Trafikudvalget 2010-11 (1. samling)

TRU Alm.del Bilag 5

Offentligt

Your used tyres are a valuable resourcethat should not be dumped or burnedBesøg af Transportudvalget i Mindelheim, 22. september 2010

Page 1

Program

15.0015.10

Velkomst, Genan generelt og Genans historie med asfalt (MH)Modificering af asfalt i Tyskland (Prof. Damm)

15.3016.1516.2516.4517.0017.30

Rundvisning på fabrikkenPause, forfriskningStøjreducerende gummiasfalt (Carsten Rickers)Diskussion og spørgsmålLife Cycle Assessment, besparelse i drivhusgasser og miljø (LR) samt diskussionAfgang til München

Indlægsholdere:Professor, dr. Ing., Klaus-Werner Damm, en af Tysklands førende eksperter i asfaltteknologi ogmedlem af flere udvalg under FGSV, der står for udarbejdelsen af det tyske RegelwerkCarsten Rickers, Amt für Strassen und Verkehrstechnik, Stadt KölnMichael Hvam, Global Sales Director, Genan Gruppen GmbHLars Raahauge, Director of Business Development, Genan Business & Development A/S

Page 2

“True recycling requires processing at a level where theoutput substitutes virgin materials.Consequently this leads to avoided production and a profoundsaving of resources.”

Page 3

Verdens største recycler af brugte dæk

35,000 tons fabrikViborg, Danmark, I drift siden 1990Kapaciteten fordobles til 70,000 tons i 2011

