Miljø- og Planlægningsudvalget 2010-11 (1. samling)

MPU Alm.del Bilag 508

Offentligt

Report number: 809027RSPOCUCRPT -2010-01-AS

RSPO 2 Annual SurveillanceAssessment Report (ASA2)UNITED PLANTATIONS BERHADPENINSULAR MALAYSIAThis public summary has been prepared in accordance with RSPO requirementsand the information included is the result of a full RSPO assessment of the Millsand supply base as included in the scope of the certificate.

nd

Report prepared by: A. Senniah (Lead assessor).Certification decision made by: Gerben Stegeman.

Control Union (Indonesia)Jl Kramat 3A,Cilandak TimurJakarta Selatan 12560Phone: 062-21-7884 2016

Control Union (M) S/BPersiaran Raja Muda Musa,Off Jalan Sg Berith,Teluk Gadong, 41100, Klang,Selangor. Malaysia.Phone 03-3377 1600 / 1700

Control Union Certifications. (Head office)Meeuwenlaan 4-6,P.O. Box 161.8000 AD Zwolle.The Netherlands.Phone: 0031 38436 0100Control Union Certifications is a member of the Control Union World Group - an international inspection andcertification body. CU performs assessments and certification in many agricultural based fields such asFSC, RSPO, and Organic production, Sustainable Textile Production, Organic Exchange, Eurepgap,HACCP, BRC, GMP and GTP.CU is accredited by the Dutch Council of Accreditation (RVA) on the European quality standard EN 45011for the inspection and certification of CU Organic program (according to the EU regulation 2092/91) andEUREPGAP program. When requested a copy of the accreditation certificate can be obtained from CU.

Annual Surveillance Assessment Report, November 2010

Page1of26

Report number: 809027RSPOCUCRPT -2010-01-ASContents.....................................................................................................................................PageScope of the Certification Assessment................................................31.1.31.41.51.61.71.11.2

1.81.9

Company details...............................................................................................3Surveillance assessment details....................................................................3RSPO membership details..............................................................................3Location maps...................................................................................................4Location addresses of mills.............................................................................6Metric tonnages certified and projected outputs..........................................6Description of supply base..............................................................................61.7.1General description........................................................................61.7.2Location address of the supply base...........................................6•Control Union code for the certificate•Location address•GPS reference1.7.3Statistics of supply base................................................................7•Control Union code for the certificate.•Area of oil palm.•Mature area.•Estimated annual FFB production in tonnes.•Planting years.•Replanting Cycle.1.7.4Percentage of planted areas of different ages...........................71.7.5Calculation of the number of production units (N) to sample for eachmill......................................................................................................7Progress of associated smallholders toward compliance............................7Rules for Partial Certification............................................................................8Certification body................................................................................................9Qualification of the audit team..........................................................................92.2.1Qualification of the lead assessor.................................................92.2.2Qualification of the audit team member.......................................92.2.3Timing of the Annual Surveillance Assessment.........................11Assessment methodology.................................................................................112.3.1General overview..............................................................................112.3.2Assessment agenda.........................................................................12•Assessment dates.•Sites visited.•Main activities.•Total number of person days spent on site.

2.

2.12.2

Assessment Process......................................................................................9

2.3

3

3.13.23.33.4

Assessment Findings..................................................................................... .......14

Lead assessor’s summary and recommendation for certification........ .......14Summary of the findings.............................................................................. ......15Non conformity register............................................................................... .......21Stakeholder consultation and interview............................................................22

4

Certified organisation’s acknowledgement of internalresponsibility...............................................................................................................244.14.24.34.4

5

Appendix: Abbreviations used...........................................................................25

Date of next annual assessment.........................................................................24Date to close major non-conformities.................................................................24Date to close minor non-conformities.................................................................24Formal sign-off of the assessment findings.......................................................24

Annual Surveillance Assessment Report, November 2010

Page2of26

Report number: 809027RSPOCUCRPT -2010-01-AS

1.

SCOPE OF THE CERTIFICATION ASSESSMENT.United Plantations BerhadJendarata Estate, 36009 Teluk Intan,Perak Darul Ridzuan, Malaysian/a+605 6411 411Mr C Mathews+601 9339 2298+605 641 2337[email protected]www.unitedplantations.com

1.1 Company details:Company name:Business address:

Group name if applicable:Office telephone:Contact person:Mobile telephone:Fax:e-mail:Web site:

1.2 Surveillance assessment detail:Dates of the assessment:

Assessment number (1 to4).

1. Field and Documents assessment:1 – 5 August 20102. Field and Document assessment andStakeholders consultation(DOSH, LabourthDepartment, NUPW, Dr. Ravindran, workers):13 September 20103. Stakeholders consultation (DOSH, LabourrdDepartment, NUPW and Tenaganita) :23 September 20104. Field and Documents assessment andStakeholder consultationsth( Danish Energy Agency) :28 September 20105. Stakeholder consultationth(NUPW and Tenaganita):11 October 20106. Stakeholder consultation (Representative ofrdMinistry of Climate and Energy, Denmark):3 November 2010Annual Surveillance Assessment number : 2 (ASA2)

th

1.3 RSPO membership details:RSPO membership number:Child numbers for eachcertification unit:Certificate number:Date of original certification:Date of last assessment:

1-0004-04-000-00CU809027D01, CU809027D02, CU809027D03, CU809027D04,CU809027D05, CU809027D06CUC809027RSPO-1.2008st21 August 2008th23 – 25 November 2009

Annual Surveillance Assessment Report, November 2010

Page3of26

Report number: 809027RSPOCUCRPT -2010-01-AS

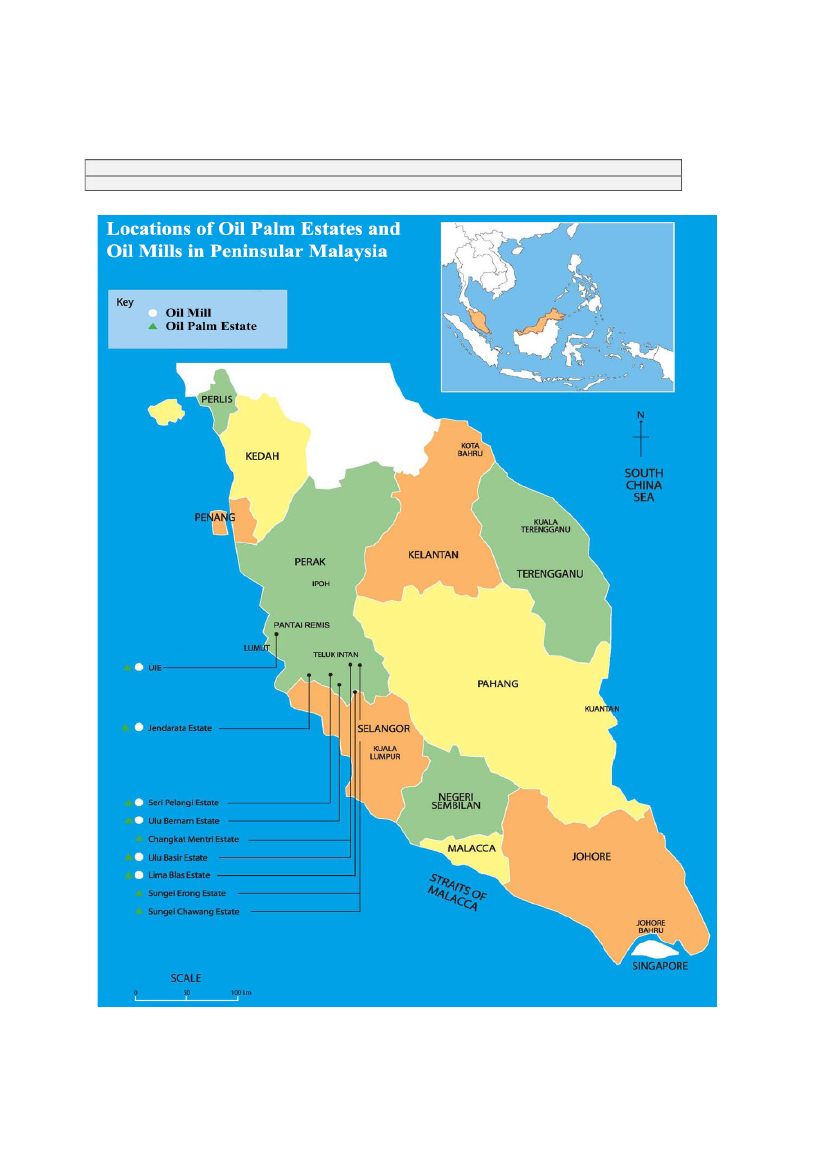

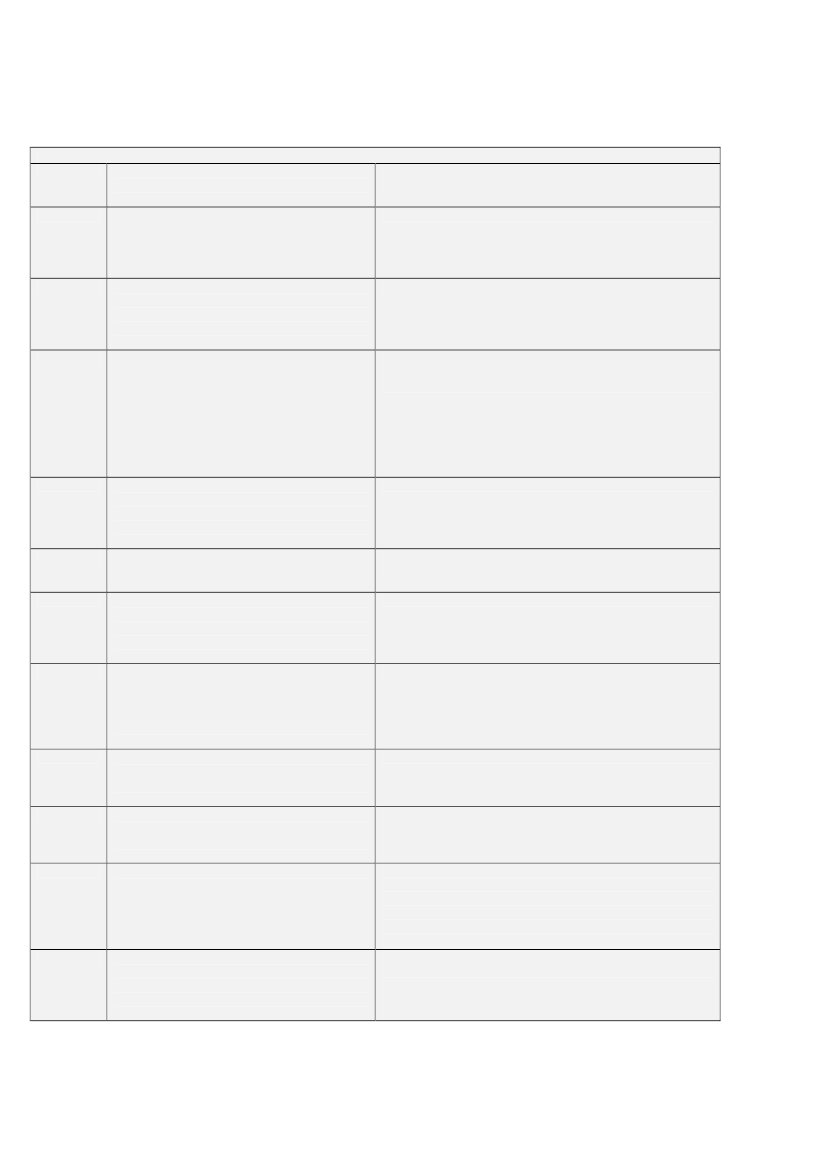

1.4 Location maps.

Map 1: Location of the estates and mills included in the assessment.

