Miljø- og Planlægningsudvalget 2010-11 (1. samling)

MPU Alm.del Bilag 444

Offentligt

Report and Executive SummaryCritical Review of Produced Water Sampling,Analysis and Reporting Procedures: DanishOffshore OperationsMaersk Oil DenmarkOur refABN1191601/002.001

LIFE MATTERS

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Contactsa)b)c)d)Registered nameRegistration numberRegistered addressAberdeen Office addressWritten by:Per Christofferson (Senior Consultant,Lloyd's Register Scandpower)Linda Murray (Consultant, ConsultingServices, Lloyd's Register EMEA)Amy Annand (Principal Consultant/TeamLeader, Consulting Services, Lloyd'sRegister EMEA)Lloyd’s Register EMEA29592R71 Fenchurch Street, London, EC3M 4BSDenburn House, 25 Union Terrace, Aberdeen,AB10 1NNMain Tel: + 44 (0)1224 267400[email protected]M +46 (0)708 690211[email protected]T+44 (0)1224 267872[email protected]M +44 (0)7770 958246T +44 (0)1224 267400F +44 (0)1224 267401M +44 (0)7768 214797

e)

f)

Approved by:Nick Jackson (Head of Consulting,Lloyd's Register EMEA)

Lloyd's Register EMEA, its affiliates and subsidiaries and their respective officers, employees oragents are, individually and collectively, referred to in this clause as the ‘Lloyd's RegisterGroup’. The Lloyd's Register Group assumes no responsibility and shall not be liable to anyperson for any loss, damage or expense caused by reliance on the information or advice in thisdocument or howsoever provided, unless that person has signed a contract with the relevantLloyd's Register Group entity for the provision of this information or advice and in that caseany responsibility or liability is exclusively on the terms and conditions set out in that contract.� Lloyd’s Register EMEA 2011

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

ContentsExecutive Summary1.1.12.2.12.23.3.13.23.33.43.5Introduction and Scope of WorkMethodologyKey FindingsCommendationsAreas for ImprovementRecommendationsOiW Procedural RecommendationData Integrity RecommendationsRobust Verification RecommendationsCompetency Assurance RecommendationsTyra East specific improvements2910121213171718181919

AppendicesAppendix 1.Appendix 2.Appendix 3.Appendix 4.Appendix 5.Appendix 6.Appendix 7.Appendix 8.Asset Specific Review: Tyra WestAsset Specific Review: Tyra EastAsset Specific Review: HalfdanAsset Specific Review: DanAsset Specific Review: Gorm (including Skjold)Asset Specific Review: HaraldDocumentation ReviewedPrinciples of Good Laboratory Practices

Lloyd's Register EMEA

Page 1

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Executive SummaryIntroductionDuring December 2010, Maersk Oil Denmark was subject to allegations published in the Danishnewspaper,Politiken, regarding the integrity of their produced water management processes,including Oil-in-Water (OiW) analysis and reporting. Maersk Oil Denmark engaged Lloyd'sRegister EMEA to conduct an independent review of the associated environmental processesand procedures (including implementation). Initial reviews of the Tyra production unit wereconducted by Nick Jackson and Amy Annand of Lloyd's Register EMEA, and Stig Stangeland ofLloyd's Register Scandpower. Subsequent reviews of the DUC operations were conducted byPer Christofferson of Lloyd's Register Scandpower and Linda Murray of Lloyd's Register EMEA;they were also supported onshore (Esbjerg) by Amy Annand and Nick Jackson.Scope of WorkLloyd's Register EMEA reviewed and determined the degree to which Maersk Oil Denmark’sproduced water sampling, analysis and reporting (i.e. specifically Oil-in-Water/OiW) processestruly reflected accepted industry practice. The review evaluated existing documented processesand procedures, and compared their implementation onshore and offshore to recognisedindustry practice, best laboratory practice, and also compliance with the current OiW dischargepermits for operating in the Danish sector of the North Sea. The review also included a series ofinterviews with workforce representatives who developed and used these processes andprocedures. Additionally, the review verified a number of samples of reported concentrations,following the path along data transfer points.The LR EMEA review teams visited:•••••••FindingsTyra West.Tyra East.Dan.Halfdan.Gorm (including Skjold).Harald.Esbjerg offices.

Commendations•Maersk Oil Denmark has established appropriate procedures (specifically OPM 2B Part 3Rev 9) and associated guidance documents and initiatives which enable operations tomeet expectations of the discharge permits associated with the Danish production units.It is noted that in response to the recent changes to the discharge permit, Maersk OilDenmark has already commenced a review and revision of the OiW procedures andpractices.

Lloyd's Register EMEA

Page 2

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•

Processes are established for employee engagement in procedural change (i.e. theupdated Rev 9 of the OiW procedure and Rev 10 that is a work in progress).Feedback indicated that the response and reporting culture relating to dischargeconcentrations greater than 20 mg/l appears to be supportive and reflective of goodpractice.The action level for OiW is 20 mg/l, although the permit defines average monthlydischarge limit of 30mg/l. This means that corrective action is often applied before apermit breach occurs. It is also noted that Maersk Oil Denmark has stipulated variousinternal KPIs, some as low as 5 mg/l for specified discharge points.As part of their continual improvement processes, Maersk Oil Denmark hasimplemented a number of initiatives to improve the efficiency of produced watertreatment on board. These have included increasing heating capacity in order toimprove separation efficiency, improving flow and skimming properties of the de-gasser,relocating the injection points for the water clarifier, and reducing flow throughputfluctuations.Evidence indicated that further improvements to the produced water treatmentprocesses will be introduced. These include exploring the use of online OiW monitoringand investigating the accuracy of overboard flow metering systems.Daily production checks are conducted on individual produced water process trains.These checks include levels, pressures and temperatures of specific treatmentequipment and processes. This data is then used to troubleshoot and define correctiveactions if the 20 mg/l limit is exceeded. Some platforms have also implemented in-linecontinuous OiW monitoring processes to enhance process control and troubleshooting.Evidence obtained from offshore conversations confirmed that employees (e.g. the CCR)are empowered to shut down wells/operations and have done so when necessary.Communication with regard to OiW appears to be open and honest, and the workforceis actively encouraged to report on any observed undesired emissions and processdeviations. The "eyes and ears" of the workforce were seen to be an important tool inmonitoring OiW treatment.It is clear that some sound practices have been established and individuals know how torespond and troubleshoot when OiW KPIs are exceeded.It is clear that the overwhelming majority of the workforce has great pride in workingfor Maersk Oil Denmark and cares deeply about their responsibilities. People reportedthat they did not understand what prompted the newspaper allegations, which theybelieved did not represent the Maersk Oil organisation that they work for, or the realityof OiW management.

•

•

•

•

•

•

•

•

•

Lloyd's Register EMEA

Page 3

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Areas for ImprovementThe critical OiW review identified six areas of potential improvement, which are summarisedbelow.

OiW procedureThe OiW Sampling, Analysis and Reporting procedure (OPM 2B, Part 3, Rev 9) enablesoperations to meet the expectations of the discharge permits. However, the clarity andstructure of the procedure can be strengthened. Visibility and understanding of the overall OiWsample collection, analysis and reporting process within the procedure could be improvedthrough the use of Process Mapping.It is noted that the OiW procedure differs slightly from the reference (OSPAR) method, withexamples highlighted below:•••••Sample and reagent volumes.Sample gas release.Sample clean-up.Emulsification of sample.Blank samples.

The review of the OiW procedure also identified an inconsistent approach to the level of detailcontained within the asset specific sections of the procedure. There should be a standardisedminimum amount of platform specific data included in all asset specific sections of theprocedure. Additionally, there is a lack of platform specific information relating to (whereapplicable):••Expectations relating to communication, and how knowledge or data is transferred.Details related to the use of in-line and/or continuous monitoring equipment tosupplement OiW management.Sampling (including when samples should and should not be taken), labelling,packaging, protection, storage and transporting (i.e. sample custody and integrity).Determining total volume of re-injected produced water and total volume of overboardproduced water.Post analysis reporting (i.e. cross-referencing workbooks, production logs and OiWdatabase).

•

•

•

Integrity of dataThe Lloyd's Register EMEA reviews could find no evidence that the OiW data had been falsified.However, the lack of robust and transparent sample and data management means that MaerskOil Denmark is exposed to the potential for error and misconduct. Identified examples of theseexposures include the following:

Lloyd's Register EMEA

Page 4

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•••••••

Existing sample custody practices introduce the potential for samples to be tamperedwith or to be misplaced; however, there was no evidence that this had taken place.Critical data is sometimes verbally transferred.There is a lack of written Laboratory Logbooks (denoting sample times, analyticalresults, anomalies, changes, errors, comments etc.).There is a lack of security of data contained within platform specific Excel workbooks.When changes are made to data contained within the workbook, there is no record ofthe original data or documented reason for the change.Sense checks (conducted onshore) of reported concentrations did not consistentlycapture noted data anomalies.The first point of verification (using existing practices) is the Excel spreadsheetworkbook. This is an issue because the spreadsheet is populated at an advanced stageof the OiW sampling, analytical and reporting process.

Lack of robust verificationThe overall process for OiW management should be underpinned by robust verification andQuality Assurance. The review revealed a number of areas where Maersk Oil Denmark did notdemonstrate structured processes to assure data quality and compliance with best practice.Examples of these areas include:•••••Lack of structured supervisory Quality Assurance.Lack of robust verification of On-the-Job training.No QC samples analysed to provide assurance of accuracy of results. NB: this is notaligned with good laboratory practice.Lack of robust internal audits in order to scrutinise OiW processes.The limit of the scope of the Force Technology Audits (i.e. only sampling andlaboratory practices and OSPAR correlation) did not enable complete verification ofOiW processes.

