Det Energipolitiske Udvalg 2010-11 (1. samling)

EPU Alm.del Bilag 30

Offentligt

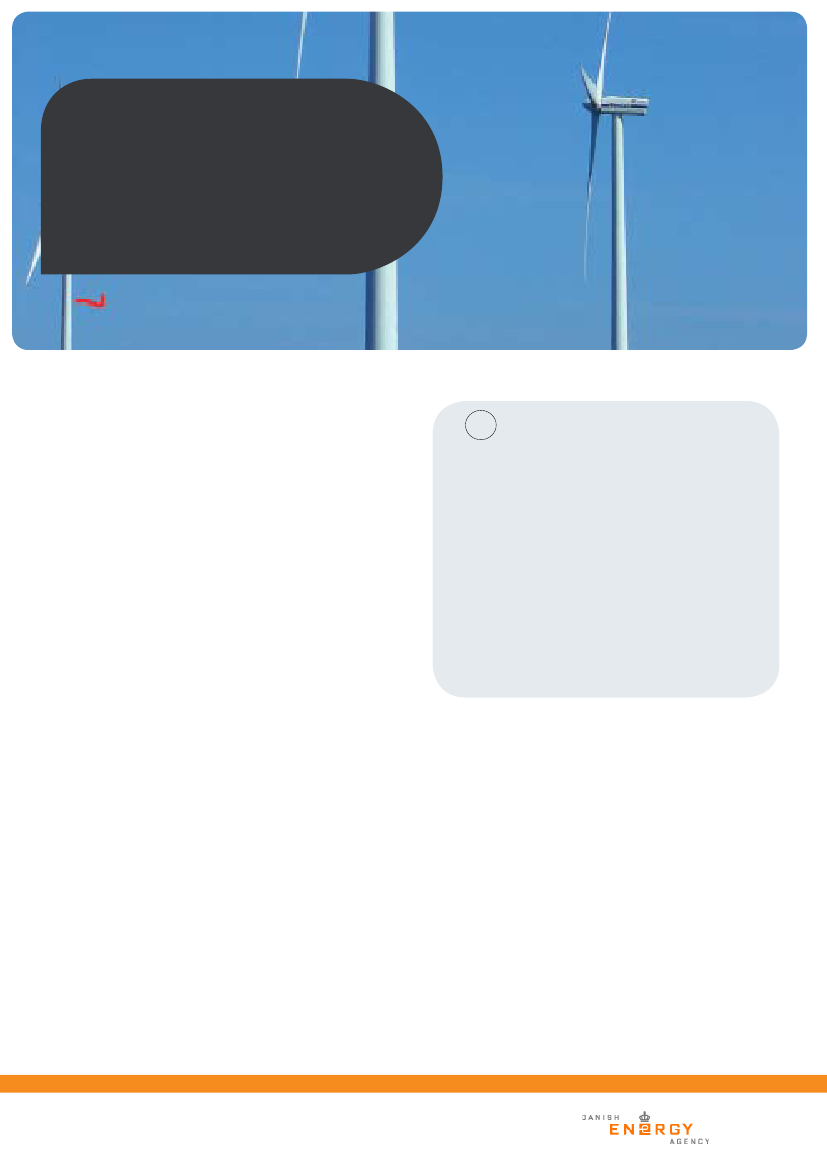

The Danish JI andCDM ProgramSeven years experience with climate projectsaround the world

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

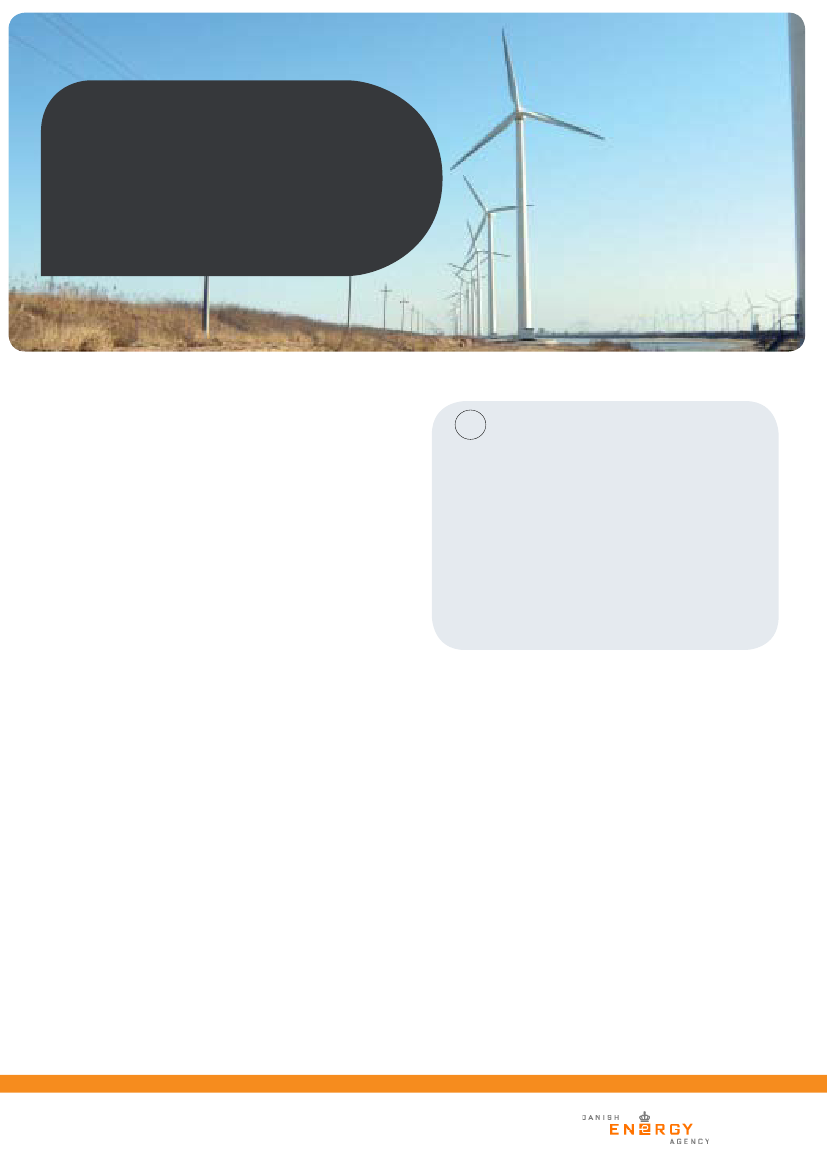

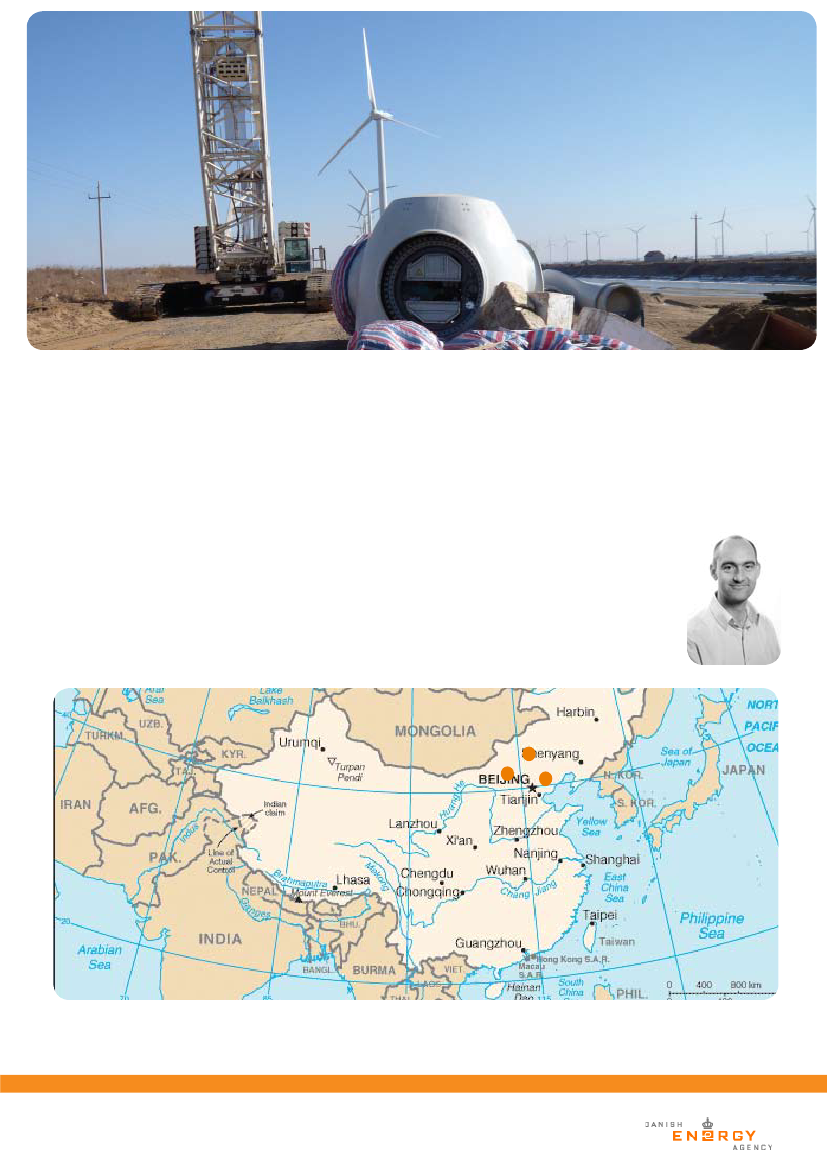

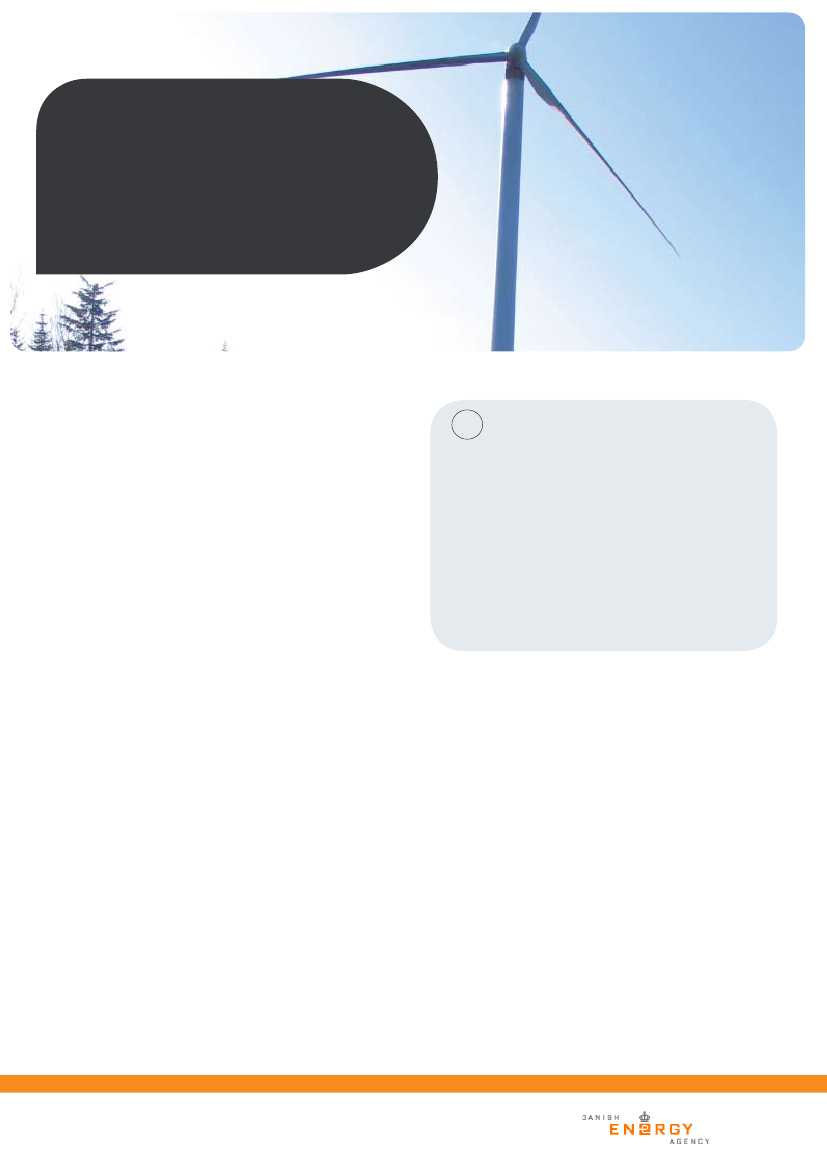

In 2003, Denmark was one of the first countries globally to enter the emerging climate project arena in developing JI/CDM-projects in Eastern Europe and developing countries. With an ambitious strategy, focused at cost efficient project developments combined with long term sustainability, close partnerships and social responsibility, we engaged in a new challenge, determined to become one of the leaders in pushing forward and developing a global market for GHG-reduction. Not only seeking to provide cost efficient reductions for Denmark, but for our globe as such. Based on the advanced Danish energy solutions we had a special opportunity engaging in the JI/CDM project development to transfer our experiences in combining support for CO2 reductions with sustainable industrial development and transfer of modern know-how, technology and capital to foreigncountries within the framework of the Kyoto Protocol. Now, having passed half way to the mile stone of the first Kyoto commitment period, we can look back and see that JI/CDM has become important mechanisms, appreciated by the many host countries, and that Denmark has a well-performing and well-founded portfolio of projects with significant environmental and social benefits for the local communities where the projects are located. The Danish way has proved that sustainability and close partnerships may go hand in hand with high performance and cost-efficiency. Through our close collaboration with project partners, our own local representatives, experiences with capacity building and support of many experts and consultants we have built a diverse and solid project pipeline in many countries with a wide range of technologies – focusing among others on biomass, fuel switch, energy efficiency and wind. Based on this partnership model, it has been possible to navigate the often complex JI/CDM processes in an efficient and cost-efficient way, whether involved in wind farm projects in China, biogas in Malaysia, biomass in Romania or district heating in Russia. In recent external reviews, the portfolio projects of the Danish State got fine ratings above average, and I believe Denmark can be very proud of our international climate projects. Recently the JI/CDM market has reached a more mature stage, where other tasks than capacity building and market development have gained importance. Thus, based on all the good experiences from the many years of dedicated work with internationalJI/CDM projects, we have launched a domestic Joint Implementation initiative with the aim of realising the many good ideas and initiatives of Danish grassroots and green-tech industries. This book presents the status of our portfolio after seven years of dedicated work in support of JI/CDM projects. The 75 projects are presented in pictures and text, representing individual stories of sustainability, collaboration and CSR in practice in Eastern Europe, Asia and Africa. I hope that the reader - when reading this book - will have the full picture of the Danish JI/CDM approach during this period to proactively engaging in the development of sustainable, climate projects - based on close partnerships with project participants. And that our experiences can be seen as a good example that the flexible mechanisms of the Kyoto Protocol in fact have made a valuable contribution to global CO2 reductions as well as social and economic wellbeing of the host countries and local communities.

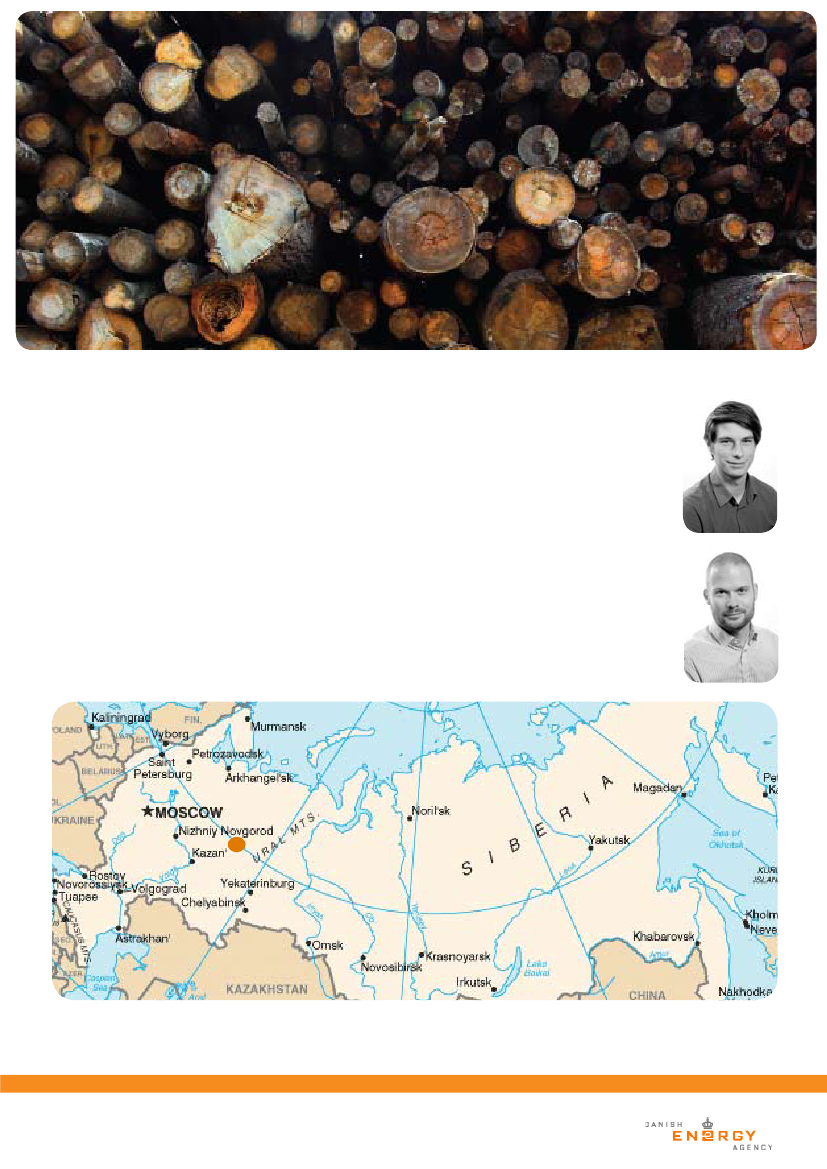

Foto: Anders Birch

Lykke Friis, Danish Minister for Climate and Energy

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

BackgroundProject Overview

Page.......................................47

Description of the JI/CDM programme

...................................................................................

CDM

The Danish Energy Agency44 AmaliegadeDK-1256 Copenhagen KTelephone:+45 33 92 67 00Fax:+45 33 11 47 43Website: www.ens.dkPublished: Number printed: September 2010400 copies

ThailandMalaysia

...................................................................................................

1024405862646668

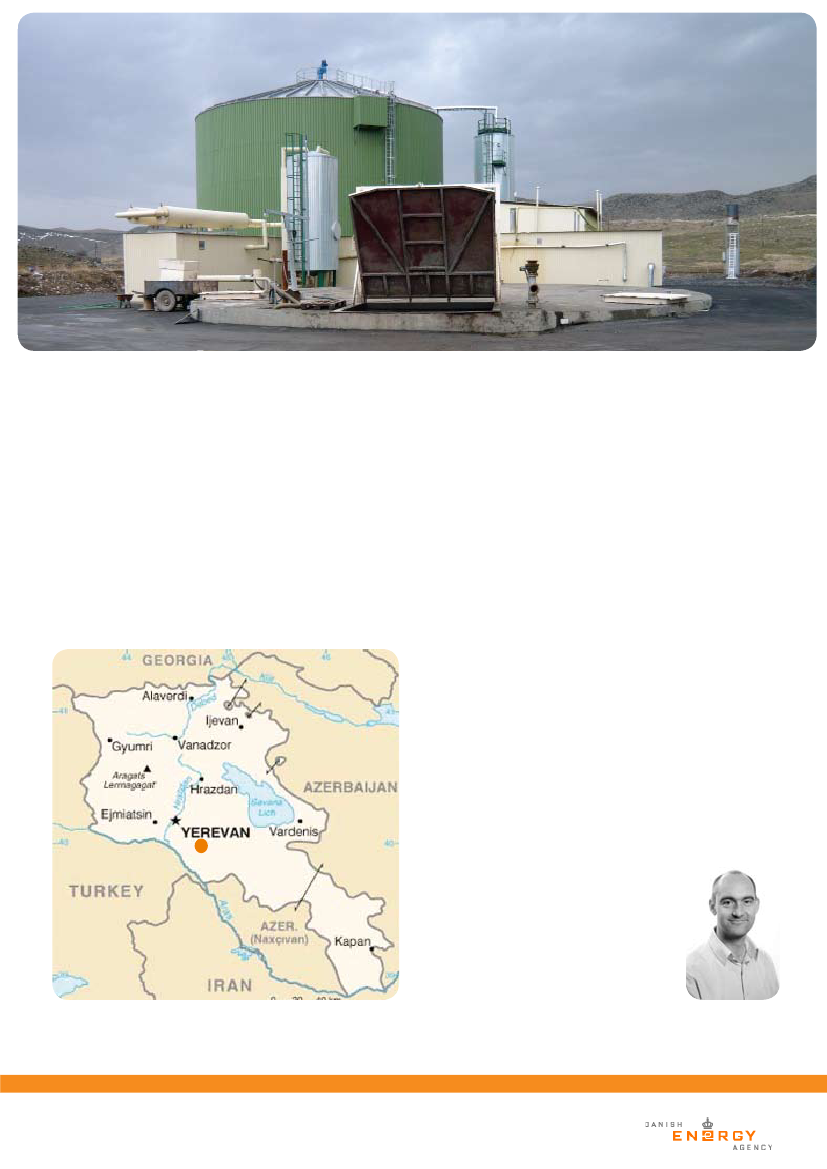

...................................................................................................China.........................................................................................................Indonesia..................................................................................................Bangladesh.............................................................................................Egypt.........................................................................................................Armenia....................................................................................................Cyprus......................................................................................................