Annual Surveillance Assessment Report, November 2010

Page4of26

Report number: 809027RSPOCUCRPT -2010-01-AS

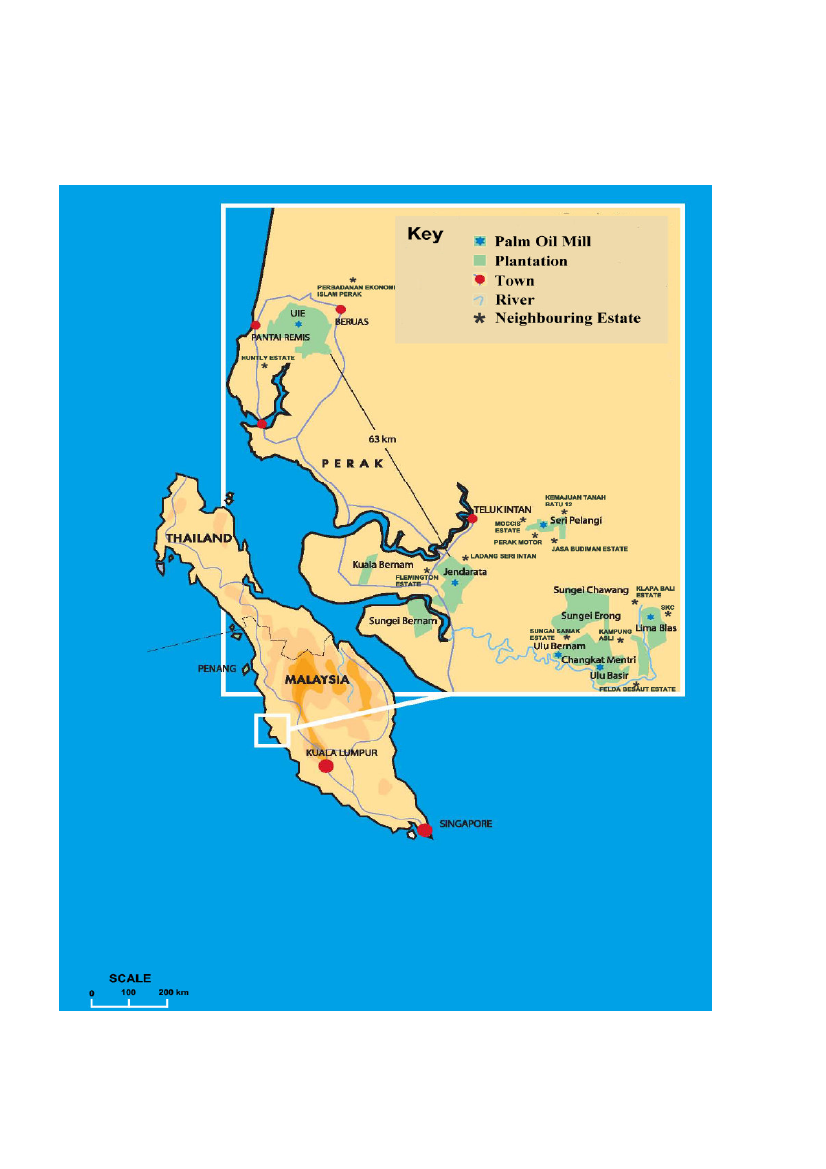

Map 2: Location of the neighbouring entities.

Annual Surveillance Assessment Report, November 2010

Page5of26

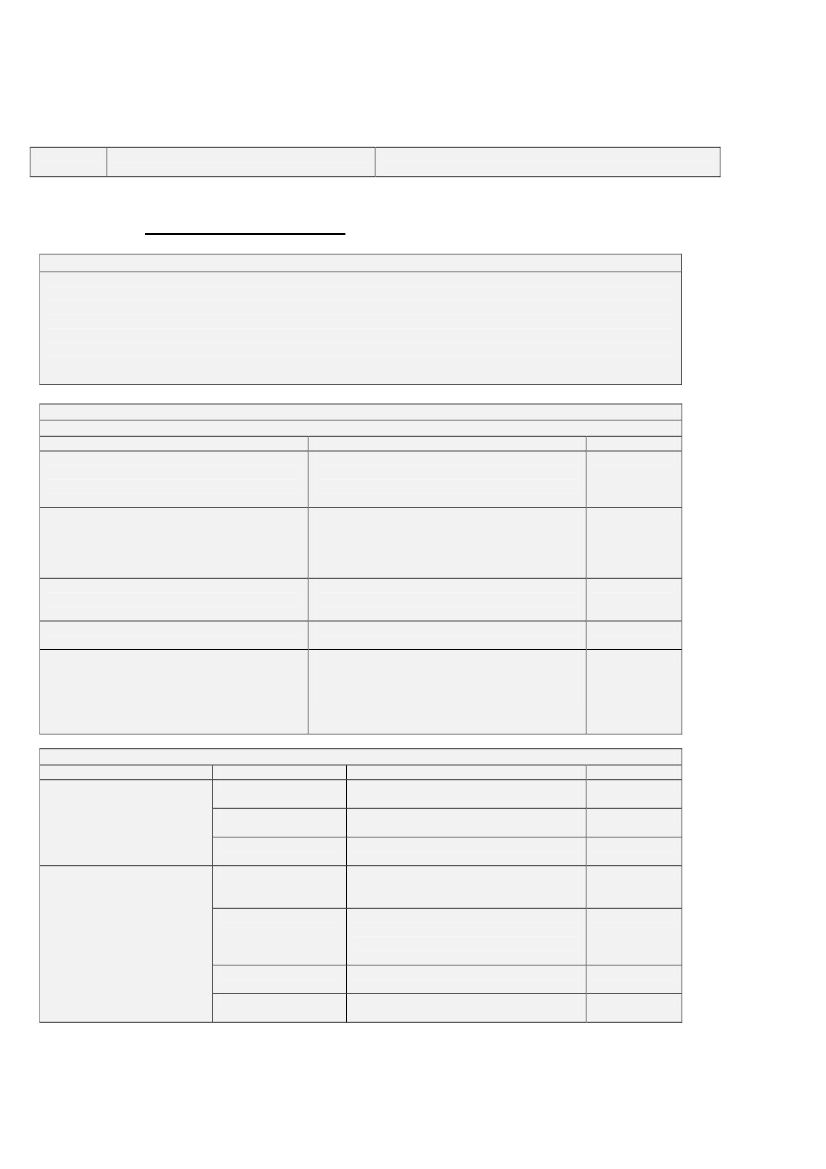

Report number: 809027RSPOCUCRPT -2010-01-AS1.5 Location address of the mills.Name of MillJendarata Palm Oil Mill.Seri Pelangi Palm Oil Mill.Ulu Basir Palm Oil MillLima Blas Palm Oil MillUlu Bernam Palm Oil Mill.United International EnterprisesPalm Oil MillLocation addressJendarata Business Unit, 36009 Teluk Intan, Perak, MalaysiaJendarata Business Unit, P.O Box 89 11� Miles, Jalan Bidor, 36008Teluk Intan, Perak, MalaysiaUp River Business Unit, 36500 Ulu Bernam, Perak, Malaysia.Up River Business Unit, 35800 Slim River, Perak, Malaysia.Up River Business Unit, 36500 Ulu Bernam, Perak, Malaysia.United International Entreprise (Malaysia), Mail Bag No 1, 34900,Pantai Remis, Perak, Malaysia.

