Miljø- og Planlægningsudvalget 2010-11 (1. samling)

MPU Alm.del Bilag 96

Offentligt

Report number: 809027RSPOCUCRPT –2009-01-MD

RSPO Annual SurveillanceAssessment ReportUNITED PLANTATIONS BERHADPENINSULAR MALAYSIAThis public summary has been prepared in accordance with RSPO requirementsand the information included is the result of a full RSPO assessment of the Millsand supply base as included in the scope of the certificate.

Report prepared by: Manivannan Duraisamy (Lead assessor).Certification decision made by: Gerben Stegeman.

Control Union (Indonesia)Jl Kramat 3A,Cilandak TimurJakarta Selatan 12560Phone: 062-21-7884 2016

Control Union (Malaysia) S/BPersiaran Raja Muda Musa,Off Jalan Sg Berith,Teluk Gadong, 41100, Klang,Selangor. Malaysia.Phone 03-3377 1600 / 1700

Control Union Certifications. (Head office)Meeuwenlaan 4-6,P.O. Box 161.8000 AD Zwolle.The Netherlands.Phone: 0031 38436 0100Control Union Certifications is a member of the Control Union World Group - an international inspection andcertification body. CU performs assessments and certification in many agricultural based fields such asFSC, RSPO, and Organic production, Sustainable Textile Production, Organic Exchange, Eurepgap,HACCP, BRC, GMP and GTP.CU is accredited by the Dutch Council of Accreditation (RVA) on the European quality standard EN 45011for the inspection and certification of CU Organic program (according to the EU regulation 2092/91) andEUREPGAP program. When requested a copy of the accreditation certificate can be obtained from CU.

Annual Surveillance Assessment Report, December 2009

Page 1 of 26

Report number: 809027RSPOCUCRPT –2009-01-MDContents1.1.11.21.31.41.51.61.7

Scope of the Certification Assessment.

1.81.9

Company details.Surveillance assessment detail.RSPO membership details.Location maps.Mills and location addresses.Metric tonnages certified and projected outputs.Description of supply base.1.7.1General description.1.7.2Location of the supply base including:•Control Union code for the certificate.•Location address.•GPS reference.1.7.3Statistics of supply base including:•Control Union code for the certificate.•Area of oil palm.•Mature area.•Estimated annual FFB production in tonnes.•Planting years.•Cycle.1.7.4Calculation of the number of production units included in sample.Progress of associated smallholders toward compliance.Audit against the rules for Partial Certification.Certification body.The audit team.Assessment methodology.2.3.1General overview.2.3.2Assessment agenda including:•Assessment dates.•Sites visited.•Main activities.•Total number of person days spent on site.Lead assessor’s summary and recommendation for certification.Summary of the findings by principle.Non conformity registers.Issues raised during stakeholder consultation and company responses.

2.

2.12.22.3

Assessment Process

3

3.13.23.33.4

Assessment Findings

4

Certified organisation’s acknowledgement of internal responsibility.4.14.24.34.4Date of next annual assessment.Date to close major non-conformities.Date to close minor non-conformities.Formal sign-off of the assessment findings.

5

Appendix: Abbreviations used.

Annual Surveillance Assessment Report, December 2009

Page 2 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

1.

SCOPE OF THE CERTIFICATION ASSESSMENT.United Plantations BerhadJendarata Estate, 36009 Teluk Intan,Perak Darul Ridzuan, Malaysian/a+605 6411 411Mr. C. Mathews+601 9339 2298+605 641 2337[email protected]www.unitedplantations.com

1.1 Company details:Company name:Business address:

Group name if applicable:Office telephone:Contact person:Mobile telephone:Fax:e-mail:Web site:

1.2 Surveillance assessment detail:Dates of the assessment:Date of Partial certificationVerification and StakeholderConsultationAssessment number (1 to4).

23 – 25 November 2009th6 – 8 December 2009andth29 December 2009 (Bogor, Indonesia)ASA 1

th

1.3 RSPO membership details:RSPO membership number:Child numbers for eachcertification unit:Certificate number:Date of original certification:Date of last assessment:

013-04(O)CU809027D01, CU809027D02, CU809027D03, CU809027D04,CU809027D05, CU809027D06CUC809027RSPO-1.2008st21 August 2008th26 -30 May 2008