JI Projects

Photos:Front and back page: Collage of project photos.”Top right front and back photos from Vestas.Project photos by the DEA team, LPCs and project hosts.Editor:Asger Olesen, the DEAGraphics: Elisabeth Rasmusen and Andreas W. Karlsen, the DEAPrint: Cool GrayPrinted on: Cover: 400g; content: 130gLayout: Antistandardand the DEAISBN: 978-87-7844-869-9This report went to press August 2010.and tables, is also available at the DEA’s website, www.ens.dk.ISBN www: 978-87-7844-871-2

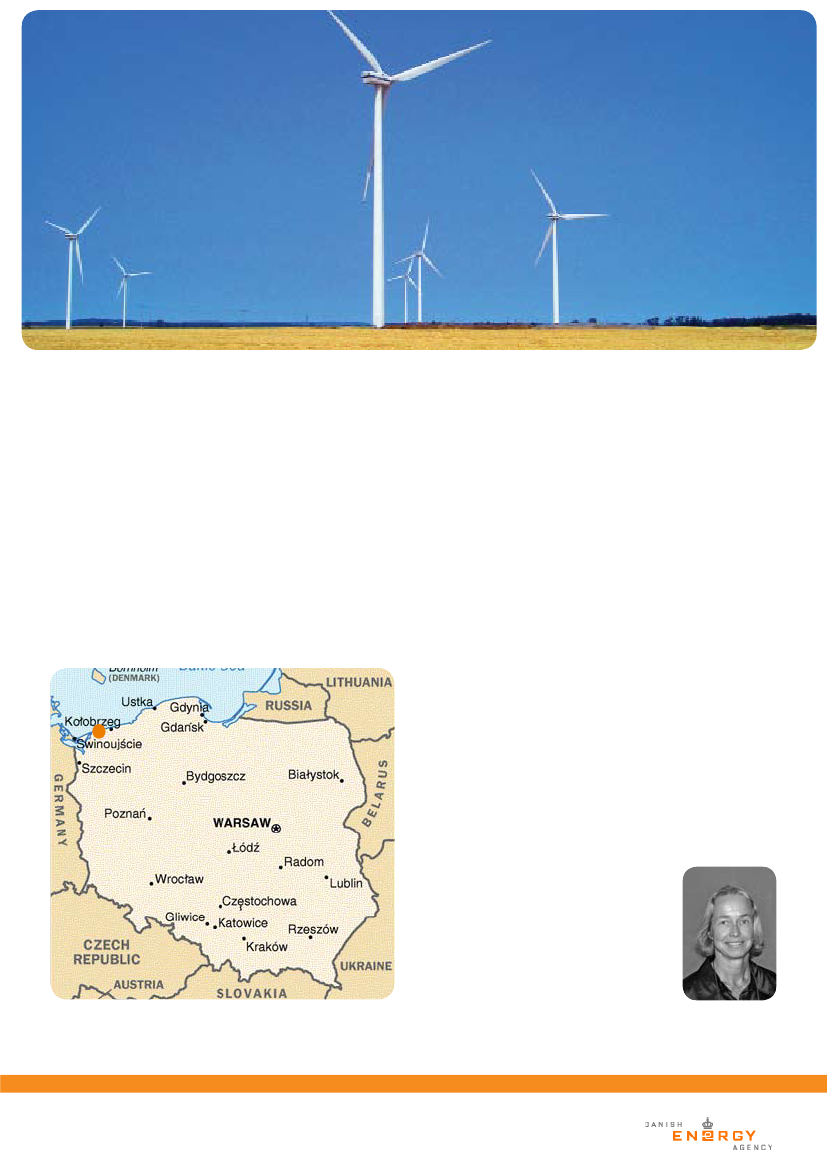

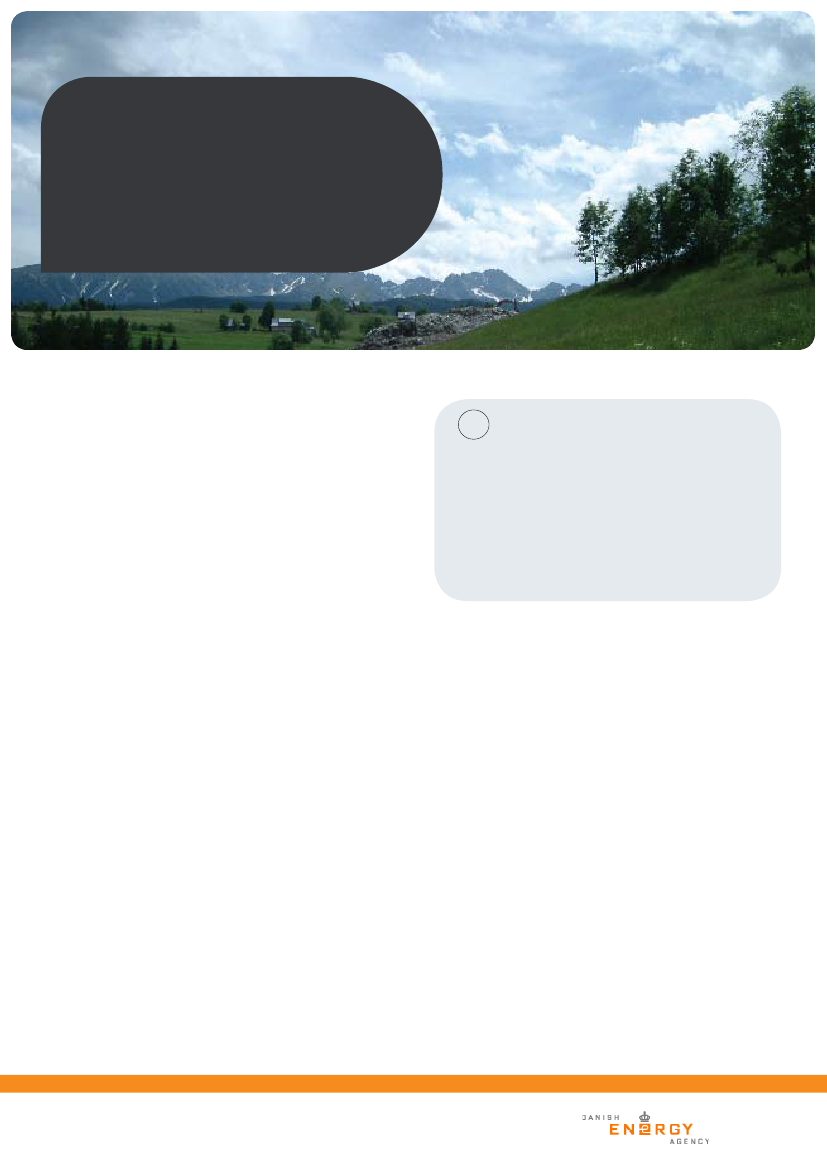

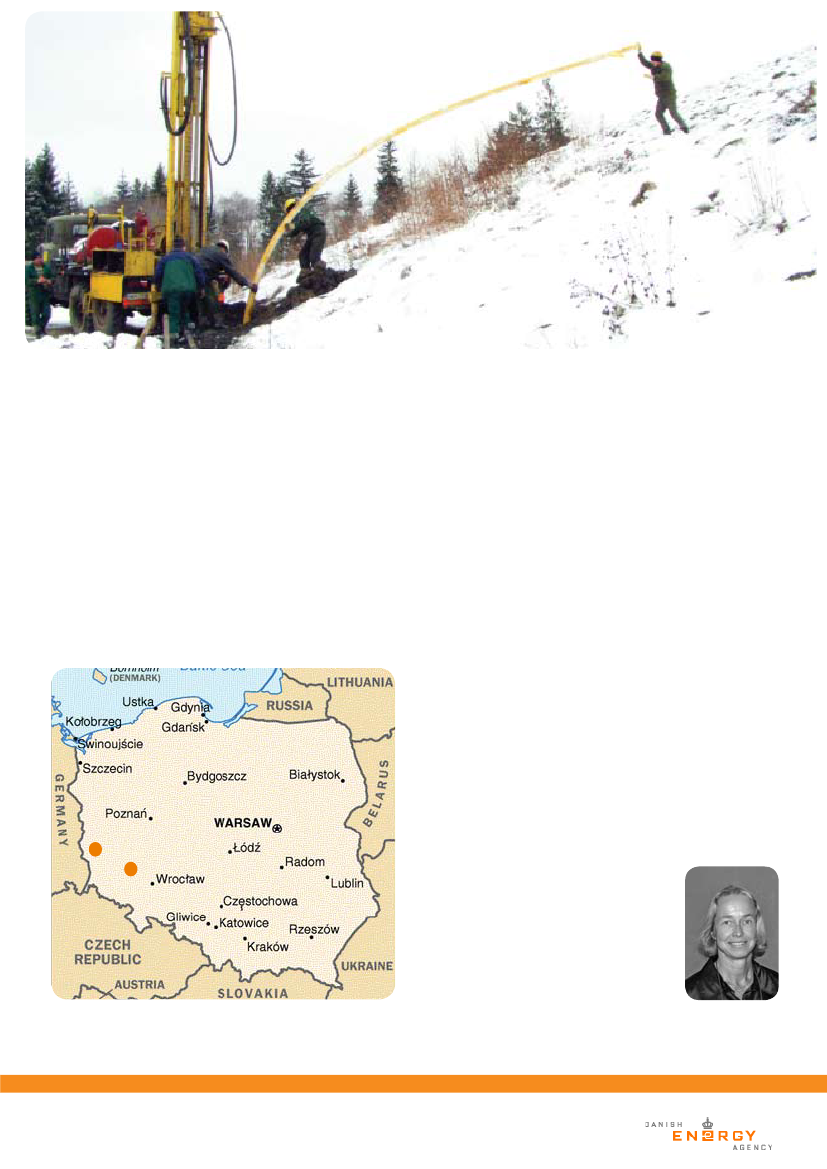

Romania....................................................................................................Poland.......................................................................................................Bulgaria....................................................................................................Russia

728292

........................................................................................................96......................................................................................106Czech RepublicUkraine......................................................................................................108NewZealand...........................................................................................110

Local Project CoordinatorsMap of project locations

...............................................112

.......................................................113

The project briefs describe the positive climate impact of the JI/CDM projects in the Danish Energy Agency’s (DEA) portfolio, theirwith the impact of the projects on everyday lives, rather than the technical side of the projects. For further information and details pleasesee the individual Project Design Document (PDD) for each project, which can be downloaded from the DEA homepage www.ens.dk,

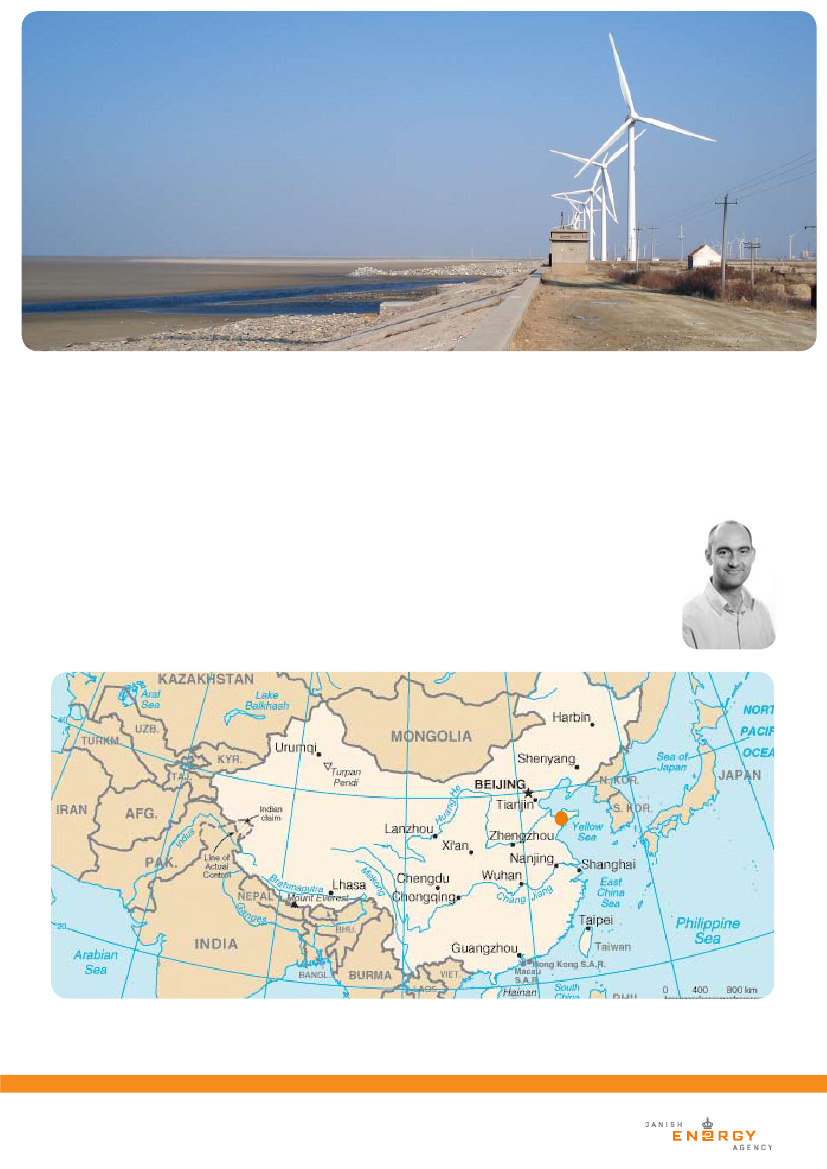

The project briefs follow a template so that the same issues are covered for all projects, including an introduction, a short description ofconsistent and easy to overview. However, individual project conditions mean that every story is unique and may divert from the template. Each project brief contains a map, showing the location of the project, as well as pictures taken by the DEA during site visits or by the project proponent or local project consultants.The In brief box inserted in every project brief provides an overview of the project, including the total emission reductions for the project’sbut is the best estimate of the total greenhouse gas emission reduction of the individual project. In The index the total expectedemissionreduction amount is listed alongside the amount contracted by the DEA.Please also note that the full name of the project, as it is described in its PDD may not correspond to the title of the project briefs.For the complete name see the index.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Denmark’s Joint Implementation/Clean Development Mechanism (JI/CDM) programme

Background

Denmark’s public JI/CDM programme supports climate-related projects in Eastern Europe and developing countries. Denmark initiated its JI programme in 2003 by redefining and building upon the Danish support programme for environmental projects in Eastern Europe, which was phased out as countries became members of the EU. The JI programme was administrated by the Danish Environmental Protection Agency. The CDM programme was initiated in 2004 with a focus on capacity building of national CDM institutions as well as support for project development. A specific budget was allocated for entering into contractual agreements for purchasing CDM credits. As with the JI programme, the new CDM programme built on the environmental support programme for developing countries with a focus on South-East Asia, and was administrated by the Ministry of Foreign Affairs. Since 2008, both programmes have been administered by the Danish Energy Agency.

JI/CDM Strategy

The Cost Efficient Climate Strategy was adopted by the Danish parliament in 2003, setting out the overall guidelines for prioritizing domestic versus international action to meet the Danish Kyoto target of reducing emissions in 2012 to 21 per cent below their level in 1990. Initially, in 2003, funds were allocated for Government procurement of JI credits, while CDM was included from 2004 and onwards. The quantity of credits to be purchased was set out in the national Allocation Plan defining the credit limits both for ETS operators and the Danish state based on the Commissions interpretation of the principle of supplementarity. Following the allocation plan, a common strategy for implementing the JI/CDM programme was published in 2007 and relates to the first Kyoto commitment period 2008-12. The Danish JI/ CDM programme is based on the overall aim to make a cost-efficient contribution to fulfillment of Denmark’s Kyoto obligations, through acquisition of GHG emission reductions from JI/CDM projects, combined with four strategic goals: • To contribute to global climate protection through sustainable climate-related projects in Eastern Europe and developing countries• To promote sustainable development in developing countries and Eastern Europe via transfer of technology and capital, social development and capacity building• To compensate for CO2emissions related to COP-15 and government flights• To support Danish industry in the form of facilitating JI/CDM credit purchases by companies covered by the EU ETS, and to promote the export of Danish technology and know-how to JI/CDM projects.The JI/CDM programme has been based on the government’s participation early on during project development through a close cooperation with project participants, local and national authorities, etc. The Danish government has refrained from purchasing secondary credits in order to ensure compliance with sustainability criteria for carbon credits and inclusion of Corporate Social Responsibility criteria in the carbon contracts.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

An important aspect of the Danish JI/CDM programme is to ensure long term environmental, social and financial benefits for communities hosting the projects. From the initial project screening to the actual project implementation the programme aims at providing all-round solutions in the Danish tradition of social responsibility. The JI/CDM projects in the Government’s portfolio often create positive spin-offs, such as reducing air pollution, new jobs, better land use, improved water quality, improved health and safety and reliable, cost-effective energy supply. When engaging in projects the Danish Energy Agency prioritises the long-term sustainability of JI/CDM projects, and most activities are planned to last beyond the JI/CDM lifespan. In practice, this means that apart from the sales of CO2 credits, additional forms of income are built into most of the projects.