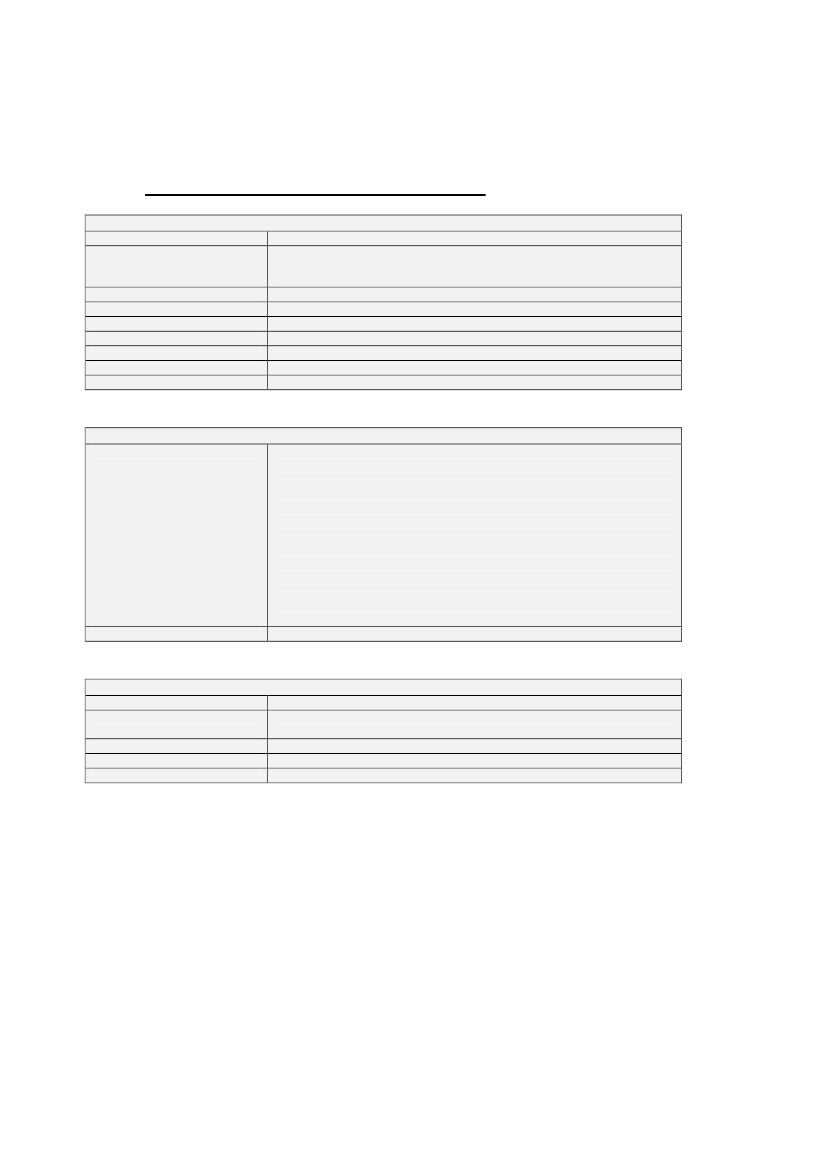

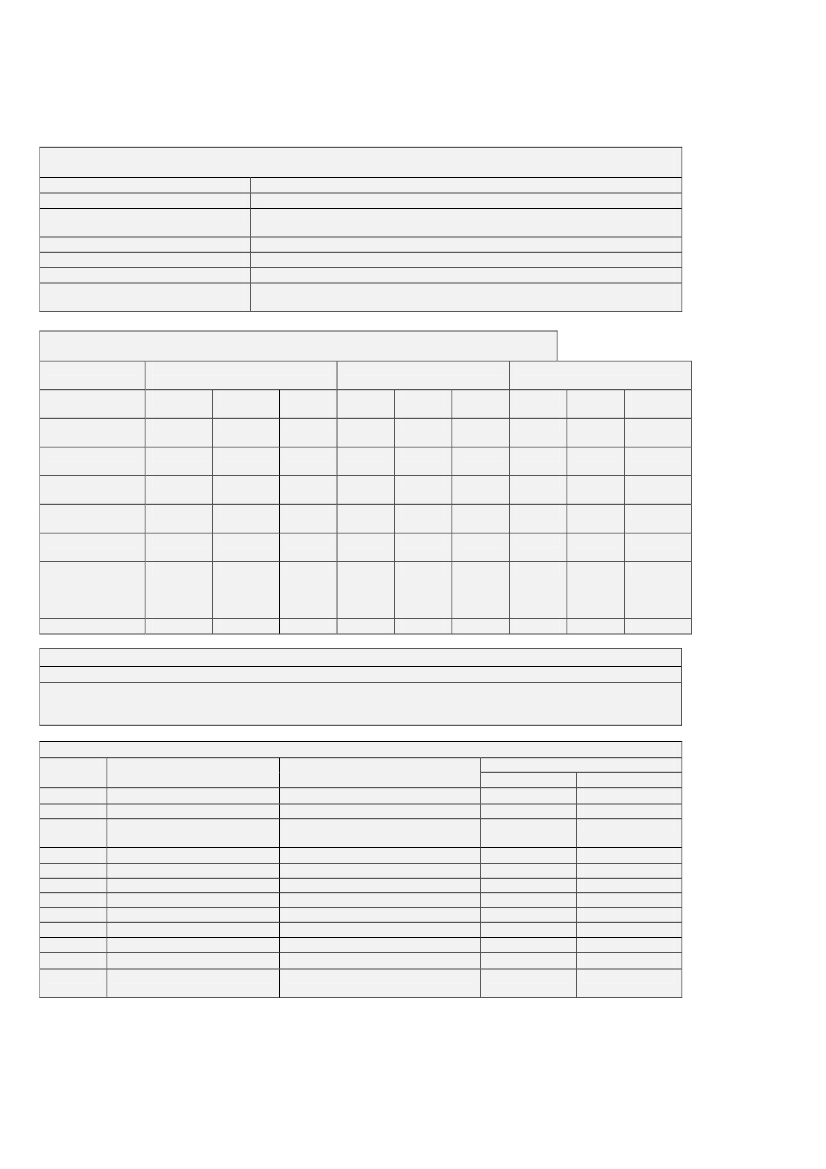

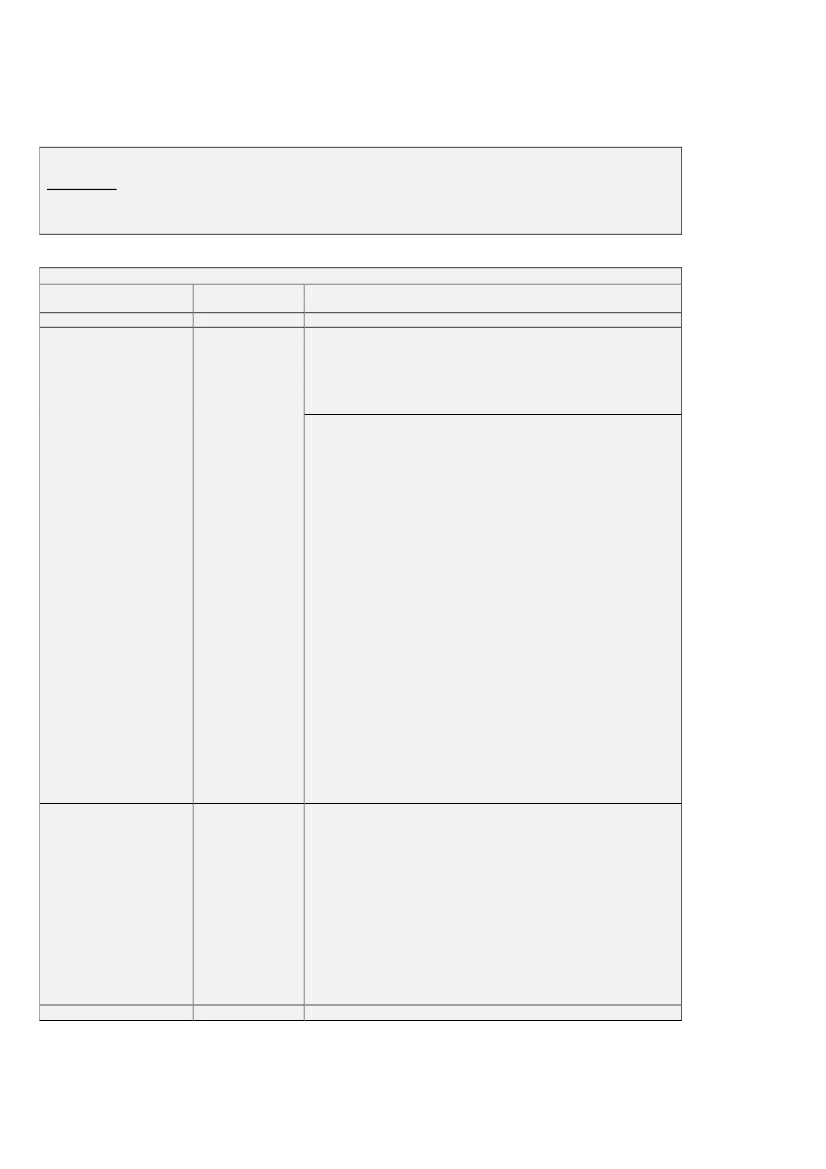

1.6 Metric tonnages certified and projected outputs.

(These figures exclude any output product from non-certified suppliers).Name of millProjected from last audit. (tonnes)Actual production (tonnes)2009(ASA1)FFBCPOPalmFFBCPOPalmKernelKernel8,749Jendarata Palm171,00039,0009,000165,993 37,423Oil Mill.40,5829,8002,078Seri Pelangi41,22010,0002,200Palm Oil Mill.173,947 37,7889,735Ulu Basir Palm158,64035,0009,070Oil Mill63,21713,0833,162Lima Blas Palm56,40012,7003,400Oil Mill181,589 39,14511,007Ulu Bernam156,97034,6008,910Palm Oil Mill.18,402United262,50044,77013,100289,866 61,645InternationalEnterprisesPalm Oil MillGrand Total846,730176,070 45,680915,194 198,884 53,133

Projected production for next12 months(2010)(tonnes)FFBCPOPalmKernel145,000 32,0007,60035,000142,66056,000175,740218,4008,24030,81411,58038,19044,7701,8107,9842,8009,70013,100

772,800

165,594

42,994

1.7 Description of supply base.The supply bases are the 9 plantations that make up the 3 business units of the United Plantations holdings locatedin Peninsular Malaysia. There are no plans to expand the land holding in Peninsular Malaysia and thereforePrinciple 7 is not applicable to this annual surveillance assessment.

1.7.1 General description.

1.7.2 Location of the supply base.CU CodeName

Location address.

GPS referenceLongitudeLatitude3� 52’ N3� 59’ N3� 42’ N3� 44’ N3� 46’ N3� 50’ N3� 42’ N3� 45’ N4� 25’ N101� 01’ E101� 08’ E101� 15’ E101� 13’ E101� 12’ E101� 14’ E101� 27’ E101� 07’ E100�.40’ E

PO1PO2PO3PO4PO5PO6PO7PO8PO9

Jendarata Business UnitJendarata EstateSeri Pelangi Estate

UP River Business Unit.Ladang Ulu BasirChangat Mentri EstateLadang Sungei ErongLadang Sungei ChawangLima Blas EstateUlu Bernam Estate

36009 Teluk Intan,PerakBatu11 3/4 Jln Bidor,36000,TelukIntan36500 Ulu Bernam,Perak36500 Ulu Bernam,Perak36500 Ulu Bernam,Perak36500 Ulu Bernam,Perak35800 Slim River,Selangor36500 Ulu Bernam,PerakPantai Remis,Perak

UIEM Business Unit

UIEM Sdn. Bhd. Estate 1and Estate 2

Annual Surveillance Assessment Report, November 2010

Page6of26

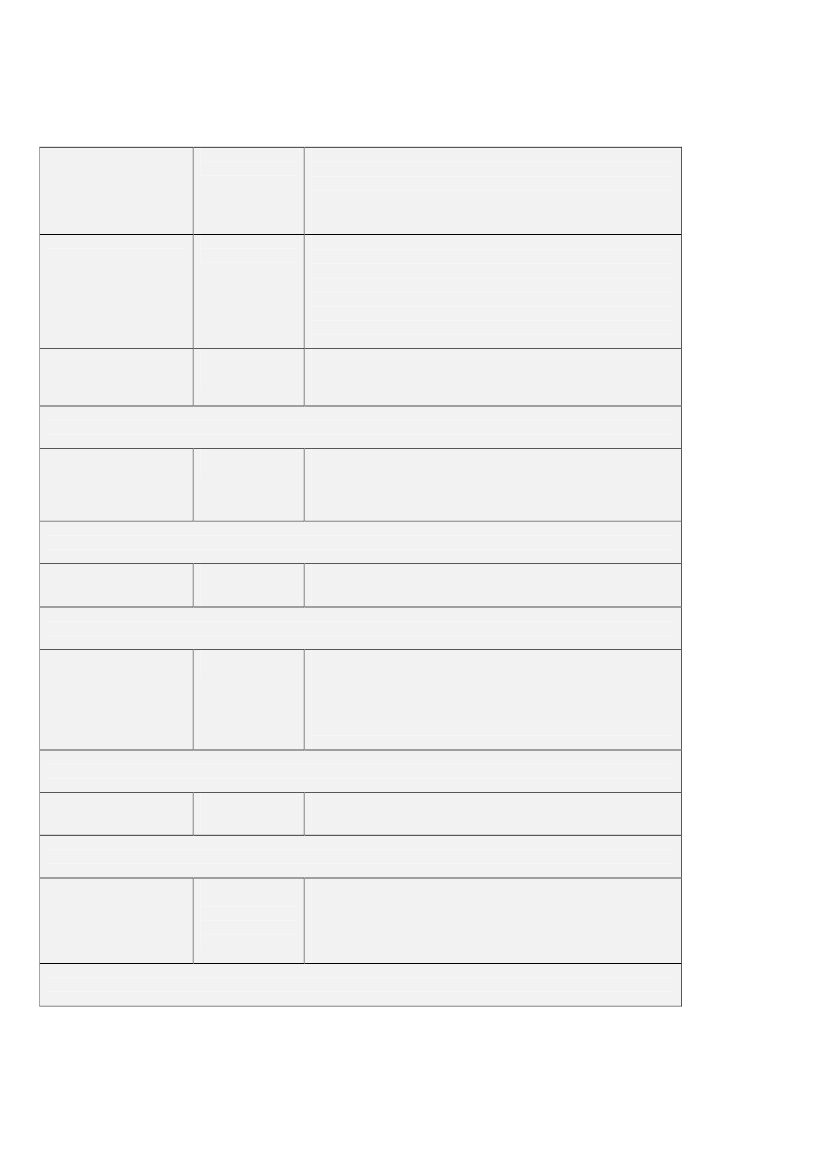

Report number: 809027RSPOCUCRPT -2010-01-AS1.7.3 Statistics of the supply base.CUCodeName

Area of oil palm (ha)OilMature ImmaturePalm6,0241,3373,7142,4113,4993,2482,7403,1549,8635,682.101,3372,604.401,945.202,3892,9992,3833,021.809,38731,748.5341.90-1,109.60465.801,1102493571,32.204764,241.5

Jendarata EstateSeri Pelangi EstateLadang Ulu BasirChangkat MentriEstatePO5Ladang Sungei ErongPO6Ladang SungeiChawangPO7Lima Blas EstatePO8Ulu Bernam EstatePO9UIEM Sdn. Bhd.Estate 1 and Estate 2Grand TotalCU CodePO1PO2PO3PO4PO5PO6PO7PO8PO9

PO1PO2PO3PO4

EstimateTonnesFFB(2010)145,00035,00060,00048,50059,76069,39056,00080,750218,400772,800

Plantingyears1975-20101994-20041983-20101988-20091985-20101986-20091985-20091986-22091988-2010

ReplantingCycle(years)252525252525252525

35,990

1.7.4 Percentage of planted areas of different ages.Before 199012.59-42.270.7338.2057.9331.5716.5277.011991 – 199534.6229.32-8.641.10-12.7036.4616.941996-200034.6347.34-51.429.500.2714.2327.552.77

2001 – 200513.7723.3420.5319.8923.4013.1215.6213.02-

2006 -20104.39-37.2019.3227.8028.6825.886.453.28

2011-2015---------

2016+---------

1.7.5 Calculation of the number of production units (N) to sample for each mill.

N = 0.8 y, where y is the number of units, with the result always to be rounded UP to the next whole integer.Where only a sample of the supply base is assessed, units not previously assessed, or assessed earlier in thecertification programme, are to be preferred over those more recently assessed.How many mills?6For each mill, how many units make up the production base?Name of POMOwned estates N = 0.8 YSmallholders (Z)N = 0.8 Z(Y)Jendarata Palm Oil Mill.11 (Jendarata Estate)n/an/aSeri Pelangi Palm Oil Mill.11 (Seri Pelangi Estate)n/an/aUlu Basir Palm Oil Mill42 (Sungei Erong Estate)n/an/a(Ulu Basir Estate)Lima Blas Palm Oil Mill11 (Lima Blas Estate)n/an/aUlu Bernam Palm Oil Mill.32 (Ulu Bernam Estate)n/an/a(Sungei Chawang Estate)United International11 (UIE Estate 1 and 2)n/an/aEnterprises Palm Oil Mill

1.8 Progress of associated smallholders or outgrowers towards compliance with relevantstandards - should be in accordance to the 3 year implementation plan.

Not applicable for this assessment. During the surveillance assessment, it is noted that there is no associatedsmallholders or outgrowers within the company’s control. The existing smallholders are independent smallholders whoare free to sell their crop to any POM that can offer higher FFB price.