65,000 tons fabrikOranienburg, Berlin, Tyskland, i drift siden2003

70,000 tons fabrikDorsten, NRW, Tyskland, i drift siden2008

70,000 tons fabrikMindelheim, Bayern, Tyskland, 2010

100,000 tons fabrikFørste amerikanske fabrik åbnes i Houston, Texas i 2011

Total kapacitet i 2011: 365,000 tonsPage 4

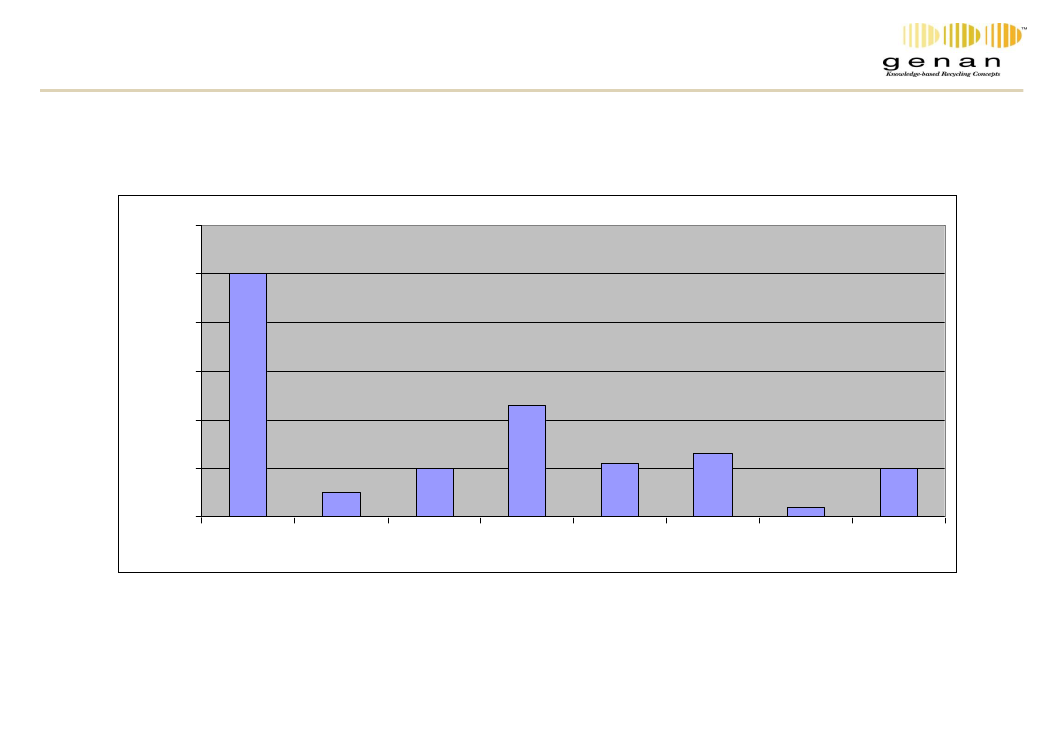

Polymer modificering af bitumen i Europa 2006

605040

%

3020100AustriaDenmarkFranceGermanyItalySpainSwedenSchweiz

Kilde: European Asphalt Pavement Association 2008

Page 5

Polymer modificering af bitumen i Tyskland

25

20

15

%10

5

019992000200120022003200420052006

YearKild: European Asphalt Pavement Association 2008

Page 6

Hvad er Road+ ?100 dele gummipulver fraGenan4,5 deleVestemaner� fraEvonik

Road+

Page 7

Sammenligning af Road+ vs. SBS i forholdet 2,5:1Dokumenteret bedre performance når det drejer sig om:

SporkørselRevnerStøjdæmpningHøje såvel som lave temperaturerHøje såvel som lave belastninger