Sustainability

About the portfolio

Sourcing of new projects has changed significantly during the last 1-2 years, as we are closing in on 2012. Until recently, the DEA predominantly developed its own projects using consultants for the PDD work and based on the Danish Government’s extensive network in a number of host countries, as well as proposals received through tenders and an open door policy. Today almost all new projects are acquired through brokers and intermediaries who offer projects that have been developed to a more advanced stage or by bidding on projects that are on offer in the market. The reason for this shift is obvious: there is no longer time to develop new projects from scratch if credits should be issued before 2012. However, it is still a prerequisite for DEA to be able to track the projects and perform own due diligence before contract signing, checking that they are in compliance with important portfolio criteria:• Projects must be consistent with UNFCCC guidelines, modalities and procedures and be consistent with relevant national criteria and laws of the host country• Projects must be eligible under the EU ETS, which with one exception has excluded forestry projects from the portfolio• Priority is given to projects in Asia, Africa and Eastern Europe• Preference is given to renewable energy and energy efficiency projects but projects are not limited to these sectors• Projects must make use of proven technology. The use of Danish technology is not compulsory, but where Danish equipment or know-how can make a cost-effective difference to a project, DEA will advise on its use• Projects should meet standard viability criteria and adhere to the 10 principles of the UN Global Compact• Payments for ERUs/CERs are predominantly made against delivery in the Danish registry, with up-front payment to a maximum of 50 per cent being possible on a case by case basis and against a bank guarantee from a bank acceptable to DEA• Generally, DEA requires seniority on generated credits, the ERPAs include a sweeping clause, and DEA should have the option to buy any additional credits that may be generated from the projects• Preference is given to projects that deliver above 100,000 pre-2012 creditsAlso the DEA programme does not include HFC and large hydro. N2O projects need to include a greening element demonstrating that the proceeds from sales of carbon credits are invested in environmental improvements at the industry. Also, DEA does not buy AAUs except if these are backed by one to one verifiable emissions reductions in the form of early credits from JI projects from which DEA also buys ERUs or in the stand-alone case of the New Zealand permanent forestry scheme.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

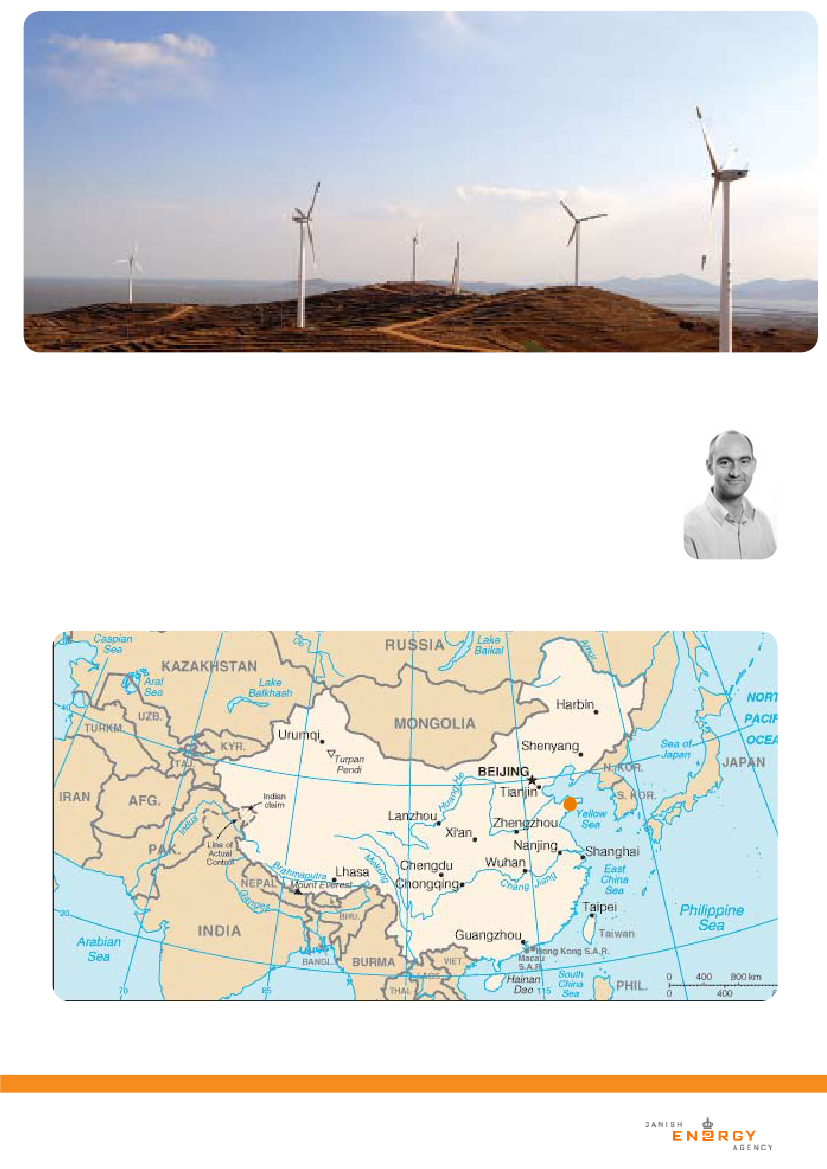

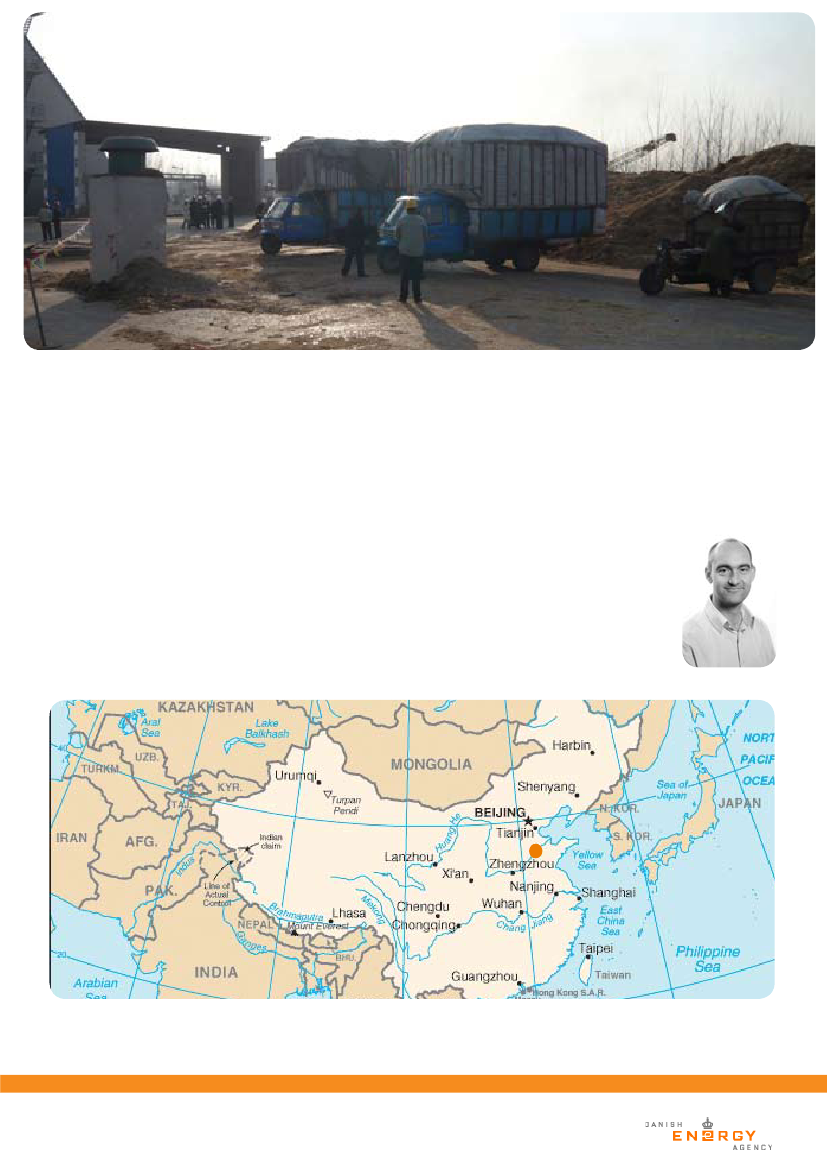

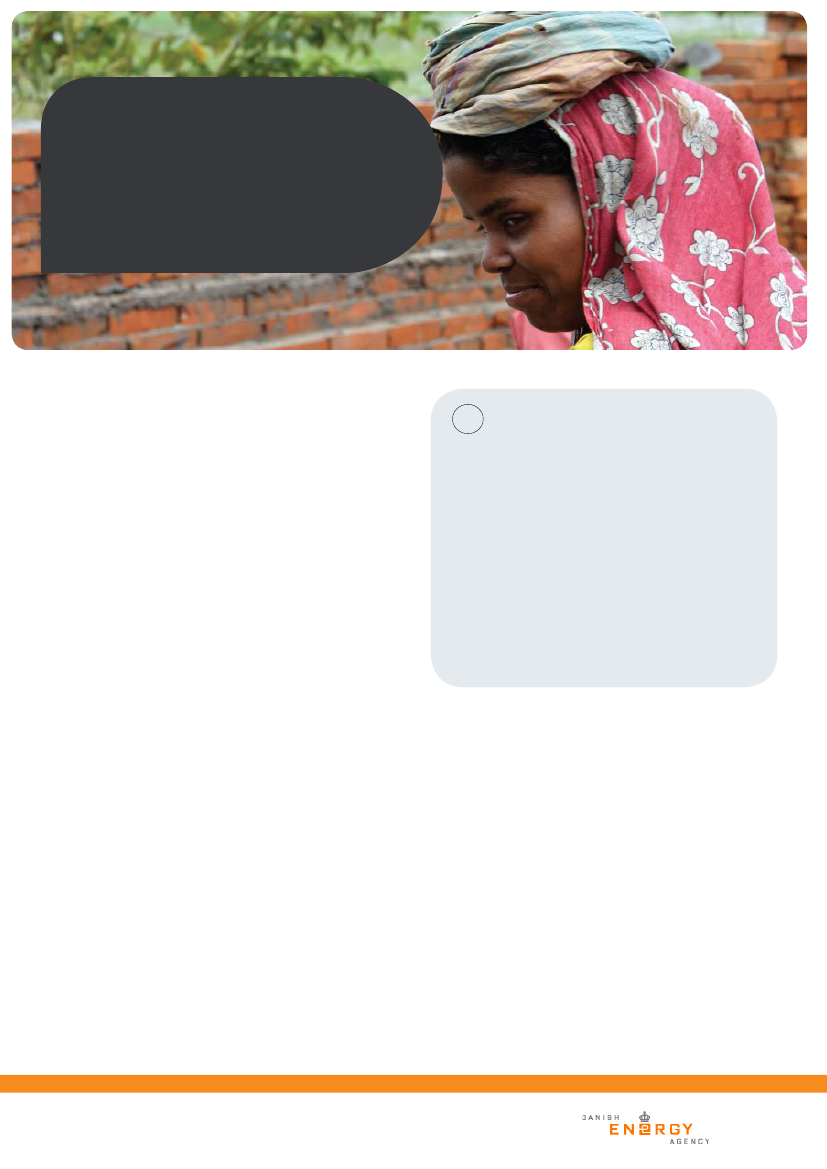

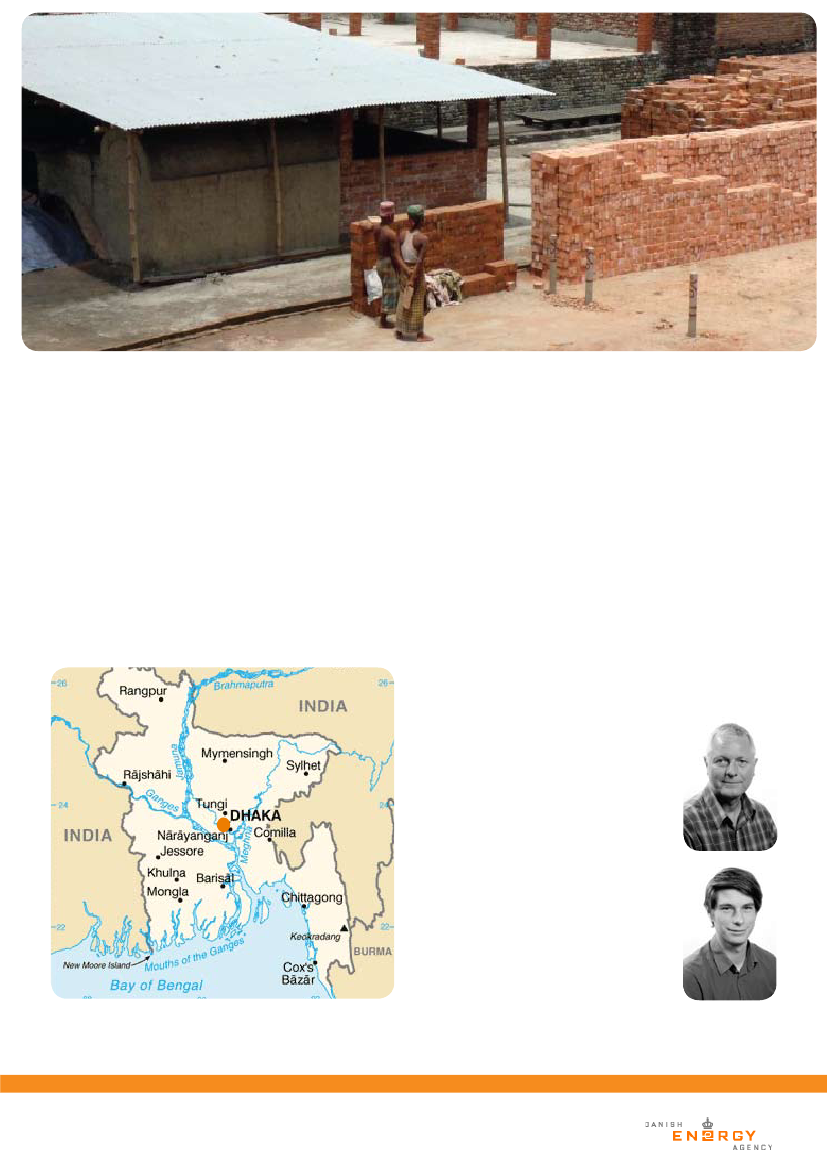

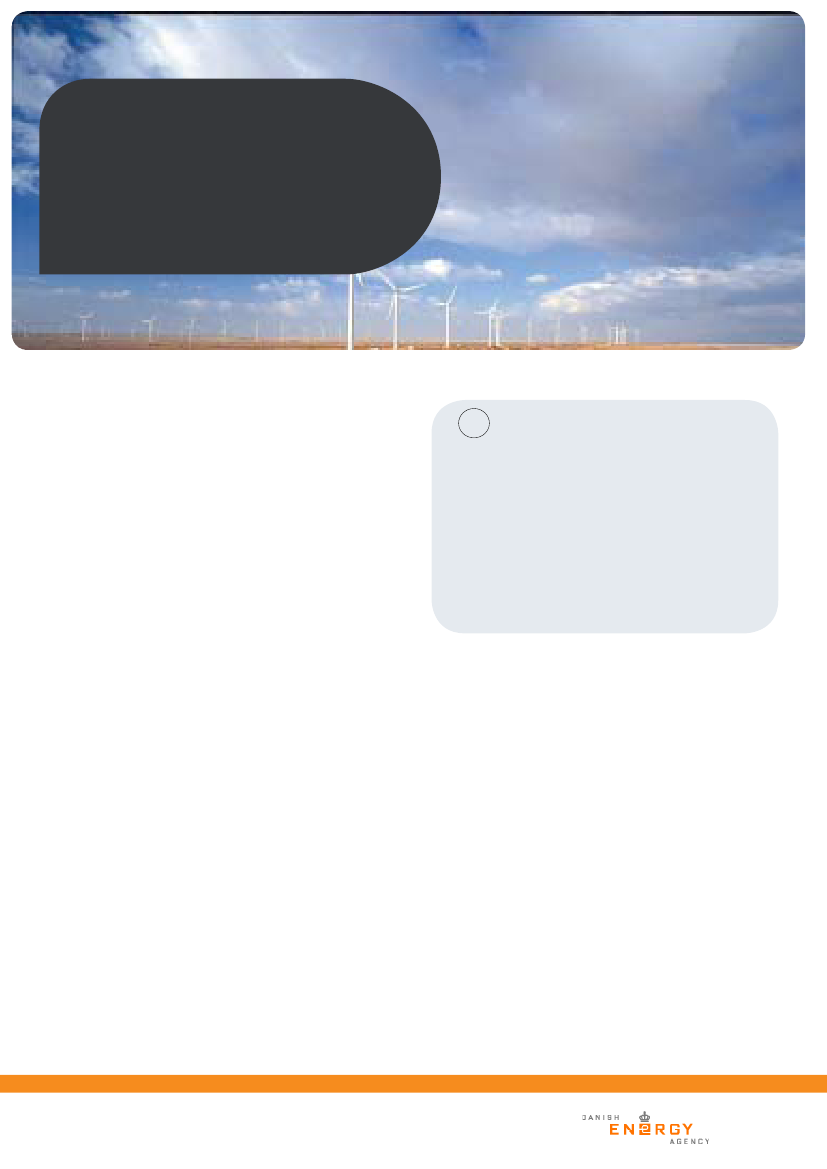

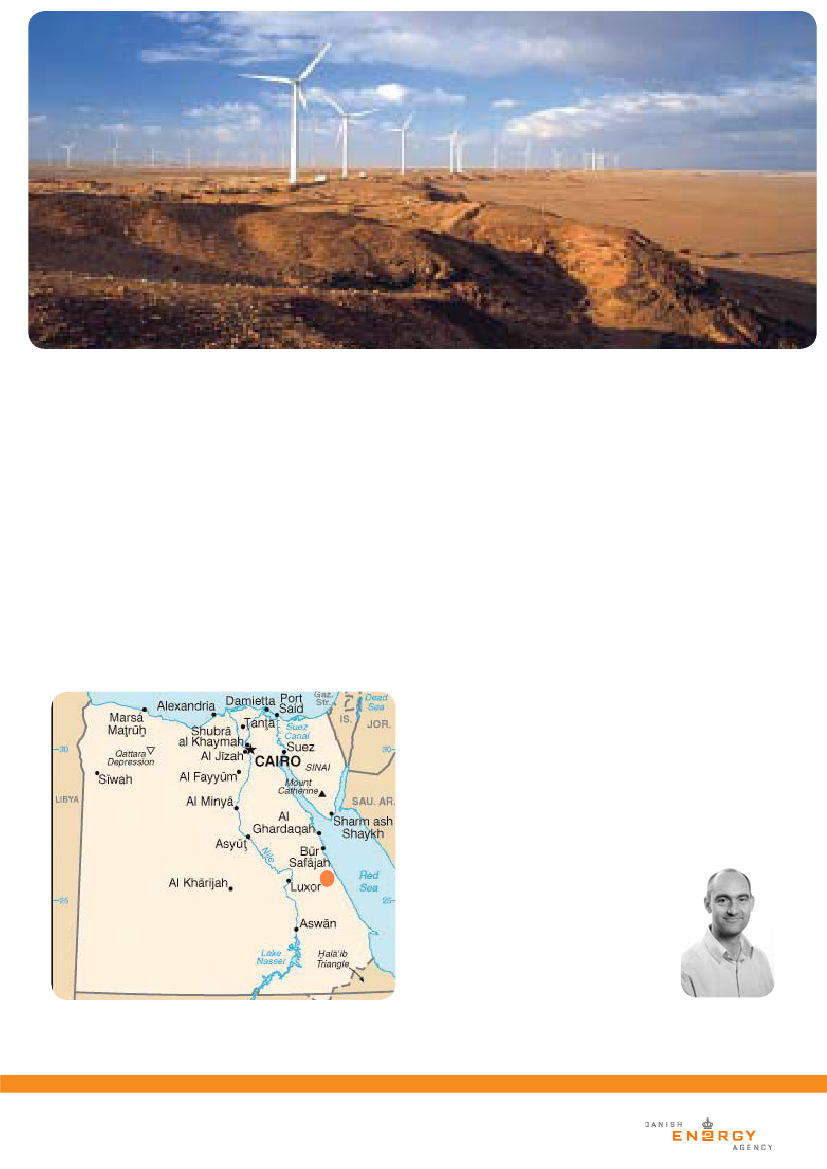

The history of environmental support explains the geographical focus of the DEA programme, South-East Asia and Eastern Europe, which is atypical to the average global distribution of projects. So far the DEA has had no presence in Latin America, a comparatively low presence in India, but a number of projects in China and relatively many JI/European projects. This tendency is, however, changing as DEA is now buying mature projects from project developers; India is among the new focus areas. Almost 75 per cent of the JI /CDM projects in DEAs portfolio are from renewable energy projects, especially wind, biomass and biogas reflecting Danish technological expertise. Another 14 per cent of the projects are energy efficiency and fuel switch projects. It should be noted that when looking at contracted volumes instead of number of projects, only 68 per cent come from these three sectors, as the industrial gas projects are usually very large projects. This is also the case on a global scale. Via the JI/CDM programme, the Danish state offsets all air-travelling of government employees. A credit amount corresponding to 130,000 tonnes CO2 will be cancelled in order to compensate for the emissions from air-travelling in the period 2008-2011. Also the Danish state has decided to compensate the emissions caused by the transport of COP15 delegates. This is done through a project in the Bangladeshi brick sector where new efficient and environmentally friendly brick kilns are build, and thereby replacing the traditional and highly polluting technology. The project will cut 100,000 tonnes of CO2 emissions each year and improve air quality in one of the world’s most polluted cities. Also investments in fundsDEA participates in the Danish Carbon Fund (DCF) together with private investors. The fund is administrated by the World Bank. Funding criteria mitigate climate change and promote sustainable development. A share of 3.8 per cent of the funds capital is invested in the Community Development Carbon Fund (CDCF) with the aim of supporting carbon finance to projects in the poorer areas of the developing world that combine community development with emission reductions. Also the DEA participates in the two Nordic funds run by NEFCO: the Testing Ground Facility focusing on projects in Eastern Europe and Russia, and the NEFCO Carbon Fund with a broader geographical scope.