Annual Surveillance Assessment Report, November 2010

Page7of26

Report number: 809027RSPOCUCRPT -2010-01-AS1.9 Rules for partial certification.1.9.11.9.2••Progress made from the last assessmentagainst the time-bound plan for certifyingother units within the organisation.Any alteration made to the time-boundplan, for example, due toacquisitions/disposals, emergence/re-emergence of land disputes and/or labourconflicts must be reported.The company’s justifications for anyrevision are also to be reported; with theaudit team’s considered opinion on thematter and recommendation foracceptance/rejection.Where the structure of the holdingcompany is changed during the course ofthe implementation of the time-bound plan,so as to alter the plan, the change instructure must be legal and registered withthe relevant authorities. Thedocumentation relating to such structuralchanges must be presented to the auditteam for verification, if necessary.Where there is evidence that the timebound plan is not being adhered to, or theconditions justifying a time-bound planhave changed, the audit team mustsummarise this evidence here.The audit team must be satisfied that thecompany has not opened new land withoutHCV assessment since first certified.New acquisitions by the company whichhave not replaced primary forests or HCVareas are required to comply withcertification requirements within threeyears of the date of acquisition.New acquisitions which have evidentlyreplaced primary forests or HCV areas willnot be eligible for RSPO certification andwill, by the rules of partial certification,render the entire company ineligible forcertification.Where there is a dispute whether aprimary forest or HCV has been replacedor lost, the company shall, at its own cost,provide RSPO with expert opinion.The organisation is a member of RSPO

The time bound plan remains as 2011 to certify the operatingunit in Indonesia.There is no change to the time bound plan.

1.9.3

•

There is no change to the time bound plan.

1.9.4

•

There are no changes in the structure of the holdingcompany noted during the ASA2. Discussion with topmanagement confirms that there are no such changes.

1.9.5

•

There is no change to the time bound plan.

1.9.61.9.7

••

There is no new acquisition and opening since the firstcertified and ASA1.There are no new acquisitions since last assessment.

1.9.8

•

There are no new acquisitions since last assessment.

1.9.9

•

There is no new dispute reported since the last assessment.

1.9.10

•

Invoice and evidence of payment.1.9.11••There are no significant land conflicts.For ALL land disputes. Location maps,area involved. People involved. Contactdetails. Timetable of events and asummary as to the actions taken by allparties.•No labour disputes that are not beingresolved through an agreed process.Summary of any labour disputes. Peopleinvolved. Timetable of events and summary asto the action taken by all parties.

1.9.12

Membership number: 1-0004-04-000-00Invoice no.: 0331-10/SPEMembership payment Date: July 2010-07-23Amount: Euro 2000.00The negotiation on land conflict at PT SSS1 with one of thetraditional land owner has been settled and companyrepresentatives in Indonesia have conducted severalmeetings with concerned parties and settled the negotiation.Compensation has been paid. Full details of negotiations areavailable to stakeholders on request to the company.There are no labour disputes since the last audit at propertyin Peninsular Malaysia, where this assessment wasconducted. Stakeholder consultation was conducted withWorkers Union leaders, NUPW national and statesecretaries, DOSH Official and Labour Department officials.Page8of26

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-AS1.9.13•No evidence of non-compliance with law inany of the non-certified holdings.PT SSS1 HGU (2500ha) was received and the remaining isin progress.

2.

ASSESSMENT PROCESS.

Control Union Certifications is a member of the Control Union World Group - an international inspection andcertification body. CU performs assessments and certification in many agricultural based fields such as FSC, RSPO,and Organic production, Sustainable Textile Production, Organic Exchange, Eurepgap/GlobalGAP, HACCP, BRC,GMP and GTP.CU is accredited by the Dutch Council of Accreditation (RVA) on the European quality standard EN 45011 for theinspection and certification of CU Organic program (according to the EU regulation 2092/91) and EUREPGAPprogram. When requested a copy of the accreditation certificate can be obtained from CU.

2.1 Certification Body.

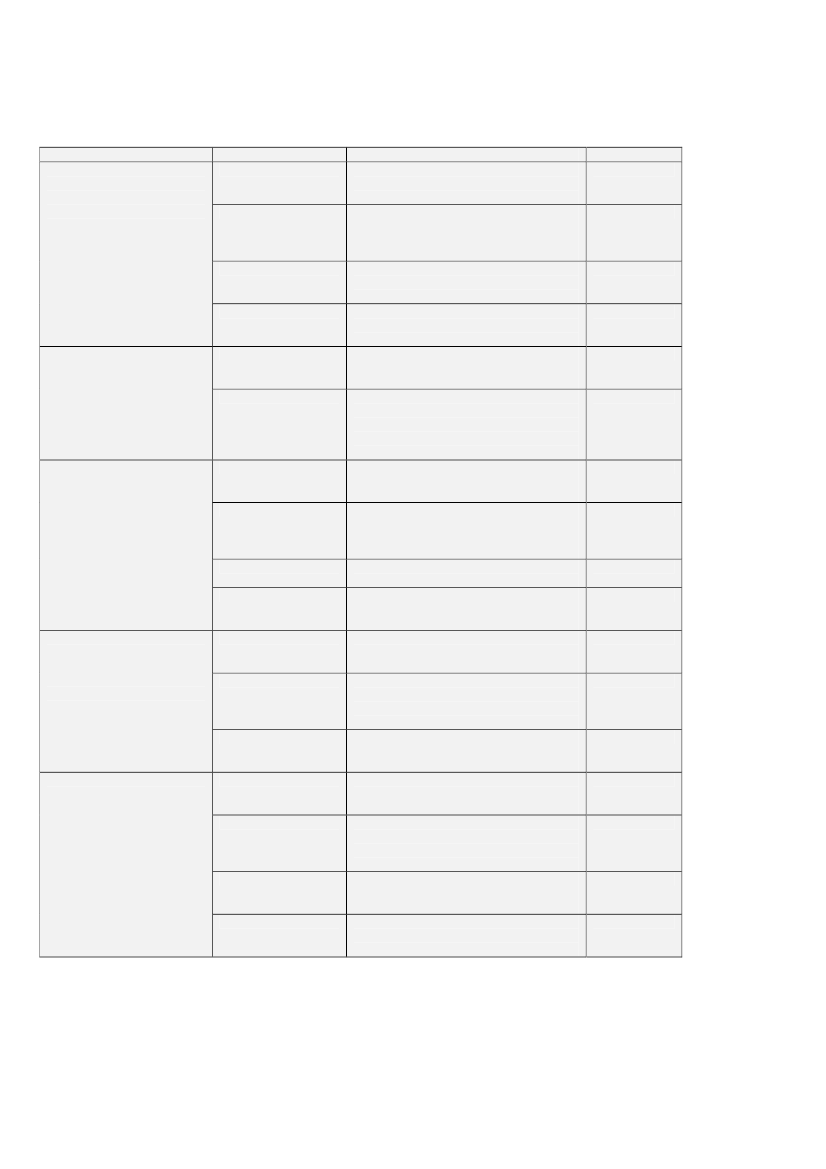

REQUIREMENTA minimum of post high school (postsecondary school) training in eitheragriculture/forestry, environmental science orsocial sciences;At least 5 years professional experience inarea of work relevant to the assessment (e.g.,palm oil management; agriculture/forestry;ecology; social science);

2.2 Qualifications of the audit team.2.2.1 Qualifications of the lead assessor: A. Senniah

QUALIFICATIONSPost graduate qualification in human resourcemanagement with more than 10 years workingexperience in plantation.More than 10 years working experience inplantation. Involved in RSPO auditing since April2009. Fully trained in similar agriculturecertification programmes such as RSPO SCCS,Global Gap, ISCC and GMP.Involved in RSPO assessment since April 2009.Member of CUC RSPO audit team. Involved inaudits conducted in Malaysia and Indonesia.Completed ISO 9001:2008 lead auditor coursein September 2009.Member of CUC RSPO audit team since April2009. Involved in audits conducted in Malaysiaand Indonesia since April 2009 in 8 differentcompanies in Malaysia and Indonesia.

ComplianceYes

Yes

Training in the practical application of theRSPO criteria, and RSPO certificationsystems;Successfully completion of an ISO 9000:19011lead assessors course;A supervised period of training in practicalassessmenting against the RSPO criteria orsimilar sustainability standards, with aminimum of 15 days assessment experienceand at least 3 assessments at differentorganisations.RSPO REQUIREMENTFluent in main locallanguages and English.ASSESSORA. Senniah

YesYesYes

2.2.2 Qualifications of the audit team member.

Muhammad HarisD. Manivannan

Field working experience inthe palm oil sector, or ademonstrable equivalent.

A. SenniahKongpichit

Muhammad HarisD. Manivannan

QUALIFICATIONSAble to speak and understand locallanguage and English.Able to speak and understand locallanguage and English.Able to speak and understand locallanguage and English.Working experience in palm oilplantation. Involved in RSPO audits sinceApril 2009.RSPO auditing experience in palm oilsector since October 2009. Fully trainedin other programmes such as GlobalGap, GMP and Organic farming.Working experience in palm oil plantationfor two years.Two years of plantation management. 7years with corporate agriculture

ComplianceYesYesYesYesYes

YesYesPage9of26

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-ASfinancing. Degree in agribusiness.Working experience in palm oilplantation. Involved in RSPO audits sinceApril 2009.RSPO auditing experience in palm oilsector since October 2009. Fully trainedin other programmes such as GlobalGap, GMP and Organic farming.Working experience in palm oil plantationand familiar with GAP, IPM and estatepractices.Two years of plantation management. 7years with corporate agriculturefinancing. Degree in agribusiness.Working experience in palm oilplantation. Involved in RSPO audits sinceApril 2009.RSPO auditing experience in palm oilsector since October 2009. Fully trainedin other programmes such as Global Gap(lead auditor), GMP and Organic farming(lead auditor).Working experience in palm oilplantation. Involved in RSPO audits sinceApril 2009.RSPO auditing experience in palm oilsector since October 2009. Fully trainedin other programmes such as GlobalGap, GMP and Organic farming.Working experience in palm oil plantationand able to conduct workers interview.Two years of plantation management. 7years with corporate agriculturefinancing. Degree in agribusiness.Working experience in palm oilplantation. Involved in RSPO audits sinceApril 2009.RSPO auditing experience in palm oilsector since October 2009. Fully trainedin other programmes such as GlobalGap, GMP and Organic farming.Two years of plantation management. 7years with corporate agriculturefinancing. Degree in agribusiness.Working experience in palm oilplantation. Involved in RSPO audits sinceApril 2009.RSPO auditing experience in palm oilsector since October 2009. Fully trainedin other programmes such as GlobalGap, GMP and Organic farming.Working experience in palm oil plantationfor two years. Graduated in BusinessAdministration.Two years of plantation management. 7years with corporate agriculturefinancing. Degree in agribusiness.

Good agricultural practices(GAP), integrated pestmanagement (IPM),pesticide and fertilizer use.

A. SenniahKongpichit

YesYes

Muhammad HarisD. ManivannanHealth and Safetyassessment on the farm andin processing facilities. (Forexample OHSAS 18001 oroccupational. Health andsafety assurance system).Workers welfare issues andsocial assessmentexperience. (For examplewith SA8000 or related socialor ethical accountabilitycodes).A. SenniahKongpichit

YesYesYesYes

A. SenniahKongpichit

YesYes

Muhammad HarisD. ManivannanEnvironmental andecological assessment. (Forexample experience withorganic agriculture, ISO14001 or environmentalmanagement systems).A. SenniahKongpichit

YesYesYesYes

D. ManivannanEconomic issues.A. SenniahKongpichit

YesYesYes

Muhammad HarisD. Manivannan

YesYes

Annual Surveillance Assessment Report, November 2010

Page10of26

Report number: 809027RSPOCUCRPT -2010-01-AS2.2.3Timing of the Annual Surveillance Assessment

Not earlier than 9 months after the anniversary of theawarding of the certificate.