Annual Surveillance Assessment Report, December 2009

Page 3 of 26

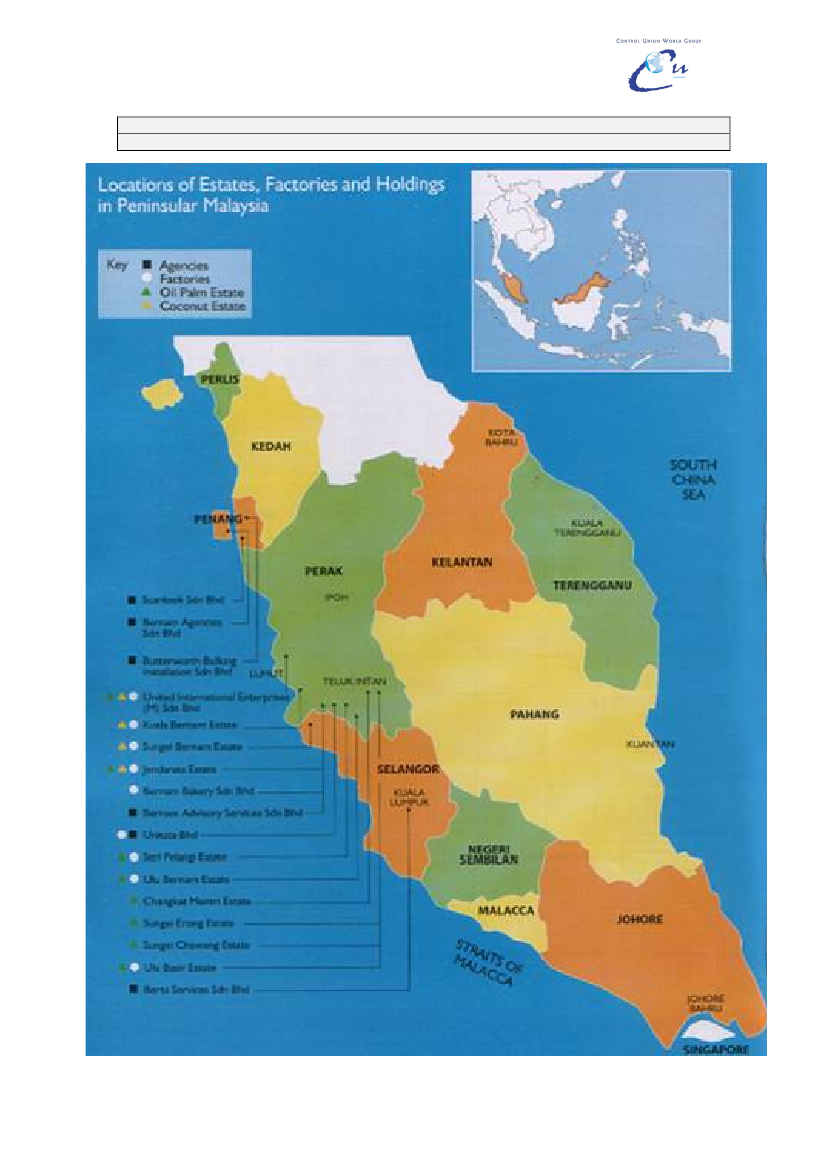

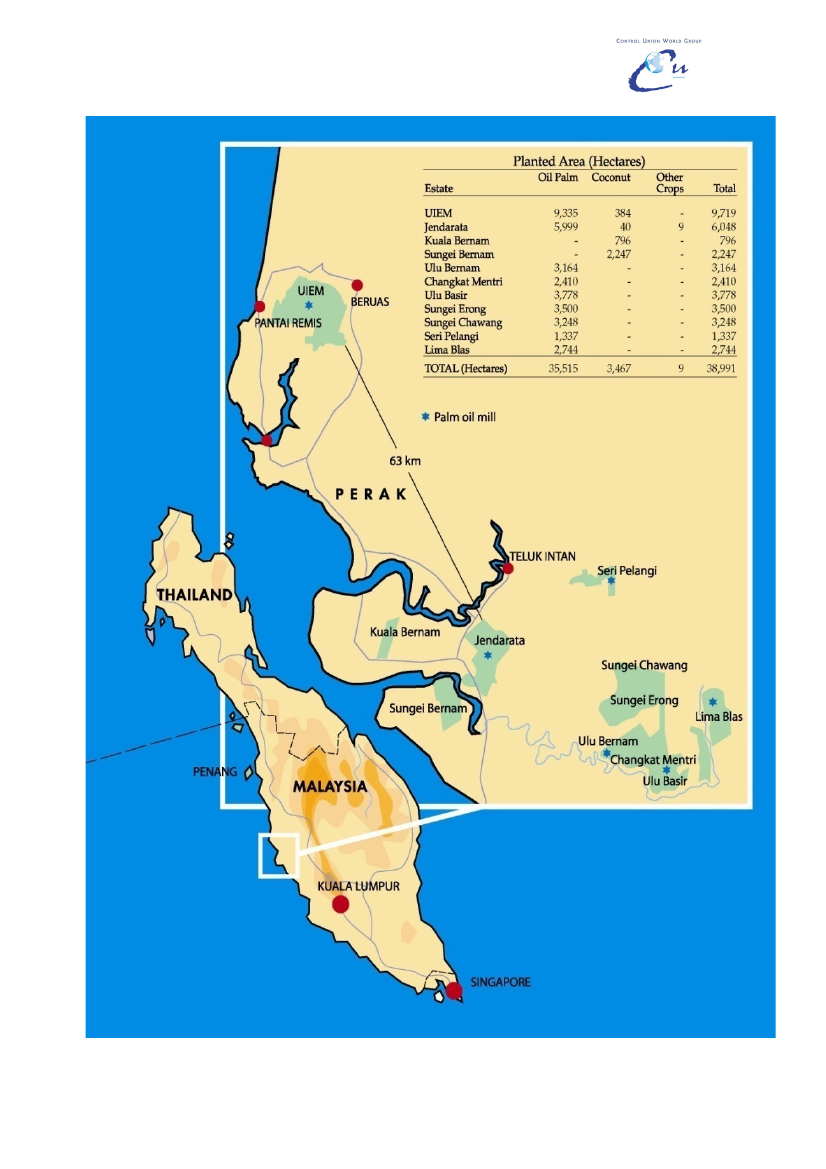

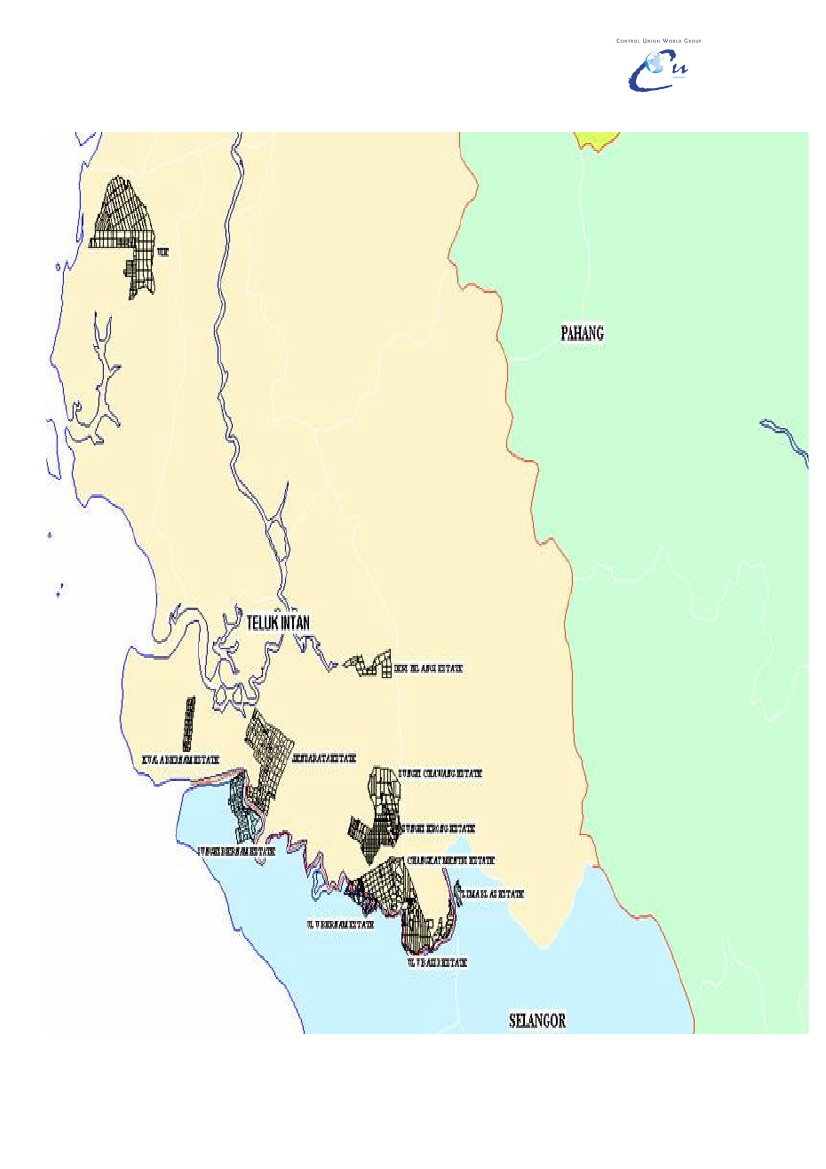

Report number: 809027RSPOCUCRPT –2009-01-MD1.4 Location maps.Maps showing the location of estates included in the assessment.

Annual Surveillance Assessment Report, December 2009

Page 4 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

Annual Surveillance Assessment Report, December 2009

Page 5 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

Annual Surveillance Assessment Report, December 2009

Page 6 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD1.5 Location of mills.Name of MillJendarata Palm Oil Mill.Seri Pelangi Palm Oil Mill.Ulu Basir Palm Oil MillLima Blas Palm Oil MillUlu Bernam Palm Oil Mill.United International EnterprisesPalm Oil MillLocation addressJendarata Business Unit, 36009 Teluk Intan, Perak, MalaysiaJendarata Business Unit, P.O Box 89 11� Miles, Jalan Bidor, 36008Teluk Intan, Perak, MalaysiaUp River Business Unit, 36500 Ulu Bernam, Perak, Malaysia.Up River Business Unit, 35800 Slim River, Perak, Malaysia.Up River Business Unit, 36500 Ulu Bernam, Perak, Malaysia.United International Entreprise (Malaysia), Mail Bag No 1, 34900,Pantai Remis, Perak, Malaysia.

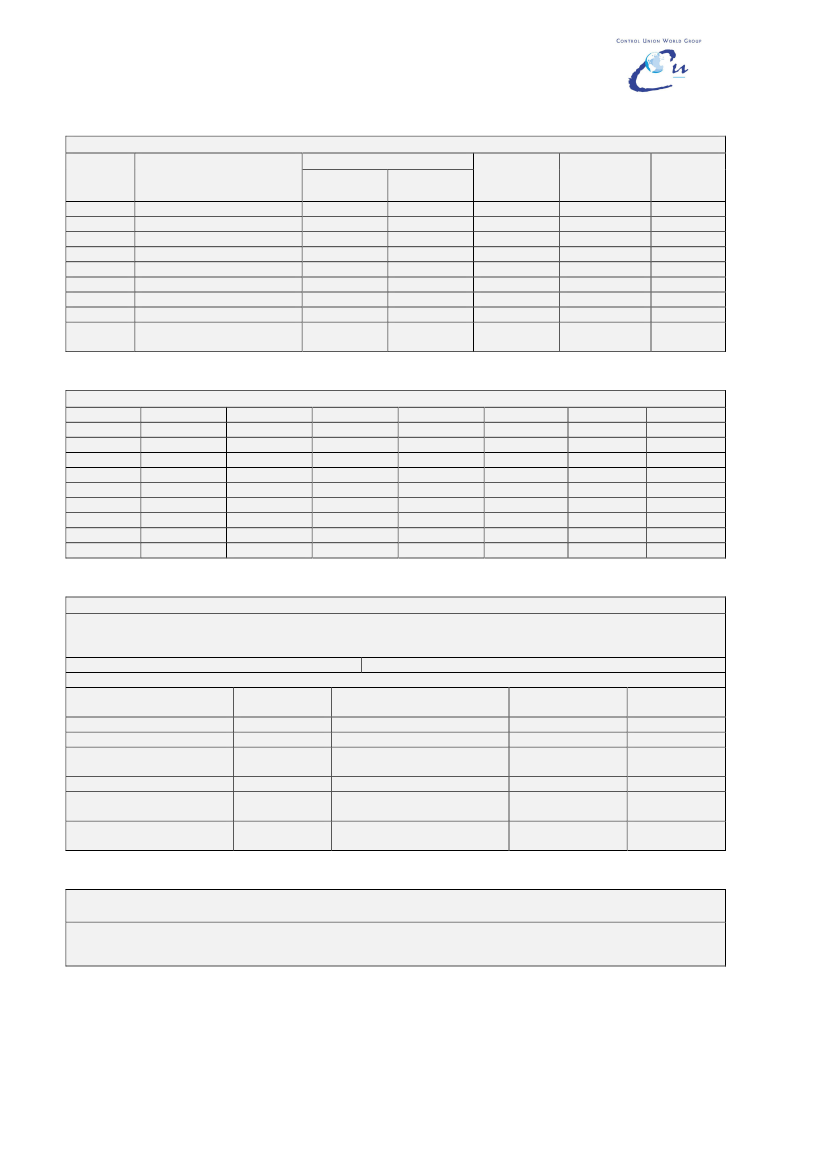

1.6 Metric tonnages certified and projected outputs.

(These figures exclude any output product from non-certified suppliers).Name of millActual production (tonnes)Projected from last audit.FFBJendarata Palm Oil Mill.Seri Pelangi Palm Oil Mill.Ulu Basir Palm Oil MillLima Blas Palm Oil MillUlu Bernam Palm Oil Mill.United International EnterprisesPalm Oil MillTotalCPO35,1419,37635,93310,53036,13658,205855,400185,321PalmKernel8,2112,1309,6952,64110,51317,005FFBCPO37,6039,78138,39312,92739,46462,288200,456PalmKernel8,7642,0829,9343,18211,10718,53953,608

Projected productionfor next 12 months.CPOPalmKernel39,0009,00010,0002,20035,0009,07012,7003,40034,6008,91044,77013,100176,07045,680

50,195915,194

1.7 Description of supply base.The supply base are the 9 plantations that make up the 3 business units of the United Plantations holdings locatedin Peninsular Malaysia. There are no plans to expand the land holding in Peninsular Malaysia and thereforePrinciple 7 is not applicable to this annual surveillance assessment.To comply with the RSPO rules for partial certification, verification assessment were carried out by the audit team atthPT SSS1 in Central Kalimantan on 6 – 8 December 2009. Subsequently stakeholder consultation/discussion wasthconducted with interested NGO, Sawit Watch in Bogor, Indonesia on 29 December 2009.