Organization and cooperation

The Danish Energy Agency is responsible for the implementation of the Danish credit programme under the authority of the Ministry of Climate and Energy. Currently, the programme employs team project managers in the Danish Energy Agency comprisingeconomists, legal experts and engineers supplemented by local project co-ordinators normally based at the Danish embassies in the main host countries. This approach ensures that DEA has a day-to-day contact with project owners, relevant authorities, validators and other stakeholders. The vast majority of time and responsibilities are directly related to procurement (from initial project development and ERPA signing, through validation to monitoring, verification and issuance of credits); however the JI/CDM team in the DEA is also involved in policy development, service to theparliament, EU issues and international negotiations which have a direct link to the carbon market and other related issues.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

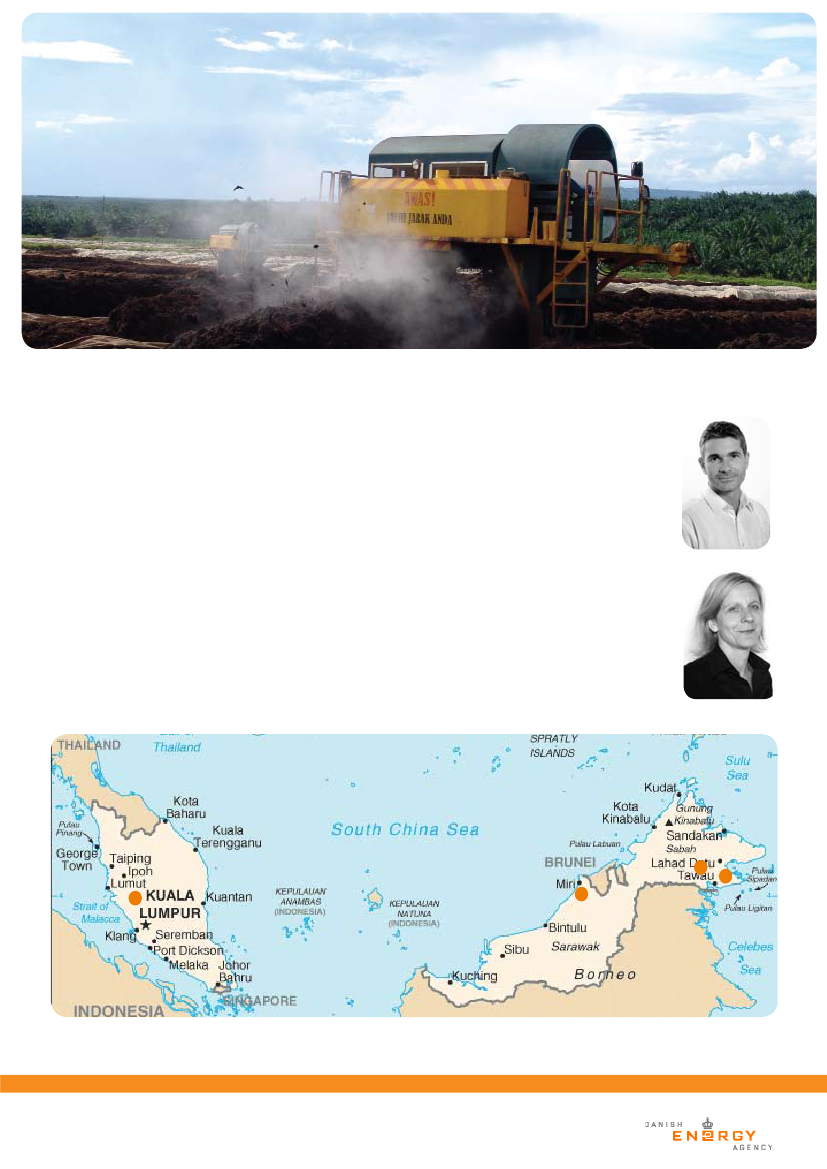

CountryProject NameCDMThailandThailandThailandThailandThailandThailandThailandMalaysiaMalaysiaMalaysiaMalaysiaMalaysiaMalaysiaMalaysiaMalaysiaChinaChinaAdvance Bio PowerBua YaiNatural Palm Oil Company LimitedNortheastern StarchRatchaburiSima 1-5South Thailand biogas no. 1 - 5Brite TechGolden HopeLumutMalaysian Newpaper IndustriesSouthern Waste SeelongUnited Plantations 1 - JendarataUnited Plantations 2 - BerhadUnited Plantations 3 and 4Gansu GuazhouHebei Weichang Yangshugou,Hebei Zhangbei Baimiaotan,Hebei Weichang DishuihuFujian Putian Nanri Phase IIIShandong Haiyang QiuershanShandong ShanxianShenyang DaxinSongshan Waste Heat RecoveryZhejiang Zhoushan CengangYantai Dongyuan LaizhouKencanaPinagoBrick KilnZafaranaLusakertPig farms

Total estimated emissionreduction due to project activity inpresent registration period (tonnesCO2e)TechnologyBiomassBiomassBiomassBiomassBiogasBiogasBiomassBiomassBiomassBiomassBiomassLandfill gasBiomassBiomassBiomassWind powerWind powerWind powerWind powerWind powerBiomassLanfill gasEnergy efficiencyWind powerWind powerBiomassBiomassEnergy efficiencyWind powerBiogasBiogas230,000195,000115,000150,000345,0001,000,000765,000800,000700,000199,000740,000750,00062,000175,000330,0004,400,0002,250,000

Contracted be-fore 2013by the DEA(tonnes CO2e)

112,00094,00038,00064,000251,000763,000292,000150,000227,000199,000160,000233,00052,000130,00070,000800,000400,000

ChinaChinaChinaChinaChinaChinaChinaIndonesiaIndonesiaBangladeshEgyptArmeniaCyprusJI ProjectsRomaniaRomaniaRomaniaRomaniaRomaniaPolandPolandPolandPolandPolandBulgariaBulgariaBulgariaRussiaRussiaRussiaRussiaCzech RepublicUkraineNew Zealand

810,000218,000890,0001,050,000999,000522,000664,000569,000676,000930,0001,468,000377,000405,000

165,00095,000630,000330,000200,000105,000300,000102,000135,00060,000600,00070,000151,000

Holboca CET II IasiTargu MuresSawdust 2000Oradea and BeiusTurnu-SeverinLubnaMazurskiePoldanorZagorzeZakopaneAgropolychimBourgasPleven and Veliko TarnovoAmurskSouthwest Leningrad OblastKirov RegionPriozerskLovochemieOdessa GasPermanent Forest

Energy efficiencyLandfill gasBiomassGeothermal energyEnergy distributionLandfill gasLandfill gasBiogasWind powerLandfill gasEnergy efficiencyEnergy efficiencyEnergy efficiencyEnergy efficiencyEnergy efficiencyBiomassEnergy efficiencyEnergy efficiencyEnergy efficiencyAfforestation/Reforestation

131,00078,000456,000191,000335,000622,000598,000750,000477,000127,0002,300,000470,000977,000400,000340,0001,400,000150,0004,300,0007,100,00022,000

132,00078,000456,000191,000335,000400,000598,000708,000405,000127,0002,300,000470,000977,000400,000145,000320,00081,0001,700,0001,260,00022,000

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Clean DevelopmentMechanism (CDM)“The CDM allows emission-reduction (or emission removal) projectsin developing countries to earn certified emission reduction (CER)credits, each equivalent to one tonne of CO2. These CERs can betraded and sold, and used by industrialized countries to a meet apart of their emission reduction targets under the Kyoto Protocol”

UNFCCC homepage – about CDM

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

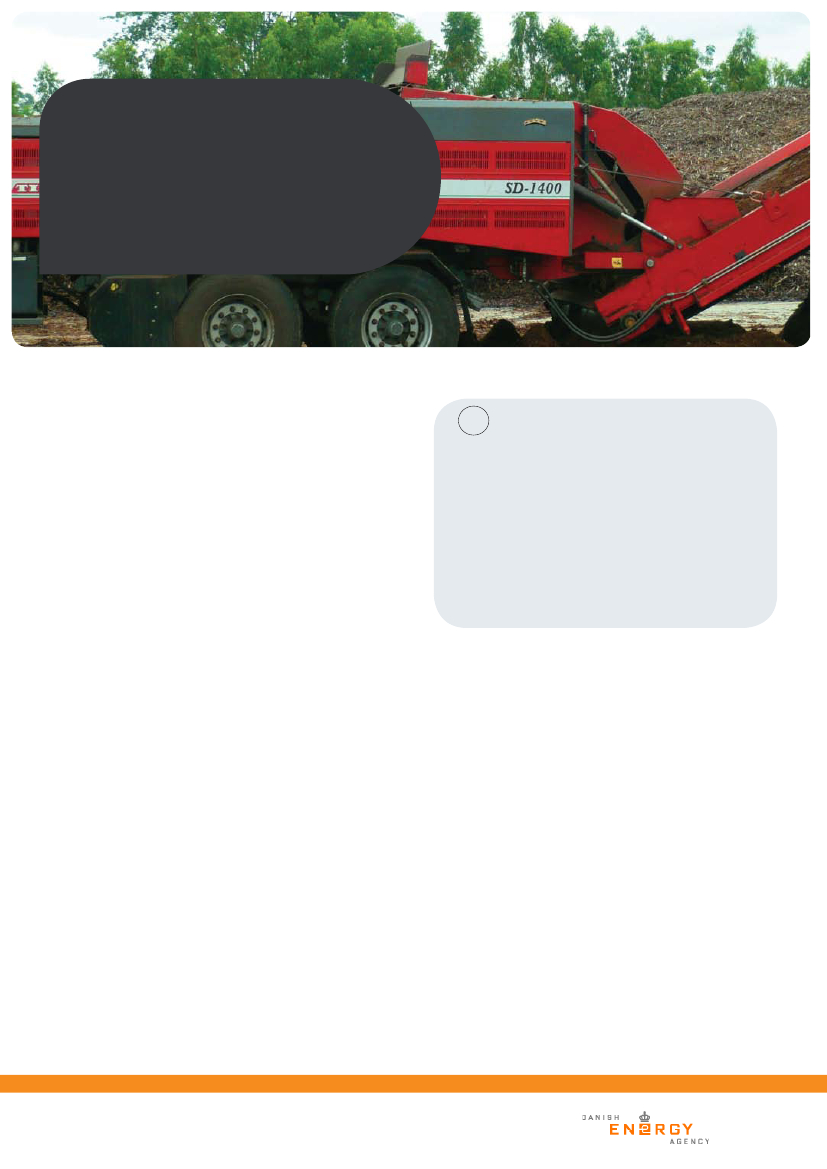

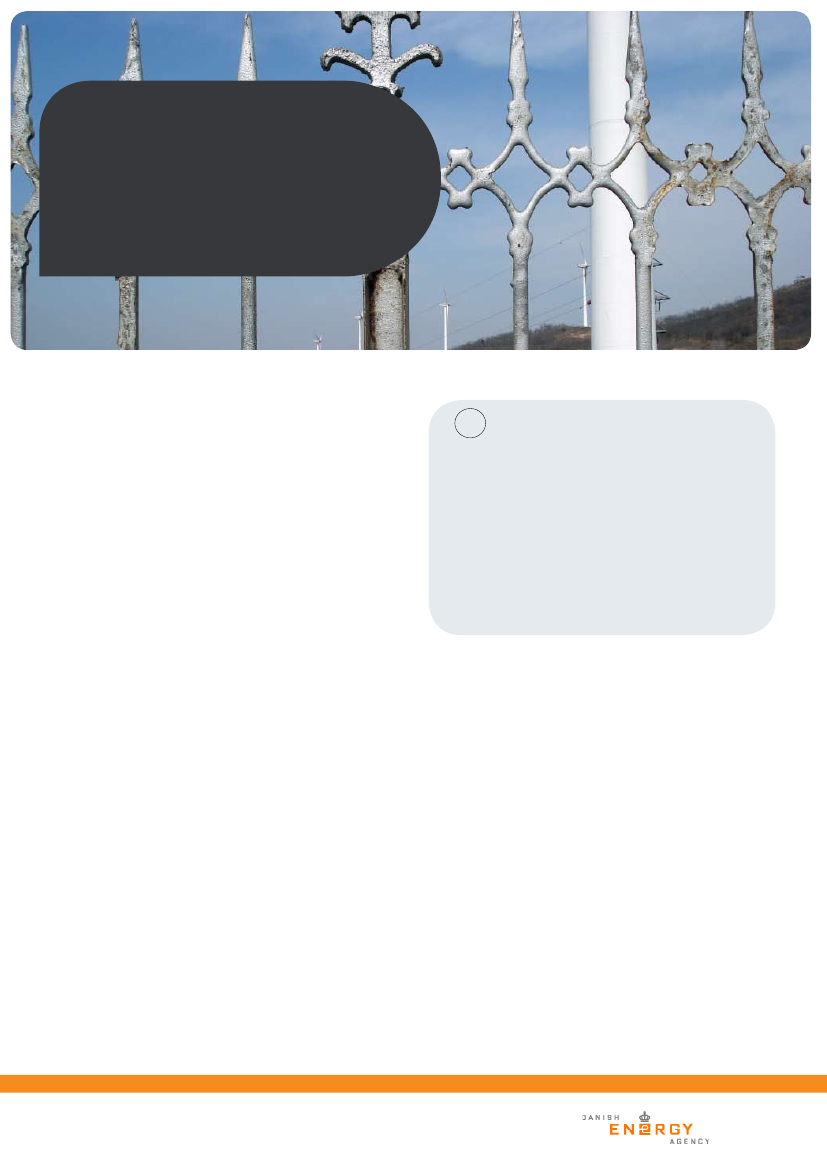

Advance Bio-PowerGreen electricity fromeucalyptus bark in Thailand

Electricity generation from eucalyptus bark residues contribute a small but important step in the struggle against climate change.

The long tradition for cooperation betweenThailand and Denmark also includes climatemitigation. A bio power project using residuefrom Eucalyptus trees, presents a new waytowards green electricity andsustainability.

i• • •

Advance BioPower in Brief:

The Idea

The eucalyptus tree grows quickly and it is well known as a source of fuel and oil. It is often used to drain swamps to reduce the risk of malaria. In Thailand, the tree is also used by the paper industry as a source of cellulose and for the production of bio fuel. As early as 1969, Danida assisted an eucalyptus plantation project in Thailand. The Danish involvement in Advance BioPower marks yet another offshoot in longterm Danish - Thai development cooperation andclimate change mitigation.

of 230,000 tonnes of CO2 equivalents

fuels • Introduces a new green technology in Thailand• Reduces GHG emissions by an estimated total

Became one of the first electricity plants in Thailand to use eucalyptus bark residuesUses residues in the form of wood chips and barkGenerates electricity for the Thai power grid where it displaces electricity produced by fossil

drives a turbine - it is difficult to control the combustion. So support to facilitate technology and knowledge transfer as well as financial security was needed to promote investment in the green technology and tocapitalise CO2 reductions.This assistance was provided by the CDM mechanism, which generates the additional revenue for investors, convincing them to accept the greater risk associatedwith installing equipment which only few local technicians can repair and which even fewer have theexperience to operate. Therefore, the implementation of the project leads to a need for training and capacitybuilding amongst local engineers and tradesmen making the process more expensive. In this, the Advance BioPower project is a true pioneer and demonstrates a way to accelerate transfer of newgreen technology and knowhow to countries such as Thailand.

The Project

The Advance BioPower project involves the construction of a new power station for carbon-neutral electricity production to supply the people of Thailand’s eastern provinces. The tree-processing industry of the Burirum province is located in northeastern Thailand between forest-covered, extinct volcanoes. A large share of factories in the area has bark and wood chips as residue products. Collecting these residues provides fuel to produce green electricity at the new power station. Green energy can be a risky investment. Although the method is well-known - a boiler combusts wood chips to produce heat which

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Wood chips and bark residue from eucalyptus trees is now used for electricity generation.

Everyday Benefits

About 36,000 hectares of Thailand’s 94,000 hectares The project provides a number of advantages for the eucalyptus forest is in northeastern Thailand and many environment and the local community: The transfer of the trees are used for paper pulp. Thepotential forof skills to the local workforce and the environmentalusing wood chips and other wood residues for green gainsas a result of the substitution of fossil fuels, energy production is therefore substantial, provided the namely lower SO2 and NOx emission and less soot and technology gains a firm foothold. Hopefully, this CDM ash around power plants. project will work as inspiration for similar initiativesthroughout Thailand.

Future Prospects

The introduction of electricity generation from biomass using eucalyptus bark residues will contribute to a small but important step towards climate mitigation. It will supply Thailand with domestically produced green energy, thereby strengthening Thailand’s energy independence and reduce energy imports.

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788The tree-processing industry of the Burirum province is located in North-eastern Thailand between forest-covered, extinct volcanoes.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Bua Yai

From rice to clean,climate-friendly energy

The Bua Yai Bio Power project utilises rice husks as a fuel to generate electricity in a biomass-fired steam power plant.

Rice is essential for the Thai society. Forcenturies the rhythm of rice production hasdominated the rhythm of society, not leastfeasts and celebrations. Today, rice is animportant industry. At Bua Yai Bio Power innortheastern Thailand, the CDM system hasmade use of rice husks to produce greenelectricity possible. Rice husks are a wasteproduct from rice processing, and an abundantsource of biomass. The project illustrates theenormous potential for biomass energy inThailand and how the CDM system can helpfinance it.

i

Bua Yai in Brief:

• Utilises rice husks, a residual product of rice production• Generates up to 6.7 MW green electricity for the Thai power grid• Launches innovative use of a waste product from Thailand’s most important export sector• Assists Thailand to become less dependent on fossil fuels• Demonstrates the potential of the CDM system• Reduces GHG emissions by an estimated total of 195,000 tonnes of CO2 equivalents

The Idea

Historically, rice has been the dominant source of food in both Thailand and the rest of Asia. Rice is a basic ingredient in a plenitude of dishes and is used in many innovative ways. However, a small part of the fully ripened rice, the husk protecting the individual grain, has not previously been utilized.The Bua Yai Bio Power project utilises rice husks as a fuel to generate electricity in a biomass-fired steam power plant. The rice husks mainly come from local rice mills.

gasses are reduced by utilising a waste product from rice processing as green fuel.

Everyday Benefits

The factory treats water for use at the power plant, and treated surplus water is donated to monasteries and others without access to clean drinking water.The ashes from the rice husks combustion contain silica. Silica is a natural product, that can be used as input in cement production as substitute for other energy demanding inputs.

The Project

The plant at Bua Yai consumes 220 tonnes of rice husk a day, and the electricity produced displaces electricity based on fossil fuels. The majority of the electricity pro-duced at the power plant is sold to the national electricity grid. In this way, emissions of greenhouse

Future Prospects

Thailand’s rice production is enormous. Around nine million hectares of paddy-fields produced around 30 million tonnes of rice, primarily jasmine, in 2006. With a production of this size, and as the world market leader,

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

The plant at Bua Yai consumes 220 tonnes of rice husks a day, and the electricity produced displaces electricity based on fossil fuels.

Thailand is centre in making rice production more environmentally sustainable. Harnessing energy from rice husks requires the installation of an entirely new and expensive biomass plant which rice mill owners have no experience inmanaging and operating. In this project, the CDM system provided additional financing, secured by the Danish purchase of carbon credits generated from GHG emission reductions. Thus, the potential of the CDM system for overcoming financial barriers to implement green but costly technology, is demonstrated. Hopefully, this will inspire

similar initiatives in Thailand and the wider region. Thailand’s goal is to have eight per cent of its energyconsumption covered by renewable sources in 2011, and to develop an economy which is less dependenton expensive and polluting fossil fuels. With Danish assistance Thailand is a step closer towards this goal.

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788The Bua Yai project is located in the eastern part of Thailand.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Natural Palm OilSun, power and palm oil- the green way

Wastewater from a palm oil production plant is now treated with new technology.

A small CDM project in the same regionas many popular tourist destinations inThailand provides greener palm oil for localsand tourists, as well as for green electricityproduction. The foul odour from the palm oilmill has been removed, residual products arereused and Denmark is proud to assist themitigation of climate change.

i• • • • • • •

Natural Palm Oil in Brief:

The Idea

Southern Thailand is a popular destination for many tourists. The sun and the beaches draw tourists as well as adventure-seeking back-packers, travelling through the Surat Thani province. In the centre of this province, away from well-known and picturesque destinations such as Ao Nang Beach and Koh Lanta, is one of the Danish government’s smaller climate projects, theNatural Palm Oil project, situated in the midst of large plantations. Palm oil is an essential ingredient in Asian cuisine, both for the local communities and at the tourist resorts along the coast. However, palm oil is also being used increasingly as a nutritionally correct ingredient in many European food products.The production of palm oil has traditionally resulted in large quantities of wastewater in open lagoons, where the decomposed organic plant residues emitted substantial amounts of methane to the atmosphere. However, with Danish assistance the emissions have been heavily reduced, to the benefit of the environment, climate-change mitigation and the local community.

