Trafikudvalget 2009-10

TRU Alm.del Bilag 204

Offentligt

Lincoln Special Engineering OperationsLimousine Vehicles

QVM Programs - Engineering

To:Potential Limousine Vehicle - QVM Program ApplicantSubject:QVM Program Qualification Requirements – 2009 Model Year Update-----------------------------------------------------------------------------------------------------------------------------------BackgroundThe Qualified Vehicle Modifier (QVM) program focuses on the manufacturing of safe limousines, inconjunction with compliance with Federal Motor Vehicle Safety Standards (FMVSS), process andquality control, and a commitment to continuous improvement. This document is a review of thepolicies that are currently in place to coincide with the on-going changes of the QVM program and ofthe conversion industry.The following provides a general overview of the QVM program requirements for new applicantsand related conversion information for the Town Car & Expedition/Navigator. Complete conversioninformation is contained in the latest QVM Limousine / Hearse Builders Guide, &Expedition/Navigator Builders Guide. The information that follows pertains to the QVM Program for2008 and later model year vehicles until further revised. Builders Guides can be viewed at ourwebsite: www.fleet.ford.com/limoQVM Program - New Builder ApprovalsThe following outlines the general process and highlights some of the major requirements forprospective QVM program applicants to qualify for the QVM Limousine Vehicles conversionprogram. The information provided is not meant to be complete, but is intended to provide ageneral overview of the QVM qualification process. Complete information regarding the qualificationprocess can be obtained by contacting the QVM Engineering Office @ 313 / 322 - 7926.Note:Neither Ford Motor Company or QVM Engineering makes any determination as to the safety of anyspecific QVM built vehicle. The information reviewed by QVM Engineering is for the purpose of auditing QVMmanufacturers to determine if they comply with our recommendations. All QVM manufacturers are solelyresponsible for the certification and safety performance of their products.

PHASE 1- A prospective applicant will be required to comply with the following as well as all otherQVM program requirements to receive QVM Program approval:•Written Request for Consideration- A prospective QVM applicant must first submit a writtenrequest stating their desire to be considered for QVM program approval. The request mustcontain the following:Detailed Company / Corporation information - including parent company names or other substantialholding interests. Also, the names of all chief operating officers and key management.√Offices and manufacturing facility information - including location and facility size. Also, include anyintended affiliation with other manufacturing organizations if the entire conversion process will not beperformed at the main facility.NOTE:A prospective QVM applicant or current QVM builder may not be involved in any way with anothermanufacturing facility that manufactures vehicles and is NOT intending to be, or, is not a member ofthe QVM program. This includes facilities / companies which build non-QVM compliant Ford MotorCompany vehicles.√Demonstrate the ability to secure a minimum of $5 Million of General Liability Insurance.√Projected start-up date.J.MetzNewQVM03.doc

√

Page 1 of 10

1/13/2009

QVM Program - New Builder Approvals (con't)•Design / Model Information- A prospective QVM applicant must provide the followinginformation for each model or group of converted vehicles intended for production:√√√√√•Vehicle model or type (Limousine, funeral coach, 6-door, 24 hour car)Wheelbase extension lengths to be offered for each vehicle typeSeating configurations available for each wheelbase extension and vehicle type, showing thedesignated seating positionsandseating area dimensions for each seating position.Number of doors (if not the standard; 4), for each wheelbase extension and vehicle type (i.e.;5,or 6)Total rated passenger capacityINCLUDING DRIVERfor each wheelbase extension andvehicle type.

Weight Analysis- In addition to a design report each QVM must submit a weight study detailingthe actual or estimated weight of all added structure, including wiring, carpet, trim materials andincluded options (i.e.- sunroof, auxiliary A/C unit and hardware, electrical accessories,…). Theweight analysis should start with the curb weight of a Town Car 418 Package (as received fromthe factory) or Navigator, and provide detail demonstrating that the added weight of thestructure, passengers and luggage meets the QVM Gross Vehicle Weight (GVW) guideline of7500 pounds for Town Car and 9900 (140 inch) for Expedition/Navigator. For analysispurposes, assume that the curb weight of a 418 Package Town Car is 4420 pounds, and theExpedition/Navigator is 5564 pounds. (see page 5 - section titled 'Vehicle PlatformRequirements' for GWV information for hearse applications).Product Design Assumptions- The following design assumption or standards are to be usedduring the conversion design and development process. These standards are only guidelinesand not intended to cover all situations.√√√√

•

Weight / Passenger = 150 poundsCasket & Contents = 350 poundsStandard Luggage Load = 200 pounds*Minimum Luggage Load = 100 pounds(requires a restriction label)* [luggage loadrestriction does NOT apply to hearse conversions.]