1.7.1 General description.

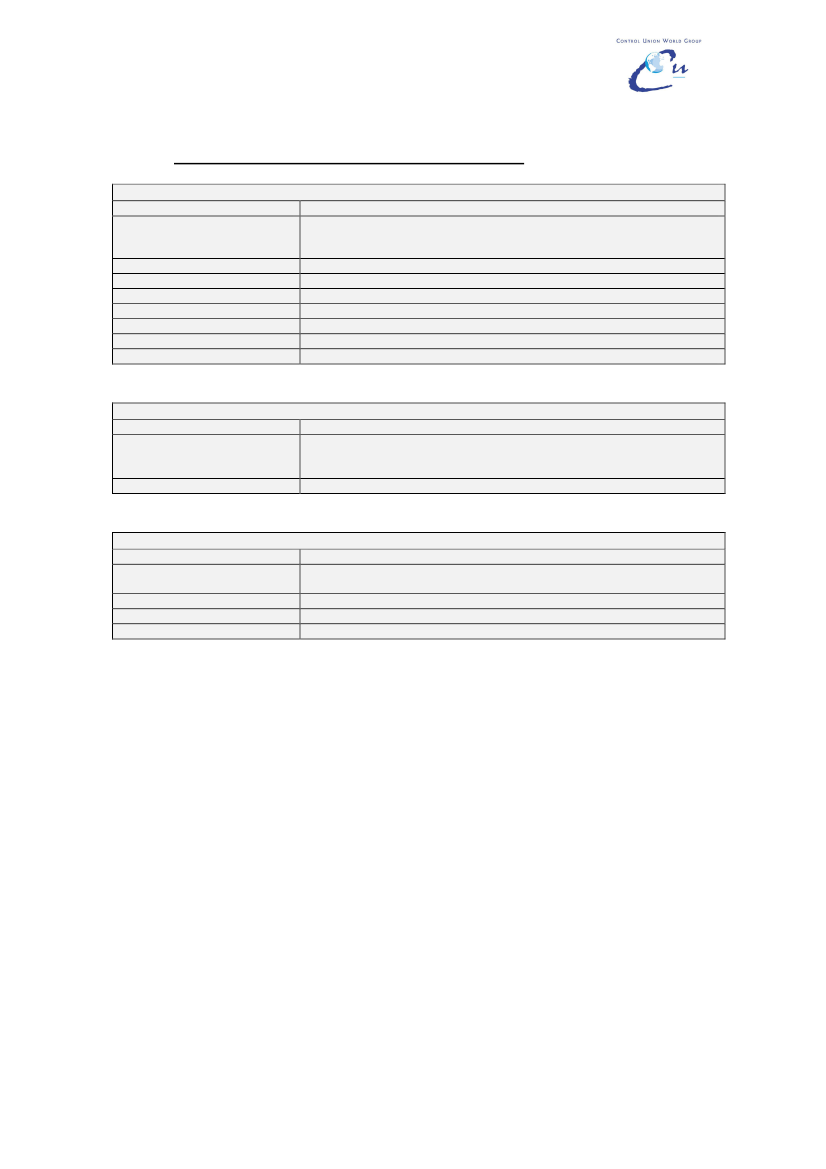

1.7.2 Location of the supply base.CU CodeName

Location address.

GPS referenceLongitudeLatitude3� 52’ N3� 59’ N3� 42’ N3� 44’ N3� 46’ N3� 50’ N3� 42’ N3� 45’ N4� 25’ N101� 01’ E101� 08’ E101� 15’ E101� 13’ E101� 12’ E101� 14’ E101� 27’ E101� 07’ E100�.40’ E

PO1PO2PO3PO4PO5PO6PO7PO8PO9

Jendarata Business UnitJendarata EstateSeri Pelangi Estate

Teluk Intan, PerakPerak/Selangor

UP River Business Unit.Ladang Ulu BasirChangat Mentri EstateLadang Sungei ErongLadang Sungei ChawangLima Blas EstateUlu Bernam Estate

SelangorPerak

UIEM Business Unit

UIEM Sdn. Bhd. Estate 1and Estate 2

Pantai Remis, Perak

Annual Surveillance Assessment Report, December 2009

Page 7 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD1.7.3 Statistics of the supply base.CU CodeName

Area of oil palm (ha)Oil PalmMature602413373714241134993248274031549622567913372388195326562727222729469307

PO1PO2PO3PO4PO5PO6PO7PO8PO9

Jendarata EstateSeri Pelangi EstateLadang Ulu BasirChangat Mentri EstateLadang Sungei ErongLadang Sungei ChawangLima Belas EstateUlu Bernam EstateUIEM Sdn. Bhd. Estate 1and Estate 2

EstimateTonnesFFB/yr171,00042,47060,00056,17059,76064,25061,40077,090218,400

Plantingyears1975-20091994-20041983-20091988-20091985-20091986-20091985-20091986-22091988-2009

Cycle(years)252525252525252525

1.7.4 Percentage of planted areas of different ages.CU CodePO1PO2PO3PO4PO5PO6PO7PO8PO9Before 199012.59-42.270.7338.2057.9331.5716.5277.011991 – 199534.6229.32-8.641.10-12.7036.4616.941996-200034.6347.34-51.429.500.2714.2327.552.77

2001 – 200513.7723.3420.5319.8923.4013.1215.6213.02-

2006 -20104.39-37.2019.3227.8028.6825.886.453.28

2011-2015---------

2016+---------

1.7.5 Calculation of the number of production units (N) to sample for each mill.

N = 0.8 y, where y is the number of units, with the result always to be rounded UP to the next whole integer.Where only a sample of the supply base is assessed, units not previously assessed, or assessed earlier in thecertification programme, are to be preferred over those more recently assessed.How many mills?6For each mill, how many units make up the production base?Name of POMOwned estates N = 0.8 YSmallholders (Z)N = 0.8 Z(Y)Jendarata Palm Oil Mill.11 (Jendarata Estate)n/an/aSeri Pelangi Palm Oil Mill.11 (Seri Pelangi Estate)n/an/aUlu Basir Palm Oil Mill42 (Ulu Basir Estate)n/an/a(Changat Mentri Estate)Lima Blas Palm Oil Mill11 (Lima Blas Estate)n/an/aUlu Bernam Palm Oil Mill.32 (Ulu Bernam Estate)n/an/a(Sungei Erong Estate)United International11 (UIE Estate 1 and 2)n/an/aEnterprises Palm Oil Mill

1.8 Progress of associated smallholders or outgrowers towards compliance with relevantstandards - should be in accordance to the 3 year implementation plan.

There are 2 out growers associated with Seri Pelangi POM. The mill management already started to have RSPOfamiliarisation meetings with them and get them involved in trainings and meetings related to RSPO P&C. Once thestandard for independent smallholder is ready, these out growers will be addressed accordingly.