Degree of variability of reported concentrationsThe uncertainty (standard deviation) of reported concentrations and overboard oil volumes isnot fully quantified. Variability levels will be associated with:•The sensitivity of Wilkes Analyzer at lower concentrations (NB: Maersk Oil Denmark hasdetermined the Limit of Detection to be approximately 4mg/l).Page 528/02/2011Maersk Oil Denmark

Lloyd's Register EMEA

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

••••

Individual pieces of laboratory equipment (e.g. balances, volumetric flasks, measuringcylinders etc.).Differing approaches by individuals with regard to sample collection, storage,extraction and clean-up.The OSPAR correlation method.Accuracy of overboard flow meters.

The cumulative variability with the aforementioned elements creates an unknown level ofuncertainty for the method. Understanding the lower limits of detection is particularlyimportant for reporting lower concentrations, especially those concentrations related to OiWKPIs.

Competency assurance processesMaersk Oil Denmark is currently establishing a structure for offshore workforce trainingprogrammes which includes: training needs analysis, job descriptions, technical trainingprogrammes, On-the-Job training programmes etc. This is documented and managed onshorevia the Learning Management System (LMS). This framework is still under development andtherefore is not fully implemented.The offshore workforce’s individual training programmes are documented in the LMS. It is theexpectation that employees will be trained by experienced team members based on tailored rolespecific training programmes.

Tyra East specific improvementsSome participants on board Tyra East described strong feelings of mistrust towardsmanagement both on and offshore. This was supported by perceptions of exclusion and lack ofinvolvement, which are further compounded by stated beliefs that communications betweenoffshore and onshore are ineffective.Conclusions and Recommendations

OiW procedureIn line with our findings, the OiW procedure (OPM 2B, Part 3, Rev 9) requires a significantupdate to meet the requirements of the new discharge permit. This upgrade should alsoaddress the expectations of OSPAR and strengthen the clarity and structure of the procedure.The platform specific information (e.g. platforms without laboratory facilities, platforms that re-inject produced water etc.) should also undergo a critical review to ensure adequacy. This willenable consistent understanding and application of the overall OiW sample collection, analysisand reporting process.

Integrity of data

Lloyd's Register EMEA

Page 6

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

The findings indicate that there is a lack of robust and transparent sample and datamanagement meaning that Maersk Oil Denmark is exposed to the potential for error andmisconduct. It is therefore recommended that Maersk Oil Denmark implements a number ofdata integrity control measures in order to reduce the risks associated with inaccurate OiWreporting. These measures include:••••••The platform specific instructions should be developed to include a documentedsampling plan and procedure.Formally document and log verbal transfer of critical information.Establish ‘Good Laboratory Practice’ with the use of written Laboratory Logbooks.Introduce data security controls within platform specific workbooks.Formalise onshore based sense checks to capture noted data anomalies.Introduce robust verification processes that would verify the data trail from samplecollection to reporting.

Lack of robust verificationThe overall process for OiW management should be underpinned by robust verification andQuality Assurance. The review revealed a number of areas where Maersk Oil Denmark did notdemonstrate structured processes to assure data quality and compliance with best practice.These processes should include:••••••Structured supervisory Quality Assurance.Robust verification of On-the-Job training.Analyse QC samples to provide assurance of accuracy of results.Robust internal audits.Third party audits.Update procedures: ensure that the verification processes add value, and are alignedwith revised OiW procedures.

Degree of variability of reported concentrationsInevitably sample collection, custody, analysis and reporting processes will introduce somedegree of variability in reported OiW concentrations. The Limit of Detection is likely to beimportant when the data is utilised for the setting and achieving of internal KPIs, where theseare at levels lower than those that can be reasonably detected. It is therefore recommendedMaersk Oil Denmark attempts to quantify the lower Limit of Detection for the OiW method andrecognises it when setting internal OiW KPIs.

Competency assurance processesMaersk Oil Denmark is currently establishing a structure for offshore workforce trainingprogrammes. They must formalise arrangements to ensure that:

Lloyd's Register EMEA

Page 7

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•

Existing and new Laboratory Technicians should either complete the newly developedOiW training programme, or verify competency levels of existing Laboratory Techniciansagainst the programme requirements.All relevant job descriptions are cohesive and complete. They must accurately reflectproduced water management tasks and responsibilities.Training programmes are implemented as per identified needs.On-the-Job training is formalised, including verification.

•••

Tyra East specific improvementsCritical review findings relating to the Tyra East installation differ from the other DUC assets.Specific recommendations pertaining to this asset are:•Maersk Oil Denmark has processes to enable individuals to report concerns. It isimportant that these processes are not only established, but are fully supported andpeople are encouraged to use them. While recognising that this process is supportedby Maersk Oil Denmark, it is clear that some individuals on Tyra East elected to choosea different vehicle to communicate concerns. In support of this recommendation, aculture of openness in reporting and communicating should be further nurtured andembraced within the organisation.Maersk Oil Denmark should carefully consider the internal communication andmanagement actions to be taken in the aftermath of these events. This would includecommunication (i.e. internal/external announcements, lessons learned, and individualresponse actions) to the workforce and relevant stakeholders. This should clearly definethe expectations of onshore and offshore management, and those actively involved inthe OiW processes.

•

Lloyd's Register EMEA

Page 8

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

1.

Introduction and Scope of WorkDuring December 2010, a series of newspaper allegations raised a number of significantconcerns within the Maersk Oil operations in Denmark. As a result, Lloyd's Register EMEA wasengaged to conduct a critical review of procedures relating to produced water management.These reviews were carried out via a series of onshore and offshore visits between lateDecember 2010 and February 2011.The scope of that review examined the adequacy and suitability of the existing Maersk OilDenmark procedures for sampling, analysis, and reporting of overboard produced waterdischarges on board DUC installations, including:••••••Tyra West.Tyra East.Dan.Halfdan.Gorm (including Skjold).Harald.

The review also conducted some verification of the procedures as implemented both on andoffshore, and commented on the effectiveness of the procedures and how they are applied.Specific elements of the review included:•A detailed review of the procedures employed for sampling, analysis, and reporting ofoverboard produced water discharges.An independent comparison of the procedures when compared to recognised industrypractice (e.g. UK Department of Energy and Climate Change Guidance Notes for theSampling and Analysis of Produced Water and other Hydrocarbon Discharges).The identification of any omissions or inaccuracies within the procedures.The review of associated documentation i.e. calibration procedures and certification,historical analytical results, Laboratory Technicians' sampling and analysis notes,competency assurance documentation, maintenance records, audit reports, dischargepermits, job descriptions, production logs etc.Independent verification of the implementation of the procedures both on and offshore;this would include comment on the effectiveness of the procedures and how they areapplied.A number of samples of reported concentrations were verified, following the pathalong data transfer points: from sample collection to analysis to concentrationcalculations to reported figures.Detailed reporting of the Lloyd’s Register EMEA findings and recommendations,including the chain of consistency and integrity relating to the Maersk Oil Denmarkprocedures.

•

••

•

•

•

Lloyd's Register EMEA

Page 9

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

The scope of work for the Tyra East asset varied slightly in focus from the other assets, in that itincluded an investigative process into the circumstances leading to the publication of thenewspaper articles, and detailed discussions with individuals connected with the allegations, aswell as the OiW review. As a result, the review that was conducted on board Tyra East hadmore emphasis relating to the newspaper allegations and did not go into the depth ofverification and sampling of the produced water procedure and processes. There was, however,an onshore based review of Tyra East data and reported figures.It is noted that at the conclusion of the review, new discharge permit requirements were issuedby the Danish Environmental Protection Authority. These new requirements dictate thatMaersk Oil Denmark will need to revise their oil in water sampling and analysis procedures andassociated practices. Although the scope for this review did not explicitly include anassessment of Maersk Oil Denmark's ability to meet these more stringent permitry requirements,we have included some commentary relating to the new permit requirements in the body ofthis report. Maersk Oil Denmark have committed to conduct a further OiW review in 6-8months time to ensure that new discharge requirements have been embedded and that therevised procedure is effective and adhered to.

1.1

MethodologyThe critical review process included:•••••Review of relevant documentation provided to Lloyd's Register EMEA by Maersk OilDenmark.A series of interviews with relevant personnel on the chosen installations, as wellrelevant beach based personnel with involvement in produced water management.Observations of laboratories and laboratory equipment.Observations of water sampling, sample custody and transport, analysis and reportingprocedures being performed onsite.Visiting and study of water treatment process equipment and sampling points.

Each report from individual installations identifies personnel that were interviewed as part of theonsite reviews. Interviews were also conducted with onshore team members who haveproduced water management responsibilities. These people included:•••••••Steffen Fredberg Hansen – Chemistry & Environment Department.Joan Jacobsen – Training Coordinator.Lars Hvejsel Hansen – Head of Chemistry & Environment Department.Hans Henrik Kristensen – Head of Production Operations.Britt Gydesen – Chemistry & Environment Department.Jette J Østergaard – Chemistry & Environment Department.Ole Andersen – Metering Department.

A number of documents were reviewed and are listed in Appendix 7. These documents relateto various aspects of produced water management, including procedures, organisational charts,discharge permits, analytical results contained in spreadsheets, training programmes, jobdescriptions etc. There were also several other documents that were reviewed onsite. TheLloyd's Register EMEAPage 1028/02/2011Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

documents were used as input and planning of the review and the content was followed up byinterviews and observations.