Certificate anniversary is on 21 August. ASA2 wasscheduled and conducted with few trips to thethoperating units on 1 – 5 August 2010, Fieldassessment and stakeholder consultation conductedthrdthon 13 September 2010, 23 September 2010, 28thSeptember 2010 and 11 October 2010. Lastrdstakeholder consultation was conducted on 3November 2010 with the representative from theMinistry of Climate and Energy, Denmark who wasinterested on the RSPO assessment towardscompliance to criteria 4.6 RSPO P&C. Extensive fieldassessment and stakeholder consultation wasconducted during this ASA2 to verify the feedbackfrom NGO and foreign media news on paraquathandling in United Plantations and there were requestfrom Denmark Energy Agency and Ministry of Climateand Energy of Denmark for a stakeholderconsultation. It was necessary to allow all thestakeholder queries addressed accordingly during thisannual assessment and close all the issues raised bythe stakeholders.

st

2.3

The annual assessment was carried out in conformity with the procedures as laid down in the CUC RSPOProcedure Manual for ASA and the program manual for the assessor and certifier. During the assessment qualifiedCUC assessors used the RSPO standard as endorsed for the country in which the assessment took place andrecorded their findings.For each estate and small holder identified to be included in the sample for this audit, the original main assessmentchecklist was used, which includes any updates from previous annual surveillance audits.Workers and local communities were interviewed and evidence sought to confirm ongoing compliance whichincludes:•Chemical stores.Storage. MSDS leaflets. Herbicide mixing areas. PPE. Ventilation. Security.•Field inspections.Herbicide application programmes. Harvesting sites and efficiency. Fertilising operations.SOP’s. Soil maps. Land preparation. Ground cover. IPM. First aiders and boxes. Ground cover. Soil erosion.Field observations of all operations.•Worker interviews.OSH. Sexual, religious, racial harassment. Pay and contracts. Child labour. First aid.Awareness.•Re-planting sites.Zero burn.•HCV’s.Identification. Management plans. Environmental Impact Assessments. Implementation.•Riparian zones.Width. Current and future management. Non maintenance regimes.•Water management.Water courses. Water monitoring.•Road maintenance.Run off.•Social amenities.Social Impact Assessments.•Local communities.Contributions made. Employment opportunities. Social impacts. Complaints procedures.•Workshops.Oil traps. Safe working environment. PPE. Diesel tanks. Environmental waste management.•Line sites.Interviews with householders. Inspection of water discharge points. Water improvement plans. Wastedisposal.•Documentation review.Palm Oil mill audits include:•Mill and workshop inspections.Documentation. Worker interviews.•Mill.SOP’s. Safe working environment. Gen sets. Walk ways. Signs. EFB. POME treatment. Emissions. Massbalance. Diesel tanks. PPE. Fire extinguishers. First aiders and boxes. Fuel and water usage.•OSH.Training. Management structure. First aiders.•Full document review.Completion of the checklist. Review and documentation of evidence. All aspects ofRSPO P&C’s are applicable.Annual Surveillance Assessment Report, November 2010

2.3.1 General overview.

Assessment methodology.

Page11of26

Report number: 809027RSPOCUCRPT -2010-01-AS•Worker interviews.OSH. Sexual, religious, racial harassment. Pay and contracts.Verification.Verification of implementation was done through field observations, workshop and chemical store inspections,worker and community interviews and mill inspections as summarised above.

2.3.2 Assessment Agenda.Date1st August 20102nd August 2010

Location /mainsitesGuest HouseUlu BernamEngineeringDept.ConferenceRoom

Main activitiesArrival of the Auditors at the location.•Discussion on progress made to time bound plan and partialcertification progress.•Opening meeting. Introduction by team leader. Introductionof team members and assessment agenda.•Presentation by respective mill and estate managers onContinuous improvement status of Upriver Business Unit.Assessment at Sg Erong Estate, Sg Chawang Estate, Ulu BasirEstate, Ulu Bernam Estate.•Chemical stores.Storage. MSDS leaflets. Herbicide mixingareas. PPE. Ventilation. Security.•Field inspections.Herbicide application programmes.Harvesting sites and efficiency. Fertilising operations. SOP’s.Soil maps. Land preparation. Ground cover. IPM. First aidersand boxes. Ground cover. Soil erosion. Field observations of alloperations.•Worker interviews.OSH. Sexual, religious, racial harassment.Pay and contracts. Child labour. First aid. Awareness.•New planting sites.Zero burn.•HCV’s.Identification. Management plans. EnvironmentalImpact Assessments. Implementation.•Riparian zones.Width. Current and future management. Nonmaintenance regimes.•Water management.Water courses. Water monitoring.•Road maintenance.Run off.•Social amenities.Social Impact Assessments.•Local communities.Contributions made. Employmentopportunities. Social impacts. Complaints procedures.•Work shops.Oil traps. Safe working environment. PPE. Dieseltanks. Environmental waste management.•Line sites.Interviews with householders. Inspection of waterdischarge points. Water improvement plans. Waste disposal.•Document inspection and assessment.Assessment at Ulu Bernam POM and Ulu Basir POM•Mill and workshop inspections.Documentation. Workerinterviews.•Mills.SOP’s. Safe working environment. Gen sets. Walk ways.Signs. EFB. POME treatment. Emissions. Mass balance. Dieseltanks. PPE. Fire extinguishers. First aiders and boxes. Fuel andwater usage.•OSH.Training. Management structure. First aiders.•Full document review.Completion of the checklist. Reviewand documentation of evidence. All aspects of RSPO P&C’s.•Worker interviews.OSH. Sexual, religious, racial harassment. Pay and contracts.•Document inspection and assessment.•Opening meeting. Introduction by team leader. IntroductionPage12of26

3rd August 2010

UIEM

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-ASConferenceRoomof team members and assessment agenda.Presentation by respective mill and estate managers onContinuous improvement status of UIEM Business Unit.UIE Estate and POM assessment as per above for estate andmill.Lima Blas Estate and POM assessment.Opening meeting. Introduction by team leader. Introductionof team members and assessment agenda.Presentation by respective mill and estate managers onContinuous improvement status of Upriver Business Unit.

••

4th August 2010

JendarataBusiness Unit

•••

5th August 2010

Borge Bek-NielsenAuditorium.

Number of assessors participating: 3Number of days spent for the assessment on site: 4Total number of person days used for the assessment on site: 1213th September 2010Jendarata•Stakeholder consultation with Perak State DOSH official, PerakEstateState Labour Department officials, National Secretary of NUPW,Perak State Secretary of NUPW, Dr. Ravindran (Sabak BernamDispensary), VMO and workers.•Field and Documents assessment.Number of assessors participating: 1Number of days spent for the assessment on site: 1Total number of person days used for the assessment on site: 123rd September 2010Borge Bek-•Stakeholder consultation with Tenaganita, Perak State DOSHNielsenofficial, Perak State Labour Department officials and PerakAuditorium.State NUPW secretatry.Number of assessors participating: 2Number of days spent for the assessment on site: 1Total number of person days used for the assessment on site: 228th September 2010Jendarata•Field, field operation, facility and Document assessment atEstateJendarata Estate in the present of Representatives from DanishEnergy Agency.•Stakeholder consultation with the representatives from DanishEnergy Agency (Denmark), Perak State NUPW secretary,Jendarata Estate NUPW representatives and GenderCommittee representatives.Number of assessors participating: 1Number of days spent for the assessment on site: 1Total number of person days used for the assessment on site: 111th October 2010Borge Bek-•Stakeholder consultation with Tenaganita, NUPWNielsenrepresentatives and workers.Auditorium.Number of assessors participating: 1Number of days spent for the assessment on site: 1Total number of person days used for the assessment on site: 13rd November 2010Telephone•Stakeholder consultation with the representative from theconversationMinistry of Climate and Energy, Denmark. The stakeholdersAnd documentsrequested that the queries raised by them to be included in theReference toannual assessment report as a part of stakeholder feedbackmonocrotophosand comments. Queries refer to the criteria 4.6 in general andreference to the use of monocrotophos in specific.Number of assessors participating: 1Number of days spent for the assessment: 1Total number of person days used for the assessment: 1

Seri Pelanggi Estate, Jendarata Estate, Jendarata POM andSeri Pelanggi POM assessment as per above for estate andmill.Interim closing meeting.Welcome and introduction by the team leader.Presentation of findings by the assessment team.•Questions and answers.

Annual Surveillance Assessment Report, November 2010

Page13of26

Report number: 809027RSPOCUCRPT -2010-01-AS

3.

ASSESSMENT FINDINGS.3.1 Lead assessor’s summary and recommendation for certification:

During this second annual assessment there was a need for extensive stakeholder consultation due to theallegation made by the Danish Newspaper. There were series of articles published related to UnitedPlantations. The allegations was that the United Plantations employees (workers) are exposed to unsafeworking environment, pesticide poisoning and without adequate medical attention. It was necessary toaddress this issue during this annual assessment before a positive recommendation to maintain the certificateis made.The extensive stakeholder consultation was incorporated with field operation verification, field workersinterview, site visit such as chemical store, chemical mixing area, interview with those handling chemical store,and inspection of all the requirement with Occupational safety and Health.The stakeholder consultation was conducted in few separate occasions with Perak State DOSH official, PerakState Labour Department officials, National Secretary of NUPW, Perak State Secretary of NUPW,representatives from Tenaganita, Doctor from Sabak Bernam Dispensary, United Plantations Visiting MedicalOfficer, Representatives from Danish Energy Agency, Representative from Danish Environmental ProtectionAgency, Representative from Danish Ministry of Climate and Energy, Workers, representatives from Gendercommittee, representatives from foreign workers, staff, executives and managers. It was necessary to conductfew stakeholder consultations because the stakeholders were also engaged with tight schedule and othercommitments. It is also the wish of the stakeholder’s especially from the Danish Energy Agency and Ministryof Climate and Energy that the feedback gathered from this stakeholder consultation is highlighted during thisannual assessment report. The stakeholder’s comments are listed at the bottom of this report.During this assessment, it is noted that paraquat is completely eliminated since 1 October 2010. This was thecommitment by the company since certified in 2008. The audit team find this achievement as one of thecontinuous improvement committed and implemented successfully by the company. Now the company islooking into further reducing and eliminating monocrotophos by cooperating with two globally known leadingagrochemical producers to find the best possible alternative to replace monocrotophos.The second annual assessment process ensures that all the stakeholders who have shown interest in theRSPO P&C assessment is attended accordingly before closing of the assessment report. It was necessary toensure that all the issues related to the chemical handling under the RSPO P&C is checked and verified forcompliance in the presents of the interested stakeholders.Based on the findings during the Annual Surveillance Assessment, the audit team concludes that UnitedPlantations Berhad’s operation comply with the requirement of RSPO P&C. It is therefore the recommendationof the assessment team leader that:•A certificate of compliance is maintained.Signed:st