Replaces large foul-smelling lagoons with modern CSTR technologyUses methane from wastewater for electricityproduction replacing coal-based electricityTreats and reuses sludge and wastewaterFurthers Thailand’s move toward sustainable energy supply Introduces climate-friendly technology to the rapidly growing palm oil sectorIs one of the very first biogas projects in the Thai Palm Oil sector Reduces GHG emissions by an estimated total of 115,000 tonnes of CO2 equivalents

The Project

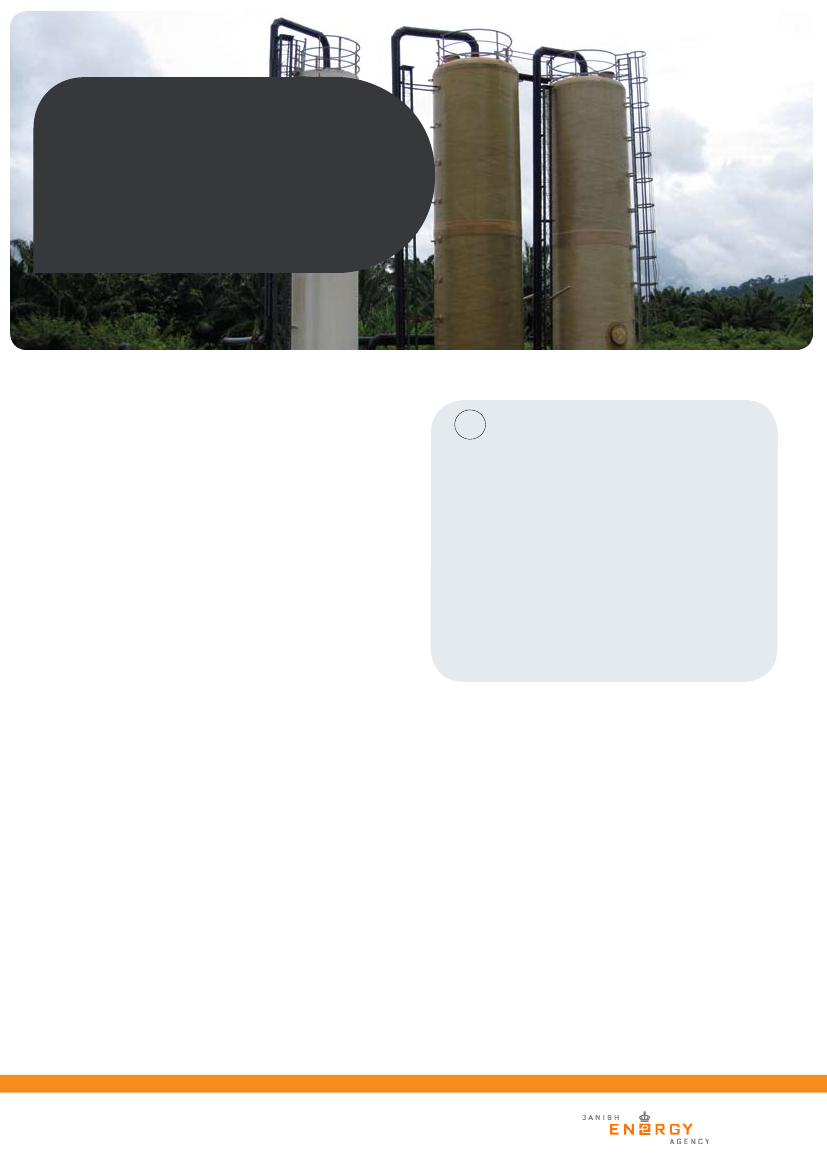

A new Complete Stirred Tank Reactor (CSTR) system is now installed at the palm oil mill. The system consists of five parts: a biogas tank, a compressor unit, a gas storage unit, a desulphurisation plant, and a 1MW gas generator. When the wastewater is sent through the CSTR system, the methane is collected in a controled environment and combusted to generate electricity. The reduction of GHGs equals 115,000 tonnes of CO2equivalents replacing fossil fuels with green and carbon neutral electricity.

Everyday Benefits

The CSTR system improves the quality of the wastewater, which is reused in the mill. The

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Palm oil plantation in southern Thailand.

closed lagoons have removed a breeding ground for flies and insects reducing health risks. This is combined with a reduction of foul odours in the surrounding community. In addition, the project assists Thailand in reachingits ambition of a sustainable palm oil sector and eight procent more renewable energy by 2011.

system. Sensible and climate-friendly development of Thailand’s palm oil sector is important to enhance thecountry’s future sustainability.The project demonstrates how climate-friendlytechnology and methods can be furthered by successful international cooperation. The use of the CDM system with Danish assistance has great potential in Thailandand the wider region.

Future Prospects

The Thai palm oil industry produced six million tonnes of oil in 2005, with annual growth rates of almost 10 per cent. However, fitting the palm oil mills with the CSTR technology means overcoming technological barriers and is still expensive, which emphasises the needfor the additional finance available through the CDM

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788Away from well known and picturesque destinations such as Ao Nang Beach and Koh Lanta, is one of the Danish government’s smaller climate projects, theNatural Palm Oil project.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Northeastern StarchOne project, three companiesand a lot less methane

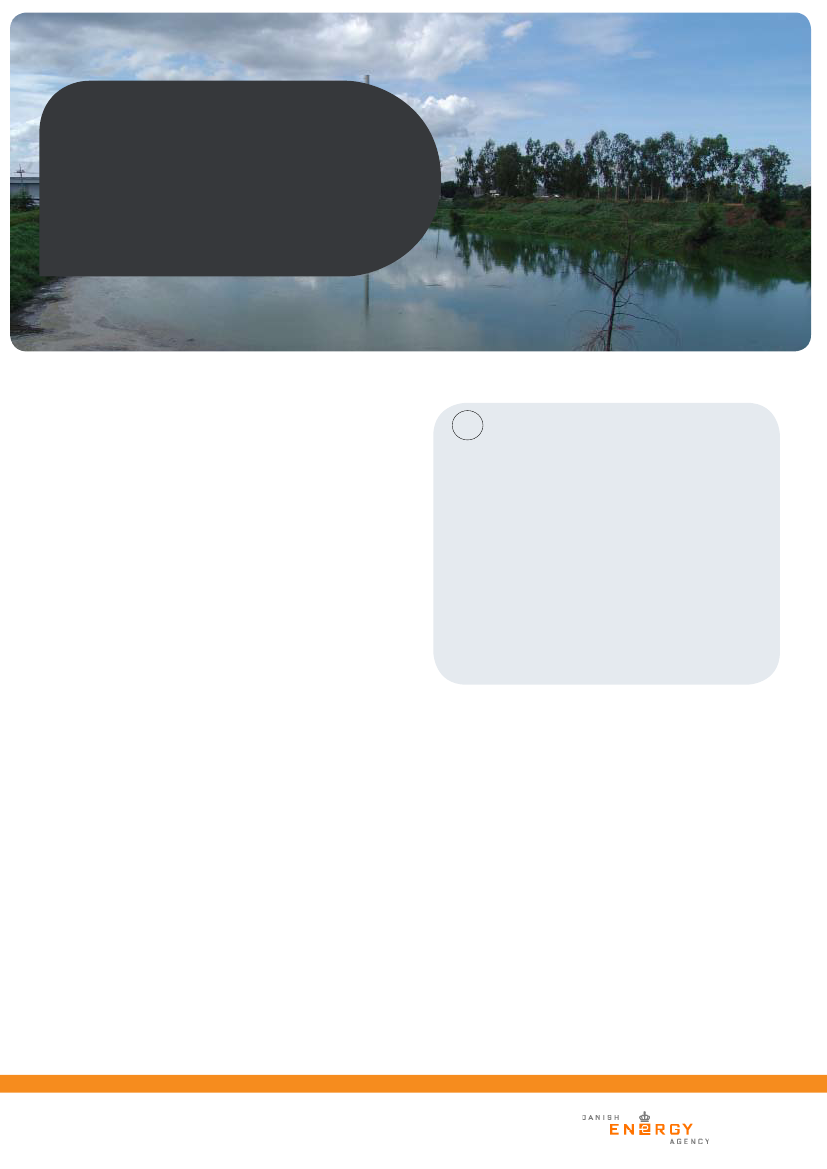

Today the wastewater from the starch plant is treated before it enters the open lagoons that used to store untreated, foul-smelling wastewater.

At a Thai starch factory, foul-smellingwastewater is now utilised for production ofheat and electricity while emissions of methanegas is reduced. Danish-Thai CDM collaborationhas made it financially viable to apply a newand energy-efficient technology, demonstratingthat energy improvements and climate changemitigation are complementary and goodbusiness.

i• • • • • •

Northeastern Starch in Brief:

The Idea

Nakhon Ratchasima is one of Thailand’s largest and most populous provinces. Agriculture provides jobs for most of the population and fields characterise the flat landscape. In addition to sugar cane and fruit, farmers cultivate large quantities of tapioca plants, the roots of which are used in starch production. And numerous starch factories are dotted around the region making Thailand the world’s largest exporter of tapioca starch, which isused in food products such as wine gums, cakes and beers. Starch production requires substantial amounts of water and North Eastern Starch (NES) discharges 2,200 m3of wastewater every day containing high concentrationsof organic material which releases methane as itdecomposes. Methane is a powerful greenhouse gas and was previously emitted to the atmosphere from large open lagoons around the factory. Today the wastewater is treated in modern tanks filled with plastic media on which a consortium of bacteria attach and grow as a slime layer or “biofilm”. The

Integrates a starch factory and two factories thatproduce activated carbon in a simple form of industrial symbiosis Treats and extracts methane from 2,200 m3wastewater per dayConverts methane to electricity, which displaceselectricity based on fossil fuelsSupports climate change mitigation measures in an essential and large industry Eliminates obnoxious odours and health problems originating from wastewaterReduces GHG emissions by an estimated total of 150,000 tonnes of CO2 equivalents

bacteria digest the organic content in the waste water and convert it into biogas. The methane content in the biogas is then collected and utilized.

The Project

The CDM project at the tapioca root factory in Thailandinvolves three factories. The NES starch factory uses electricity from two generators which combust the methane recovered from the wastewater. This substitutes electricity from the power grid, which is produced using fossil fuels. The process also produces heat, which is used by the the neighbouring factory Calgon Carbon Co., Ltd. to manufacture activated carbon: heat which the factory previously had to generate itself by burning fossil fuels with resulting emissions of greenhouse gases. Finally,

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

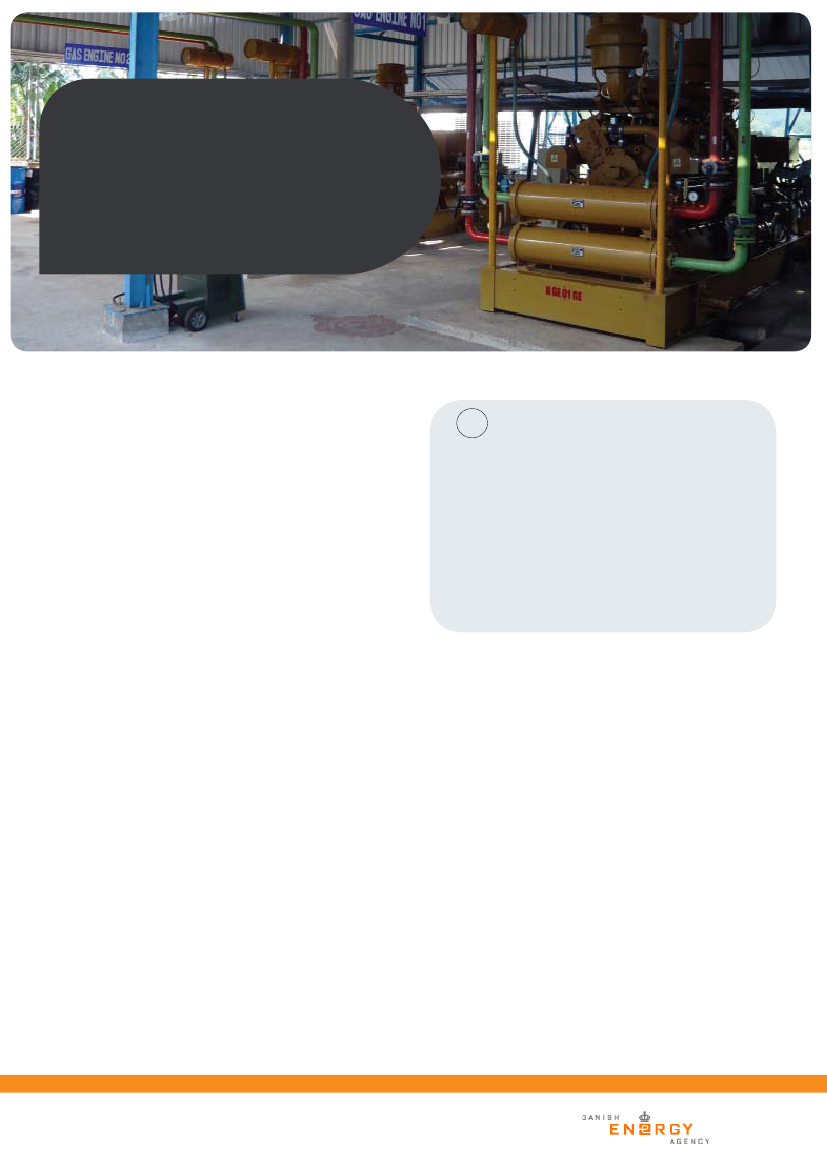

One of the tanks where bacteria digest the organic content in the wastewater and convert it to biogas.

part of the biogas produced at NES is also utilized by Gigantic Carbon Co., Ltd. in their co-generation power plant. The collaboration on heat and gas supply is a very simple form of industrial symbiosis, and will reduce GHG emissions by a total of nearly 150,000 tonnes of CO2equivalents over a ten-year period.

technology, the project has provided many new jobs for the local community.

Future Prospects

Everyday Benefit

As a result of the new method of managing wastewater, the large lagoons are no longer necessary and theodour problems for the workers at the factory, and the people living around it, have disappeared. The swarms of flies and insects attracted by the energy-rich stagnant water in the lagoons are also gone, as is the associatedhealth risk from the germs they carried. Building on local

Starch from the tapioca root is an ingredient in manyfood products, while more recent developed products include degradable plastic bags, indicating diverse future usage. This emphasises the need to make integration of energy saving and carbon mitigating solutions in starch production more common.The Thai government is well-aware of this and it issupporting the initiative, but it still requires CDM projects and assistance to make the investment possible for the numerous rural factories in Thailand. This CDM project is an excellent example of simple industrial symbiosis and works as a showcase for future climate-friendly projects.

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788

The project is located in the Eastern part of Thailand.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

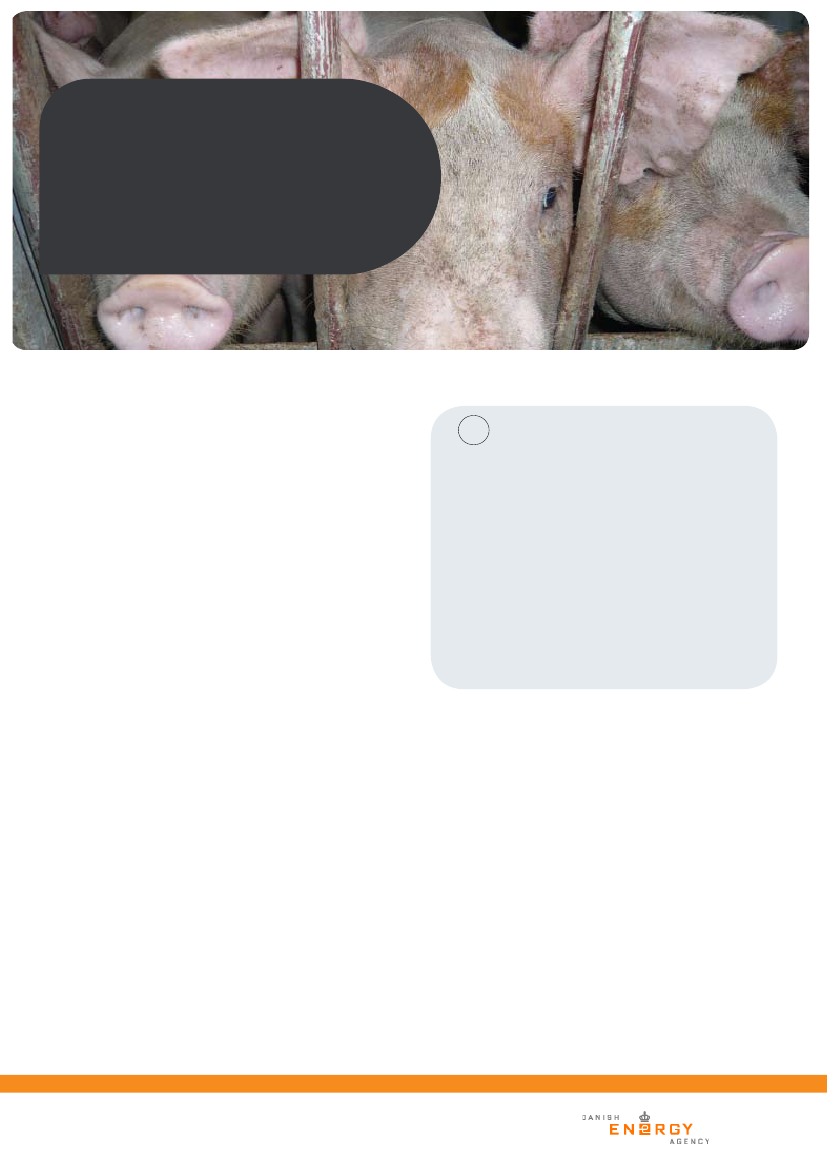

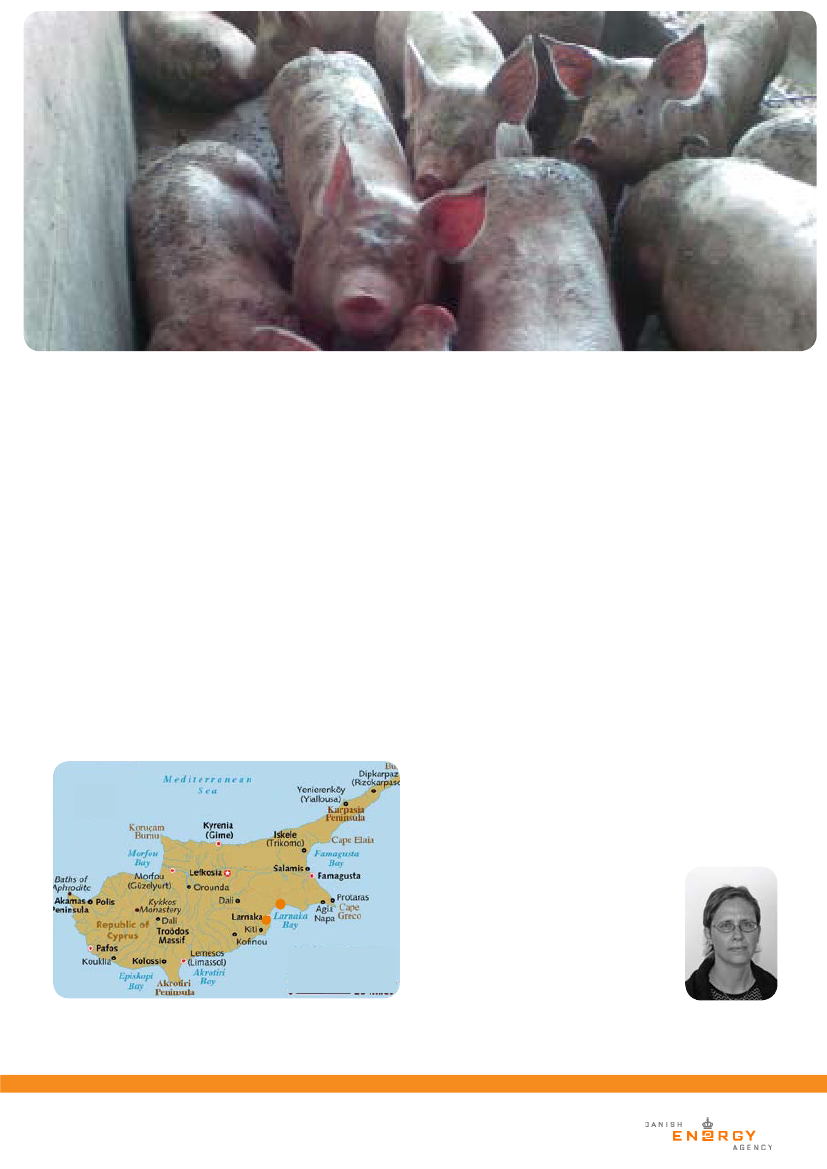

RatchaburiClimate-friendly improvementsat Thai pig farms

The Ratchaburi project involves three Thai pig farms with a total stock of 255,000 pigs, the pigs originate from a Danish breed.

At three Thai pig farms, Denmark has co-financed a slurry-biomass CDM project whichexploits methane gas for electricity production,recycles water and produces organic fertilizer.The project is an example of how intelligentindustrial conversion can promote climatechange mitigation and stop environmentaldegradation.

i

Ratchaburi in Brief:

The Idea

The Ratchaburi project involves three Thai pig farms with a total stock of 255,000 pigs. Wastewater from the slurry-sluicing pig sheds is treated in new biogas-recovery systems which capture methane gas from the organic material. Previously, the wastewater was stored in large open lagoons from which methane evaporated into theatmosphere. Using the new technology, the gas is now captured and burned in gas motors, which generate electricity for the pig farms.