Lloyd's Register EMEA

Page 11

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

2.2.1

Key FindingsCommendations•Maersk Oil Denmark has established appropriate procedures (specifically OPM 2BPart 3 Rev 9) and associated guidance documents and initiatives which enableoperations to meet expectations of the discharge permits associated with the Danishproduction units. It is noted that in response to the recent changes to the dischargepermit Maersk Oil Denmark has already commenced a review and revision of the OiWprocedures and practices.Processes are established for employee engagement in procedural change (i.e. theupdated Rev 9 of the OiW procedure and Revision 10 that is work in progress).Feedback indicated that the response and reporting culture relating to dischargeconcentrations greater than 20 mg/l appears to be supportive and reflective of goodpractice.The action level for OiW is 20 mg/l, although the permit defines average monthlydischarge limit of 30mg/l. This means that corrective action is often applied before apermit breach occurs. It is also noted that Maersk Oil Denmark has stipulated variousinternal KPI s, some as low as 5 mg/l for specified discharge points.As part of their continual improvement processes, Maersk Oil Denmark hasimplemented a number of initiatives to improve the efficiency of produced watertreatment on board. These have included increasing heating capacity to in order toimprove separation efficiency, improving flow and skimming properties of the de-gasser, relocating the injection points for the water clarifier, and reducing flowthroughput fluctuations.Evidence indicated that further improvements to the produced water treatmentprocesses will be introduced. These include: exploring the use of online OiWmonitoring and investigating the accuracy of overboard flow metering systems.Daily production checks are conducted on individual produced water process trains.These checks include: levels, pressures and temperatures of specific treatmentequipment and processes. This data is then used to troubleshoot and define correctiveactions if the 20 mg/l limit is exceeded. Some platforms have also implemented in-linecontinuous OiW monitoring processes to enhance process control and troubleshooting.Evidence obtained from offshore conversations confirmed that employees (e.g. theCCR) are empowered to shut down wells/operations and has done so when necessaryon some occasions.Communication with regard to OiW appears to be open and honest, and theworkforce is actively encouraged to report on any observed undesired emissions andprocess deviations. The ‘eyes and ears’ of the workforce were seen to be an importanttool in monitoring OiW treatment.It is clear that some sound practices have been established and individuals know howto respond and troubleshoot when OiW KPIs are exceeded.It is clear that the overwhelming majority of the workforce has great pride in workingfor Maersk Oil Denmark and care deeply about their responsibilities. People reportedthat they did not understand what prompted the newspaper allegations, which theybelieved did not represent the Maersk Oil organisation that they work for, or the realityof OiW management.

••

•

•

•

•

•

•

••

Lloyd's Register EMEA

Page 12

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

2.2

Areas for ImprovementA number of emerging themes or issues were identified during the review, as identified below.

2.2.1

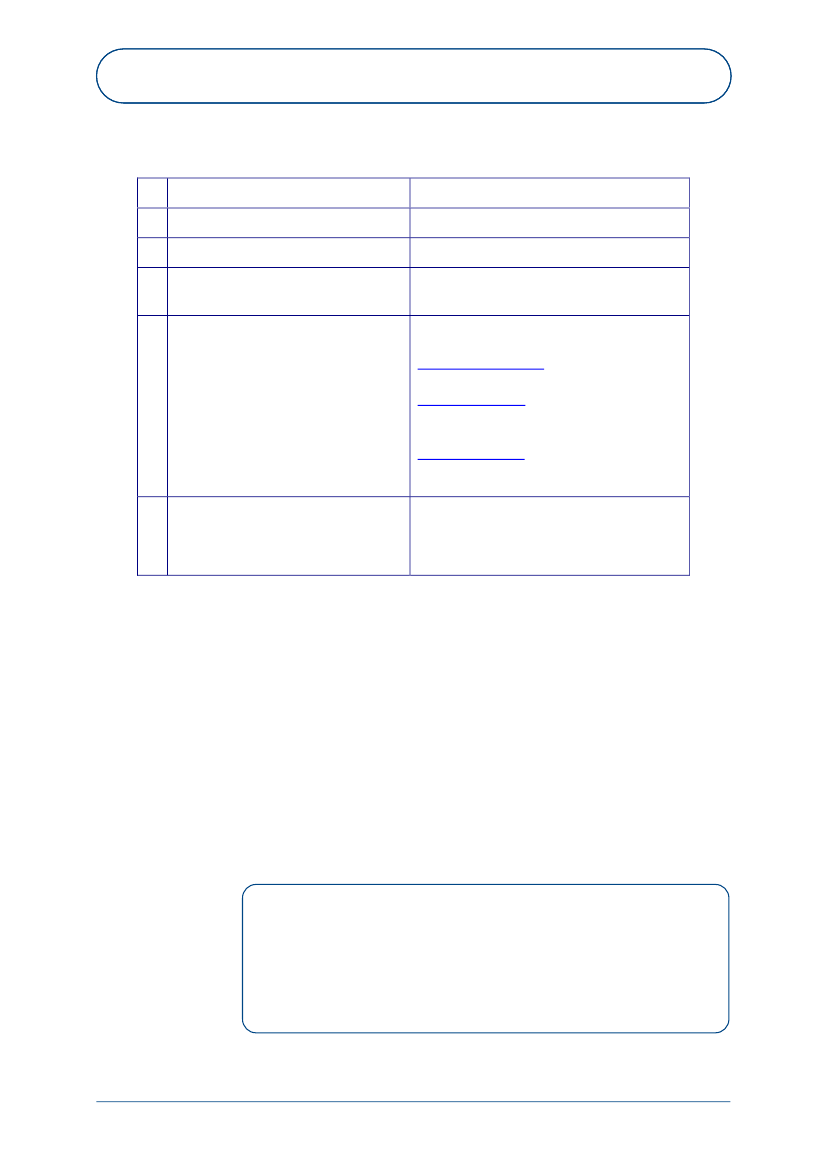

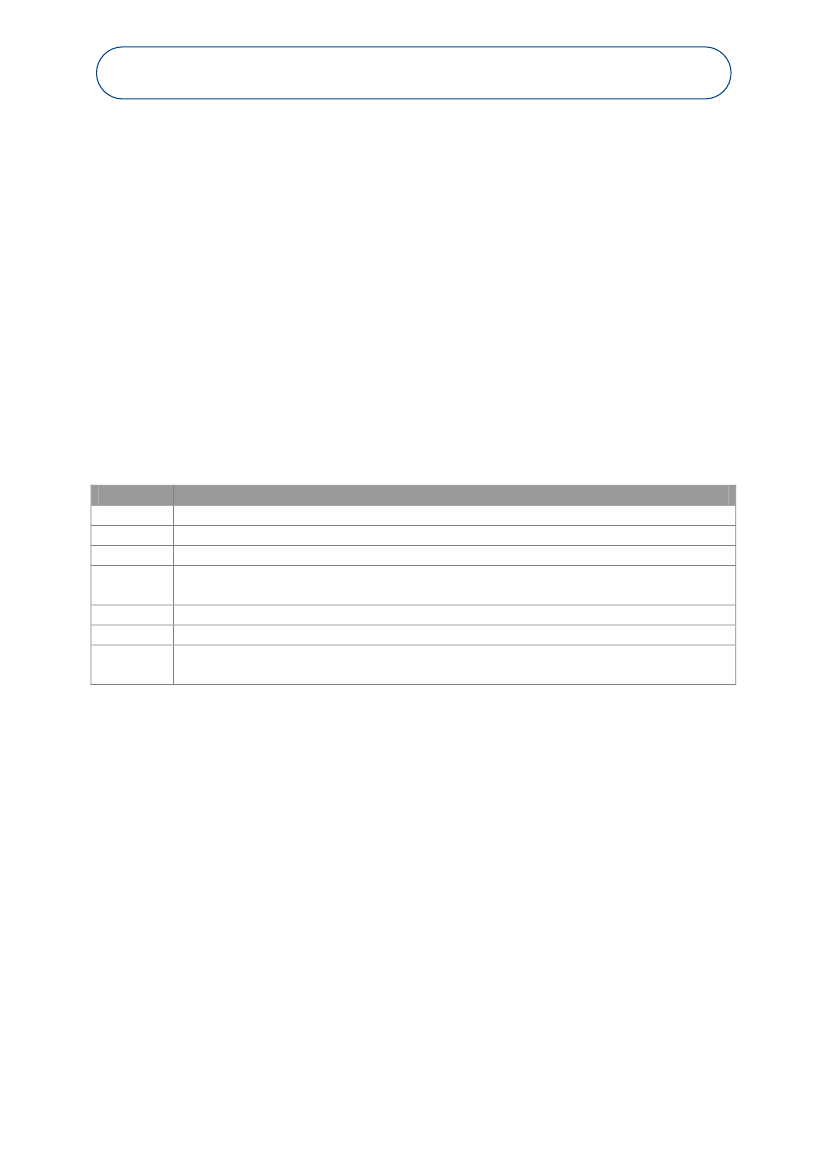

OiW ProcedureThe OiW Sampling, Analysis and Reporting procedure (OPM 2B, Part 3, Rev 9) enablesoperations to meet the expectations of the discharge permits. However, the clarity andstructure of the procedure can be strengthened. Visibility and understanding of the overallOiW sample collection, analysis and reporting process within the procedure could be improvedthrough the use of Process Mapping.It is noted that the OiW procedure differs slightly from the reference (OSPAR) method, withexamples highlighted below:IssueOiW Procedure500ml bottle for 400ml sample.25ml n-pentane.Shake the sample bottle torelease gasses.Use non-activated florisil.No use of sodium sulfate.OSPAR reference method1 litre bottle, 90% full.50ml n-pentane.Cap the sample, release cap,allow it to cool, and re-tighten.Use activated florisil.Use of sodium sulfate.Use of centrifuge.Addition of magnesium sulfate.

Sample volume.Reagents.Sample gas release.

Sample clean-up.

Emulsification of sample.

No guidance.

Blank samples.

No guidance.

Blank tests should be carried outwith each series of tests.