Annual Surveillance Assessment Report, December 2009

Page 8 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

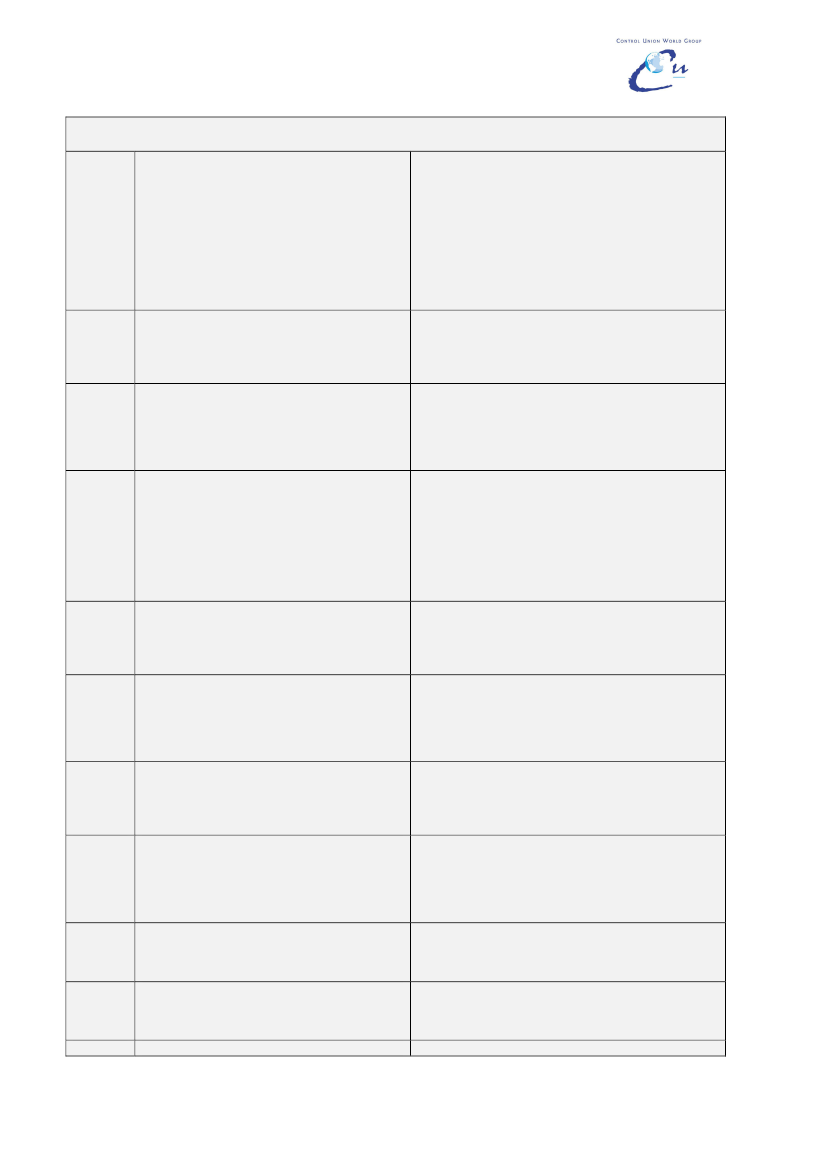

1.9 Rules for partial certification(NOTE: there are still ongoing discussions on the partial certificationissue; report will be submitted later as an Annex)1.9.1•Progress made from the last assessmentagainst the time-bound plan for certifyingother units within the organisation.Company’s Greenfield development at PT SSS1 is inprogress. The Palm Oil Mill is expected to becompleted by mid 2010. As per RSPO requirementthe mill is the base for certification. Due to this PTSSS1 audit will commence once the mill is ready. Thetime bound plan revised to 2011, earlier that the timebound reported during main audit. As for PT SSS2,process of getting legal documents is ongoing.Management expects to go for certification by 2016as reported during main audit, if all the permit issuesare completed. It will be reviewed annually.Plan to certify PT SSS1 has been revised from 2013to 2011. There is no change on time bound plan forPT SSS2.The time bound plan for PT SSS1 has been broughtforward to 2011 because the progress of developingthe Greenfield and constructing the POM is expectedto be completed earlier by mid 2010. The progressmade by the company to comply with the time boundplan is acceptable.There are no changes in the structure of the holdingnoted during the ASA1. Discussion with topmanagement confirms that there are no suchchanges.

1.9.2

•

1.9.3

•

Any alteration made to the time-boundplan, for example, due toacquisitions/disposals, emergence/re-emergence of land disputes and/or labourconflicts must be reported.The company’s justifications for anyrevision are also to be reported; with theaudit team’s considered opinion on thematter and recommendation foracceptance/rejection.Where the structure of the holdingcompany is changed during the course ofthe implementation of the time-bound plan,so as to alter the plan, the change instructure must be legal and registered withthe relevant authorities. Thedocumentation relating to such structuralchanges must be presented to the auditteam for verification, if necessary.Where there is evidence that the timebound plan is not being adhered to, or theconditions justifying a time-bound planhave changed, the audit team mustsummarise this evidence here.The audit team must be satisfied that thecompany has not opened new land withoutHCV assessment since first certified.

1.9.4

•

1.9.5

•

The company is bringing forward their plan to 2011 forPTSSS1

1.9.6

•

1.9.7

•

1.9.8

•

1.9.9

•

1.9.10

•

New acquisitions by the company whichhave not replaced primary forests or HCVareas are required to comply withcertification requirements within threeyears of the date of acquisition.New acquisitions which have evidentlyreplaced primary forests or HCV areas willnot be eligible for RSPO certification andwill, by the rules of partial certification,render the entire company ineligible forcertification.Where there is a dispute whether aprimary forest or HCV has been replacedor lost, the company shall, at its own cost,provide RSPO with expert opinion.The organisation is a member of RSPO

There is no new acquisition and opening since thefirst audit. HCV assessment for PT SSS2 carried outfor Arut has been completed however Kumai andAmin Jaya are in progress and no development sincethe last audit. HCV assessment for Runtu verifiedduring the visit to PT SSS1.There are no new acquisitions since mainassessment.

There are no new acquisitions since mainassessment.

There is no new dispute reported since the last audit.

Invoice and evidence of payment.1.9.11•There are no significant land conflicts.

Membership number: 013-04(O)Invoice no.: 0221-09Membership payment Date: 27/7/09Amount: RM10,038.00The negotiation on land conflict at PT SSS1 is

Annual Surveillance Assessment Report, December 2009

Page 9 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD•For ALL land disputes. Location maps,area involved. People involved. Contactdetails. Timetable of events and asummary as to the actions taken by allparties.ongoing and company representatives in Indonesiahave conducted several meetings with concernedparties. Full details of negotiations are available tostakeholders on request to the company.Four documented meetings with Sawit Watch andRuntu Lama villagers have been verified during themeeting with top management. Subsequently a visitthto this property conducted on 6-8 December 2009 toverify the status with the stakeholders involved in thisnegotiation process. Documented discussions wereheld on 28/3/2009, 16/4/2009, 30/4/2009, 11/5/2009,2/11/09 and 16/11/09. Meeting with Runtu villagers,Pak Syaridan and Sawit Watch is documented.Grievances procedure is socialised with the Runtuvillagers by company representative (Ibu Dewi)attended by Pak Syaridan, Pak Ali Badri, PakHermansyah and other representatives from Runtu.Meeting took place during RT7on 2/11/09 with theconcerned parties involved in the land dispute alongwith Sawit Watch. On 16/11/09 Ibu Dewi andcompany representatives met the concerned partiesto continue the discussion and paper trails areavailable as evidence. This meeting was attended by14 representatives (Runtu Lama villagers, and SawitWatch representative). Dialog is ongoing andprogressing with both parties engaging positively tosolve the dispute. During the interview with the Runtuthvillage representative on 7 December 2009, he saidthat he is satisfied with the progress and understandthat the negotiation process will take some time. As apositive response, he told the auditors that he iswilling to sell his FFB to PT SSS1 once the mill iscommissioned although he has a choice of not to doso. He was positively engaged in conversation withthe auditors and indicated there is room for solutionbetween two parties.Interview with the company’s representative revealthat the Company will continue to have discussionwith the concerned parties until a positive solution isfound. The company is willing to compensateaccordingly when all the evidence are in place andverified accordingly by their legal department.Interview with the Runtu village head, Pak Hasanudinthconducted on 7 December 2009. He is aware of theongoing negotiation process and stressed that if allthe documented evidence is submitted, he will ensurethat the parties involved in the dispute arecompensated accordingly. As positive response, hehighlighted that PT SSS1 has created more that 1500jobs to the local communities and is looking forwardfor their continuous positive contribution to the localcommunities.There are no labour disputes since the last audit.During visit to PT SSS1, interview with the workersrevealed that no labour disputes.PT SSS1 HGU (2500ha) and remaining is inprogress. United Plantation has suspended alldevelopments at PT SSS2 as a self mitigationprocedure until all the relevant law documents are inplace. Field visit confirmed that no operations takingplace. The process and documentations includingcorrespondence to this effect were seen during audit.This document is available for stakeholders. Anyinterested stakeholders can approach the company

1.9.12

•

1.9.13

No labour disputes that are not beingresolved through an agreed process.Summary of any labour disputes. Peopleinvolved. Timetable of events and summary asto the action taken by all parties.•No evidence of non-compliance with law inany of the non-certified holdings.Indonesia: A list of the following:Ijin Prinsip, Ijin Lokasi, Ijin Usaha Perkebunan,Cadastral, HGU.

Annual Surveillance Assessment Report, December 2009

Page 10 of 26

Report number: 809027RSPOCUCRPT –2009-01-MDfor verification.

2.

ASSESSMENT PROCESS.2.1 Certification Body.

Control Union Certifications is a member of the Control Union World Group - an international inspection andcertification body. CU performs assessments and certification in many agricultural based fields such asFSC, RSPO, and Organic production, Sustainable Textile Production, Organic Exchange,Eurepgap/GlobalGAP, HACCP, BRC, GMP and GTP.CU is accredited by the Dutch Council of Accreditation (RVA) on the European quality standard EN 45011for the inspection and certification of CU Organic program (according to the EU regulation 2092/91) andEUREPGAP program. When requested a copy of the accreditation certificate can be obtained from CU.

2.2 AUDIT TEAM.2.2.1Audit team.•Lead auditor.•Legal.•••2.2.22.2.3Technical.Environmental.Social.

Fluent in main local languages.CV’s for new team members whowas not part of any previousaudits of this company should beavailable.Timing: Not earlier than 9 monthsafter the anniversary of theawarding of the certificate.

Manivannan DuraisamySenniah ( Pratama Agung Sedayu – PT SSSvisit)•Senniah ; Kong Pichit•Senniah ; Kong Pichit (Pratama Agung Sedayu– PT SSS visit)•Senniah (Pratama Agung Sedayu – PT SSSvisit and Stakeholder Consultation)Manivannan DuraisamySenniah (Pratama Agung Sedayu – PT SSS visit)SenniahKong Pichit(Pratama Agung Sedayu – PT SSS visit)ASA procedure was made available on 20 Oct 2009 byRSPO. Subsequently CUC developed the “CUC RSPOProcedure Manual for ASA for CUC auditors”. Discussionand arrangement was made with the company to conductththe ASA1 on 23-25 November 2009. Subsequently averification visit to PT SSS1 arranged to seek compliancewith the rules for partial certification. The visit was carriedthout on 6-8 December 2009 and a separate visit wasthorganised on 29 Dec 2009 to Sawit Watch Office in Bogoras part of stakeholder consultation.th

••

2.2.4

2.3

The annual assessment was carried out in conformity with the procedures as laid down in the CUC RSPOProcedure Manual for ASA and the program manual for the assessor and certifier. During the assessmentqualified CUC assessors used the RSPO standard as endorsed for the country in which the assessmenttook place and recorded their findings.For each estate and small holder identified to be included in the sample for this audit, the original mainassessment checklist was used, which includes any updates from previous annual surveillance audits.Workers and local communities were interviewed and evidence sought to confirm ongoing compliancewhich includes:•Chemical stores.Storage. MSDS leaflets. Herbicide mixing areas. PPE. Ventilation. Security.•Field inspections.Herbicide application programmes. Harvesting sites and efficiency. Fertilisingoperations. SOP’s. Soil maps. Land preparation. Ground cover. IPM. First aiders and boxes. Groundcover. Soil erosion. Field observations of all operations.•Worker interviews.OSH. Sexual, religious, racial harassment. Pay and contracts. Child labour. Firstaid. Awareness.