• Is one of the first Asian Clean Development Mechanism (CDM) pig farm projects in Thailand• Uses an original Danish pig breed• Reduces the consumption of electricity from the primarily fossil fuel-based Thai electricity grid• Eliminates methane gas emissions• Generates organic fertilizer to replace chemical fertilizer• Treats and reuses wastewater for keeping the pigs cool using sprinklers• Reduces foul odour and fly nuisance in the area• Reduces GHG emissions by an estimated total of 345,000 tonnes of CO2equivalents

The project will benefit from Danish financial support through the CDM system without which the efficiency improvements would not have taken place. In this way, the project is a text-book example of how successful climate-friendly integrated industrial solutions are made possible through international cooperation.

The Project

The electricity generated from the biogas replaces electricity that otherwise would have been produced by burning fossil fuels, thereby reducing CO2 emissions. Moreover, electricity consumption is reduced as treated wastewater is sprayed into the sheds to cool downthe pigs in hot weather replacing energy intensiveaircondition. The wastewater is also reused to clean out the sludge from the sheds. Once the gas has been recovered, drained dry-matter from the wastewater isused as fertilizer by local farmers thereby reducing the consumption of chemical fertilizers.

Everyday Benefits

The project provides several advantages for theenvironment and the local community: treatment and reuse of wastewater, extraction of biogas for electricity production and production of inexpensive organic fertilizer for local farmers. Local farmers save money as the dry-matter fertilizerfrom the pig-farms is much cheaper than the chemical

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

The pig farms are situated in the Ratchaburi Province, where local farmers benefit from inexpensive fertilizer that is a by-product from treating the wastewater.

fertilizers, they previously used. Some of the fertilizer is also given to local schools, and used to grow vegetables for the children.

Future Prospects

The project is an example of how the CDM mechanismtrough international financial assistance and technology transfer can overcome barriers for climate-friendly interventions.It is expected that the technology will have anoperational life of 20 years. During this period the

pig farmers will become familiar with the application of biogas technology. Hopefully, this knowledge and experience will contribute to the wider integration of biogas technology on pig farms and in other sectors throughout Thailand. Integrating electricity production from waste products may very well become a key competition parameter for Thailand’s agricultural and industrial sectors in the future. For now, a showcase example of Danish-Thai CDM collaboration to mitigate climate change and environmental degradation is on display in theRatchaburi province.

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788The Ratchaburi project is located about 100 km west of Bangkok.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

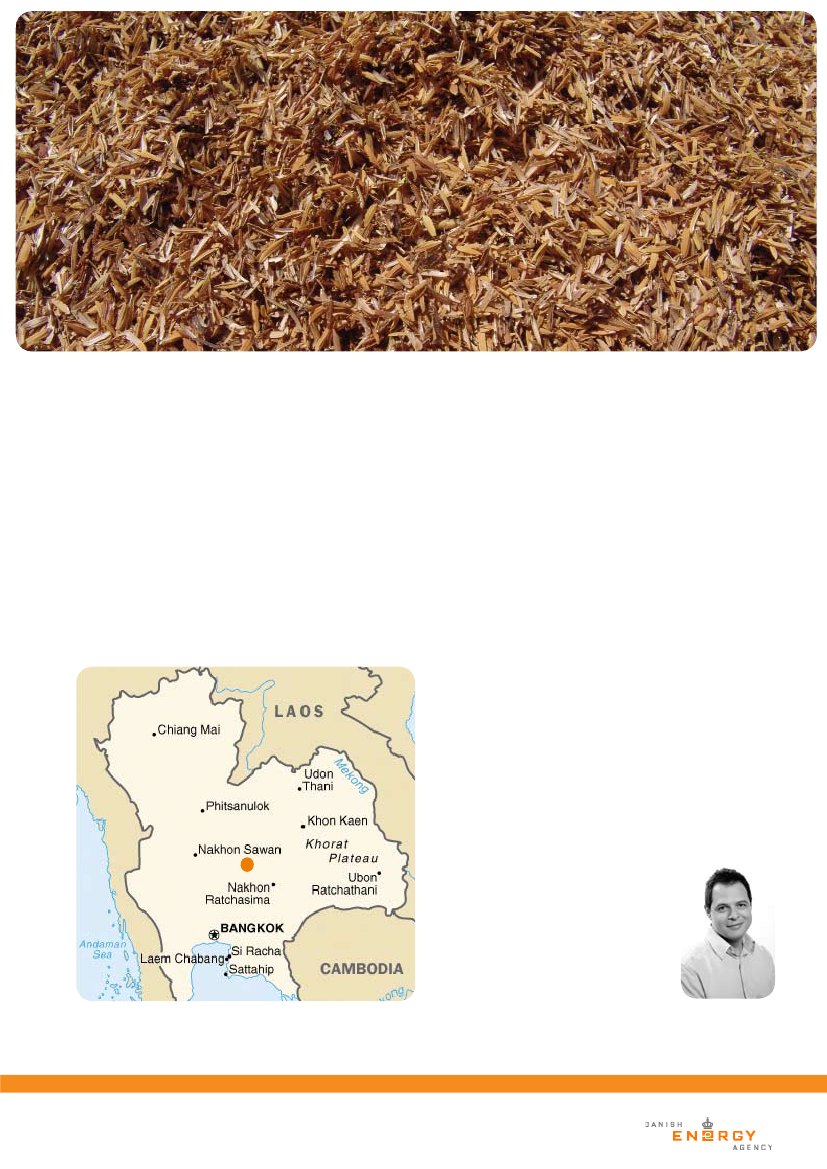

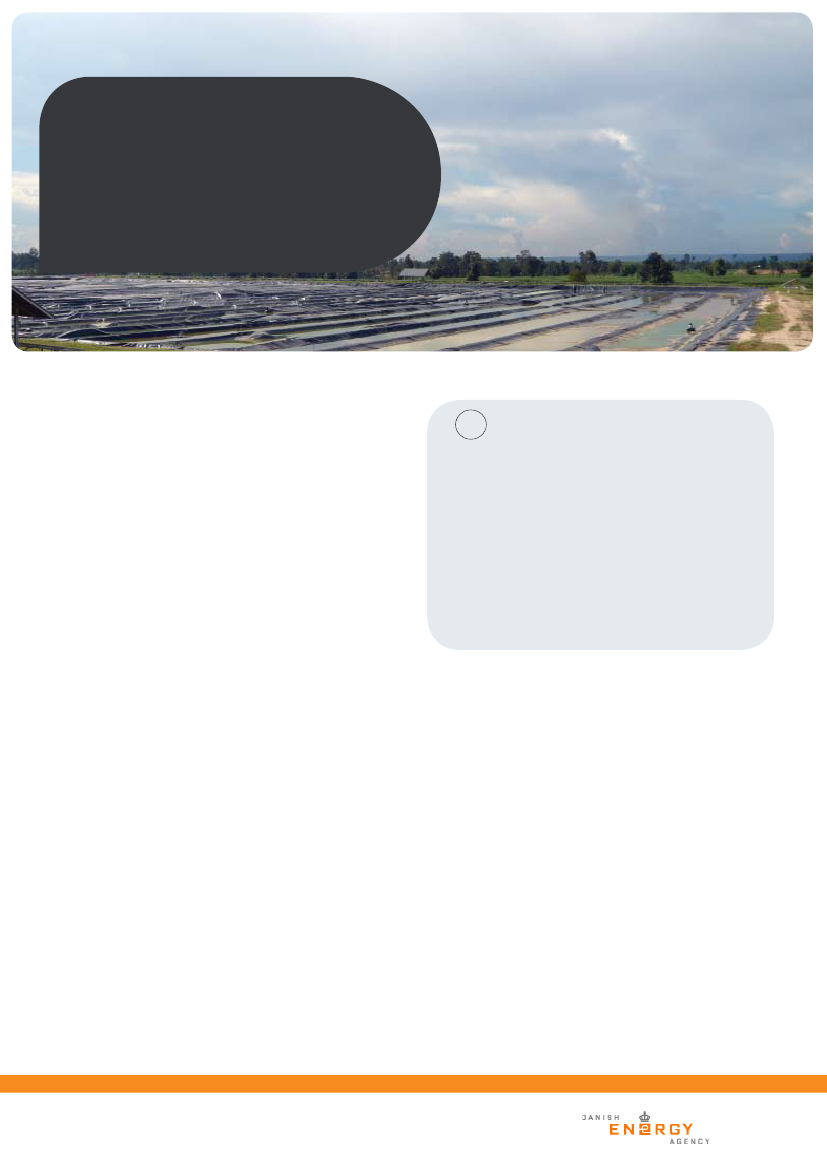

Sima 1-5

Great perspectives for climate-related projects in the Thaistarch industry

When starch decomposes in the open lagoons, it produces and emits methane, a potent greenhouse gas, to the atmosphere.

Thailand is the world’s biggest exporter ofstarch from cassava and tapioca roots. Thecountry also has an ambition for renewableenergy to make-up eight per cent of total ener-gy supply by 2011. At the starch factories (SimaInterproducts) five biogas-from-wastewaterprojects in eastern Thailand have been imple-mented with Danish assistance.

i

Sima 1-5 in Brief:

The Idea

Thailand is the world’s biggest exporter of starch from cassava and tapioca roots. Used in a wide range of products such as snacks, baby food, alcohol and noodles, the starch is a part of everyone’s life. It is extracted from the roots through a process which results in large amounts of wastewater with high concentrations of organic residues. When decomposing in large open lagoons, the residues produce and emit methane, a potent greenhouse gas, to the atmosphere. In a number of starch factories east and northeast of Bangkok, the Sima project developer,a local business man, has been the driving force behind five Danish assisted biogas-from-wastewater CDM projects.

• Consists of five small projects but similar projects• Introduces Upflow Anaerobic Sludge Blanket and Anaerobic Fixed Film Reactor technologies • Produces ‘green’ climate-friendly energy• Removes foul odours from open wastewater lagoons• Uses residue from the treated wastewater from the factories as fertilizer on neighbouring fields• Reduces GHG emissions by an estimated total of 1 million tonnes of CO2 equivalents

generators which produce heat and electricity. The electricity is partly used on site and partly sold on to the Thai electricity grid. In this way the projects secure GHG emission reductions in two ways. First, by removing the open lagoons from which large quantities of methane gas were emitted and, second, by replacing fossil fuel based electricity with bio-power. The visionary developer discovered early that the CDMsystem can be used to overcome the financial barriers that stop implementation of new, climate-friendlytechnologies in the Thai starch industry. As the main driver behind the five Sima projects, the developer is a living example of local capacity building and knowledge transfer. During the project development phase, assistance was also received from Denmark, which willacquire the generated CDM carbon credits.

The Projects

The five project starch factories are fitted with new technology which by recycling their bio-waste increases energy-efficiency and mitigates climate change. Thousands of cubic metres of wastewater is collected in new closed tanks where methane is degasified under controlled conditions. The methane is led to gas

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

One of the factories is situated amongst vast tapioca fields.

Everyday Benefits

The five projects have had significant positive impacts on the surrounding communities. By installing closed tanks for wastewater treatment, the large, open,foul-smelling and gas-leaking waste water lagoons, which used to be breading grounds for disease-carrying insects, have been drained. This has also reduced the risk of fire and explosions as the flammable gases are now treated in a secure environment. The new technology, which has partially been developed locally, required training of a great number of local factory employees. This has increased the

local knowledge-base on climate-friendly wastewater treatment.

Future Prospects

The projects will generate CDM carbon credits over a ten-year period: however the installed technology has alifespan of at least 20 years. Through the five projects, Sima Interproducts business group has gained valuable experience in using the CDM system to overcome financial barriers to installation of new green technology. Inspired by the Sima projects, others factories will hopefully implement similar improvements to increase energy-efficiency and mitigate climate change.

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788The starch factories in the Sima projects are located in the eastern part ofThailand.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

South ThailandBiogasSmall-size palm oil mills madeclimate-friendly

New technology provides small size palm oil mills with independent electricity generation.

A number of small palm oil mills, mostly fa-mily run, have become more climate-friendlythrough the use of new technology. The tech-nology would have been too expensive forthe small mills, without the income from CDMcarbon credits. Denmark plays a key role inproject development and by contracting CDMcredits.

i

South Thailand Biogas in Brief:

The Idea

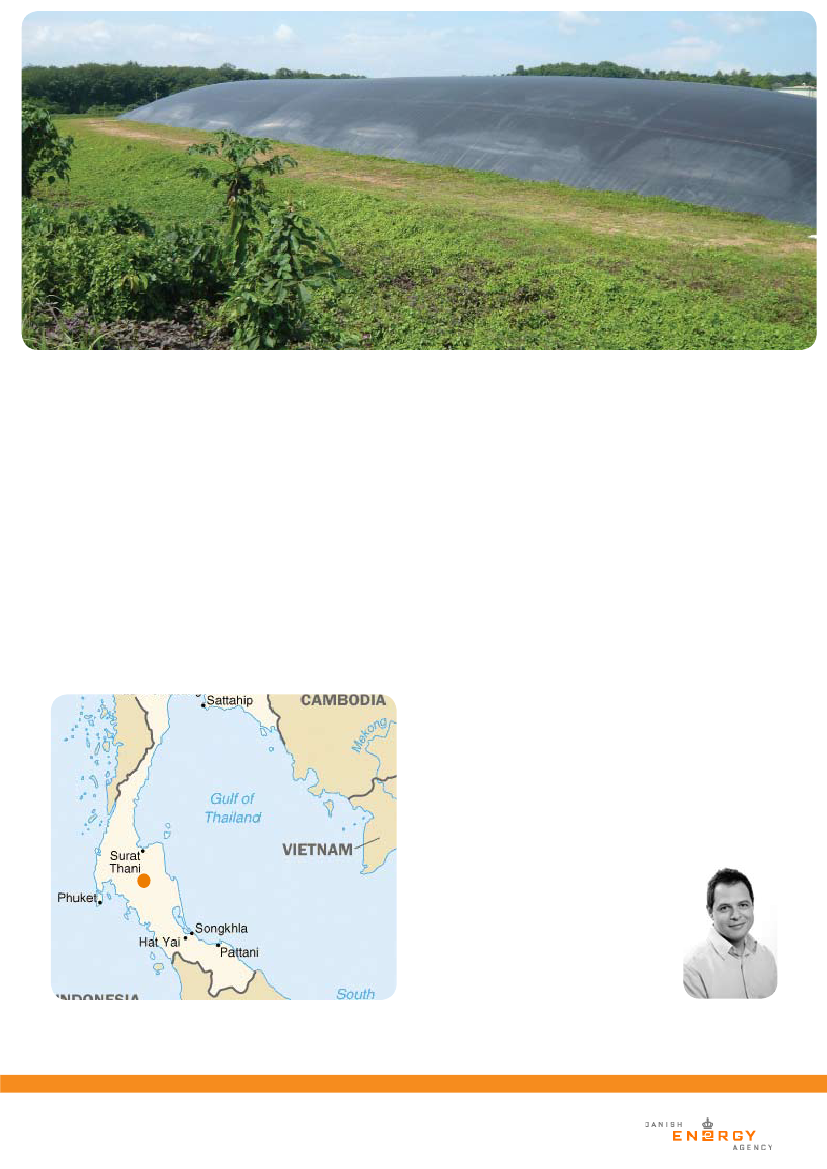

The rainforest spreads out between well-known holiday destinations such as Krabi, Phuket and Phi Phi on the Malacca peninsula which makes up the southern part of Thailand. Inland, palm trees are cultivated in plantations for palm oil production.This production generates large quantities of wastewa-ter. Previously, the wastewater decomposed in open lagoons under oxygen-free conditions creating methane - a potent greenhouse gas which escaped into the at-mosphere adding to the global climate change. Although there are actually several small individual (but similar) projects, they are described here as one.

• Reduces large amounts of methane emissions - a potent greenhouse gas• Provides the mills with an independent electricity generation• Using the CDM mechanism to make investments in new technology feasible• Assists Thailand in achieving their goal of 8 per cent renewable energy by 2011• Reduces GHG emissions by an estimated total of 765,000 tonnes of CO2 equivalents

The new technology is partly the result of years of research at Thai universities. With a growing agroindustry much research has been targeted at improving wastewater treatment. As a result, tested methods and technology on sustainable wastewater treatment are now available. But significant financial barriers stop many palm oil mills from implementing the methane utilization technology. A majority of palm oil mills in southern Thailand are small, some family run. They do not have the capital to finance new, expensive technology. This project, however, presents a solution to the lack of financing. Through Danish assistance, the CDM system has made it financially feasible to implement the technology at the mills involved. The project generates carbon credits by reducing CO2 emissions. These credits are then sold to Denmark creating additionalincome to secure financing of the climate-friendly technology.

The Projects

Newly introduced technology now capture the methane gas in an enclosed balloon and a stirring tank reactor. The collected gas is then combusted in generators producing electricity which is used as a stable and sustainable energy source at the mills ensuring higher income for the small firms and families and green, climate-friendly palm-oil production. Excess electricity is sold to the power grid, where it replaces fossil fuel-based electricity.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

The membrane captures the methane gas produced from the wastewater used at the palm oil mill.

Everyday Benefits

Collecting the methane from the lagoons ensures better air quality by removing the methane-generated stench which used to pester the mills’ surroundings. In addition, bacteria and disease-carrying insects have lost a habitat and have been greatly reduced. Also the generated electricity reduces the electricity bill and supply the mills with their own independent eco-friendly clean energy.

but as this project demonstrates, the emissions can be significantly reduced by introducing new methods and technology. The project functions as a showcase for other palm oil mills on how to apply energy efficiency technology to the benefit of sustainable development, climate change mitigation and the mill owners themselves. Initially, the project will generate credits for ten years,but the technology and methane mitigation have a lifespan far beyond this.

Future Prospects

Palm oil is the most commonly used cooking oil globally, and most of it is produced in South-East Asia. The traditional production methods cause large quantities of greenhouse gases to be emitted in the atmosphere,

For further information, please contact:Bo Riisgaard PedersenEmail: [email protected]Telephone: +45 3392 6788The five projects are located in the southern part of Thailand.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Danish knowledge kick startsgreen technology development inMalaysian business sector