There is a potential for these deviations have the potential to introduce a degree of error intothe method (e.g. sample clean up may not be as effective when using non-activated Florisil,resulting in potentially higher results). Additionally, shaking the sample could potentiallyrelease VOCs, with a resultant reduction in OiW concentrations and errors in reported data.The review of the OiW procedure also identified an inconsistent approach to the level of detailcontained within the asset specific sections of the procedure. There should be a standardisedminimum amount of platform specific data included in all asset specific sections of theprocedure. Additionally, there is a lack of platform specific information relating to (whereapplicable):••Expectations relating to communication, and how knowledge or data is transferred.Details related to the use of in-line and/or continuous monitoring equipment tosupplement OiW management.Page 1328/02/2011Maersk Oil Denmark

Lloyd's Register EMEA

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•••

Sampling (including when samples should and should not be taken), labelling,packaging, protection, storage and transporting (i.e. sample custody and integrity).Determining total volume of re-injected produced water and total volume of overboardproduced water.Post analysis reporting (i.e. cross-referencing workbooks, production logs and OiWdatabase).

Note: the procedure at the time of the review was not aligned with the new discharge permitrequirements (in particular relating to extra sampling, verification and according to theprinciples of ‘good lab practice’). Maersk Oil Denmark is currently revising the procedure tomeet the expectations of the new permit. This process should also incorporate the principles of'good lab practice'. Lloyd's Register EMEA has included a summary of ‘good lab practice’ asAppendix 8 of this document.This procedural revision reinforces the feedback received from the offshore visit where peoplerecognised the need for an overhaul of the documented processes. Some felt that minorchanges are frequently implemented, creating a collection of instructions, rather than acohesive procedure.2.2.2Integrity of DataThePolitikennewspaper allegations questioned the accuracy and integrity of the data used toreport OiW concentrations. The Lloyd's Register EMEA reviews could find no evidence thatdata had been falsified. However, a lack of robust and transparent sample and datamanagement means that Maersk Oil Denmark is exposed to the potential for error andmisconduct. Examples of these exposures include the following:•••Existing sample custody practices introduce the potential for samples to be tamperedwith or to be misplaced; however, there was no evidence that this had taken place.Critical data is sometimes transferred verbally, in particular OiW concentrations for theHalfdan and the Harald.There is a lack of written Laboratory Logbooks (denoting sample times, analyticalresults, anomalies, changes, errors, comments etc.). NB: the absence of logbooks doesnot reflect good laboratory practice.There is a lack of security of data contained within the workbook, which has openaccess to all Laboratory Technicians and the Chemistry & Environment Department.When changes are made to data contained within the workbook, there is no record ofthe original data or documented reason for the change.Sense-checks (conducted onshore) of reported concentrations did not consistentlycapture noted data anomalies.The first point of verification (using existing practices) is the Excel spreadsheetworkbook. This is an issue because the spreadsheet is populated at an advanced stageof the OiW sampling, analytical and reporting process. This leaves a lack ofopportunity to verify any of the data that is associated with the early stages of theprocess. Also see the findings associated with lack of robust verification below.

••••

Lloyd's Register EMEA

Page 14

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

2.2.3

Lack of Robust VerificationThe overall process for OiW management should be underpinned by robust verification andQuality Assurance. The review revealed a number of areas where Maersk Oil Denmark did notdemonstrate structured processes to assure data quality and compliance with best practice.Examples of these areas include:•••••Lack of structured supervisory Quality Assurance.Lack of robust verification of On-the-Job training.No QC samples analysed to provide assurance of accuracy of results. NB: this is notaligned with good laboratory practice.Lack of robust internal audits in order to scrutinise OiW processes.The limit of the scope of the Force Technology Audits (i.e. only sampling andlaboratory practices and OSPAR correlation) did not enable complete verification ofOiW processes.

In order to ensure that the verification processes add value, they must be aligned with revisedOiW procedures and processes (once they are reflective of discharge permit requirements).2.2.4Degree of Variability of Reported ConcentrationsThe uncertainty (standard deviation) of reported concentrations and overboard oil volumes isnot fully quantified. Variability levels will be associated with:•The sensitivity of Wilkes Analyzer at lower concentrations (NB: with an extraction ratioof 1:20 as used in the OiW method, the Wilks Infracal analyser HATR T/T2 has anapproximate Limit of Detection of 4mg/l).Individual pieces of laboratory equipment (e.g. balances, volumetric flasks, measuringcylinders etc.).Differing approaches by individuals with regard to sample collection, storage,extraction and clean up.The OSPAR correlation method.Accuracy of overboard flow meters.

••••

The cumulative variability with the aforementioned elements creates an unknown level ofuncertainty for the method. Understanding the lower limits of detection is particularlyimportant for reporting lower concentrations, especially those concentrations related to OiWKPIs.2.2.5Competency Assurance ProcessesMaersk Oil Denmark is currently establishing a structure for offshore workforce trainingprogrammes which includes: training needs analysis, job descriptions, technical trainingprogrammes, On-the-Job training programmes etc. This is documented and managed onshorevia the Learning Management System (LMS). This framework is still under development andtherefore is not fully implemented.

Lloyd's Register EMEA

Page 15

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

The offshore workforce’s individual training programmes are documented in the LMS. It is theexpectation that employees will be trained by experienced team members based on tailoredrole specific training programmes.The review also identified the following competency assurance issues related to produced watermanagement:•A training programme for Laboratory Technicians has been developed (dated 28-06-2010) reflecting laboratory requirements. All existing Laboratory Technicians weretrained well before the training programme was developed. The new programme hastherefore not been applied to any of the current Laboratory Technicians. It is unclearto the review team if there has been any process applied to compare their knowledgeand competency with stated expectations within the training programmes.There was evidence that Production Technicians regularly take samples and on boardthe Harald, the Production Technicians conduct laboratory analyses. The ProductionTechnician job descriptions do not accurately disclose these important produced watermanagement tasks. This will become more of an issue when Production Technicianswill be required to take additional samples, as per the 2010-2011 discharge permit. Itis also noted that there are other offshore team members with critical roles relating toproduced water management (e.g. Production Assistant, Control Room Assistant, andProduction Supervisor). The different job descriptions of these team members lack acoherent specification that reflect responsibilities associated with produced watermanagement.Although laboratory related training had been identified for Production Technicianswho were conducting laboratory operations, there was evidence that this training hasnot been completed.A greater degree of clarity and focus is required in relation to the development andapplication of Production Operations Guidelines (POGs) that specifically relate toproduced water management On-the-Job training.On-the-Job training (againspecifically for produced water management) lacks formality, thereby raising questionsabout the consistency of application.There was no evidence that robust verification of On-the-Job training had been carriedout for Laboratory and Production Technicians.

•

•

•

•2.2.6

Areas for Improvement Specific to Tyra EastSome participants on board Tyra East described strong feelings of mistrust towardsmanagement both on and offshore. This was supported by perceptions of exclusion and lack ofinvolvement, which are further compounded by stated beliefs that communications betweenoffshore and onshore are ineffective.