2.3.1 General overview.

Assessment methodology.

Annual Surveillance Assessment Report, December 2009

Page 11 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD•••••••Re-planting sites.Zero burn.HCV’s.Identification. Management plans. Environmental Impact Assessments. Implementation.Riparian zones.Width. Current and future management. Non maintenance regimes.Water management.Water courses. Water monitoring.Road maintenance.Run off.Social amenities.Social Impact Assessments.Local communities.Contributions made. Employment opportunities. Social impacts. Complaintsprocedures.•Workshops.Oil traps. Safe working environment. PPE. Diesel tanks. Environmental wastemanagement.•Line sites.Interviews with householders. Inspection of water discharge points. Water improvementplans. Waste disposal.•Documentation review.Palm Oil mill audits include:•Mill and workshop inspections.Documentation. Worker interviews.•Mill.SOP’s. Safe working environment. Gen sets. Walk ways. Signs. EFB. POME treatment. Emissions.Mass balance. Diesel tanks. PPE. Fire extinguishers. First aiders and boxes. Fuel and water usage.•OSH.Training. Management structure. First aiders.•Full document review.Completion of the checklist. Review and documentation of evidence. All aspectsof RSPO P&C’s are applicable.•Worker interviews.OSH. Sexual, religious, racial harassment. Pay and contracts.Verification.Verification of implementation was done through field observations, workshop and chemical storeinspections, worker and community interviews and mill inspections as summarised above.

Date

2.3.2 Assessment Agenda.Location /mainsitesAuditorium

Main activities•Meeting with Top Management on partial certification.•Opening meeting. Introduction by team leader. Introductionof team members and assessment agenda.•Presentation by respective mill and estate managers onContinuous improvement status.Jendarata Estate and POMSeri Pelangi Estate and POM

23 Nov. 2009

JendarataBusiness Unit

Annual Surveillance Assessment Report, December 2009

Page 12 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD24 Nov. 2009MorningUp RiverBusiness Unit•Chemical stores.Storage. MSDS leaflets. Herbicide mixingareas. PPE. Ventilation. Security.•Field inspections.Herbicide application programmes.Harvesting sites and efficiency. Fertilising operations. SOP’s.Soil maps. Land preparation. Ground cover. IPM. First aidersand boxes. Ground cover. Soil erosion. Field observations of alloperations.•Worker interviews.OSH. Sexual, religious, racial harassment.Pay and contracts. Child labour. First aid. Awareness.•New planting sites.Zero burn.•HCV’s.Identification. Management plans. EnvironmentalImpact Assessments. Implementation.•Riparian zones.Width. Current and future management. Nonmaintenance regimes.•Water management.Water courses. Water monitoring.•Road maintenance.Run off.•Social amenities.Social Impact Assessments.•Local communities.Contributions made. Employmentopportunities. Social impacts. Complaints procedures.•Work shops.Oil traps. Safe working environment. PPE. Dieseltanks. Environmental waste management.•Line sites.Interviews with householders. Inspection of waterdischarge points. Water improvement plans. Waste disposal.•Document inspection and assessment.•Interview with stake holder.AfternoonUp RiverBusiness Unit•Mill and workshop inspections.Documentation. Workerinterviews.•Mills.SOP’s. Safe working environment. Gen sets. Walk ways.Signs. EFB. POME treatment. Emissions. Mass balance. Dieseltanks. PPE. Fire extinguishers. First aiders and boxes. Fuel andwater usage.•OSH.Training. Management structure. First aiders.•Full document review.Completion of the checklist. Reviewand documentation of evidence. All aspects of RSPO P&C’s.•Worker interviews.OSH. Sexual, religious, racial harassment. Pay and contracts.•Document inspection and assessment.••Field visit, Mill visit and Document verification as above.•Closing meeting. Chaired by the assessment team leader.Welcome and introduction by the team leader.Presentation of findings by the assessment team.Questions and answers.•Final summary by team leader.•

25 Nov. 2009

UIE Estate andPOM

Number of assessors participating: 3Number of days spent for the assessment on site: 3Total number of person days used for the assessment on site: 96 Dec. 20097 Dec. 2009Jakarta

2.3.3 Verification visit to PT SSS1 & 2 under the Rule for Partial certification.CUC auditors Travelling to JakartaPT SSS1 & 2Travelling to location – PT SSS1 & 2

Annual Surveillance Assessment Report, December 2009

Page 13 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD-Opening meeting. Introduction by team leader.-Introduction of team members and assessment agenda.-Presentation by the Company Representative.-Discussion with the Management on the issues related toPartial Certification.-Interview with workers.-Field visit to village lands.-Interview with Runtu Village Head.-Interview with representative involve in the land dispute andfamily.-Visit to the construction area of the Palm Oil Mill.8 Dec. 2009PT SSS1 & 2Closing Meeting.

Number of assessors participating: 3Number of days spent for the assessment on site: 2Total number of person days used for the assessment on site: 6

2.3.4 Stakeholder Consultation visit to Sawit Watch, Bogor, Indonesia.29 Dec. 2009BogorMeeting with Sawit WatchNumber of assessors participating: 2 (Winaryo and Pratama Agung Sedayu)Number of days spent for the assessment on site: 1Total number of person days used for the assessment on site: 2

3.

ASSESSMENT FINDINGS.3.1 Lead assessor’s summary and recommendation for certification:

Based on the findings during the Annual Surveillance Assessment, the audit team concludes that UnitedPlantations Berhad’s operation comply with the requirement of RSPO P&C. It is therefore the recommendationof the assessment team leader that:•A certificate of compliance is maintained.Signed:

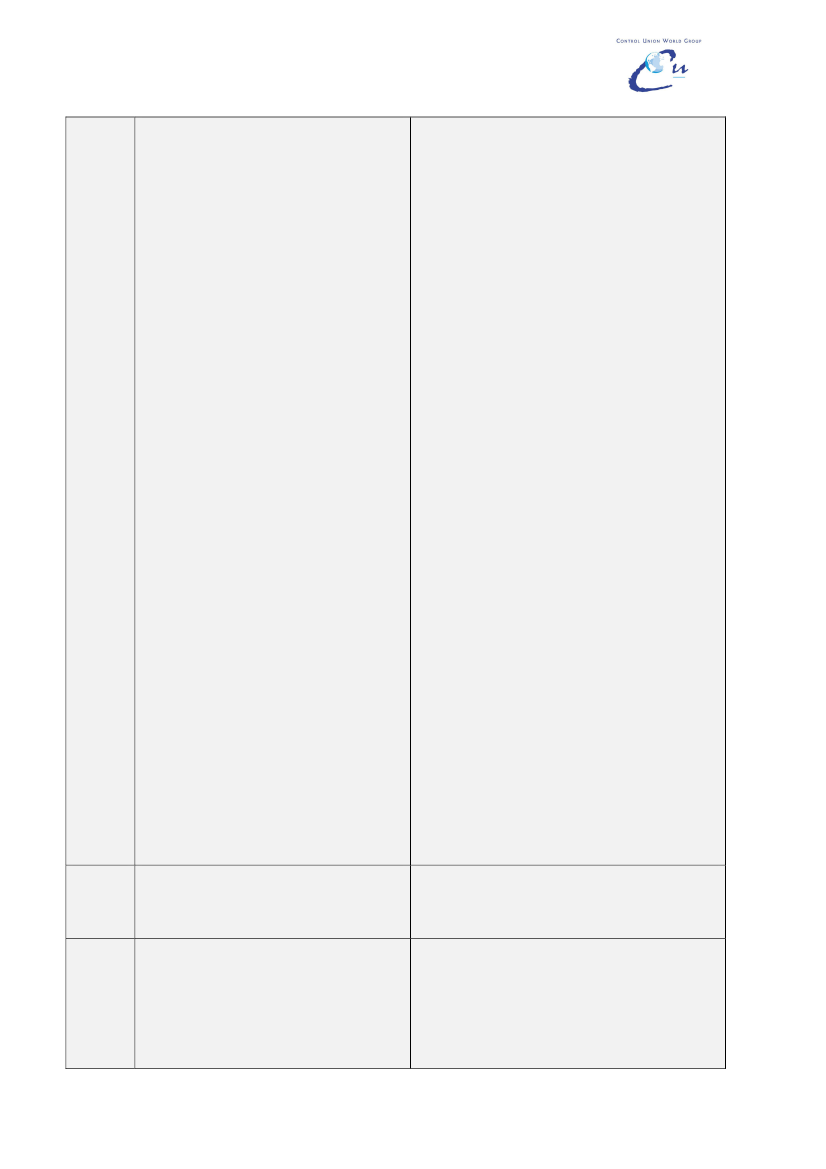

Name: D. ManivannanthDate: 5 January 20103.2 Summary of the findings.•Over the 5 year period of the life of the certificate, there will be 4 annual surveillance assessments and a sample ofthe criterion will be summarised each year.•Identified Non-Conformities and noteworthy Positive and Negative Observations.3.2.1Principle 1All the Business Units have updated records of request for information from internal andexternal stakeholders. This includes request for assistance such as donations.Stakeholders meeting conducted regularly by individual operating estates to fulfil anyinformation required by stakeholders. Visits by the regulatory bodies and governmentdepartments are recoded.1.1All the information request are updated regularly and well documented. i.e. visit bydelegates from German Federal Food, Agriculture and Consumer production to getinformation on CSPO.

