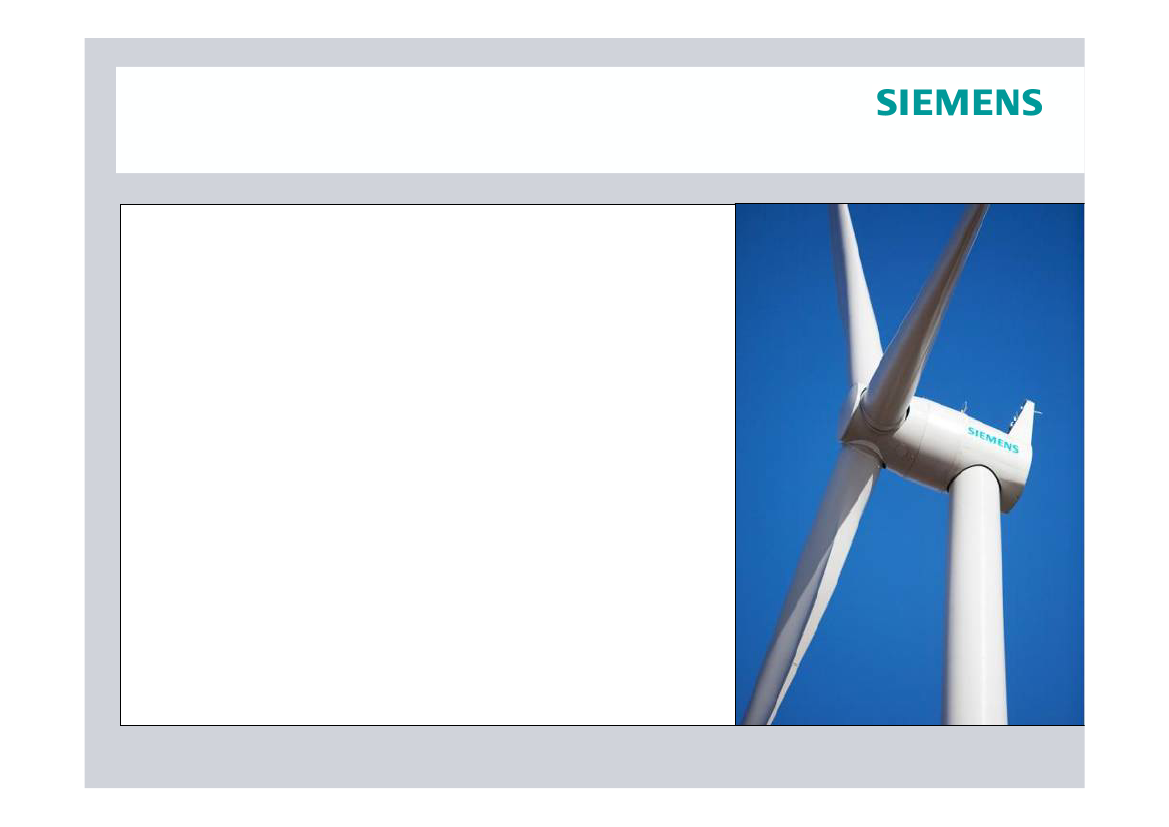

Siemens is also growing strong in onshore wind

In FY 2011, onshore projects accounted for 70%of the wind power revenueSiemens is particularly strong in the large U.S.market and other key marketsSiemens isNo. 1 in the UKNo. 3 in the U.S.No. 2 in Canada

� Siemens AG 2012. All rights reserved.

EKF – an essential and reliable partner

EKF support is essential for the market entrance of newtechnologies, e.g. direct drive turbines, new tower concepts,new & larger bladesEKF is key partner for financing in Siemens Wind Power’skey / growth marketsOnshore:Offshore:in Europe (e.g. Turkey) and many other growthmarkets (e.g. Africa & Asia Pacific)investors increasingly seeking project financeincl. construction phase which is still extremelychallenging; increasing project size & missingproper syndication market; high capital needsnecessary to realize the multitude of futureprojects

EKF is the premier ECA when it comes to Offshore WindFinancing (strong track record)

� Siemens AG 2012. All rights reserved.

EKF – an excellent relationship

First two Siemens Wind Power projects with EKF participationhave been closed in 2004 (Norway, Statkraft AS) and 2006(Sweden, Vattenfall AB)Siemens leading market share and #1 in offshore orders coupledwith the strong growth and high capital needs have strengthenour relationship with EKFMeanwhile, the total exposure involving Siemens Wind Power isof today > EUR 700’. A significant number of transactions is inthe pipeline (~ EUR 1.500’)EKF has of today supported Siemens in installing more than1,500 MW world wideA substantial EKF contribution (volume-wise) is a significant partof today's offshore financing structures

� Siemens AG 2012. All rights reserved.

EKF – project exampleMeerwind 288 MW Offshore Wind FarmCountry: GermanySponsor: Blackstone (80%)Financial Close: 08/2011Expected Take Over: Q1/2014Project & financing key factsLocation: ~23 km NW of the island of Helgoland, North SeaInstalled capacity: 288 MWScope of Supply: 80 x SWT 3.6 – 120Total investment: ~EUR 1,200’Financial Advisors: KfW IPEX, Dexia Bank & Green GiraffeTotal debt financing: ~EUR 820’EKF’s share (guarantee) of total debt is ~30%

Project highlightsGermany‘s largest fully financed Offshore Wind Farm includingconstruction phaseFirst offshore wind project to reach financial close under the KfW 5’’offshore programWill provide green electricity for more than 400,000 homes inGermany

� Siemens AG 2012. All rights reserved.

How EKF can support our growth endeavors

Ensuring competitive financial terms & conditions (stayingcompetitive towards i.e. Euler, Hermes and KfW)Support in challenging countries (e.g. Greece, CEE & Africancountries)

Support for projects with new technology (DD machines/ new towerconcepts/ new and larger blades)

� Siemens AG 2012. All rights reserved.

Thank you very much for your attention!

Page 22

Revision 2.0

� Siemens AG 2012. All rights reserved.