Lloyd's Register EMEA

Page 16

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

3.3.1

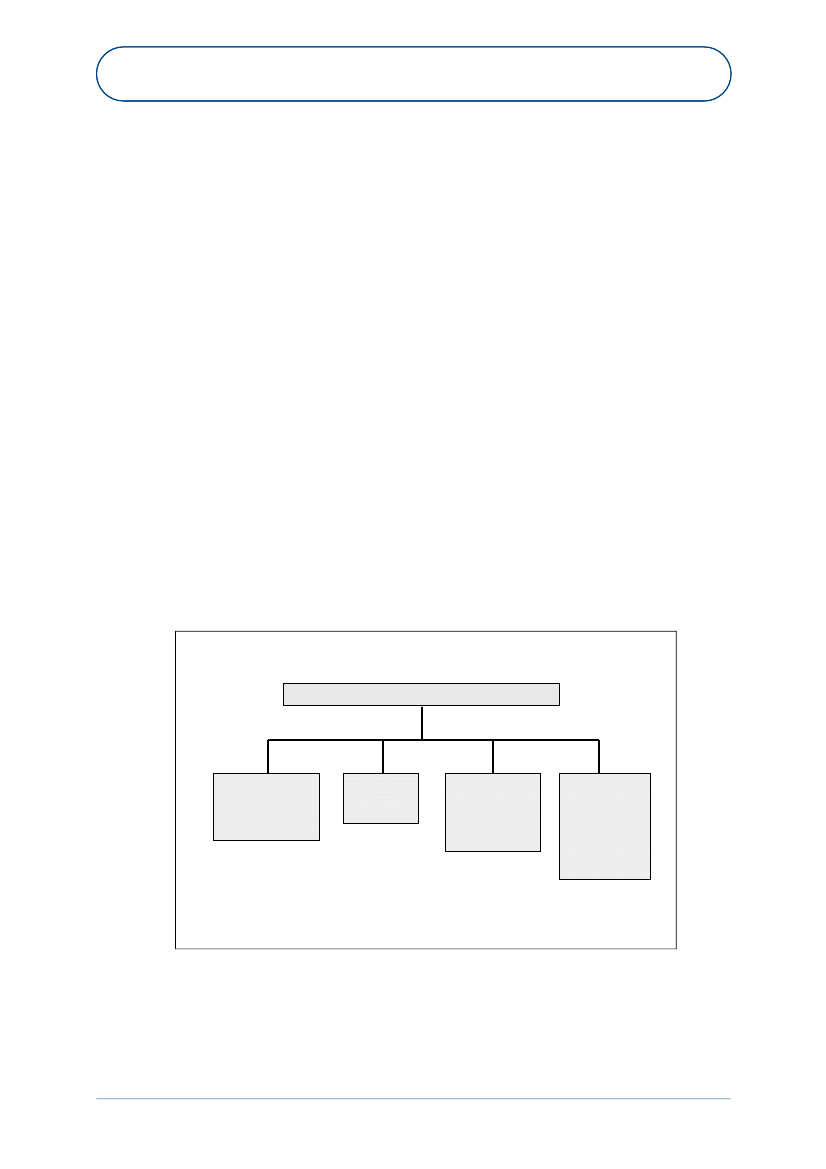

RecommendationsOiW Procedural RecommendationAt the time of the review, the OiW Sampling, Analysis and Reporting procedure (OPM 2B, Part3, Rev 9) enabled operations to meet the expectations of the existing discharge permits.In line with our findings, the OiW procedure (OPM 2B, Part 3, Rev 9) requires a significantupdate to meet both the requirements of the new discharge permit. This upgrade should alsoaddress the expectations of OSPAR and strengthen the clarity and structure of the procedure.This will enable consistent understanding and application of the overall OiW sample collection,analysis and reporting process. It is recommended Maersk Oil Denmark adopts a workshopbased approach when updating this procedure, with active participation from the Chemistry &Environment Department as well as relevant offshore personnel. The updated procedure wouldbe greatly improved through the use of Process Mapping.There is also a need to cross-reference relevant procedures and guidelines, such as thespreadsheets used to calculate platform specific OiW concentrations (including the correlatedcalculations).The platform specific information (e.g. platforms without laboratory facilities, platforms that re-inject produced water etc.) should also undergo a critical review to ensure adequacy. It is alsonoted that this procedure, together with associated guidelines (e.g. guidance used to completestatutory reporting of weighted daily average concentrations, monthly average concentrationsand total oil overboard) should be brought together to form a suite of Produced WaterManagement Procedures, as illustrated in the diagram below. An important element of thisincludes the adoption of ‘Good Laboratory Practice’ – see Appendix 8 for details.

OiW Procedural Suite

Platform Specific- Sampling- Communications- Sample custody

Analytical- Method-Instrument

Calculation &Reporting- Laboratory- Control Room- Beach

VerificationProcess-Activesupervision-Internal audits-3rdparty audits

Figure 3-1 Recommended Procedural Suite for Produced Water Management

Lloyd's Register EMEA

Page 17

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

3.2

Data Integrity RecommendationsThe findings indicate that there is a lack of robust and transparent sample and datamanagement meaning that Maersk Oil Denmark is exposed to the potential for error andmisconduct. It is therefore recommended that Maersk Oil Denmark implements a number ofdata integrity control measures in order to reduce the risks associated with inaccurate OiWreporting. These suggested measures include:•The platform specific instructions should be developed to include a documentedsampling plan and procedure which includes specific instructions on sample: collection,labelling, handling, storage and protection, transportation and receipt for normal andabnormal operations.The verbal transfer of critical information related to OiW concentrations should beformally recorded and logged.Establish a ‘Good Laboratory Practice’ with the use of written Laboratory Logbooks(denoting sample times, analytical results, anomalies, changes, errors, comments etc.).Introduce a process to ensure the security of data contained within the platformspecific workbooks. Additionally, when changes are made to data contained withinthe workbook, ensure there is a record of the original data (i.e. data history) anddocumented reasons for changes.Formalise the onshore base sense-checks of reported data in order to capture potentialnoted data anomalies.Introduce robust verification processes that would verify the data trail from samplecollection (as denoted in the written laboratory logbooks) to reporting.

•••

••

3.3

Robust Verification RecommendationsIn addition, the scope of third party audits of the laboratory processes (as currently conductedby Force Technology) should be extended to include reporting. This would provide even moreassurance that the calculated figures that are reported to the Danish Government are accurateand traceable to specific samples from specified dates.At the time of the review, the offshore QA/QC and verification processes relating to OiWsampling, analysis and reporting tend to rely on third party and beach based annual reviews. Itis therefore recommended that Maersk Oil Denmark enhances the existing OiW managementby the introduction of robust verification processes. These processes should include:•Structured supervisory Quality Assurance: in order to achieve greater ownership andactive quality control, there is an opportunity for line management to engage in skilfulconversations while witnessing application of various produced water managementprocesses, including treatment plant troubleshooting, sampling and analysis.Processes should be introduced and established to ensure the robust verification of On-the-Job training.Analyse QC samples to provide assurance of accuracy of results: planned andAd Hocquality checks are in line with ‘good laboratory practice’.Robust internal audits: enhance existing internal auditing processes to ensure that OiWprocesses are effectively scrutinised.

•••

Lloyd's Register EMEA

Page 18

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•

Third party audits: expand the scope of the Force Technology audits to enablecomplete verification of OiW processes (from sample collection all the way toreporting).Update procedures: ensure that the verification processes add value, and are alignedwith revised OiW procedures and processes (once they are reflective of dischargepermit requirements).

•

3.3.1

Degree of Variability of Reported ConcentrationsInevitably sample collection, custody, analysis and reporting processes will introduce somedegree of variability in reported OiW concentrations. Therefore validation of a laboratorymethod is important (and is Good Laboratory Practice) to determine the suitability of an analysismethod for the concentrations to be measured. During the verification there was no evidencethat Maersk Oil Denmark has quantified the Limits of Detection (LOD) or the Limits ofQuantification of the reported data. The LOD for the OiW method is unlikely to be at a levelwhich will impact on the concentrations set in the permits (20 and 30 mg/L). However, theLOD is likely to be important when the data is utilised for the setting and achieving of internalKPIs, where these are at levels lower than those that can be reasonably detected. It is thereforerecommended Maersk Oil Denmark attempts to quantify the lower Limit of Detection for theOiW method and recognises it when setting internal OiW KPIs.

3.4

Competency Assurance RecommendationsWhen conducting produced water management tasks offshore, teams must rely on each other’scompetency. Although Maersk Oil Denmark is currently establishing a structure for offshoreworkforce training programmes, they must formalise arrangements to ensure that:•Existing and new Laboratory Technicians should either complete the newly developedOiW training programme, or verify competency levels of existing Laboratory Techniciansagainst the programme requirements.All relevant job descriptions are cohesive and complete. They must accurately reflectproduced water management tasks and responsibilities.This should includetroubleshooting, sampling, analysis and reporting.Training programmes are implemented as per identified needs.On-the-Job training is formalised, including verification.

•

••

3.5

Tyra East specific improvementsCritical review findings relating to the Tyra East installation differ from the other DUC assets.Specific recommendations pertaining to this asset are:•Maersk Oil Denmark has processes to enable individuals to report concerns. It isimportant that these processes are not only established, but are fully supported andpeople are encouraged to use them. While recognising that this process is supportedby Maersk Oil Denmark, it is clear than some individuals on Tyra East elected to choosea different vehicle to communicate concerns. In support of this recommendation, aculture of openness in reporting and communicating should be further nurtured andembraced within the organisation.

Lloyd's Register EMEA

Page 19

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

•

Maersk Oil Denmark should carefully consider the internal communication andmanagement actions to be taken in the aftermath of these events. This would includecommunication (i.e. internal/external announcements, lessons learned, and individualresponse actions) to the workforce and relevant stakeholders. This should clearly definethe expectations of on and offshore management, those actively involved in the OiWprocesses.

Lloyd's Register EMEA

Page 20

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendices

Lloyd's Register EMEA

Page 21

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 1.

Asset Specific Review: Tyra West

Lloyd's Register EMEA

Page 23

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 2.

Asset Specific Review: Tyra East

Lloyd's Register EMEA

Page 24

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 3.

Asset Specific Review: Halfdan

Lloyd's Register EMEA

Page 25

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 4.

Asset Specific Review: Dan

Lloyd's Register EMEA

Page 26

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 5.

Asset Specific Review: Gorm (including Skjold)

Lloyd's Register EMEA

Page 27

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 6.

Asset Specific Review: Harald

Lloyd's Register EMEA

Page 28

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 7.

Documentation Reviewed

Lloyd's Register EMEA

Page 29

28/02/2011

Maersk Oil Denmark

REPORT AND EXECUTIVE SUMMARY:CRITICAL REVIEW OF PRODUCED WATER S AMPLING,AN ALYSIS AND REPORTING PROCEDURES: DANISH OFFSHORE OPERATIONS

Appendix 8.

Principles of Good Laboratory Practices

Lloyd's Register EMEA

Page 30

28/02/2011

Maersk Oil Denmark

APPENDIX 1. ASSET SPECIFIC REVIEW: TYRA WEST

IntroductionDuring December 2010, Maersk Oil was subject to allegations published in the DanishnewspaperPolitikenregarding the integrity of their produced water managementprocesses, including oil-in-water (OiW) analysis and reporting. Maersk Oil Denmarkengaged Lloyd's Register EMEA to conduct an independent review of the associatedenvironmental processes and procedures (including implementation). The review wasconducted by Nick Jackson and Amy Annand of Lloyd's Register EMEA, and StigStangeland of Lloyd's Register Scandpower.Scope of WorkLloyd's Register EMEA reviewed and determined the degree to which Maersk Oil’sproduced water sampling, analysis and reporting (i.e. specifically OiW) processes trulyreflected accepted industry practice. The review evaluated existing documentedprocesses and procedures, and compared their implementation onshore and offshore(on board the Tyra West installation) to recognised industry practice. The review alsoincluded a series of interviews with workforce representatives who developed and usedthese processes and procedures. It is important to note that this was a critical review,which should not be construed as a formal audit. Information was gathered frominterviews with representatives of management and of the workforce (both on andoffshore), but in-depth verification sampling of the data collected was not carried out.Key questions (not exhaustive) included:•••How does the current sampling method compare to industry practices?Can we confirm it is aligned with requirements?Are the procedures adhered to offshore?