Page 8

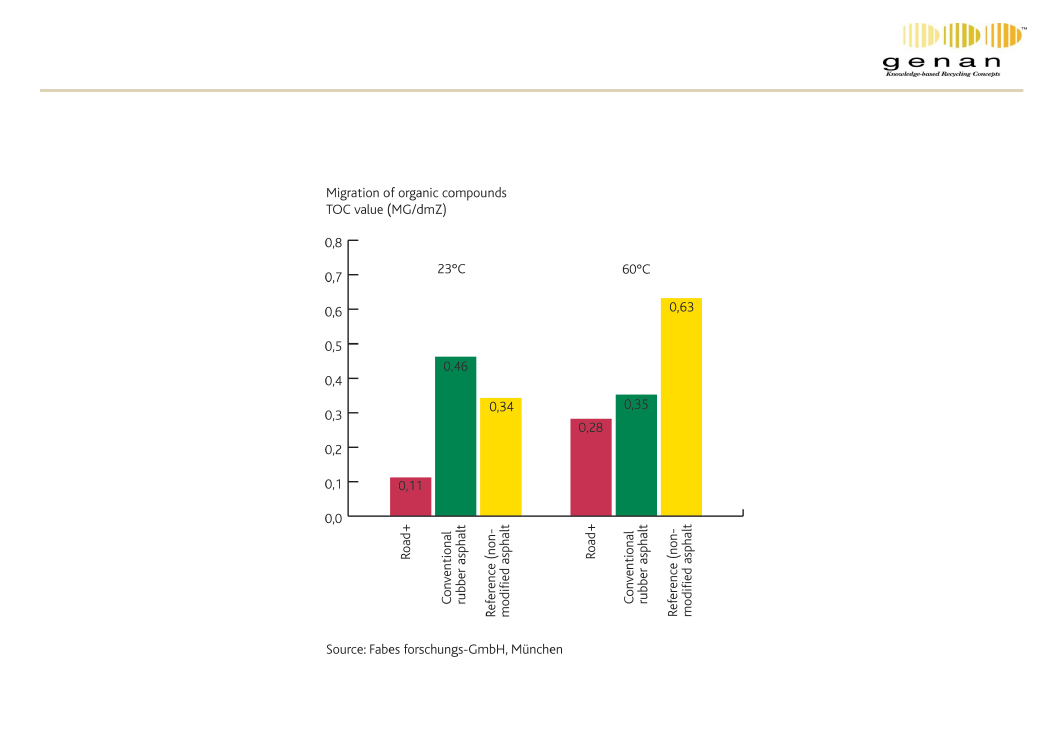

Miljøet - Udvaskning

Mindre udvaskning af organiske materialer

Page 9

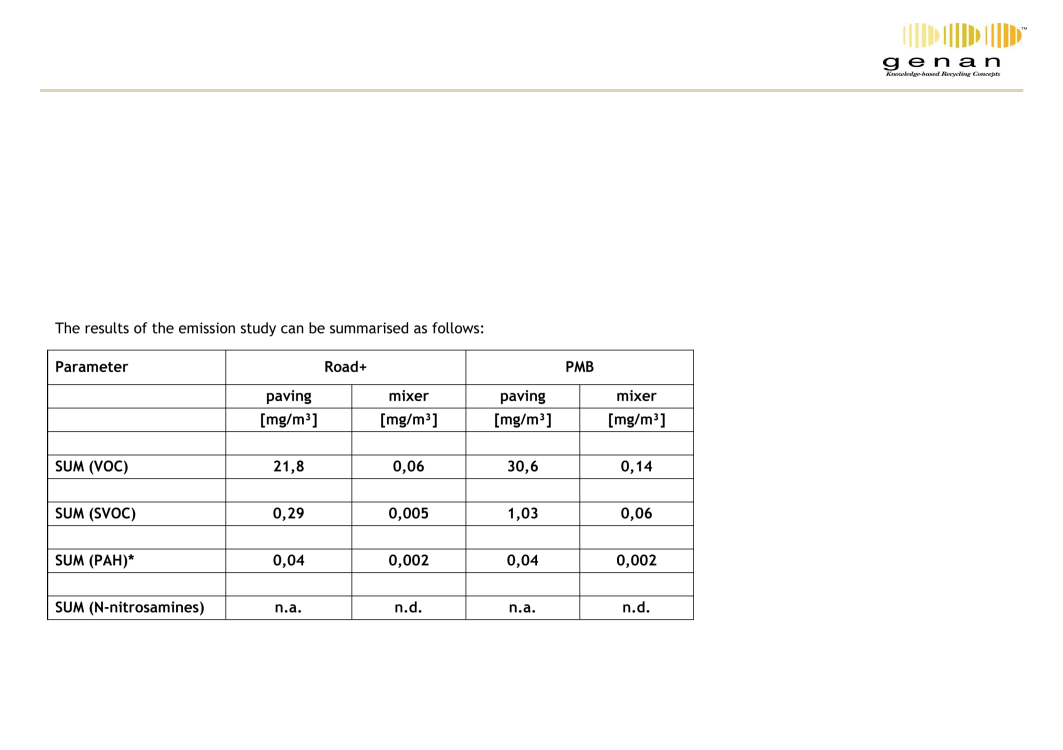

Miljøet - Emissioner

Emissioner er målt både ved blanding og udlægningIngen konstatering af N-nitrosaminesMindre emissioner af VOC’er og SVOC’er sammenlignet med konventionel polymer modificeretasfalt

*) according to EPA (Environmental Protection Agency)n.d. – not detectable, i.e. amount below detection limit(DL = 0,1 μg/m�)n.a. – not assessedAbbreviations:VOC – volatile organic compoundsSVOC – semi-volatile organic compoundsPAH – polycyclic aromatic hydrocarbonsPmB - polymer modified bitumenSource: FABES Forschungs-GmbH für Analytik undBewertung von Stoffübergängent

Page 10

Life Cycle Assessment

Recycling versus Co-incineration and Civil Engineering Applications

Page 11

What is a LCA-study?Evaluates and measures all known environmental impacts of a specific choice

….. of all steps in the complete life cycle of a particular product

Page 12

Waste Hierarchy - TyresBest solutionDoes the waste hierarchyadopted by the EU standfor a detailedLCA-analysiswithin thetopic ofscraptyres?

Reduction- Traffic policyRetreading- UneconomicMaterial recovery- Genan conceptIncineration- Cement kilnsLandfill- Now banned in the EU