Annual Surveillance Assessment Report, December 2009

Page 14 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD1.2Except for the confidential documents, stakeholders are able to access documents thatpublicly available. Interview with Union Leader, contractor and external stakeholderconfirm that this is in practise. No changes noted in land title and restrictions. The OSHpolicy has been reviewed on 9/9/09 and the date amended accordingly to ensure that thepolicy still relevant to United Plantations. New training matrix has been developed andnewly recruited employees given necessary training. Continuous improvement planshave been implemented as planned during the main audit and the evidence verified onsite during field and mill visits. Under continuous improvement plans, development of bio-gas plant at Ulu Basir POM and UIEPOM are ongoing and expected to be completed by2010.Annual review on social and environmental plans has been carried out for all theoperating units and new plans have been identified where necessary. Internal audit onRSPO on 14/5/09 and HIRARC conducted on 17/11/09. Pollution prevention planreviewed on 14/10/2009 and new plan has been developed to continue maintaining theexisting plans. Grievances are recorded and acted promptly. All the issues raised by thestakeholders during the main assessment have been addressed and interview with thesestakeholders confirmed that action has been taken. i.e. insufficient water supply –overhead water tanks have been installed at the housing area. During interview withworkers union representative, they confirmed that water supply is sufficient.Group HR, Safety and Environmental Department and Company Secretary ensurecompliance with relevant legal indicators. Group HR, Safety and EnvironmentDepartment ensures that information from the company secretary is disseminated atoperating units. There are 4 existing laws revised by government and has been informedto all units.1. Industrial Relation Act 19672. Factories and Machineries Act 19673. Holiday Act 19514. Newsflash- 5 Nov 2009The changes tracked and informed to the operating units by company secretary throughGroup HR, Safety and Environment Department and duly acknowledged by the recipientsat operating units. Interview with internal and external stakeholders revealed that no landdisputes during the ASA1. Boundaries are well maintained and visible for inspection. Allthe legal ownership remains same as per main audit.The management plan available in annual budget with attention given to quality ofplanting materials, crop projection, FFB yield trends, mill extraction rates, cost ofproduction, cost per tonne of CPO trends, Forecast prices and Financial indicators tomonitor the performance of each operating units. Budget for continuous improvementprojects have been addressed i.e. biogas plant, biodiversity enhancement project, newhousing, upgrading of road etc. Replanting is an ongoing practise. Revised replantingprogramme projected for next five years.

3.2.2

Principle 2

3.2.3

Principle 3

Annual Surveillance Assessment Report, December 2009

Page 15 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD3.2.4Principle 4Recently the SOP has been revised according to the latest requirement of the operatingunits. Revised SOP and updated documents are available during the ASA1. SOP hasbeen reviewed and updated for estate operations. Fertilizer applications are as perrecommendation from the research centre. Monitoring is carried out through field recordsand supervision in the field. Soil and Leaf analysis carried out by Research Centre. Thisresult and field observation is carried out to develop the fertilizer recommendation. Fieldvisit confirms that no burning carried out. POME and EFB applied area is monitoredthrough field records. BOD of the POME applied to land is below the stipulated DOEstandard of 5000mg/L. Latest water monitoring record dated 2/9/09 shows BOD level is97gm/L. Good ground cover has been established at the replanted area withMucunabracteata.All the harvesting path (approximately 95%) at the matured area is maintainedwith grass cutting only. Road maintenance programme include resurfacing the road withasphalt/tarmac for the main roads and at housing area. Best practices are maintainedwith POME, EFB and decanter cake application to increase the organic matter of the soil.Water management includes water usage monitoring at POM, water quality analysis fordomestic water supply and river riparian maintenance. Biodiversity enhancement is ongoing with planting of rare forest trees along the existing area. Each estate have planted1500-1700 endangered forest trees such as “Baccaureabrevipes”,“Knemehookerisna”,sentang spiecies, “Diospyrosdiepenhorstii”.The company also hasestablished tea tree corridor, santang park, silver oak avenue and tembusu park wherethe forest trees are planted to create biodiversity within the plantation. River buffer zonehas been planted with cover crop along with the above forest trees.All the chemical stores visited and found to be adequately organised, secured andperson in charge understand the OSH procedures i.e. issuing and mixing. MSDS areplaced at the chemical stores and it is available in Bahasa Malaysia and English. Theperson in charge understands the information written in MSDS. Use of paraquat isreducing gradually and during store inspection very minimum stock level was observed.Overall about 5-6% reduction is noticed. Paraquat is being replaced with glyphosate.OSH policy well briefed to all workers. Interview with workers reveal that they understandthe policy and importance of safety at work. External consultants engaged to do CHRAand audiometric test. Last test was done on March 2009. Comprehensive training recordavailable for 2009 and 2010. Latest briefing on safety has been conducted on 14/9/09 forharvesters. MSDS well understood by the store operator. OSH also covers first aidtraining, first aid box and first aiders’ availability at workplace, quarterly OSH committeemeeting, accident records and investigation and accident insurance for both local andforeign workers.Beside the existing SOP’s as reported during main audit, all SOPs have been reviewedand the following two updated ie. Locomotive and Mechanical collection of FFB. It isapplicable for the whole company. The amended SOPs have been sent to the operatingunits on 17/11/09 to update their existing SOP. The mill SOP remains same as there arestno new activities carried out (1 edition). Implementation of SOP re-verified during thisannual surveillance audit. Monitoring is carried out for all the best practices andchecklists maintained to ensure the implementation and practicality. This includesnursery practices, replanting with zero burn, improved harvesting infield collection,fertilizing, maintenance, water monitoring etc. The retention period for records ofmonitoring remains for a minimum of12 months.IPM includes planting of beneficial plant (tunera, cassia, antignon, carambola and foxtail), increasing barn owl population through proper maintenance and monitoring ofboxes, and owl population. Pesticide usage is monitored regularly. Record showsdeclining trend due to the aggressive IPM practices especially in controlling leaf eatingpest. Effective establishment of beneficial plants to control leaf eating pest has helpedthe operating units to eliminate and reduce the use of methamidophos and warfrain. TheIPM areas have been continuously increased to about 5-10 % with planting oftunerasubulata, antignonspp andcassia cobanensis.Cover cropmucuna bracteatais quicklyestablished to control weeds and reduce chemical spraying.

4.1

4.5

Annual Surveillance Assessment Report, December 2009

Page 16 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD3.2.5Principle 5An environmental Impact assessment of Oil Palm cultivation and processing in UPBerhad was completed in 2004 and includes the environmental loads, impacts andtechnical measures to mitigate these impacts. A confidential report has been prepared onthe life cycle assessment of palm oil at UP Berhad involving the growing,, milling and refining operations. It has been peer reviewed and completed.HIRARC is done internally with the facilitation by the Group HR&ESH Dept. CHRAavailable in estates and mills. The review conducted in Sept 2009 and internal riskassessment audited by Group HR, Environment, Safety and Health Manager. Resultsdiscussed with operating units and action taken accordingly. To mitigate environmentalimpact, all the diesel tanks, containment walls, pumps and pipes have been upgraded, allthe cracks have been sealed with concrete and wall size were increased toaccommodate 110% of the diesel storage capacity. Checked and found to be adequatelyaddressed with oil traps. No leakages found. HCV monitoring and latest study on birdcommunity and primate diversity was carried out by Mr. Badrul of Australian NationalUniversity on 20/7/2009 (Wildlife Ecological Research Unit, UPM). The review indicatesthat UP retains the natural forest and vegetation which have a significant conservationvalue. The archaeological site at CME is well protected and maintained with propersignages. Waste and pollutants have been identified. All the identified wastes aremanaged, monitored and sent to licensed and authorised waste disposal company ie.Pantai Medivest and G-planter. Records of delivery and collection by these collectors arekept by the operating units. Shell and fibre reused for boiler. EFB is applied to the field.POME is used for land application. Decanter cake is dried and applied to field hasorganic fertilizer. Renewable energy (shell and fibre) use and fossil fuel use in the mills ismonitored daily and summarised at the end of the month. Zero burning is practisedduring replanting. Old palms are felled and chipped and systematically stacked tofacilitate replanting.Documented plans to mitigate all polluting activities are available under pollutionprevention plan. This includes latest improvement made to reduce noise level at kernelstation with partition made to reduce noise. Construction of bund around the diesel tanks,oil traps and chemical mixing areas. Plans revised and recorded in the minutes of estateEWG and MWG meeting held on 23/10/09. G-Planter and Pantai Medivest are twowaste management companies engaged to dispose all the schedule waste in safemanner. Proper schedule waste stores are available and good records are kept forverification.Further, Control Union wishes to correct a conflict of information given in the UnitedPlantations Public Summary of the Main Assessment. In section 3.2, principle 5.6 it isstated “No peat”. This is incorrect and conflicts with 4.3 “Water management in peatareas”. The audit team inspected the water management systems for the peatland areasand noted in the checklist for 5.6.3 that “Water is maintained through a network of wearsand pumps at around 0.6m. Observed on site and supported by SOP' and file numbers5.6.3”.Stakeholder meetings are conducted to identify and address the social impacts due tothe estate and mill operations. Minutes of stakeholders meeting held on 27/2/09 isavailable, conducted to review and identify any new impacts. Another meeting was heldon 28/4/09. Interview with stakeholders confirm that they attended these meetings.Workers union meetings are held at operating units. OSH meeting is held quarterly todiscuss and improve on issues related to safety and health. Female employees areattending Gender Committee meetings to discuss their issues.Payment records and employment contracts were checked and verified. All the workersare paid based on MAPA/NUPW terms and condition. During field and mill visit interviewwith employees and document audit confirms that it has been implemented among allemployees. Housing complex visited. Improvement on going to upgrade housingcomplex. Water supply to housing improved with bigger storage tank installed. Besidesgood housing there is school, kindergarten, crèche, hospital, old folks home, playground,football field, community hall and other facilities within the plantation to cater for all theemployees.NOT APPLICABLE TO UNITED PLANTATIONS BERHAD