Name: A. SenniahthDate: 8 November 2010

Annual Surveillance Assessment Report, November 2010

Page14of26

Report number: 809027RSPOCUCRPT -2010-01-AS

3.2 Summary of the findings.•Over the 5 year period of the life of the certificate, there will be 4 annual surveillance assessments and a sample ofthe criterion will be summarised each year.•Identified Non-Conformities and noteworthy Positive and Negative Observations.3.2.1Principle 1All operating units provide adequate information to other stakeholders (when requested) onenvironmental, social and legal issues relevant to RSPO criteria. Information is given inappropriate languages and forms. The system available is also allowing stakeholders toeffectively participation decision making through stakeholder meeting.1.1All the operating units maintain and updating all request and response records including recordsof meeting held with stakeholder during information sharing session. Information request andresponse to Hilir Perak Health Department, MPOB and Statistic Department of Malaysia wassited during document audit. During this assessment, information was given to the stakeholderswho was interested in agrochemical handling in United Plantations in general and Jendarataestate in specific.1.2No any changes noted in the land title and restrictions. S&H plan covers training, policy, riskassessment and OSH meeting. In May 2010 review was done. Internal Operational Review ofEIA and SIA by the Group Environmental department on 14/4/10. Pollution Prevention Plansreviewed on 13/4/10 with new plans developed to address pollution prevention such continuousimplementation of pollution control devises (spillage kits). Grievances are recorded and actedpromptly. All the issues raised by the stakeholders during the main assessment have beenaddressed and interview with these stakeholders confirmed that actions have been taken.Negotiation procedure is maintained and available in stakeholder booklet and stakeholder awareof such procedures. Continuous improvement plans have been implemented as planned duringthe last audit. Details as per Principle 8 below.3.2.2Principle 2Tracking of changes in law was done for the changes in Law for foreign workers permit whichwas extended from 5 years to 10 years effective 20/1/10, Pos Malaysia Domestic Tariff 2010-domestic standard mail rate increase to RM0.60 effective from 1/7/10, New requirement forgetting permit to purchase, store and use sodium hydroxide. Permit 024824 Exp.31 Dec 2010.Altogether there are 16 permits sited.Relevant sampling of documents sited are: Quit rent no. 0001899, DOE license 000401, dieselstorage permit number: PPDNKK.TPH/PK/SK/SK/(PD)/052 009/10, MPOB permit: 500371-004000, Foreign Worker Recruitment Permit Number: E3302360, Deduction Permit number:0049.CDM project completed in UIE, the following permit available: Global Environmental Facilityproject (UNFCC), letter of approval dated 24/2/10 by the DOE.Similar to the first Annual Surveillance Assessment, Group Human Resource, Safety andEnvironment department ensures that information from the Company Secretary is disseminatedto all the operating units. There are 4 laws revised by relevant authorities.The changes tracked and informed to the operating units by Company Secretary through GroupHR, Safety and Environment Dept and duly acknowledged by the authorised personnel at theoperating units.All the legal ownership remains same as per main audit. No changes in the land title. Boundarystones along the perimeter adjacent to other properties are being located and visibly maintained.No conflict or dispute over the land is noted. No customary rights issues noted during theassessment.3.2.3Principle 3Latest budget is available and projected for 2 years. Budget includes projection of FFB3.1production, OER, CPO yield/ha, operational expenses and budget for continuous improvementprojects i.e. biogas plant and biodiversity enhancement project. Replanting programme isverified. Replanting is carried out with zero burning technique. Old palms are felled and chipped.3.2.4Principle 4SOP/Field manual updated for Ganoderma control (under Oil Palm Disease section).Latest HIRARC done in May 2010.Standard Operating Procedure (SOP) for buffalo evacuation was done in Nov 2009. Latestvaccination for buffalo by Vetenary Department conducted on 2/8/10 as per SOP. UIEPOMdeveloped SOP for the biogas plant, and safe operating procedure for enclosed flare, SOP forburner and enclosed flare, HIRARC for burner and enclosed flare, SOP for biogas burner, shutdown procedure for burner and safety manual for biogas plant.The peat areas are mapped. Water management is carried out to maintain a water table at 0.5mand this is done by water gates, sand bag weirs. One weir on average per 40ha. The systemswere inspected on site. Ground cover is also maintained to reduce oxidation at the peat. Noblanket spraying. Only selective spraying. Flat area is maintained with grass cutting.Annual Surveillance Assessment Report, November 2010

Page15of26

Report number: 809027RSPOCUCRPT -2010-01-ASBiodiversity enhancement is on going with planting of rare forest trees along the existing area.Each estate has planted endangered forest trees and continuously planting tress such as“Baccaureabrevipes”,“Knemehookerisna”,sentang spiecies, and “Diospyrosdiepenhorstii”.The company also has established tea tree corridor, sentang park, silver oak avenue andtembusu park to enhance biodiversity within the plantation. River buffer zones have been plantedwith cover crop along with natural vegetation. All this areas are well maintained and ensuring thebiodiversity enhancement.Good ground cover has been established at the replanted area withMucuna bracteata.Allharvesters’ path (approximately 95%) at the matured fields is maintained by mowing grasses.During the field visit there were no serious erosions observed.For road maintenance, map available, upkeep of roads recorded and SOP for road maintenanceis used as guidance. Budget allocation verified during document audit.Rainfall checked daily in the morning and recorded by the staff concerned.Water usage at POM is ranging from 1.2m� - 1.5m� to process per mt FFB.Water management includes water analysis for domestic water supply and mill processing wateranalysis. IPM includes planting of beneficial plant (tunera,cassia , antignon, and carambola andfox tail),increasing barn owl population through proper maintenance and monitoring of boxes.Effective establishment of beneficial plants to control leaf eating pest has helped the operatingunits to eliminate/reduce the use of methamidophos and warfrain.OSH policy as per main audit. OSH policy well briefed to all workers. Interview with workersreveal that they understand the policy and importance of safety at work. OSH meeting onquarterly basis. Awareness training programme includes safe working procedure. Morningbriefing carried out to ensure workers are aware of safe working practices. Company providesappropriate PPE at the place of work to cover all potentially hazardous operations such aspesticide application, land preparation, harvesting and all other works with necessary PPE. Acertified first aid trainer/ paramedic is on standby 14 hrs per day and there is a local clinic. Firstaiders also available at work site and verified. First aid equipment sited at work place. JKKP6 isprepared to inform any accidents if happened in the operating units. Accident investigation iscarried out to review and formulate necessary training. There are no any agrochemical poisoningreported. It was confirmed by the Visiting Medical Officer and DOSH officials.Workers covered by insurance. SOCSO number: D4501132 and Workmen compensationnumber: WWBOAG 000315 by Tokio Marine Insurance. Training programme is reviewedannually and new programme developed. Every operating units and POM keep the trainingrecords. Beside workers training, staff and executives are sent for internal and external training.Soil analysis conducted once in 5-10 years. Annual foliar analysis, yield productivity, age ofpalm, soil type, and field visit carried out by the Research and Development department beforefertiliser recommendation is made. Based on this analysis fertilizer recommendation developedand applied accordingly. EFB applied at rate of 40mt/ha applied to reducing in-organic fertilizerapplication.Zero burn during replanting has been practised as per principle 3 above. Field visit confirms thatno burning carried out. POME application area has been increased compared to the last audit.POME and EFB applied areas are monitored through field records. BOD of the POME applied toland is below the stipulated DOE standard of 5000mg/L.All the POM has developed Safe Operating Procedures which incorporated with HIRARC formain 12 stages, ramp, sterilizer, hoisting, threshing, EFB station, pressing, oil room, nut plant,boiler room and engine room, water treatment plant, effluent treatment plant and workshop.DOSH visits the estates and POMs to monitor the risk, action plans prepared by estates andPOMs and its implementation. CHRA is reviewed every 5 yrs by DOSH certified Assessor.There is an approved list of pesticides for oil palm. Written justification for all agrochemicals usedavailable. All pesticides are officially registered. Records show that the agrochemicals used areappropriate and in accordance with product label recommendations for target species.DOSH visits periodically to ensure that USECHH regulation is followed and implemented.Pesticide stores are secured and well ventilated. Only authorised staff and executive allowedentering the store. Stores are well ventilated. Chemical stores with MSDS leaflets. First aid kitavailable at work site. Workers are trained in the use of agrochemicals and this training isrecorded.Agrochemicals arranged according to the class and clearly marked. There were no paraquat andmonocrotophos in the store during the visit on 28/9/2010. MSDS available in local language andEnglish with all the information regarding the chemicals and its usage, hazards, trade andgeneric name. Policy on no work with pesticides for confirmed pregnant and breast-feedingwomen is continuously implemented.Medical check up is carried out annually for all those in high risk including agrochemicalPage16of26

4.2

4.6

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-ASapplicators. Medical check up dated 15/9/2010 confirms that all the agrochemical applicators arefir to work and no chemical poisoning. Medical check up includes hemathology, renal, liverfunction; chest x-rays other than physical examination of hand, fingers, leg, face, eyes, bloodpressure and fitness. CHRA was done in May 2009. Monthly medical check up by internaldoctor.The use of WHO type 1a or 1b chemicals such as monocrotophos is on reducing trend.Monocrotophos is used for trunk injection directly into the palm. The use is on reducing trendabout 50%. United Plantations is also looking into further reducing and eliminatingmonocrotophos by cooperating with two globally known leading agrochemical producers to findthe best possible alternative to replace monocrotophos.paraquat was eliminated completely since 1/10/2010. Paraquat is replaced with glyphosate andthglufosinate. During the assessment on 28 September 2010 in the present of the Danish EnergyAgency representative, it is noted that there were no paraquat in the store and stock recordsshows that there are no paraquat. It is completely eliminated from United Plantations during theassessment and company confirm that all the operating units are completely eliminated paraquatsince 1/10/2010 which is earlier than the targeted date.No aerial spraying of agrochemicals. Records of pesticide use (including active ingredients used,area treated, amount applied per ha and number of applications) are maintained by eachoperating units.Records of pesticide usage are updated regularly and verified during document audit. The detailsinclude date of application, ha, type, quantity, field and workers involved.Plantations and mill management that have environmental impacts are identified, and plans tomitigate the negative impacts and promote the positive ones are made, implemented andmonitored, to demonstrate continuous improvement.Schedule waste collected by Aliran Segar Sdn. Bhd.(license number 000394) and GBR Birch.Chemical containers collection record: GBR Birch Enterprise and it is used for industrial purpose.Medical waste sent to Pantai Medivest.Shell and fibre reused for boiler. EFB is applied to the field. POME is used for land application.Please refer to 4.2 above for POME monitoring. Fossil fuel usage is 2.31L/mt CPO, renewableenergy used is monitored and recorded. Average is Fibre 6.12GJ/tome and shell 3.65GJ/tonneof CPO.HCV was followed the first assessment. Now mainly on enhancement of biodiversity area byplanting jungle trees. Monitoring and management is ongoing. The HCV area is 11 ha of wildlifesanctuary ( Grut Wildlife Sanctuary), Archaeological site( HCV 6) and 7th century site. "BukitSejarah at Changkat Mentri Estate". All this areas are well conserved and monitored.At Lima Blas Estate 200 acres of primary forest with a rich flora and fauna is maintained andmonitoring carried out by the internal staff to ensure it is preserved.Pollution prevention plans reviewed and there were no new pollutants arise because theoperation remains same but recently water filters are included as one of waste to be collected.Previous pollution prevention measures are maintained.Monitor and reduce peat subsidence rate through water table management is implemented atpeat area by maintaining water table at a mean of 60 cm (within a range of 50-75cm) belowground surface through a network of weirs and sandbags.Latest HIRARC was done 24/3/10 and ongoing all the time and when ever new workers arejoining the company.Letter from DOE, Perak dated 28/10/10 approved the biogas plant to be commissioned withoutEIA (EIA is not required )All the pollution control devices such as diesel bund, spill kit, waste oil traps are well maintainedand monitored. Visit to these facilities confirmed that mitigation plans are implemented andmonitored.Zero burning is practiced during replanting. Progress reports and checklist to support this isavailable. Clear evidence on the ground to support this is noted during field visit. Replanted areainspected and found that previous palm are felled, chipped and used as a mulching to reduceand avoid exposing soil. Household waste goes for land filling and field waste are recycled backto the field such as EFB, fronds and chipped materials.Latest social impact assessment for operating units conducted on 14/5/10, attended by internaland external stakeholders. Group level social impact assessment conducted on 15/5/10 attendedby 166 internal and external stakeholders.EIA reviewed on 26/1/10. Stakeholder meeting conducted on 12/5/2010. During this assessmentthere were several stakeholder meeting conducted after the release of reports in foreign mediaregarding the use of paraquat and mishandling of agrochemicals in Jendarata Estate. It wasnecessary to conduct this stakeholder meeting to close out all the issues raised by thePage17of26

3.2.5

Principle 5

5.1

5.5

3.2.6

Principle 6

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-ASstakeholders including Danish Energy Agency, Tenaganita, DOSH, Labour Department, NUPWand Danish Ministry of Climate and Energy. Last stakeholder consultation and verification ofdocuments related to used of 1a and 1b agrochemicals was conducted with representative fromMinistry of Climate and Energy, Denmark. During this assessment stakeholder meeting was heldwith workers who was mentioned in the foreign media report on use of paraquat in JendarataEstate. The workers interviewed were ableto express their views through their own present

and through representative institutions (NUPW) during the identification of impacts,reviewing findings and plans for mitigation, and monitoring the success of implementedplans on use of paraquat and elimination.