Worst solution

Page 13

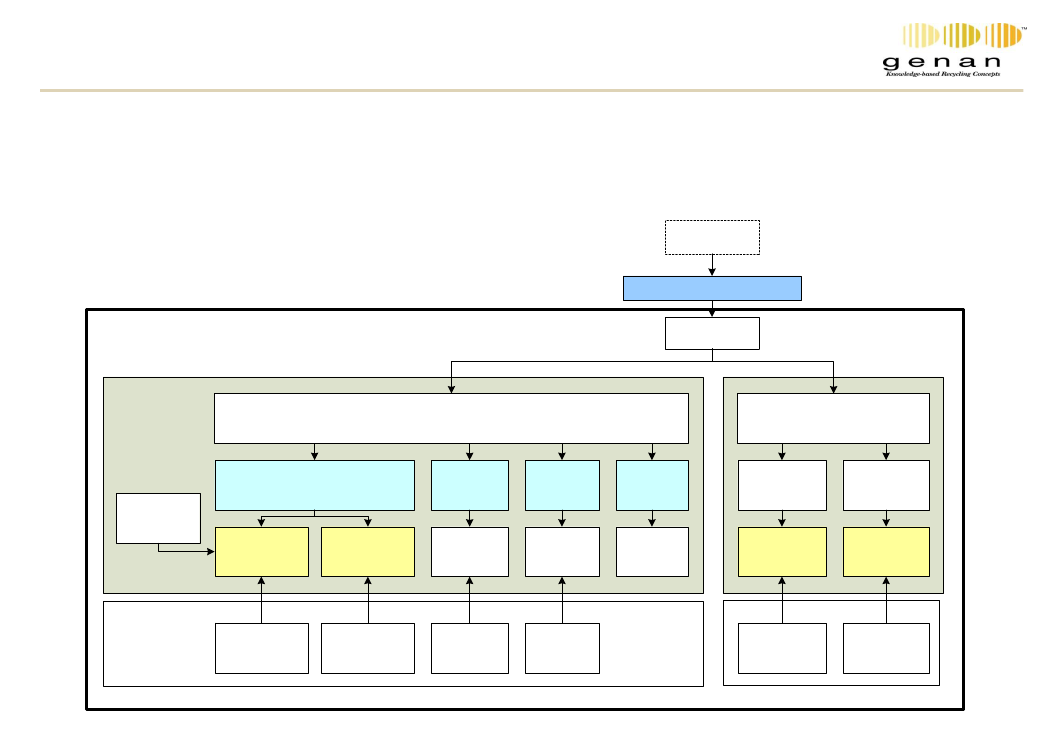

The choice to be analyzedRecycling vs. Co-incinerationUse

1 tonne of used tyres

System boundariesMaterial recycling route

Collection

Co-incineration route

Shredding, cleaning, separation, etc. at Genan’s plant

Incineration and oxidationin cement kiln

~67% rubber granulateProduction ofadditive polymer(Vestenamer)75% < 1.4 mmProduction ofrubber asphalt/PMB

~18% steel

~14% textile

<1% mineral &other waste

Combustiblecomponents(textile, rubber,carbon black, etc.)

Non-combustiblecomponents(ZnO, steel, etc.)

25% > 1.4 mmUse as infillincl. end-of-lifeco-incineration

Generation ofscrap/production ofvirgin steel

Energyproduction incement kiln

Landfilling

Energy production

Production ofcement

Avoided processesProduction ofbitumen andsynthetic rubberProduction ofEPDM/TPE infillincl. end-of-life co-incinerationExtraction ofiron oreEnergysource(s)

Avoided processesExtraction of ironore and silica

Energy source(s)