5.6

3.2.6

Principle 6

6.5

3.2.7

Principle 7

Annual Surveillance Assessment Report, December 2009

Page 17 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD3.2.8Principle 8United Plantation Berhad continuously monitors and reviews all improvement plans andactivities. New plans are developed for the following year and action plans are formulatedwith associated budget allocation to address continual improvement in the operations.Since the last audit, the following improvement have been carried out as per in 8.1 below.IPM is implemented extensively to control pest and indirectly resulted reduction inpesticide usage. All the operating units have increased the planted area of beneficialplants such as tunera, cassia, antignon, carambola sp. and fox tail. Effectiveestablishment of beneficial plants to control leaf eating pest have helped the operatingunits to eliminate/reduce the use of methamidophos and warfrain. Paraquat is beingreduced about 5-6% and is gradually replaced with glyphosate. SOPs'provided forreducing herbicide by inter row mowing/grass cutting, which covers almost 98% of thearea. Selective and spot spraying to control herbicide usage and careful calibrationcarried out to ensure no wastage.No pesticide usage at the riparian zones, weeding done manually.IPM also includes barn owl establishment. All the operating units have increased theboxes by 10% and to ensure the owl population, monthly monitoring of owl occupancy isconducted.Environmental policy is to increase biodiversity and conservation areas. All the operatingunits have begun the planting endangered forest trees around the plantation. This ismainly to create biodiversity enhancement and to ensure green environment around theplantations. 1500-1700 endangered forest trees such as “baccaureabrevipes”,“knemehookerisna”,sentang spiecies, “diospyrosdiepenhorstii”have been planted. Thecompany also has established tea tree corridor, santang park, silver oak avenue andtembusu park, to create biodiversity within the plantation. River buffer zones have beenplanted with cover crop along with the above forest trees.Zero burning is practised during replanting to reduce impact on air quality and protect theenvironment. 1983 ha have been replanted and cover crop established to eliminateimpact on soil surface.Construction of two bio-gas plants is in progress and expected to be commissioned by2010. There is one at the moment at Jendarata POM. With this bio-gas project, it isexpected that 90% of methane produced by mill effluent will be captured which isequivalent to Certified Emission Reduction Credit of 32800mt carbon dioxide per year.These noteworthy activities minimizes the waste /by-products generation, eg. EFBapplied to the land, ash from the boilers to the roads, waste water after treatment usedfor land application, methane from effluent captured and used for power generation.Used oil, battery, oil filters, chemical containers sent to licensed waste collectors. Usedoils are recycled to lubricate railing track and by the mill engineering department tolubricate machineries.All fibre and shell are recycled to operate boilers. Decanter cake is dried and used asorganic fertilizers in the field.JPOM has captured 3,730,028Nm� methane and used for generating power to operatethe mill and internal consumption.Waste products – sources & reduction plans have been revised. Waste managementaction plan for each type of waste identified, G-Planters and Pantai Medivest have beenidentified as licensed and authorised waste collectors. Chemical containers are triplerinsed and punched before released to the waste collectors.Improvement of the diesel bunds and diesel discharge areas has taken place. Properbunds as per DOSH requirements have been constructed and spillage containersavailable to prevent any spillage during discharge of lubricants and chemicals.Improvement also noticed in chemical mixing area with bunds to protect and mitigate anyspillage and there is a sum to collect any spillage.1983ha replanted with zero burning is the evidence of company’s commitment to controlair pollution. Improvement has been carried out to reduce noise pollution at kernelstations in mills.

8.1

Annual Surveillance Assessment Report, December 2009

Page 18 of 26

Report number: 809027RSPOCUCRPT –2009-01-MDEstates are converting infield FFB collection from tractors to buffalo assisted collectionwhere possible. With this the fossil fuel consumption reduced. About 10% overallreduction in fossil fuel consumed for tractors has been reduced.Cyclone dust traps installed at biomass reciprocating boiler at decanter drier systemtraps the un burnt carbon particulates and used for drying the decanter cakes.Stakeholder meetings are ongoing to review and identify new impacts. Based on thefeedback from stakeholders during main audit, improvements have been made to supplyadequate water supply, resurfacing road with asphalt/tarmac, renovation of schoolbuilding to provide conducive education facility although the school belongs to thegovernment, engaging female attendants at clinics, repainting of the facilities such ascommunity halls, housing, crèche kindergarten etc. some new housing have beencompleted and waiting for Certificate of fitness (CF) from Labour Department. Once CF isobtained, workers will be moved to these new bigger houses. There are ongoing housingconstructions in some of the operating units and will be ready by 2010.All the requestedbudget for improvements have been approved and fulfilled. New budget has beendeveloped by the top management for year 2010 to address continuous improvements.This includes budget for developing two bio-gas plant at UIEPOM and UBPOM (RM6million).Since the last main audit the following improvement has taken place and the expendituredetails as follows:Social:1. Temple renovation RM11,000.00 at LBE2. Prayer room for female Muslim workers RM4500.003. Tamil school extension RM169,979.004. Canteen for school RM79,469.005. Water supply RM109,00.00 (completed) and RM146,080.00 for UBE(completion byEarly Jan. 2010)6. Drama Hall RM88,158.007. TNB individual metering RM375,247.00 (Jendarata Business Unit)8. TNB individual metering RM476,000.00 (Upriver Business Unit)9. Road resurfacing/tarmac RM28,000.0010. Housing road RM59,000.00Environment:1. Containment wall upgrading RM40,000.002. Bio-gas plant RM6 mill (in progress)3. Continuous Emission Monitoring System (CEMS) linked with DOE completedRM10,800.004. Biodiversity enhancement-purchasing jungle fruit trees RM4000.005. Total spent on biodiversity-planting endangered jungle trees RM83,740.00

Annual Surveillance Assessment Report, December 2009

Page 19 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

3.2.9 Criterion to be summarised for each annual surveillance audit.Criterion1.11.22.12.22.33.14.14.24.34.44.54.64.74.8:5.15.25.35.45.55.66.16.26.36.46.56.66.76.86.96.106.117.17.27.37.47.57.67.78.1year 1xxyear 2xx

x

xx

year 3xxxxx

year 4xx

x

x

x

x

xx

xxxx

xx

x

x

x

xx

x

x

xxx

x

xxx

xx

xxxx

x

xx

Annual Surveillance Assessment Report, December 2009

Page 20 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

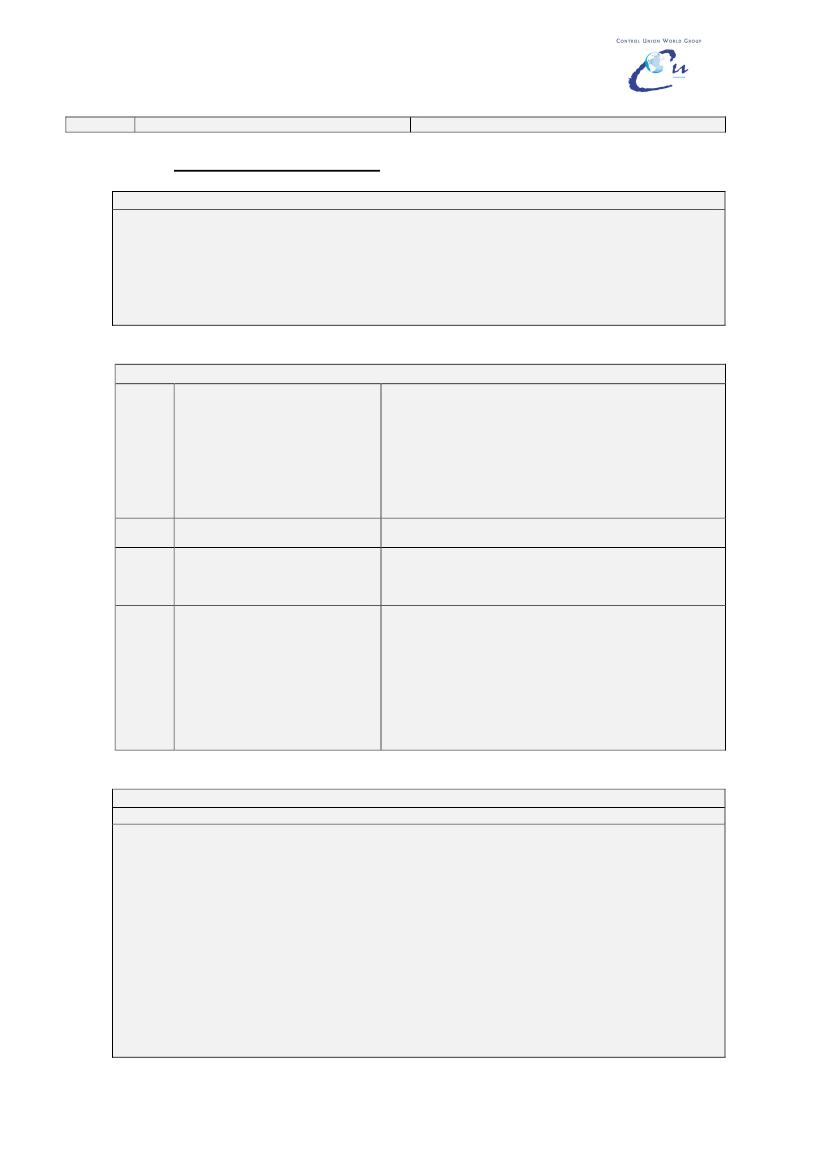

This section gives an over view of new or revised non-conformities raised during this assessment and ofaction taken to close out non-conformities raised during the previous assessments.•If a minor-non-conformity raised at the last audit, is not closed out, then this will be raised to Major statusand the company given 60 days to close this out.•The NC number is comprised of 2 parts to include the year in which the NC is raised as well as asequential number.