6.46.6

6.10

3.2.73.2.8

Principle 7Principle 8

8.1

During this assessment all the grievances highlighted in the Danish newspaper were checkedand consultation conducted with all those highlighted in the report to ensure there is no pendinggrievances especially from the employees. It is noted that there are no such grievances asreported. The workers and NUPW representatives interview revealed that the present grievancesprocedures are effective and workers confirmed that they have access to this procedures andable to find solution without the assistance from any third party. It is also noted that UnitedPlantations is open and transparent to share all the activities and stakeholders are given accessto the information required to resolve any issue concerning their interest.Pay is recorded through payslip, workers acknowledge by signing the master copy, payslip isgiven to the workers. All the operating units conducting drinking water analysis and sample resultdated 24/6/10 shows e-coli and coliform not detected. The water is suitable for drinking.Although all the operating units comply with this requirement, it is noted that drinking wateranalysis was not conducted in one of the operating unit (Seri Pelanggi POM). There is noevidence to confirm that the drinking water supplied to the labour housing at this operating unitis in compliance with WHO specification for drinking water. This was raised as a minor nonconformity during the closing meeting.All employees paid and treated equally. Gender committee meeting held on 29/6/10. It is alsonoted that during stakeholder consultation between the Danish Energy Agency representativesand Gender committee representatives, the gender committee representative confirmed thatfemale employees are treated equally as the male employees . It is confirmed that they arehappy with the present working condition.Contribution to school, Bethany Home is regularly assisted with food and cash donations.Neighbourhood Communities given access and assistance to use the hall in the estate.No customary rights issues note during this assessment.Meeting with foreign worker and NUPW members conducted on monthly basis.Again during this assessment, meeting with NUPW National Secretary and Perak StateSecretary was conducted by auditor to verify the foreign media’s claim on workers affected byparaquat, pesticide poisoning, use of PPE and inhumane working condition. It was highlighted byNUPW that there were no such case in United Plantations and the company is always vryresponsible in protecting the welfare and well being of its employees. The state and nationalNUPW is always monitoring all the estate to ensure the workers welfare is taken care. Freedomgiven to all employees to join workers union. This was confirmed by the national NUPWSecretary who attended the stakeholder consultation.The price of FFB is adjusted every month based on the price given by the MPOB. The filecontains a clear calculation of the net payment having taken into account the extraction rates,haulage and processing costs.There are no associated smallholders. FFB prices per tonne are available at Jendarata HeadOffice and suppliers directly deal with the Head office. Independent smallholders always havediscussion with the POM Managers. POMs have a copy of the payments records. Paymentrecords show that payments are made promptly. Contractors confirm that they understand theagreement entered into.Not Applicable – No new planting.All the operating units are regularly monitoring and review their activities and develop andimplement action plans that allow demonstrable continual improvement in key operations suchas in minimising use of certain pesticides, environmental impacts, maximizing recycling andminimizing waste or by-products generation, pollution prevention plans, Social impacts andmechanism to capture the performance and expenditure in social and environmental aspects.IPM is continuously implemented extensively to control pest and indirectly resulted reduction inpesticide usage. Planted area of beneficial plants such astunera, cassia, antignon, carambolasp.and fox tail are on increasing trend. Effective establishment of beneficial plants to control leafeating pest has helped the operating units to eliminate/reduce the use of monocrotophos.thOn 28 October 2010, during the assessment in the present of the Danish Energy Agency it isPage18of26

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-ASnoted that there were no paraquat in the store and stock records shows that there are noparaquat. It is completely eliminated from Jendarata Estate during the assessment and companyconfirm that all the operating units are completely eliminating paraquat since 1/10/2010, which isearlier than the targeted date. This is one of the positive continuous improvements committed bythe management since the first RSPO assessment and successfully implemented. This positiveapproach by the company has resulted in huge reduction of use of class 1a and 1bagrochemical.SOPs'provided for reducing herbicide by inter row mowing/grass cutting which covers flat area.Selective and spot spraying to control herbicide usage and careful calibration carried out toensure no wastage. No pesticide usage at the riparian zones, weeding by manually. IPM alsoincludes barn owl establishment. All the operating units have increased the boxes and to ensurethe owl population, monthly monitoring of owl occupancy is conducted. Fibre glass boxes areused. Rat bait is being eliminated.Zero burning is practised during replanting to reduce impact on air quality and protect theenvironment. Replanted area established with cover crop established to eliminate impact on soilsurface.Construction of bio-gas plant in UIEPOM completed and test run is in progress and expected tobe commissioned completely by end of this year. Jendarata POM already has bio-gas plant andstart trading for carbon credits. With this bio-gas project, it is expected that 90% of methaneproduced by mill effluent will be captured and hugely contributing to Certified EmissionReduction Credit.POME, EFB etc is all fully utilised for land application. This practice is being extended to all millsprogressively. Waste products are recycled. Used oil, battery, oil filters, chemical containers sentto licensed waste collectors. Used oils are recycled continuously to lubricate railing track and bythe mill engineering department to lubricate machineries. The Fibre and shell is recycled tooperate boilers. Excess shell is sold to outside buyers. Decanter cake is dried and used asorganic fertilizers in the field.Waste products – sources & reduction plan has been revised. Waste management action planfor each type of waste identified. Aliran Segar Sdn. Bhd.(license number 000394), GBR Birch,and Pantai Medivest has been identified as licensed and authorised waste collectors of schedulewaste. Chemical containers are triple rinsed and punctured before released to the wastecollectors.New budget has been developed by the top management for year 2010 to address continuousimprovement. Bio-gas plant at UIEPOM is in the final stage of operating. Work is in progress atthe Ulu Basir POM for bio gas plant at the cost of RM6 million. Enhancement of the biodiversityis continuously addressed with tree planting and maintaining the biodiversity.