Brite Tech

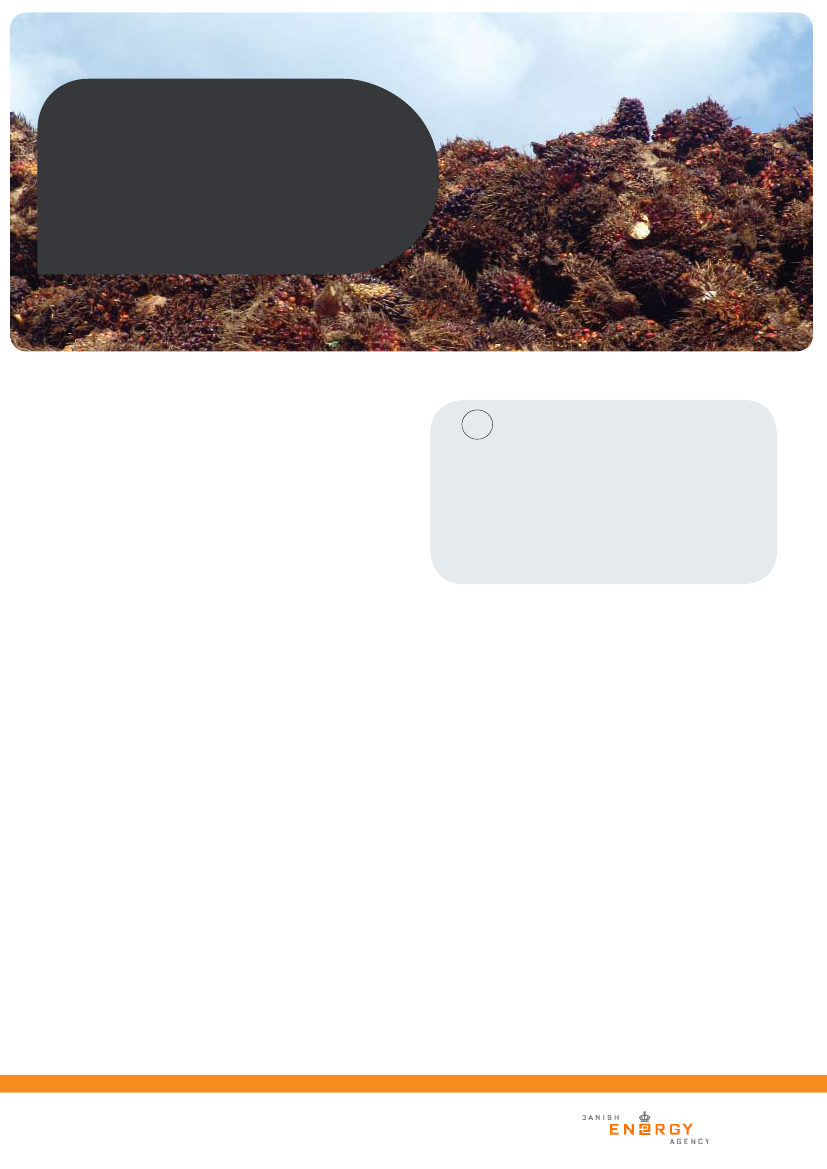

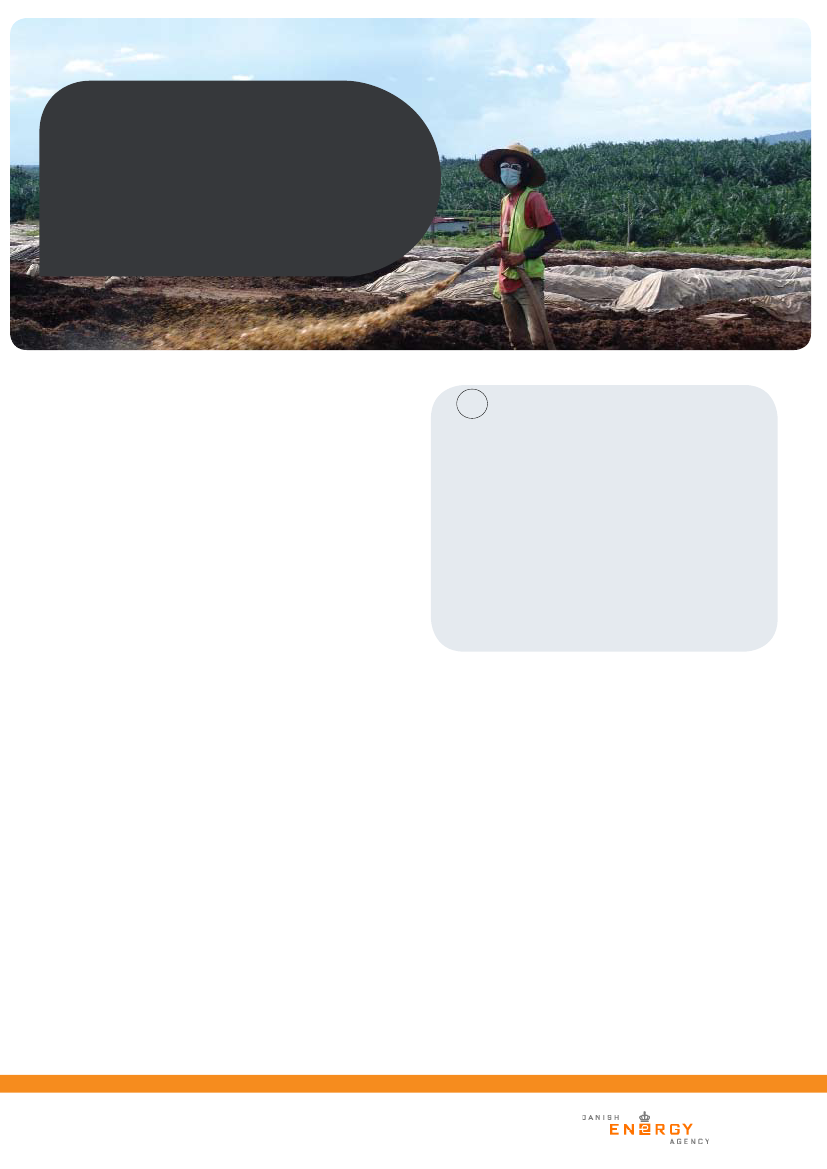

Palm oil production produces large amounts of plant residues, which the CDM project will utilize to make natural fertilizers.

Denmark has assisted in financing projectsat three palm oil mills in Malaysia, in whichcutting-edge wastewater technology isbenefitting the local environment and alsosaving the atmosphere from greenhousegases.

i• • •

Brite Tech in Brief:

The Idea

Extracting palm oil from the fresh palm oil fruits creates a large amount of organic wastewater. Wastewater which is commonly treated in large lagoons, releasinglarge quantities of the potent greenhouse gas, methane, into the atmosphere. By removing most of the water content in the waste-water by using AVC technology, the Brite Tech projects will be able to use the wastewater in a co-composting process together with other organic residues from the extraction process. This will create a high nutrient organic fertilizer while drastically reducing methane leakage from the wastewater.

Business to Business collaboration between the Danish Simon Moos A/S and local companiesAquakimia Sdn and Brite Tech SdnIntroduces new technology for wastewater treatment to the palm oil industryReduces GHG emissions by an estimated total of 800,000 tonnes of CO2 equivalents

Traditionally wastewater from palm oil mills isdecomposed over time in large and deep lagoons. This means the organic material is broken down by bacteria under oxygen-free conditions. Bacteria kept without oxygen, and the anaerobic process, produces methane, which leaks through the foul-smelling stagnant wastewater and disappears into the atmosphere. The great achievement of the Brite Tech project is thatmethane production and odour nuisance are reduced, while land use and environmental impacts will be improved.

The Project

The AVC technique used in the Brite Tech project is entirely new to Malaysia. It was developed by the Danish company Simon Moos A/S and has been in use in Denmark for several years. AVC is an innovative way of seperating the solid material from the large quantities of organic wastewater from palm oil production. The wastewater has a high concentration of organicmaterial and can, therefore, be used as fertilizer if drained and dried correctly. To achieve the right result, the leaps of accumulated composted material must be turned-over regularly and monitored throughout the process.

Everyday Benefits

The project will present several benefits for the local community, not least for the workers at the mills.The large foul-smelling lagoons with rotten water will be replaced by odour-free compost heaps leading to substantially improved air quality at the mill and its surroundings. Flies and mosquitoes breed in open lagoons, and they carry diseases such as dengue-fever and malaria. With less water surface to lay eggs on, the number of disease-carrying insects, and thus the prevalence of diseases, decreases.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

The open lagoons, with decomposing residues are emitting methane into the atmosphere. The new cdm project will reduce emissions and produce high quality organic feritilizers instead.

The new composting process will produce organic fertilizer which will replace the chemical fertilizer used in the plantations, thereby improving the soil quality significantly.

Future Prospects

With future prospects for an ever increasing demand for food in the world, palm oil could prove an even more important industry for Malaysia in the years to come. It is thus important to quickly modernise the country’s many palm oil mills and make them more climate friendly. The Brite Tech project shows that the CDM mechanism and thetransfer of Danish technology can play an important part inthis.

The Brite Tech has two biomass projects on Melaka and one in the north of Borneo.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Golden Hope

Innovation in waste processesmitigate climate change andbenefits the environment

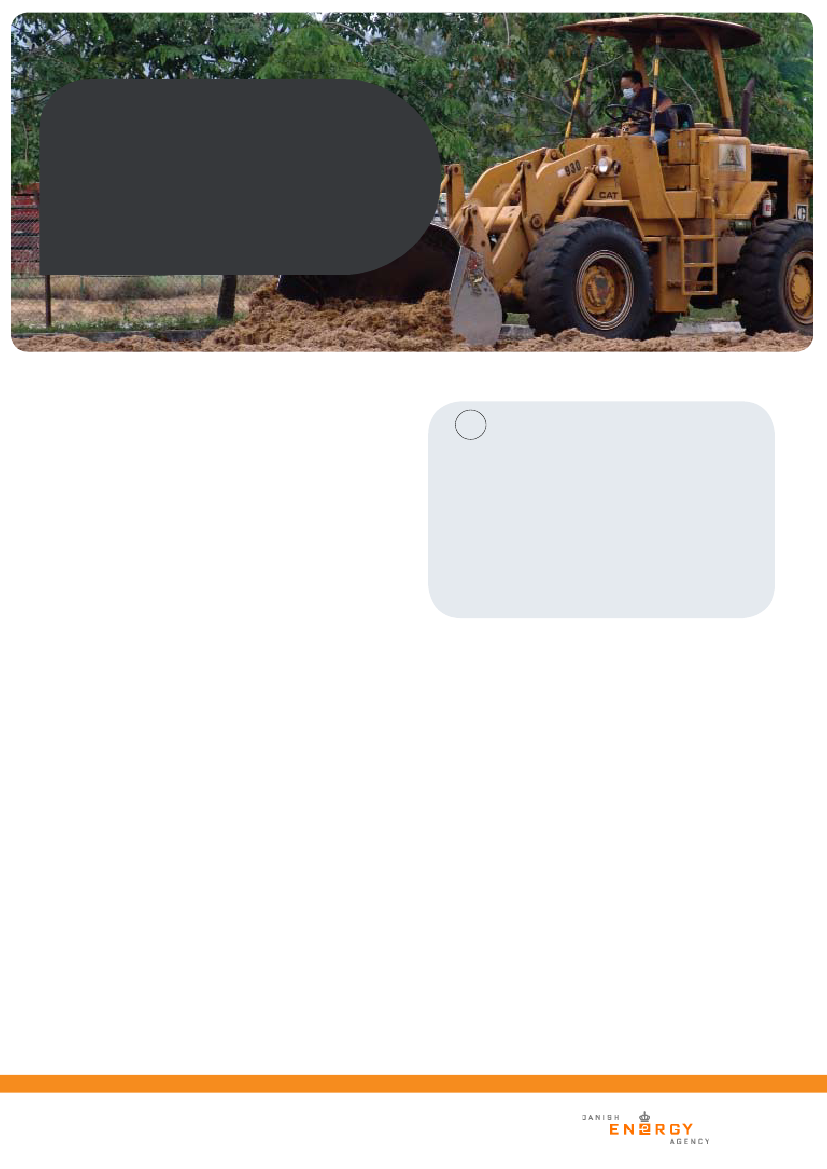

When producing palm oil the mill is left with a large amount of plant residues, which is turned into high quality organic fertilizer.

Danish knowhow has assisted optimising wa-ste processes on five Malaysian industrial palmoil plantations. The processes benefit the env-ironment, the employees and mitigate climatechange.

i

Golden Hope in Brief:

The Idea

Malaysia is a major producer of palm oil. Project partner SIME DARBY owns and operates 22 large industrial palm oil plantations throughout Malaysia, where there is a high output of purely organic waste products. The wastewater from the oil extraction process, so-calledPOME, is treated in large open lagoons where the organic residues are decomposed under anaerobic conditions. The process results in large amounts of methane, a greenhouse gas 21 times more harmful than CO2, being released into the atmosphere. To produce organic compost with a high nutritional content, the POME is sprinkled on another waste product from the process – the empty fruit bunches (EFB) - and turned regularly. This process requires a stable flow of POME and lots of oxygen, hence the procedure is carefully controlled and monitored. The whole process takes around two months after which the organic waste has been converted into a nutrition rich fertilizer that can be used in the plantations.

• Comprises five plantations• Emissions of methane, a potent greenhouse gas, are almost eliminated• Improved quality of wastewater• Odour and health risks linked to open wastewater lagoons eliminated• Consumption of chemical fertilizers reduced• Improves soil quality in the plantations by using organic fertilizer thereby making production more sustainable• Reduce GHG emissions by an estimated total of 700,000 tonnes of CO2 equivalents

plantations themselves. Most importantly, methane gas emissions have been eliminated and Malaysian GHG emissions have thereby been reduced.

Everyday Benefits

In addition to the climate change mitigation, localenvironment and health and safety conditions at theplantations have been considerably improved. The decomposition process in the old open lagoonshad an extremely obnoxious smell, attracted flies and was a breeding ground for mosquitoes. Effects that the new waste handling process have reduced dramatically.Furthermore, the local environment has been improved due to the reduced discharge of organic waste to the recipient watershed.

The Project

So far five of SIME DARBY’s plantations have used the innovative waste process to produce organic fertilizer. This has resulted in several improvements for climate change mitigation, the environment, employees and the

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

During the composting process the compost is turned regularly in order to keep the proces aerob.

Future Prospects

The composted POME is good fertilizer which can replace chemical fertilizers. This improves profitability for the plantation and improves soil quality at the plantations. All in all, the project is a clever solution to an everyday problem, which may find wide future application in an important sector for Malaysia and thewider region.Credits from the project will be earned by Denmark up to 2012, but the technology will continue to work after this and the solution will be useful elsewhere.

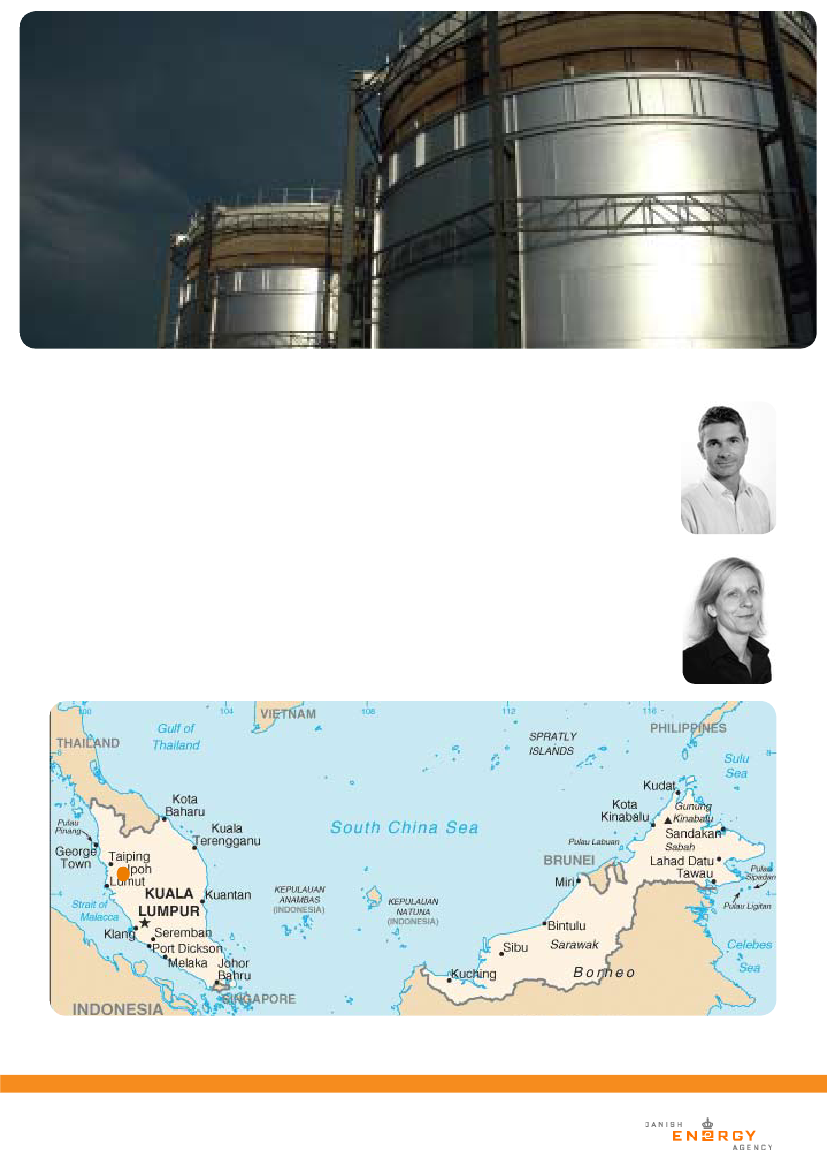

The Golden Hope projects are located on Borneo and on the Malaysian peninsula.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

LumutPalm biomass turned intogreen energy

The project will contribute to the use of sustainable renewable energy sources in a highly efficient manner and is in line with the country’s development policy of renewable energy as a fifth primary fuel.

In a small harbour town in the Malaysian part ofthe Malacca peninsula, simple industrial sym-biosis using palm biomass is bringing greenenergy to a booming area and country. Den-mark is playing its part with design, knowhowand financial security.

i• • • •

Lumut in Brief:

The Idea

The area around Lumut is experiencing dramatic development. Not so long ago Lumut was a sleepy fishing harbour with just one main street. About 15 years ago the government expanded the town’s shipyard andthe Navy base. Guests, sailors, engineers and tourists followed as the town became a local traffic hub. The town still has just one main street, but now it is vibrant with life and not least job opportunities, which have arrived with new industries shooting up by the harbour.

Uses residues from production of palm oil as fuelUses Danish-designed biomass boilers manufac tured under licence by local businesses Brings jobs and knowhow to harbour townRegistered as first Malaysian CDM project and has already inspired other projects• Reduces emissions by an estimated total of 199,000 tonnes of CO2 equivalents The bioenergy plant in Lumut is an example of a project emerged from an existing relationship between a Danish company (B&W Vølund) and a local producer (ENCO). Contact between ENCO and what was then called Ansaldo Vølund had already been established in the early 1990s. However, the refinery itself had no motive to replace its oil-fired boiler, and without revenues from carbon credits, the financial risk involved in development, construction and operation of the bio-energy plant would have been too high.In addition to the reduction of greenhouse gas emissions and introduction of more efficient waste treatment, the biomass project has overcome barriers for implementing a new and untried technology. Today many similar biomass boilers have been installed in Malaysia. This ‘domino effect’ is one of the great strengths of the CDM mechanism.

The Project

Previously, the biomass waste from local palm oil mills was dumped around the production sites. Today, the biomass waste is being incinerated at a combined heat and power plant, which supplies steam and electricity to a palm oil refinery.The renewable production is replacing energy which earlier was produced with the use of fossil fuel. The biomass plant is thereby reducing the Malaysian greenhouse gas emissions with approximately 20,000 tonnes of CO2 annually.The Danish Energy Agency has in a close cooperationwith the authorities, the Danish company B&W Vølund and local businesses assisted in establishing the biomass project in Lumut. The project is supported by Denmark through purchases of carbon credits under the Clean Development Mechanism (CDM).

Everyday Benefits

The installation process created jobs for local people, but operation of the new plant also requires personnel and not least training. At national scale the effect is small, but locally it is extremely important.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

The project activity will be able to reduce emissions in two ways. By displacing fuel oil, which is used to generate 15 t/h steam. And by displacing electricity from the national grid.

Future Prospects

The project has already inspired two other projectsand there may be more on the way. The SEO biomass project in Sandakan, Sabah and the LDEO biomass project in Lahad Datu are both a direct result of the success at Lumut.Malaysia’s declared ambition is to make biomass a primary fuel before 2020, and projects like the Lumut project are important steps on the way. The country has enormous potential for biomass-based energy production at its many factories and plantations. The project is an example of how Danish knowhow,the CDM mechanism and local businesses can be combined to secure a greener and more climate-friendly Malaysia.

The project is located in Lumut on the west coast of Malacca.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

MalaysianNewsprint IndustriesGrowing appetite for newscovered by recycled paper andenergy from biomass

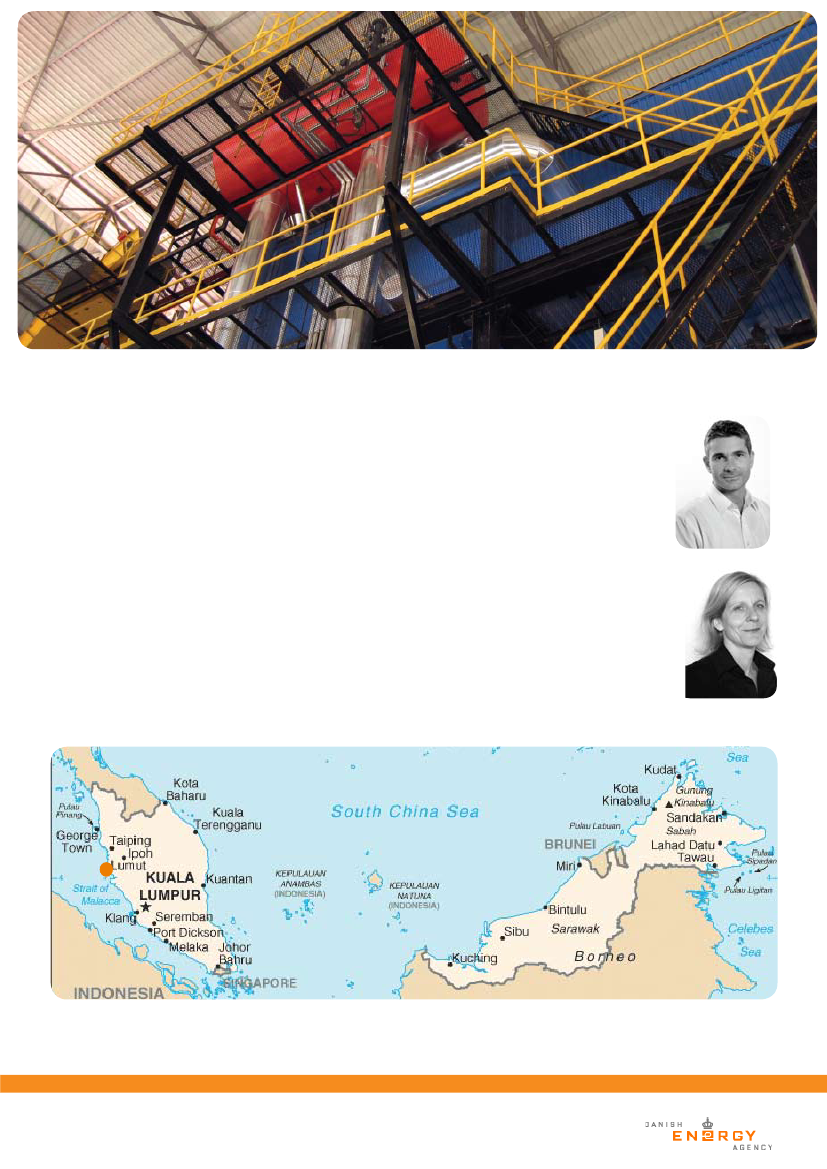

The MNI paper mill owns and operates a combined heat and power plant to produce steam and electricity for the mill’s own consumption. The installed biomass boiler is replacing the use of fossil fuels with biomass.