The report from this critical review includes both a comparison with accepted and bestindustry practice, and recommendations on how Maersk Oil Denmark can move towardsbest industry practice. Findings are reported as commendations, areas for improvement,and observations.

i. MethodologyThe review comprised a series of interviews offshore and onshore, as well as reviews ofrelevant documentation. Maersk Oil Denmark provided Lloyd's Register EMEA with anumber of documents prior to commencement of the interviews. These documentsincluded: procedures, organisational charts, copies of newspaper articles and Maersk OilDenmark's responses to those articles. There were also several other documents thatwere reviewed onsite. In total, the following Maersk specific documents were providedfor review:•••English translation ofPolitikenarticles.Maersk Oil Denmark's stated response to those articles.Danish operation organisational chart.Maersk Oil Denmark

Lloyd's Register EMEA

APPENDIX 1. ASSET SPECIFIC REVIEW: TYRA WEST

••••••••

Oil in Water Sampling, Analysis and Reporting procedure (OPM 2B, Part 3, Rev 9).Job Descriptions: Laboratory Technician, Production Supervisor, Control RoomAssistant, Production Technician.Daily logs (various dates).Daily Production Checklists.Daily Operational Highlights Report (various dates).Planned maintenance schedules for Tyra West produced water process trains (CBIand IPF).Competency matrices, and identified Production Operations Guidelines (POGs)and procedures (both OSPs and OPMs).The current Tyra production unit discharge permit, as issued by the Departmentthof Environmental Protection, 20 September 2009.

i. Programme of WorkThe following review activities were conducted over five days:Date22 Dec27 Dec28 Dec28 Dec29 Dec30 Dec30 DecActivityOnshore (Esbjerg) review of documentation, and offshore visit planning.Commence offshore review (Tyra West), kick-off meeting with OIM.Offshore review and interviews.Evening: return to beach, summarise findings to date with onshore reviewteam.Further follow-up review onshore and interviews with key personnel.Analysis and reporting.Submit Executive Summary, with a formal presentation to the managementteam.

The following people were interviewed as part of the critical review programme of work:••••••••Jørgen Juul: Platform Supervisor (Tyra West).Frank B Christensen: Production Supervisor (Tyra West).Georg Pedersen: Control Room Assistant (Tyra West).Carsten Østbo Pedersen: Laboratory Technician (Tyra West).Hans Henrik Kristensen: Head of Production Operations (Maersk Oil Denmark).Lars Hvejsel Hansen: Manager of the Chemistry and Environment Team (MaerskOil Denmark).Steffen Fredberg Hansen: Production Chemist and reporting specialist (Maersk OilDenmark).Britt Gydesen: Production Chemist and reporting specialist (Maersk Oil Denmark).

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 1. ASSET SPECIFIC REVIEW: TYRA WEST

Critical Review Findings

i. CommendationsThere were several noted positive aspects of produced water management withinMaersk Oil Denmark's operations. These included:•Maersk Oil Denmark has established appropriate procedures (specifically OPM 2BPart 3 Rev 9) and associated guidance documents and initiatives which enableoperations to meet expectations of the discharge permit for the Tyra productionunit.Evidence secured from conversations on Tyra West suggested that the OiWprocedures are fully and consistently applied on the installation.Processes are established for employee engagement in procedural change (i.e.the updated Revision 9 of the OiW procedure).Feedback indicated that the response and reporting culture relating to dischargeconcentrations greater than 20 mg/l appears to be supportive and reflective ofgood practice.There are a number of verification audits that have been established. Theseinclude third party audits of the sampling laboratory OiW processes (ForceTechnology), ISO14001 certification (DNV), and annual internal audits of OiWreporting processes.The action level for OiW is 20mg/l, although the permit defines average monthlydischarge limit of 30mg/l. This means that corrective action is often appliedbefore a permit breach occurs. It is also noted that Maersk Oil Denmark hasstipulated their own internal KPI as 9.5mg/l for each of the discharge points forthe two main produced water treatment process trains on board the Tyra West.Evidence indicated that further improvements to the produced water treatmentprocesses will be introduced. These include: exploring the use of online OiWmonitoring with improved reliability and improving flow metering systems foroverboard discharge volumes.Daily production checks are conducted on individual produced water processtrains. These checks include: levels, pressures and temperatures of specifictreatment equipment and processes. This data is then used to troubleshoot anddefine corrective action if the 20mg/l limit is exceeded.The data trail from analysis to onshore reporting to Danish EnvironmentalProtection Agency is structured and contains numerous sense checks in order tounderstand any potential anomalies that may occur at data transfer points.The OiW sampling, analysis and reporting procedure does include installationspecific guidance.Evidence obtained from conversations on board Tyra West suggested thatemployees (e.g. the CCR) are empowered to shut down wells/operations whennecessary.

•••

•

•

•

•

•

••

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 1. ASSET SPECIFIC REVIEW: TYRA WEST

Areas for Improvement•The time of sample collection is recorded at the same time (i.e. 07:30), as printedout on the Daily Log pro forma. There was no evidence to suggest that samplingtimes varied widely from 7:30, but it is still highly unlikely that samples arecollected at the same time every day. It is important that the exact sample timeshould be recorded because the weighted daily average oil/water concentration isbased upon time between samples.Offshore QA/QC and verification processes relating to OiW sampling, analysisand reporting tend to rely on third party and beach based annual audits. In orderto achieve greater ownership and active quality control, there is an opportunityfor line management to engage in skilful conversations while witnessing theapplication of various produced water management processes, includingtreatment plant troubleshooting, sampling and analysis. In addition, the scope ofthird party audits of the laboratory processes (as currently conducted by ForceTechnology) should be extended to include reporting. This would provide evenmore assurance that the calculated figures that are reported to the DanishGovernment are accurate and traceable to specific samples from specified dates.The OiW Sampling, Analysis and Reporting procedure (OPM 2B, Part 3, Rev 9)enables operations to meet the expectations of the discharge permit for the Tyraproduction unit. However, the clarity and structure of the procedure can bestrengthened. Visibility of the overall OiW sample collection, analysis andreporting process could be improved through the use of Process Mapping. It wasunclear what the 'chemical slip' was and there was little guidance within theprocedure on determining total volume of re-injected produced water and totalvolume of overboard produced water. There is also a need to cross-referencerelevant procedures and guidelines, such as the spreadsheets used to calculateplatform specific OiW concentrations (including the correlated calculations). Theplatform specific information (e.g. platforms without laboratory facilities,platforms that re-inject produced water etc.) should also undergo a critical reviewto ensure adequacy. It is also noted that this procedure, together with associatedguidelines (e.g. guidance used to complete statutory reporting of weighted dailyaverage concentrations, monthly average concentrations and total oil overboard)should be brought together to form a suite of Produced Water ManagementProcedures.A greater degree of clarity and focus is required in relation to the developmentand application of Production Operations Guidelines (POGs) that specificallyrelate to produced water management On-the-Job training. On-the-Job training(again specifically for produced water management) lacks formality, therebyraising questions about the consistency of application.

•

•

•

i. ObservationsThere were a small number of observations that Maersk Oil Denmark should consider.These included:•To provide (comparative) verification of onsite analytical results, considerationshould be given to conducting duplicate/triplicate sampling through an

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 1. ASSET SPECIFIC REVIEW: TYRA WEST

accredited third party laboratory. This is not a requirement of the dischargepermit, but it may provide additional assurances of reported oil in waterconcentrations.•To ensure sample integrity of any samples that are sent onshore for third partyanalysis, clear guidance should be provided relating to sample handling andlabelling, anti-tampering methods, sample custody paperwork etc. It is notedthat people felt comfortable with guidance relating to the actual transport ofsamples, but were unsure if there was guidance relating to maintaining sampleintegrity.The organisational chart for Tyra West shows the Laboratory Techniciansreporting directly to the Platform Supervisor, when in reality they report to andwork closely with the Production Supervisor.

•

ConclusionsFrom an overall produced water management perspective, Maersk Oil Denmark hasestablished suitable tools, processes, systems and competencies which enablecompliance with overboard discharge permit expectations. Evidence gathered duringconversations suggested that the response and recording culture on board Tyra Westrelating to produced water management was supportive and reflective of good practice.Going forward, it is clear that Maersk Oil Denmark intends to continue improvement ofits overboard discharge performance processes by the further introduction of enhancedsystems and technology. However, there are a few areas which require attention,including:•••Ensuring that sample times are accurately recorded on the Daily Log.Improving the structure and clarity of the Sampling, Analysis and Reportingprocedure (OPM 2B, Part 3, Rev 9).Enhancing ownership and active quality control offshore via line management(e.g. engage in skilful conversations while witnessing application of variousproduced water management processes, such as sampling, analysis andtroubleshooting).Formalising the On-the-Job training and mentoring programmes with regard toproduced water management.