Annual Surveillance Assessment Report, November 2010

Page19of26

Report number: 809027RSPOCUCRPT -2010-01-AS

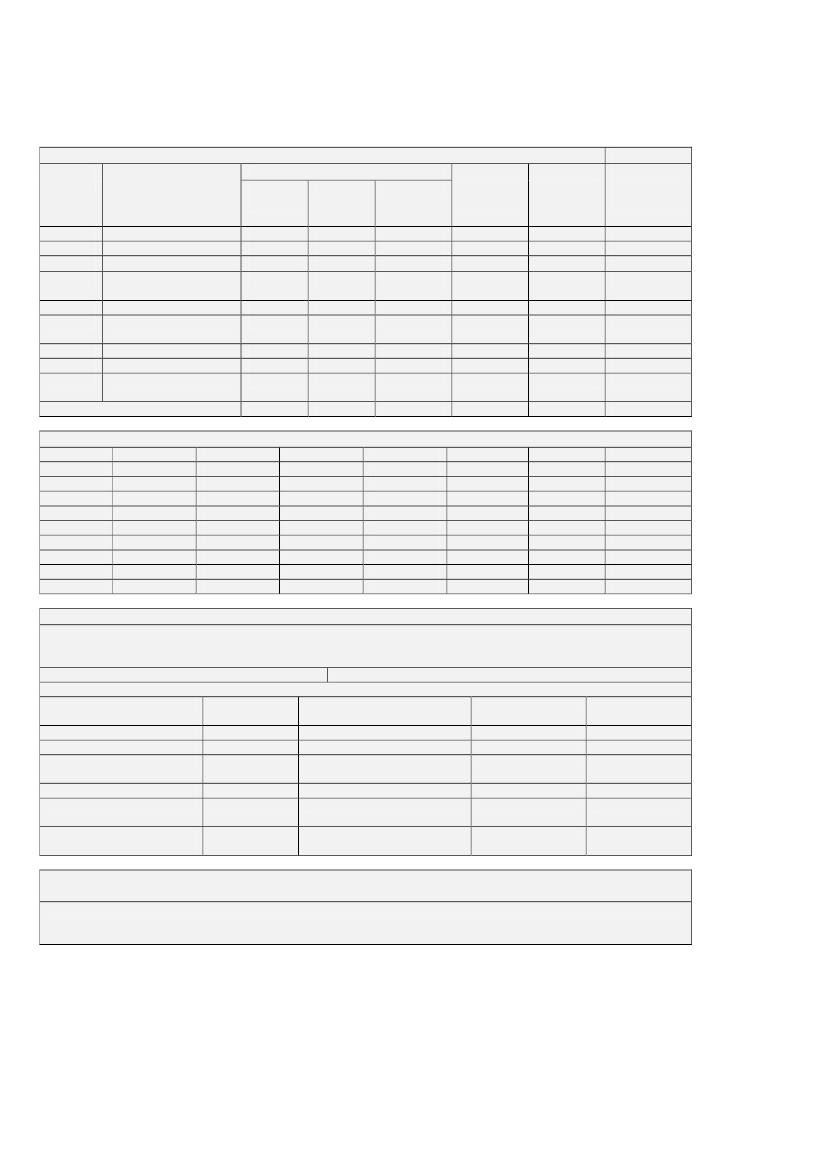

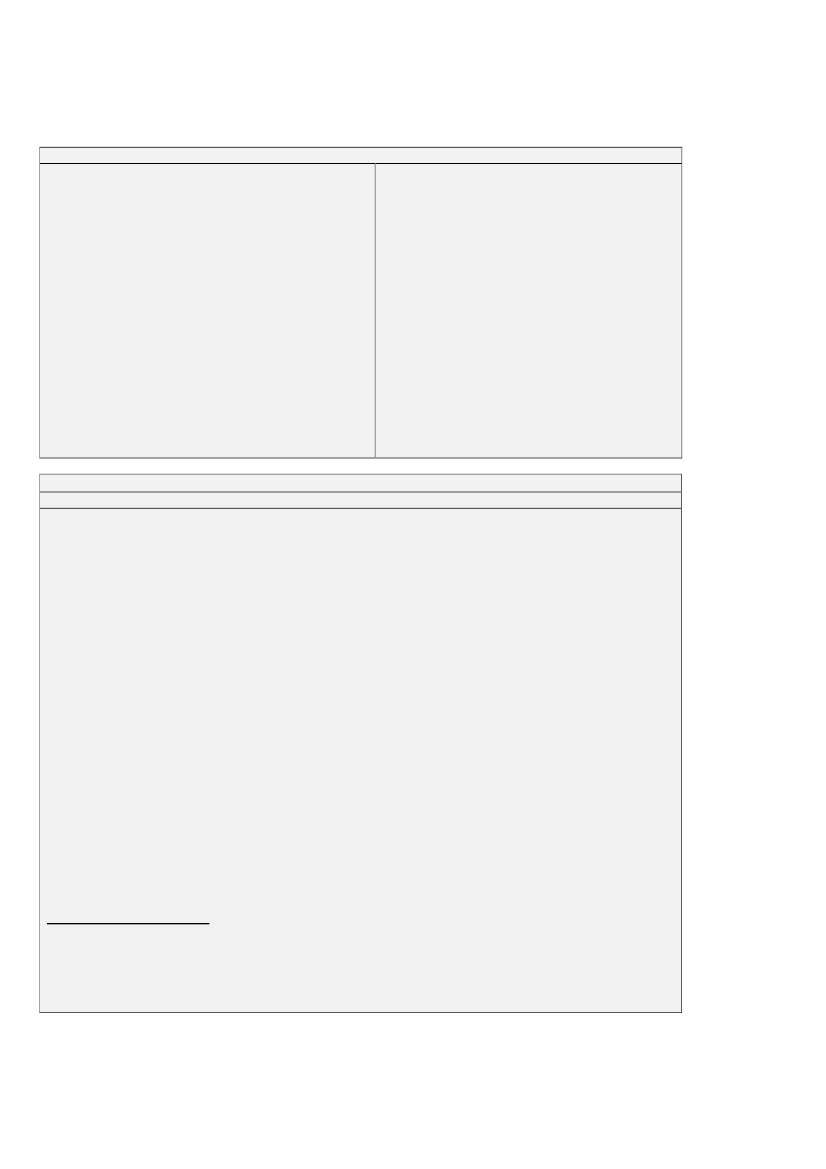

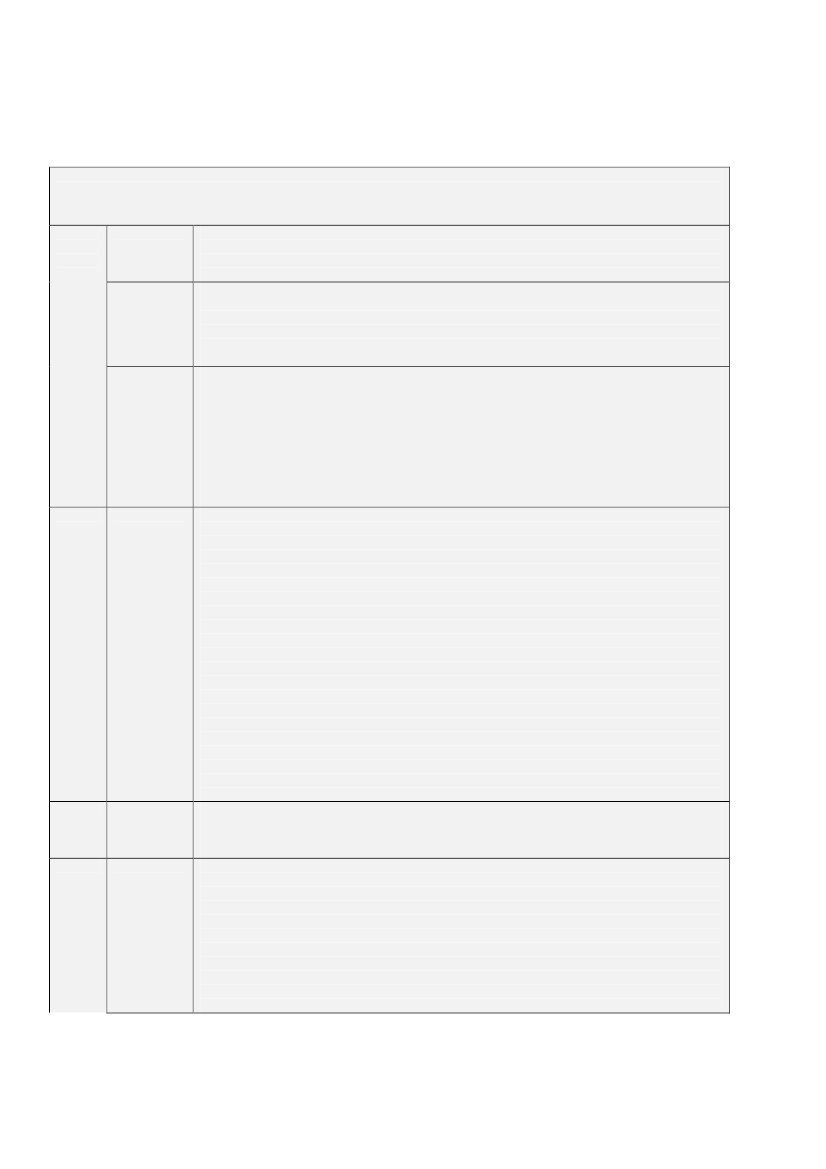

3.2.9 Criterion to be summarised for each annual surveillance audit.Criterion1.11.22.12.22.33.14.14.24.34.44.54.64.74.8:5.15.25.35.45.55.66.16.26.36.46.56.66.76.86.96.106.117.17.27.37.47.57.67.78.1year 1xxyear 2xx

x

xx

year 3xxxxx

year 4xx

x

x

x

x

xx

xxxx

xx

x

x

x

xx

x

x

xxx

x

xxx

xx

xxxx

x

xx

Annual Surveillance Assessment Report, November 2010

Page20of26

Report number: 809027RSPOCUCRPT -2010-01-AS3.3 Non conformity register.

This section gives an over view of new or revised non-conformities raised during this assessment and of action takento close out non-conformities raised during the previous assessments.•If a minor-non-conformity raised at the last audit, is not closed out, then this will be raised to Major status andthe company given 60 days to close this out.•The NC number is comprised of 2 parts to include the year in which the NC is raised as well as a sequentialnumber.

Annual assessment date(ASA2) :

Number settled (Closed):Number outstanding:

2 - 5th

August 2010th

13 September 2010rd

23 September 2010th

28 September 2010th

11 October 2010rd

3 November 2010st2 ( Closed during the 1 Annual Surveillance Assessment)nd1 (Registered during the 2 Annual Surveillance Assessment)

NON CONFORMITY REPORTNC number:1/2010Client name:United Plantation Berhad.thDate raised:5 August 2010Major or Minor:MinorRaised by:A. SenniahAspect of standard:6.5.3 Growers and millers provide adequate housing, water supplies, medical, education and welfare amenities inaccordance with Workers’ Minimum Standard of Housing and Amenities Act 1009 (Act 446) or above, where nosuch public facilities are available.Evidence of non-conformity:Although all the operating units comply with this requirement, it is noted that drinking water analysis was notconducted in one of the operating unit (Seri Pelanggi POM). There is no evidence to confirm that the drinking watersupplied to the labour housing at this operating unit is in compliance with WHO specification for drinking water.Assessors signature:

A. SenniahthDate: 5 August 2010Proposed corrective action / improvement action by company.The management of the particular operating units is taking immediate action to conduct theWater analysis.Timeline for conformance:Immediate action.Review of corrective /improvement action:will be reviewed during the next surveillance assessment.

Annual Surveillance Assessment Report, November 2010

Page21of26

Report number: 809027RSPOCUCRPT -2010-01-AS

Observations.Client name:United Plantation BerhadthDate raised:5 August 2010Raised by:A. SenniahDuring the audit it is noted that some of the operating units are not updating the documents regularly although thedocuments are available on site and sent to the units by the Group HR & Environment Department. As an area forfurther improvement, there should be a progressive inspection of the documents by the internal Person In Charge(PIC) to ensure all the records are updated and acknowledge by respective PIC.Assessors signature:

A. SenniahthDate: 5 August 20103.4 Stakeholder consultation and interview.Summary of how the stakeholder consultation was conducted.Stakeholders consultation mainly comprised by field workers, workers union representatives, foreignworkers representative, National NUPW Secretary, Perak State NUPW Secretary, Perak State DOSHOfficial, Perak State Labour Department Officials, Tenaganita, Doctor from Sabak Bernam Dispensary,Visiting Medical Officer, Representatives from Danish Energy Agency, Representatives from DanishMinistry of Climate and Energy.Representative from the Danish Energy Agency and Ministry of Climate and Energy was interested on theagrochemical handling, agrochemical poisoning, use of agrochemicals 1a and 1b, use of paraquat ,agrochemical storage and the process of RSPO assessment. Throughout the consultation they are givenaccess to all the relevant information and it was highlighted that this information should be included in theRSPO assessment report. The information are mainly covered in the assessment finding report undersection 3.2.4 above.During a separate stakeholder consultation on 28/9/2010 with the NUPW committee, workersrepresentatives and gender committee representative, the following questions were asked and theirfeedback recorded. The meeting with workers was conducted in the local Tamil and Bahasa Malaysialanguage to ensure that they understand the purpose of the consultation and to allow them to express theirfeedback freely. All the UP management representative was asked to leave the meeting room and theconsultation were conducted without their present as per RSPO requirement. This is to ensure that theworkers comfortable and free to give their comments. The representatives from the Danish Energy Agencywere present during the meeting.1. Do you have any remarks on the safe handling of chemicals in Jendarata estate?Answer: Chemicals are handled safely with the enforcement of PPE and safe working environment.2. What is your relation with the plantation being assessed?Answer: Worker’s union members, secretary and chairman, and Gender committee representative.3. Are there any plantation management practices that affect you and your health?Answer: No because we are given full and complete protective equipments for all kind of operations whichapproved by the DOSH. Medical surveillance conducted by doctor. Medical facility available at site. Thereare no issues.4. Do you consider any management practises is in conflict with the safe working environment?Answer: No5. Do you have any suggestions for management?Answer: Even before RSPO introduced, UP were having all the good practices. Our welfare and familywelfare is well taken care. That is why you can see some of us have been working here for more than 10Annual Surveillance Assessment Report, November 2010

Page22of26

Report number: 809027RSPOCUCRPT -2010-01-ASyears.6. Are you aware of any accidents related to chemical poisoning?Answer: No. If there is any we are the first one to confront the company. But we are confused and upsetwhy there are reports that such case has happened here although there are no such incident.7. Are you aware of any cases where PPE is not implemented?Answer: No. The fulltime supervisor and executive always monitor the PPE usage in the field and PPE isgiven free.8. Are there any adverse effects on workers due to poor working condition in estate?Answer: In Jendarata and in all the UP estates welfare and working condition are very well taken care.9. Additional comments.Answer: We as the Worker’s Union Representative and workers representatives would like to request anyinterested party to interview directly with us if they want to know about our working environment here.11. Do you have any comments that you would like to discuss in private with the assessment team andwould you like to meet with them in future?Answer: No. We always liaise with our NUPW officials if there are any issues. We also aware that RSPOaudit conducted annually.12. Do you have any comments of the management’s any other plantations that you are aware?Answer: Generally in Malaysia, safety of workers is given high priority. There is enforcement by governmentdepartment.All the worker’s union members, the Perak State Secretary and Chairman who attended the aboveconsultation confirmed that safety aspects during work is strictly enforced at Jendarata estate and UnitedPlantations which includes PPE use and safe working procedure. They also stressed that there are no anyherbicide or pesticide or any kind of poisoning has taken place in Jendarata estate or in UP. Theyhighlighted that they are very unhappy with the report in media about pesticide poisoning incidents becausethere are no such incident in their work place.Number of persons attended/interviewed during this stakeholder meeting30

Annual Surveillance Assessment Report, November 2010

Page23of26

Report number: 809027RSPOCUCRPT -2010-01-AS

4.

Certified organisation’s acknowledgement of internal responsibilityAugust 2011n/aWill be verified during next surveillance assessment.

4.1 Date of next annualassessment:4.2 Date to close major non-conformities.4.3 Date to close minor non-conformities.

4.4 Formal sign off of assessment findings.

Acknowledgement of internal responsibility by the client.I the undersigned, being the legal representative of the inspected company, agree with the contents ofthis report and accept the liability in execution of the instructions given in the report.Name:C. MathewsPosition:Group Manager Human Resources AndEnvironment, Safety & HealthSignature:

Date:

3 November 2010

rd

Annual Surveillance Assessment Report, November 2010

Page24of26

Report number: 809027RSPOCUCRPT -2010-01-AS5. Appendix: Abbreviations used in the reportASABMBODBPNBRCCDMCFCHRACoCCPOCSRCUDivDOEEFBEIAEUREPGAPEWGFFBFSCFPICFSC FMGGLGMPGTPGOTSGPSHACCPHCVHCVFHGUHIRARCHMHUMASIPMKKPAMAPAMPOBMSDSMWGN/A or n/aNCNIOSHNUPWOEOEROSHOSHASP&CPEFCPKPKBPKOPKSPODPOMPOMEAnnual Surveillance Assessment/AuditBahasa MalaysiaBiological Oxygen DemandBadan Pertanahan Nasional (National Land Body)British Retail ConsortiumClean Development MechanismCertificate of FitnessChemical Health Risk AssessmentChain of CustodyCrude Palm OilCorporate Social ResponsibilityControl UnionDivisionDepartment of EnvironmentEmpty Fruit BunchEnvironmental Impact AssessmentEuro-Retailer Produce Good Agricultural PracticesEstate Working GroupFresh Fruit BunchForest Stewardship CouncilFree Prior Informed ConsentForest Stewardship Council Forest ManagementGreen Gold LabelGood Manufacturing PracticeGood Trading PracticeGlobal Organic Textile StandardGlobal Positioning SystemHazard Analysis and Critical Control PointHigh Conservation ValueHigh Conservation Value ForestHak Guna Usaha (Land Right)Hazard Identification, Risk Assessment and Risk ControlHead MasterHubungan Masyarakat (Public Relation)Integrated Pest ManagementSmallholder Cooperative AssociationMalaysian Agriculture Producers AssociationMalaysian Palm Oil BoardMaterial Safety Data SheetMill Working GroupNot ApplicableNon ConformityNational Institute of Occupational Safety and HealthNational Union for Plantation WorkersOrganic ExchangeOil Extraction RateOccupational Safety and HealthOccupational Safety and Health Assessment SchemePrinciple and CriteriaProgramme for the Endorsement of Forest CertificationPalm KernelPerjanjian Kerja Bersama (Collective Agreement)Palm Kernel OilPabrik Kelapa Sawit (Palm Oil Mill)Policy DocumentPalm Oil MillPalm Oil Mill EffluentPage25of26

Annual Surveillance Assessment Report, November 2010

Report number: 809027RSPOCUCRPT -2010-01-ASPPEPTPT SSS1R&DRSPOS&HSIAPersonal Protective EquipmentPerseroan Terbatas (Limited Company)PT Surya Sawit SejatiResearch and DevelopmentRoundtable on Sustainable Palm OilSafety and HealthSocial Impact Assessment

Annual Surveillance Assessment Report, November 2010

Page26of26