3.3 Non conformity registers.

Annual assessment date:Number settled:Number outstanding:

23 – 25 Nov 2009; 6 – 8 Dec 2009 and 29 Dec 20093 (NC raised during Main Audit)-

NON CONFORMITY REPORTNC number:01/2008Client name:United Plantations BerhadthDate raised:30 May 2008Major or Minor:MinorRaised by:David Ogg FICFor.Aspect of standard:5.1.2 Environmental improvement plan to mitigate the negative impacts and promote the positiveones, is developed, implemented and monitored.Evidence of non-conformity:A number of diesel tanks inspected had inadequate drainage systems and / or pumps and pipes outside thebund. The result of this is ineffective containment of leakage.Assessors signature:

David OggthDate: 30 May 2008.Proposed corrective action / improvement action by company.Inspect ALL diesel tanks and ensure that they comply with environmental standards.Timeline for conformance:Time of next annual surveillance.Review of corrective /improvement action:NC raised during the main audit has been verified during ASA1. All the diesel tanks,containment wall, pumps and pipes checked and found to be adequately addressed with containmentwalls and oil traps. No leakages found. With this evidence the NC has been closed.Assessors signature:

D. ManivannanthDate: 25 November 2009

Annual Surveillance Assessment Report, December 2009

Page 21 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

NON CONFORMITY REPORTNC number:02/2008Client name:United Plantations BerhadthDate raised:30 May 2008Major or Minor:MinorRaised by:David Ogg FICFor.Aspect of standard:6.3.2 The system resolves disputes in an effective, timely and appropriate manner.Evidence of non-conformity:The system to resolve disputes is clearly in place and there are records of all meetings. The "grievances andcomplaints" that have been raised have been resolved in an effective and timely manner as confirmed byinterview. However, it is not clear if the issues raised at stakeholder meetings have been acted upon in aneffective and timely manner.Assessors signature:

David OggthDate: 30 May 2008.Proposed corrective action / improvement action by company.Records need to be maintained of action taken.Timeline for conformance:Time of next annual surveillance.Review of corrective /improvement action:During the ASA1 it is noted through interview with stakeholders and verification of records that theimplementation and action taken is very prompt and timely. Stakeholders confirmed that RSPO certificationprocess has brought in huge improvement. The NC raised during Main audit has been closed and verified onsite whereby interview with Workers Union representative and other stakeholders confirmed better andimproved water supply and road upgrading taken place. Immediate action was taken to install bigger capacitywater tanks to overcome the water shortage. All the records are checked and verified. NC closed.Assessors signature:

D. ManivannanthDate: 25 November 2009

Annual Surveillance Assessment Report, December 2009

Page 22 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

NON CONFORMITY REPORTNC number:03/2008Client name:United Plantations BerhadthDate raised:30 May 2008Major or Minor:MinorRaised by:David Ogg FICFor.Aspect of standard:6.5.3 Growers and millers provide adequate housing, water supplies, medical, educational andwelfare amenities in accordance with Workers’ Minimum Standard of Housing and Amenities Act 1990(Act 446) or above, where no such public facilities are available or accessible not applicable toSmallholders).Evidence of non-conformity:The housing provided and the standard varies as there is an ongoing improvement programme. However,water supply was raised as an issue by stakeholders and during worker interviews. Supplies are not alwaysadequate. (Especially Up River Business Unit). See also stakeholder record in public summary.Assessors signature:

David OggthDate: 30 May 2008.Proposed corrective action / improvement action by company.Immediate action to ensure adequate water supplies.Timeline for conformance:Time of next annual surveillance.Review of corrective /improvement action:All the facilities provided as per main audit re-visited and verified.Improvement made for the water supply with installing bigger capacity overhead water tanks. UP hasutilised RM109,000 to carry out the upgrading which include improved pipelines and repairing ofall leakages. Workers representative interviewed (Union Secretary) satisfied with the water supply and facilitiesprovided. The workers representative also mentions that there are many other upgrading works in progressincluding resurfacing/tarmac road. To date RM28,000 has been utilised and work is progressing in stages. NCclosed.Assessors signature:

D. ManivannanthDate: 25 November 2009

Annual Surveillance Assessment Report, December 2009

Page 23 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

3.4 Issues raised during stakeholder consultation held at Main Audit and companyresponses. (Verified during ASA1)Subject raisedCompany response andproposed action to be taken.Assessment teamFindings(Main Audit)Mill inspected andsound proofing noted.Further plans to extendto other mills.To be reviewed at nextaudit.

Verification duringASA1

Sound proof in mill.

Sound proofing has been builtaround the gen set.Dusty areas where thefurnaces are stoked. Willreview and try to improveVentilation.Claim that the school is not ingood physical condition andthat the government are notsupporting it due to the statusof the land which is owned bythe Estate. The estatemanagement feels that theyhave done the necessary andhave requested the HM towrite to the Education Ministryfor any assistance needed,since there is fund allocatedfor Tamil schools. The HMfurther mentioned that theEducation Ministryrepresentative have informedthat, if the land is givento the government, the ministrywill treat this school withgovernment aid. Themanagement told the HM toimmediately request theministry to write in officially ontheir request to follow up.

Sound proofing hasbeen extended to othermills.Dusty area in the millhas been well coveredand closed to containthe dust.

Dust

Education welfareand infrastructure ofcurrent school.

Meeting was held on2/4/08, with this personwho happens to thehead mistress of theDiv 1, Tamil school.Upon visiting theschool, the audit teamfound that the schoolis in good conditionwith all basic facilities.We further found outthat almost 40% of thestudents are not fromthe estate but fromsurrounding areas,whose parents do notwork in the estate.

The Tamil Schoolextension wascarried out by UPBerhad withRM169,979.00 andanotherRM79,469.00 wasspent to built aCanteen for theschool.

Annual Surveillance Assessment Report, December 2009

Page 24 of 26

Report number: 809027RSPOCUCRPT –2009-01-MD

4.

Certified organisation’s acknowledgement of internalresponsibilityAugust 2010n/an/a

4.1 Date of next annualassessment:4.2 Date to close majornon-conformities.4.3 Date to close minornon-conformities.

4.4 Formal sign off of assessment findings.Acknowledgement of internal responsibility by the client.I the undersigned, being the legal representative of the inspected company,agree with the contents of this report and accept the liability in execution ofthe instructions given in the report.Name:C. MathewsPosition:Group Manager HumanResources AndEnvironment, Safety & HealthSignature:

Date:

11thMarch 2010

Annual Surveillance Assessment Report, December 2009

Page 25 of 26

Report number: 809027RSPOCUCRPT –2009-01-MDAppendix: Abbreviations used in the checklistASABMBODBPNBRCCFCHRACoCCPOCSRCUDivEFBEUREPGAPEWGFFBFSCFPICFSC FMGGLGMPGTPGOTSGPSHACCPHCVHCVFHGUHIRARCHMHUMASIPMKKPAMAPAMSDSMWGN/A or n/aNCNIOSHNUPWOEOEROSHOSHASP&CPEFCPKPKBPKOPKSPODPOMPOMEPPEPTPT SSS1PT SSS2R&DAnnual Surveillance Assessment/AuditBahasa MalaysiaBiological Oxygen DemandBadan Pertanahan Nasional (National Land Body)British Retail ConsortiumCertificate of FitnessChemical Health Risk AssessmentChain of CustodyCrude Palm OilCorporate Social ResponsibilityControl UnionDivisionEmpty Fruit BunchEuro-Retailer Produce Good Agricultural PracticesEstate Working GroupFresh Fruit BunchForest Stewardship CouncilFree Prior Informed ConsentForest Stewardship Council Forest ManagementGreen Gold LabelGood Manufacturing PracticeGood Trading PracticeGlobal Organic Textile StandardGlobal Positioning SystemHazard Analysis and Critical Control PointHigh Conservation ValueHigh Conservation Value ForestHak Guna Usaha (Land Right)Hazard Identification, Risk Assessment and Risk ControlHead MasterHubungan Masyarakat (Public Relation)Integrated Pest ManagementSmallholder Cooperative AssociationMalaysian Agriculture Producers AssociationMaterial Safety Data SheetMill Working GroupNot ApplicableNon ConformityNational Institute of Occupational Safety and HealthNational Union for Plantation WorkersOrganic ExchangeOil Extraction RateOccupational Safety and HealthOccupational Safety and Health Assessment SchemePrinciple and CriteriaProgramme for the Endorsement of Forest CertificationPalm KernelPerjanjian Kerja Bersama (Collective Agreement)Palm Kernel OilPabrik Kelapa Sawit (Palm Oil Mill)Policy DocumentPalm Oil MillPalm Oil Mill EffluentPersonal Protective EquipmentPerseroan Terbatas (Limited Company)PT Surya Sawit SejatiPT Sawit Seberang SeberangResearch and Development

Annual Surveillance Assessment Report, December 2009

Page 26 of 26