Page 14

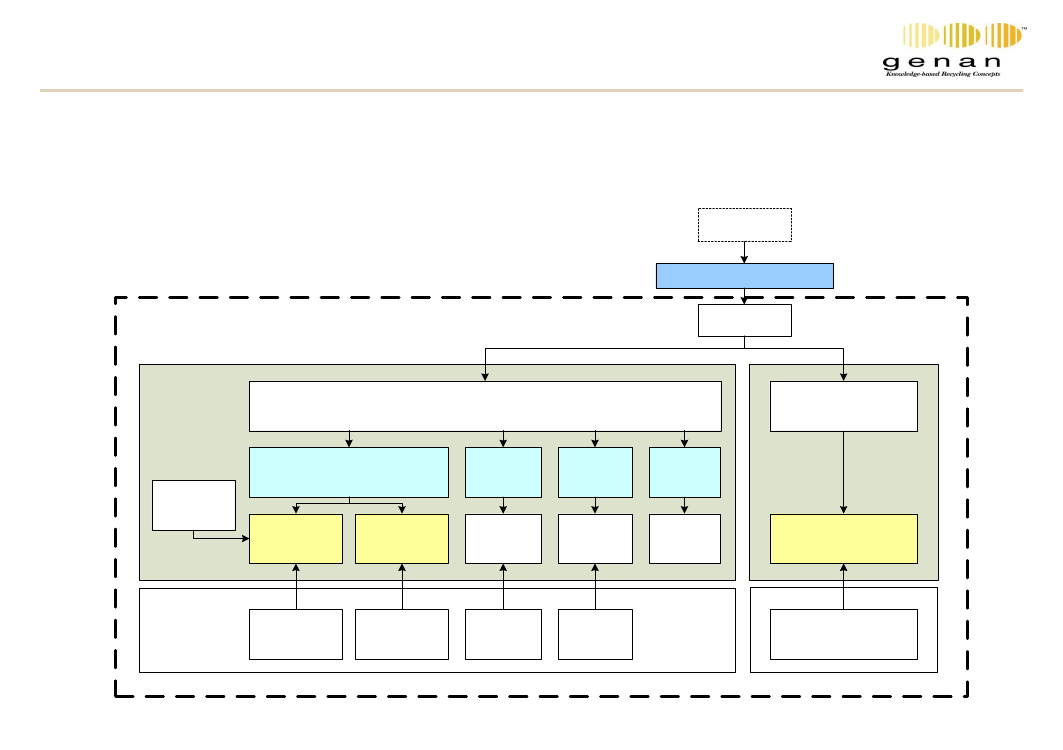

The choice to be analyzedRecycling vs. Civil Engineering ApplicationsUse

1 tonne of used tyres

System boundariesMaterial recycling route

Collection

Civil engineering route

Shredding, cleaning, separation, etc. at Genan’s plant

Shredding of tyres

~67% rubber granulateProduction ofadditive polymer(Vestenamer)75% < 1.4 mmProduction ofrubber asphalt/PMB

~18% steel

~14% textile

<1% mineral &other waste

25% > 1.4 mmUse as infillincl. end-of-lifeco-incineration

Generation ofscrap/production ofvirgin steel

Energyproduction incement kiln

Landfilling

Use as drainage layer in landfills

Avoided processesProduction ofbitumen andsynthetic rubberProduction ofEPDM/TPE infillincl. end-of-life co-incinerationExtraction ofiron oreEnergysource(s)

Avoided processes

Extraction of aggregates

Page 15

Quality Standard

ISO 14040ISO 14044

All elements described as compulsory in the above mentioned ISO standards are included.

Page 16

Report written by:

Material Recycling vs. Co-incinerationJürgen Giegrich and Regine VogtIFEUInstitut für Energie- und Umweltforschung Heidelberg GmbHAnders Schmidt, Nanja Hedal Kløverpris

Ioannis Bakas, Birgitte Jørgensen Kjær

Material Recycling vs. Civil EngineeringAnders Schmidt, Nanja Hedal Kløverpris

Ioannis Bakas, Birgitte Jørgensen Kjær

Jürgen Giegrich and Regine VogtIFEUInstitut für Energie- und Umweltforschung Heidelberg GmbHExpert knowledge by:Tommy Edeskär

Page 17

Critical review panel

Material Recycling vs. Co-incinerationOscar Salas, GAIKER, Spain (Chairman)Edorta Laurrauri, GAIKER, SpainLeire Barruetabeña, GAIKER, Spain

Dr. W. Trinius, Ingenieurbüro TriniusDr. Hans Theodor Grunder, Ökologische Bewertung von Bauprodukten, Germany

Material Recycling vs. Civil Engineering ApplicationsOscar Salas, GAIKER, Spain (Chairman)Leire Barruetabeña, GAIKER, Spain

Page 18

Impact Categories Researched

Global Warming Potential *

Acidification potential *Nutrification potential, waterNutrification potential, soilToxicity potential (carcinogenic risk)Toxicity potential (acute humane PM10)Photochemical ozone creation potentialCumulative energy demand (balance of fossil fuel use) *Non-energy resource depletion (iron)

Page 19

Results – Comparison with Co-incinerationGWP Base case1.1 ton/ton

GWP Waste subst.Acidification

2.6 ton/ton5.3 kg/ton

5 other categories Sign. positive2 other categories InsignificantIn the EU 1,098,000 tons scrap tyres are yearly incineratedThe potential CO2 savings are therefore in the area of 2.9 Mton

Comparison with civil engineering applicationsGWP savings approx. 1.8 tons CO2/ton scrap tyre input

Page 20

Overall conclusion

Civil Engineering applications are filling operations with no environmental benefitsCo-incineration in cement kilns is better than civil engineering and landfills

Recycling is, however, far more beneficial than co-incineration with robust and clearbenefits in 7 out of 9 environmental indicators2 indicators not statistically significant

Page 21