•

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 2. ASSET SPECIFIC REVIEW: TYRA EAST

Introduction and Scope of WorkDuring December 2010, Maersk Oil Denmark was subject to allegations published in theDanish newspaperPolitikenregarding the integrity of their produced watermanagement processes, including Oil-in-Water (OiW) sampling, analysis and reportingon board the Tyra East offshore installation. Maersk Oil Denmark engaged Lloyd'sRegister EMEA to conduct an independent review of the associated environmentalprocesses and procedures (including implementation). This review was based oninformation gathered from conversations and documentation obtained on board theTyra West installation and Maersk Oil Denmark offices in Esbjerg. The review wasconducted between the 27thand 30thof December 2010 by Nick Jackson and AmyAnnand of Lloyd's Register EMEA, and Stig B. Stangeland of Lloyd's RegisterrdScandpower. On the 3 of January 2011, Lloyd's Register EMEA issued a full report andexecutive summary entitled 'Independent Critical Review of Produced Water Sampling,Analysis and Reporting Procedures'.Maersk Oil Denmark then requested a follow-up independent review and offshore visitto the Tyra East offshore installation to assess the application and effectiveness of theOiW procedures. Maersk Oil Denmark also verbally requested a review into thecircumstances and causal factors that led to an individual's supplying of information tothePolitikenregarding the organisation's OiW processes and reporting. These reviewswere conducted between the 4thand 6thof January 2011 by Stig B. Stangeland.Participants engaged in the interviews included three Laboratory Technicians, oneProduction Supervisor, and two Platform Supervisors. It is important to note that thisindependent review was not meant to be a complete investigation or inquiry into theroot causes of these allegations, nor was there any objective to apportion individualresponsibility or blame.Independent Review Findings and Participant Feedback

i. Relating to OiW procedure (OPM 2B Part 3, Rev 9)•The initial Lloyd's Register EMEA critical review of the OiW Sampling, Analysisand Reporting procedures identified that Maersk Oil Denmark have establishedappropriate procedures (specifically OPM 2B part 3, Rev 9) and associatedguidance documents and initiatives which enabled operations to meetexpectations of the discharge permit for the Tyra production unit. However thereview also identified that the structure and clarity of the procedure could beimproved, and should be subject to review and enhancement.Feedback from participants on board the Tyra East supported theseaforementioned findings and suggested that the procedure left too much roomfor interpretation, opportunities for misunderstandings and the potential forinconsistent work practices.The initial review of the OiW process identified that processes are established foremployee involvement in procedural change (i.e. the updated Revision 9 of theOiW procedure). Information from the Tyra East participants indicated that theOiW procedural update did not involve the on board Laboratory Technicians.

•

•

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 2. ASSET SPECIFIC REVIEW: TYRA EAST

ii. Relating to participant feedback•Interview feedback indicated a lack of both formal and informal interaction andcommunication between the Laboratory Technicians on board the Tyra East andtheir colleagues, both onshore and offshore. Furthermore the LaboratoryTechnicians felt excluded from internal decision making processes whichinfluence their roles and responsibilities. One stated example was the recentthupdate (13 of September 2010) to the OiW procedure, which did not includeany input from or consultation with the Tyra East Laboratory Technicians. WhenLaboratory Technicians requested clarification on procedural details, they felt theywere being ignored. A further example indicated a lack of interaction andappropriate response from management when dealing with issues relating topoor personnel performance.Some individuals felt that it would be possible to manipulate the Oil-in-Waterdata (e.g. within the Excel spreadsheet), although no evidence of any malpracticewas presented, and no direct suggestion of manipulation was made.Feedback from one participant also suggested that the existing OiW proceduredoes not comply with OSPAR requirements. This individual believed that theOSPAR requirements mandated that a minimum of 30 samples per month shallbe analysed with an equal time lag. This perception is incorrect; OSPARrequirements only actually require a minimum of 16 samples per month, taken atequal time intervals. Procedure OPM 2B Part 3, Rev 9 describes the OiWdischarge sampling requirements, as defined in the Permit to Discharge, issued bythe Danish Environment Protection Agency, which requires a minimum of onesample per day. As previously mentioned, the existing OiW procedure shouldenable the Tyra production unit to fully meet the obligations of the dischargepermit.

•

•

iii. Relating to circumstances leading to allegationsFeedback from participants in this review suggested that the basis for the supply ofinformation toPolitikenand the subsequent published allegations was due to a numberof complex perceptions and circumstances, including:•Different interpretations and varying levels of understanding of the OiWprocedure created the potential for inconsistent work practices. This particularlyrelated to the number of samples to be taken and the process to be followedwhen analysed samples exceeded 20 mg/l, as per Maersk Oil Denmark'srequirements.One of the participants demonstrated a lack of understanding of the OiWprocedure (OPM 2B, Part 3 Rev 9). This may be due to a lack of clarity within theprocedure itself or a lack of communication or awareness. These reasons clearlycould have added to the frustration and dissatisfaction that contributed to thereasons for release of information to the press.Some participants described strong feelings of mistrust towards managementboth on and offshore. This was supported by perceptions of exclusion and lack

•

•

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 2. ASSET SPECIFIC REVIEW: TYRA EAST

of involvement, which are further compounded by stated beliefs thatcommunications between offshore and onshore are ineffective.•The perceived lack of clarity in the OiW procedures has led to varying degrees ofconfidence and trust in the work processes. This was further compounded by astated but incorrect belief that the OiW procedure did not meet the OSPARsampling requirements, as well as unaddressed requests for proceduralclarification.Some participants believed that there was insufficient sampling, analysis, andreporting Quality Assurance to support or challenge reported OiW concentrations.Some participants were unaware of a formal confidential and anonymousinternal reporting system for raising concerns and issues.It was also evident that the individuals who responded to the request forinformation from the freelance journalist did so because they believed that theprocesses to address their concerns on the Tyra East installation were noteffective. They indicated that this was their last resort of action.

•••

Conclusion from the Independent Review and RecommendationsThe reasons, behaviours and perceptions which led to the supply of sensitiveinformation toPolitikenare complex, and this high level review identifies some of thecauses and can only speculate on others. The review, however, did not identify anyevidence that any Maersk Oil Denmark employee or contractor had deliberatelyattempted to falsify any information or data relating to OiW discharges.Based solely on information and feedback gained from the interview processes, it isrecommended that the following activities are considered:•The OiW Sampling, Analysis and Reporting procedure (OPM 2B, Part 3, Rev 9)enables operations to meet the expectations of the discharge permit for the Tyraproduction unit. However, the clarity and structure of the procedure can bestrengthened. Visibility of the overall OiW sample collection, analysis andreporting process could be improved through the use of Process Mapping. Thereis also a need to cross reference relevant procedures and guidelines. Theplatform specific information should also undergo a critical review to ensureadequacy.Offshore QA/QC and verification processes relating to OiW sampling, analysisand reporting tend to rely on third party and beach based annual audits. In orderto achieve greater ownership and active quality control, there is an opportunityfor line management to engage in skilful conversations while witnessingapplication of various produced water management processes, includingtreatment plant troubleshooting, sampling and analysis. In addition, the scope ofthird party audits of the laboratory processes (as currently conducted by ForceTechnology) should be extended to include reporting. This would provide evenmore assurance that the calculated figures that are reported to the DanishGovernment are accurate and traceable to specific samples from specified dates.Maersk Oil Denmark has processes to enable individuals to report concerns. It is

•

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 2. ASSET SPECIFIC REVIEW: TYRA EAST

important that these processes are not only established, but are fully supportedand people are encouraged to use them. While recognising that this process issupported by Maersk Oil Denmark, it is clear that some individuals on Tyra Eastelected to choose a different vehicle to communicate concerns. In support of thisrecommendation, a culture of openness in reporting and communicating shouldbe further nurtured and embraced within the organisation.•Maersk Oil Denmark should carefully consider the internal communication andmanagement actions to be taken in the aftermath of these events. This wouldinclude communication (i.e. internal/external announcements, lessons learned,and individual response actions) to the workforce and relevant stakeholders. Thisshould clearly define the expectations of onshore and offshore management, andthose actively involved in the OiW processes.

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 3. ASSET SPECIFIC REVIEW: HALFD AN

IntroductionOn the 26 January 2011, the Critical Review of Produced Water Sampling, Analysis,and Reporting procedures were conducted on board the Halfdan installation by LindaMurray (Lloyd's Register EMEA) and Per Christofferson (Lloyd's Register Scandpower).The scope of work was conducted, as described in Section 1 of this report.Documentation reviewed as part of this process is listed in Appendix 7. The followingpeople were interviewed as part of the critical review programme of work:•••••Jimmy Johansen, Platform/Production Supervisor (Kombimester).Ib L. Pedersen, Production Supervisor.Nils Bo, Maintenance Supervisor.Erik B. Johansen, Control Room Assistant.Jonny W. Pedersen, Production Technician.th