In Malaysia, the paper mill at MalaysianNewssprint Industries not only recycles paper,but also utilizes residue biomass from localpalm oil production as its main source ofenergy. A brilliant way to improve sustainabilityand climate change mitigation in a small butenergy demanding industry.

i• • • • •

MNI in Brief:

The Idea

Malaysian Newsprint Industries (MNI) has signed up for a nationwide public-private recycling initiative calledIt’s all about recycling. Other participants include Shell, WWF, consumer organizations, Buddhist temples and the legendary Petronas Towers of Kuala Lumpur. Through information material, a homepage, 1000 recycling containers and 65 recycling stationsnationwide, the initiative aims to improve recyclinghabits in Malaysia. Everything from electronic devices over glassware to paper are included. MNI’s involvement is part of the company’s strive to use solely recycled paper. By recycling paper the need for paper fabrication is reduced and less paper ends-up at the local landfills, where it is often burned due to capacity constraints.In addition to the recycling of paper, MNI wished to make the energy hungry newspaper production processes more energy-efficient by ‘recycling’ residue biomass to produce electricity. Financially assisted by Denmark through the CDM mechanism. MNI has implemented an innovative and energy efficient but also rather costly improvement, which is not common practice in southeast Asia.

Supports the Malaysian government’s goal to position biomass as the fifth primary fuel by 2010Substitutes fossil fuel boiler with optimized biomass boilerPuts a value on former residue material, thus eliminating a waste problemIs a showcase for other energy demandingindustries, because it shows that a modern biomass boiler is just as stable as a traditional fossil fuel boilerReduces GHG emissions by an estimated total of 740,000 tonnes of CO2equivalents

The Project

Implemented in late 2009, the project introduce a renewable energy solution though installation of a 66 t/hr, 42 bar biomass boiler. The energy supply is thus turned sustainable – substituting a large oil fired boiler. The new boiler produce steam for the paper process and is furthermore able to produce up to 7 MW of electricity for own consumption.The biomass boiler uses excess biomass residue from nearby palm oil mills, which typically consists of empty fruit bunches, fibres and palm kernel shells. Apart from palm residues, the boiler is also able to use wood waste from nearby wood industry when available.The project secures carbon neutral energy production by supporting the switch from fossil fuel to biomass.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

The biomass will be sourced from palm oil mills in Malaysia, which benefit from the sale of the biomass for extra revenue.

This reduces the CO2 emissions from the MNI production significantly. The transportation and handling of biomass cause small emissions of green house gas, but these are included in the overall emission reduction calculation.

farmers, while eliminating a waste problem.As an experiment the dry ash from the combustion of biomass is ’recycled’ to the biomass-delivering plantations as cheap and organic fertilizers.

Everyday Benefits

Future Prospects

Apart from reducing the Malaysian climate change impact, the project has a range of positive spillovereffects on the community and the wider public.Showing the other industries that energy from a biomass boiler is at least as reliable as a conventional boiler using fossil fuel will improve the demand for excess biomass. A demand which will put a value on the surplus biomass and thereby improve the economy for local

The installed technology has an expected lifespan of12 years, in which it will reduce carbon emissions and mitigate climate change. Hopefully, the idea of multi-recycling can gain more ground and support through this project. It is a show case and inspiration for more widespread industrial symbiosis, and is a very good example on how the CDM can assist overcoming barriers for innovative climate change mitigation and sustainable energy solutions.

For further information, please contact:Ole Emmik SørensenEmail: [email protected]Telephone: +45 33926772orAnette NorlingEmail: [email protected]Telephone: +45 33926669The MNI plant is located in the central Melaka.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Southern WasteManagement atSeelong Landfill

Green electricity from waste

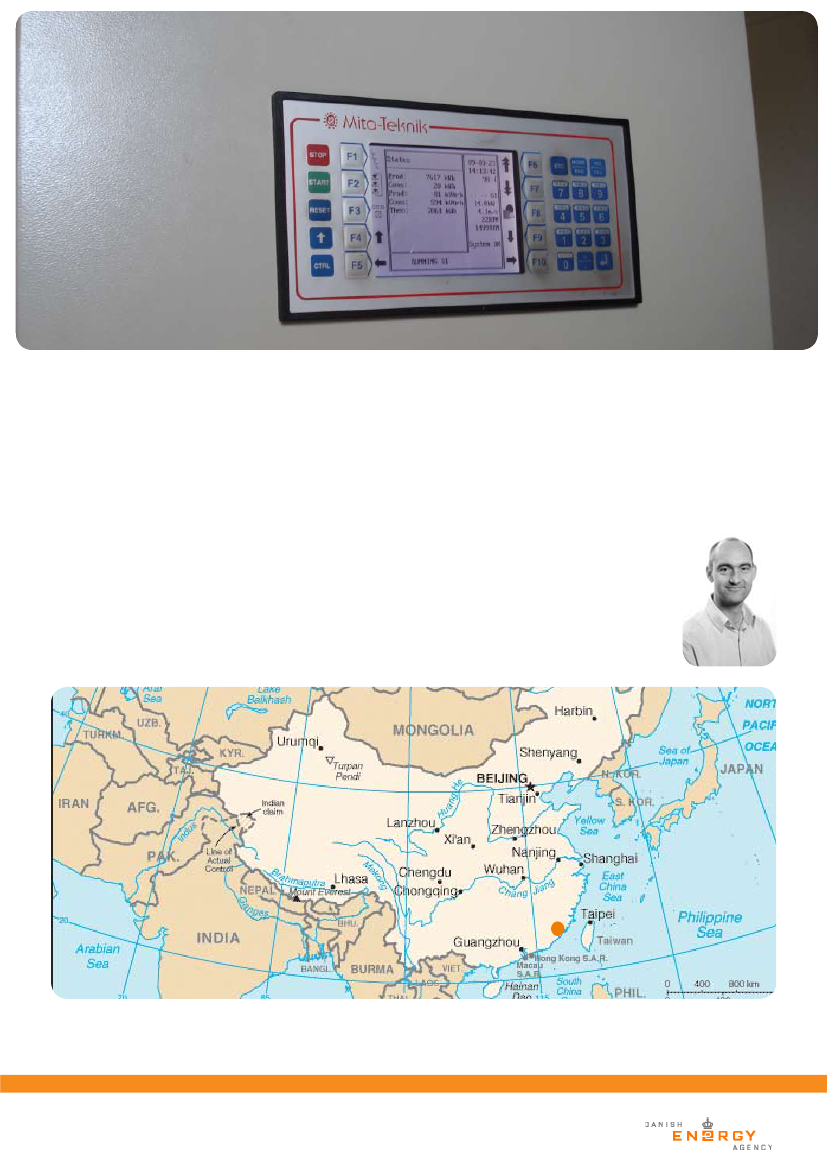

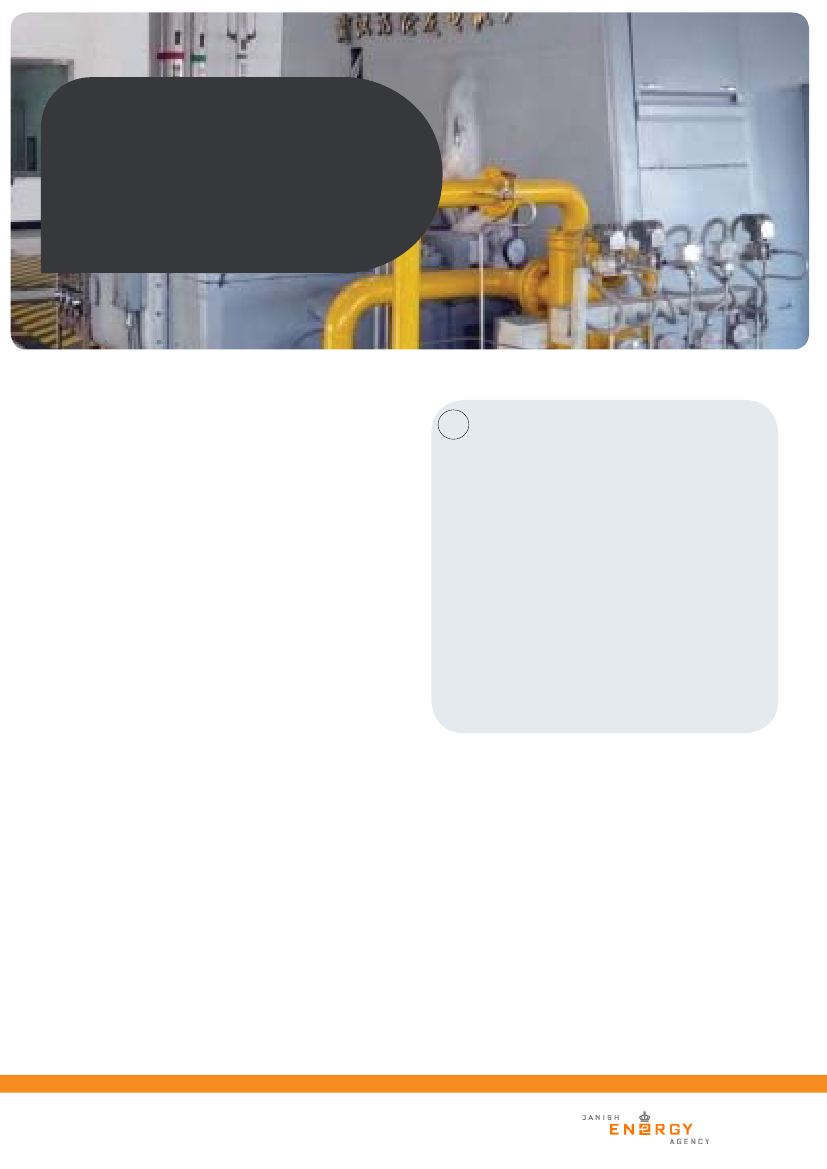

The project introduces a landfill gas recovery system, flaring equipment and a gas engine power plant, to be implemented in steps as the landfill site is expanded.

The population in Malaysia is growing, and sois the amount of waste produced. The SeelongLandfill project uses modern waste handlingtechnology to help the environment andreduce GHG emissions in Malaysia. The CDMmechanism is providing financial security for avisionary project.

i

Southern Waste in Brief:

The Idea

The burgeoning populations of Asia and simultaneous development of a middle class with increasingly westernconsumption patterns, presents great challenges for future waste management systems. The project is using modern waste technology to make a landfill environmentally safe and to collect gas from the waste to generate electricity. The project is developed in collaboration with the local company operating the landfill and is estimated to save the atmosphere from 750,000 tonnes of CO2 equivalents.

• Handles waste from 1 million people • Reduces odours and fire risks from the landfill• Installed as one of the first landfill projects in Malaysia• Implemented with assistance from the Danish company GasCon Aps• Will be in operation up to at least 2023• Reduces GHG emissions by an estimated total of 750,000 tonnes CO2 equivalents

the surface and through a treatment system, ending up in a generator to produce electricity. Although the electricity is used for internal consumption and thereby displaces electricity produced using fossil fuel, the carbon reduction calculated for this project is only based on the amount of avoided methane release. Methane is a potent greenhouse gas, 21 times more potent than CO2.The project uses knowledge and technology new to Malaysia. The Danish company GasCon Aps has provided consultancy assistance during the process and is still involved in the daily operation of the landfill. Hopefully, the knowledge transfer will pave the way for similar projects. The potential is great, but the framework is not always present and new projects willrequire risk mitigation through, for example, additional finance from the CDM system.

The Project

The Seelong landfill is brand new and is expected to be in operation up to 2023. The whole landfill is sealed with membranes, which prevent pollutant liquids from seeping into nearby water sources. Instead, the wastewater is collected and treated both mechanically and through reverse osmosis - making sure that no pollutants are discharged into the environment.In the landfill, gas wells are drilled into the waste to collect the methane, which develops naturally when waste is decomposed anaerobically i.e. under oxygen-free conditions. A pressure difference pulls the gas up to

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

Gaspipes extracting gas from the landfill.

Everyday Benefits

In addition to green electricity and reduced carbon emissions, the CDM project offers several benefits for the environment and the local residents.All wastewater is captured from the landfill and all pollutants are removed before discharge to the environment. Capturing of methane gas reduces the foul odour as well as the risk of fires and explosions. Also, all waste is sorted at the transfer stations, which thereby improves health and safety conditions for the localscavengers.

Future Prospects

There is a great potential in Malaysia and the restof Asia for waste management, but there are also technological, financial and knowledge barriers to overcome. In this regard, the Seelong project may serve as inspiration for future environment and climate-friendly initiatives at the region’s landfills.

For further information, please contact:Ole Emmik SørensenEmail: [email protected]Telephone: +45 33926772orAnette NorlingEmail: [email protected]Telephone: +45 33926669Seelong Landfill is located in a rural area 26 km north of Johor Bahru City.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

United Plantations 1CDM project integrated insustainable palm oil productionin Jendarata in Malaysia

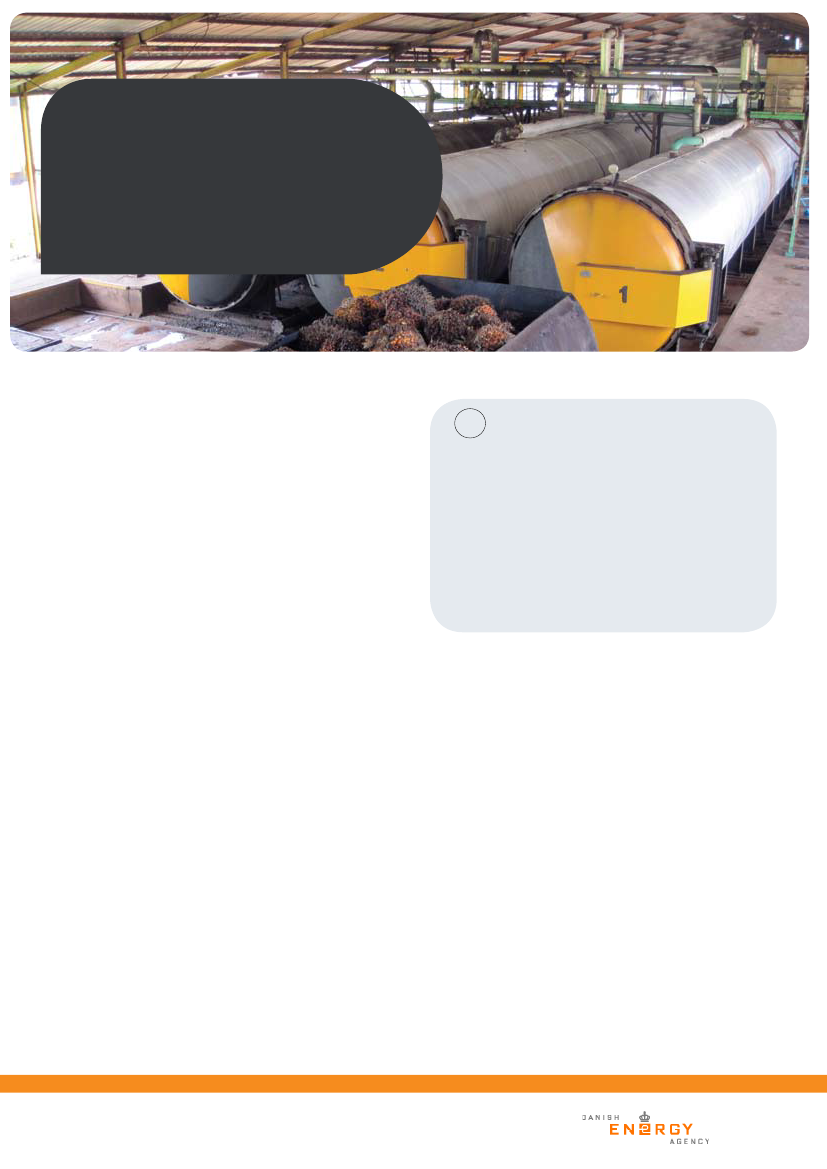

The project replaced the existing, low efficient biomass fired, fire-tube boilers with a more efficient biomass boiler in the palm oil mill.

Use of biomass for energy production on acertified sustainable plantation is the backboneof this CDM project. The project is the first ina string of four projects assisted by Denmarkon efficiency improvements at the UP palm oilplantation.

i• • • •

UP1 in Brief

The Idea

The origin of United Plantations (UP) stem from an immigrated Danish officer named Aage Westenholz, who started a rubber plantation in Malaysia around 1900. Much has happened since, but the business is still run by Danes; the Bek-Nielsen family. Sustainability and corporate responsibility are high on the family’s agenda, and they apply these concepts actively ontheir mills and plantations. The Jendarata plantation has recently been certified by the Roundtable on Sustainable Palm Oil (RSPO). The RSPO aims at setting targets for sustainability and corporate responsibility throughout the entire palm oil lifecycle. RSPO is an international non-profit-making organisation supported by NGOs, palm oil producers and banks (www.rspo.org). In light of the enormous importance of sales and exports of palm oil for many Asian economies, the RSPO has set up best practice guidelines for producing palm oil. The RSPO certification serves as an endorsement and guarantee for the state-of-the-art environmentally-friendly, andsocially responsible operation.During the RSPO approval process at UP, 180 local and international stakeholders were consulted, and all aspects of the production were investigated. In May 2008, UP was the first palm oil mill in the world to be awarded the RSPO certification.

Is the first palm oil producer to be certified sustainable by the RSPO (Roundtable on Sustainable Palm Oil) in the worldInaugurated in 2006 by the Danish Princess BenedikteImplements a joint steam turbine for the plantation and refinery, with a capacity of 2MW Reduces GHG emissions by an estimated total of 62,000 tonnes of CO2 equivalents

The Project

The project installed a new boiler to combust solid waste from the palm oil production. The waste consists of palm fibres, shells and empty fruit bunches. The boiler can handle 40 tonnes of biomass per hour and produces steam at a higher pressure than the old inefficient boiler. In order to handle the high steam pressure generated a new and energy efficient steam turbine has been installed as well.The carbon neutral energy generated at UP is applied at the neighbouring refinery, thereby replacing energy produced from fossil fuel.By the optimized utilization of solid residues from the palm oil extraction, large quantities of carbon emissionsare reduced. Danish assistance and cooperation through the CDM mechanism has enabled these modern improvements to happen.

Everyday Benefits

The RSPO certification and the implemented CDM project are just two out of several initiatives launched by the Bek-Nielsen family.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

New high yield palm trees coming to life at the UP nursery.

When Danish Princess Benedikte inaugurated the CDM project in 2006, she also handed over the keys to anumber of new and modern homes for the employees and their families near the factory. Employees are assisted by a foundation, which supports them in their old age and provides scholarships for theirchildren. The Bek-Nielsen family has also supported the building of a school, churches and mosques in the neighbouring area, and on the property itself there is a research centre and museum of palm oil production.

the Malaysian government’s 2020 ambition to secure biomass as the country’s fifth most applied fuel. The ambition requires huge reorganisation and many similar biomass projects at Malaysia’s innumerable plantations and refineries. In this respect, experience and principles from the UP1 Jendarata project will be a great help and inspiration.The CDM project will generate carbon credits to the end of 2012, but the installed technology has a service life of 20 years, and will therefore benefit the environment for many years to come.

Future Prospects

By introducing new technology and integrating the training of local employees, the project is assisting

For further information, please contact:Ole Emmik SørensenEmail: [email protected]Telephone: +45 33926772orAnette NorlingEmail: [email protected]Telephone: +45 33926669The UP1 CDM project is located at the northern part of Malaysia.

|Danish Energy Agency, Amaliegade 44, DK 1256 Copenhagen K, Tel: +45 33 92 67 00, Fax: 33 11 47 43

United Plantations 2Sustainable palm oil, renewableenergy and Greenhouse gasreductions at Malaysian plantations

Through the CDM mechanism Denmark has assisted UP to make a number of improvements on the plantations