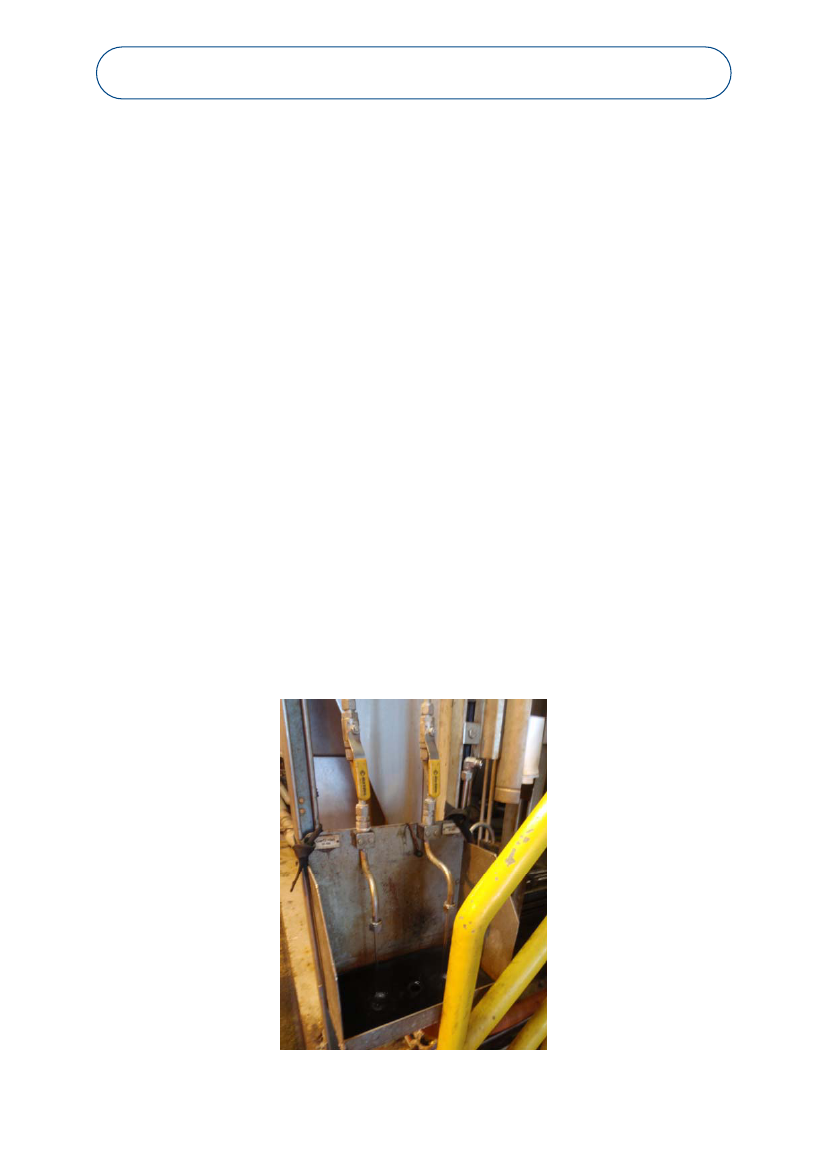

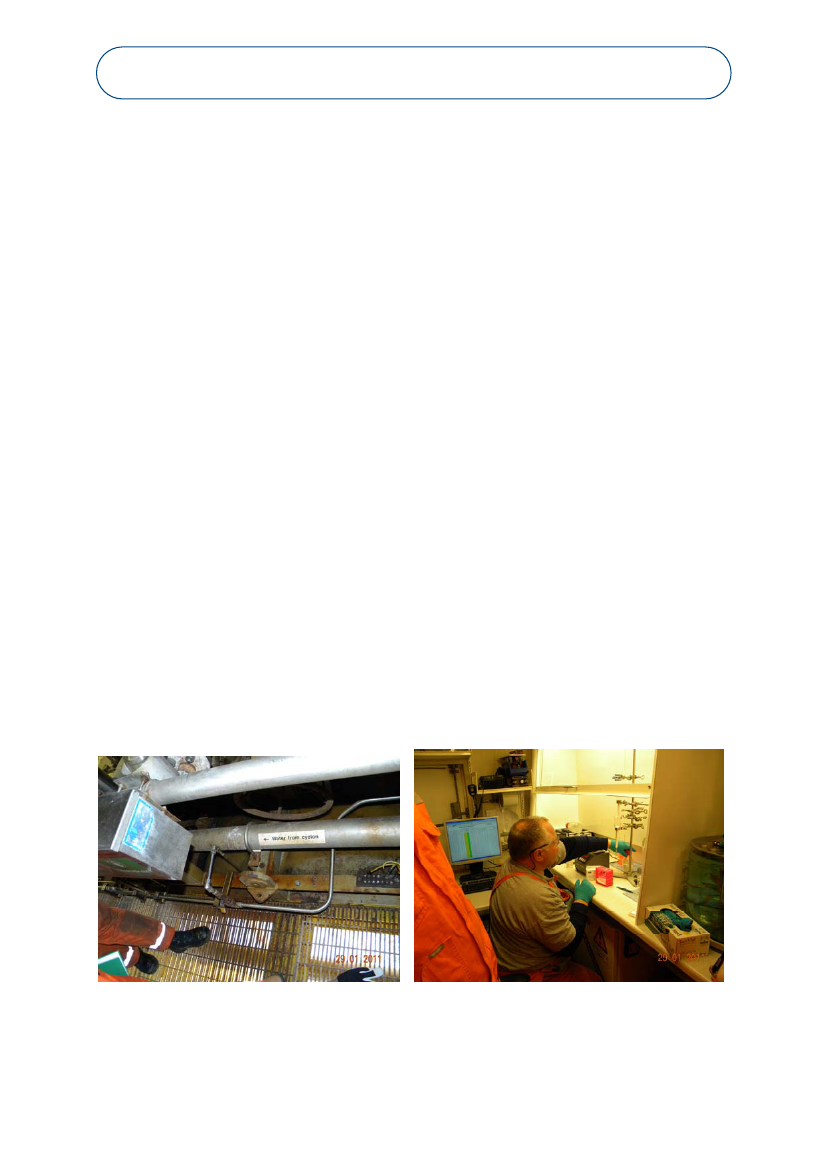

Overview of Produced Water ManagementThe water treatment process was described and demonstrated to the review team bythe on-shift Production Technician. The treatment train includes the separator (V3402),three hydrocyclones (V5012 – 14) and two degassers (V5016 A/B). Although the dailysampling had been completed, the two sampling points were viewed and the samplingprocess discussed. The continuously flowing sampling points are located after the finaldegasser treatment process (see Figure A3.1 below) and before discharge to the caisson.Individual samples collected from each treatment train are analysed and reported as amean concentration. Halfdan does not have laboratory facilities; therefore daily samplesare collected and sent by helicopter or boat to the Dan for analysis.

Figure A3.1 Post Treatment Sampling Points

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 3. ASSET SPECIFIC REVIEW: HALFD AN

Some aspects of the treatment train are subject to continuous monitoring and theresults are displayed in the Control Room on the Scada System. In addition to thismonitoring, for the past month the discharge point from each degasser (adjacent toeach sampling point) has been monitored by a continuous in-line Laser Induced UVflorescence monitor (Argus type by ProAnalysis); see Figure A3.2 below.

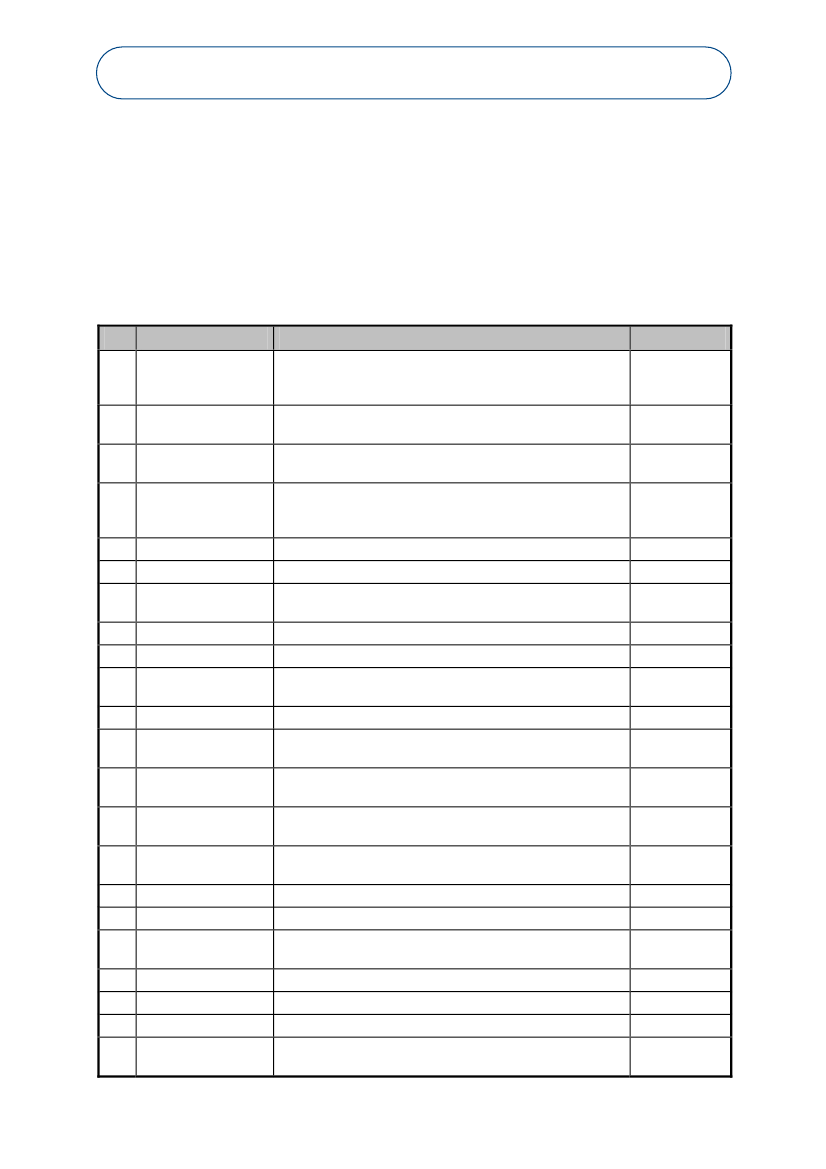

Figure A3.2 Continuous in-line Laser Induced UV Florescence Monitor

The values from the in-line monitoring are available online (soon to be available on theScada), and the Control Room is notified when a sample is taken. The results from thein-line monitoring are compiled by the Control Room Assistant to provide a basis forcorrelation with the OiW analytical results from the official samples. The comparativeresults were reviewed for the month it has been in use and no correlation has beenestablished yet. There is a limited amount of data gathered to date from the in-lineconcentrations. Therefore the data is currently used by the Control Room Assistant onlyto gather information on the OiW trend (i.e. rising or falling) for fine tuning theproduced water treatment process.The samples are collected in 500ml glass bottles (with Teflon insert) that have beencleaned by the Dan Laboratory Assistant who also adds 5ml of 6M hydrochloric acid toeach bottle. The process for labelling, packaging and transporting samples wasobserved. Printed labels are attached to individual sample bottles with elastic bands andthe bottles are then packaged in a sample box, prior to transport to Dan (see FigureA3.3 overleaf). No details were obtained regarding storage of samples prior to transport.

Lloyd's Register EMEA

Maersk Oil Denmark

APPENDIX 3. ASSET SPECIFIC REVIEW: HALFD AN

Figure A3.3 Oil in Water Sample packaged for transport to the Dan