•

**FMVSS / CMVSS Analysis-Each prospective QVM applicant must provide documentationdemonstrating compliance with all applicable FMVSS (CMVSS if exporting to Canada) for theirproposed conversion design(s). Compliance statements must be provided for all applicablestandards - including standards deemed to not be affected during the conversion process. Forstandards not affected during the conversion process, the statement should justify theconclusion as to why the standard was not affected. When providing FMVSS compliancestatements for standards affected during the limousine conversion process, each coach buildershould include a statement that answers the following fundamental questions:1.What is the standard;not just the title, but a short statement that describes the purposeand intent of the standard.2.What does it take to pass the standard;provide detail or a summary of how the standardis satisfied or what must occur to comply - this could include numeric and/or qualitativemeasures.3.Why does your vehicle pass the standard;indicate the actual or projected performanceof your vehicle design with respect to the standard under review. Make comparisons andreference the standards acceptance criteria. Also, what supports your conclusions thatyour vehicle meets the standard ? This data must be accessible for inspection andreview. Alwaysreferencetesting data used for proof of compliance by test number, VIN,etc…

J.MetzNewQVM03.doc

Page 2 of 10

1/13/2009

QVM Program - New Builder Approvals (con't)To assist the QVM Program members with determining compliance with government safetystandards, Ford Motor Company has conducted analytical analysis and physical testing forseveral FMVSS standards typically affected during the vehicle conversion process. This data(commonly referred to as "group test data") is available to all members of the QVM program.This data is only applicable if all associated conversion guidelines and assumptions presented inthis document and the QVM Limousine Builders Guides are followed. Any deviation ordeparture from these guidelines requires approval and written authorization from the QVMEngineering office. After successfully completing the requirements for 'Written Request forConsideration', 'Model/Design Information' and 'Weight Analysis' the QVM Engineering Officewill loan the prospective QVM applicant this data for use in determining FMVSS compliance.This information is confidential and the property of Ford Motor Company. The documentationmust be returned to the QVM Engineering Office if the prospective applicant does notsuccessfully qualify for QVM approval.If a prospective applicant does not have adequate experience interpreting FMVSS regulations,the QVM Engineering Office strongly encourages that assistance from an experiencedprofessional engineer be considered to assist in the interpretation of these standards. If thismethod is chosen, a full time employee of the company must be trained and dedicated as theFMVSS liaison to insure that the stated compliance is not affected during daily manufacturingoperations.*Crash test data will be provided to the perspective QVM upon request. This processstarts in PHASE 1, and is an ongoing process until statements of compliance arereviewed during the final 'on-site' inspection audit.PHASE 2- Once the steps in Phase 1 have been completed and reviewed by the QVM EngineeringOffice, the prospective builder will be authorized to begin manufacture of their first two QVMapproved builds for the vehicle inspection process (see below). All conversions manufacturedbefore completing these reviews are not eligible for QVM program consideration.•'Good Faith' Agreement- Once a prospective applicant enters into the QVM qualificationprocess they agree to follow the program guidelines as presented in this document and theTown Car Limousine / Hearse or Navigator Builders Guide. This 'good faith' agreement applieswith the onset of the Phase 2 criteria until such time that the prospective applicant is eitherapproved or disqualified from QVM consideration.Facility & Converted Vehicle Inspection Audit- After the above paper work has beenreceived, reviewed, and approved by the QVM Engineering Office, an on-sight facility andvehicle inspection audit will be scheduled. At this time the prospective QVM will be authorized toconvert two trial vehicles which will be reviewed at the audit. The vehicle inspection review willbe conducted on one completed unit that represents the highest content / weight and longestextension length authorized during the Phase 1 review process. The second vehicle must be ina partial completion stage to allow for review of the interior structure and chassis modifications.This on-site inspection will focus on the following criteria:√√

•

Facility and manufacturing process readiness(see attachment 1: The QVM principalsand rating system brochure)Converted vehicle construction and verification to submitted design analysis and QVMguidelines. See the Builders Guide for details. www.fleet.ford.com/limo

J.MetzNewQVM03.doc

Page 3 of 10

1/13/2009

PHASE 3- Once the above stages are completed successfully, the newly approved builder will berequired / restricted to the following:••Sign a QVM Agreement- The newly approved builder must sign a QVM contract and meet allthe stipulations contained within the agreement.Mandatory Probation Period- The newly approved builder will be under a one-year probationperiod to assess their capability to meet program guidelines.

√

Vehicle Weights / Requirements- For approval, a QVM manufacturer must acquire theuse of and/or purchase scales in order to weigh vehicles at the appropriate GVW thatapplies. The weight information is documented on a QVM Weight Ticket. Each vehicleproduced will require a weight ticket until written instruction from the QVM Engineering Officestates otherwise.(SeeAttachment 3 below.)Calibration information for your purchased scales must be available andscales must be recalibrated every calendar year.

•

Wheelbase Extension Length Limit– Each new potential QVM will be able to produce anylength vehicle that best suits their business case. The maximum length allowed by the QVMprogram is as follows.Town Car = 120 & Expedition/ Navigator = 140 inches.In order toensure that quality and safety are maintained, the following criteria has been established as arequirement for building vehicles at their maximum limit for new QVMs.The first 25 vehicles produced will be required to have the following documentationoA QVM weight ticket showingallweights required (see attached QVM weightticket)oOwner information for the vehicle including; Company name, address, phonenumber, email address, and contact name if different from the companyname.oA written approval (email or otherwise) from this office for the release/sale ofeach vehicle is required before they can be released to the end customer.

**The QVM Office reserves the right to review the above information and conductsurveys of vehicle customers to assess the newly approved builder's capability to meetQVM requirements for quality, customer satisfaction, and conversion design anddurability considerations.•6 - Month Interim Status Review- The QVM Engineering Office will conduct an interim statusreview to confirm the newly approved QVM builders performance to program objectives. Thisreview will examine the following:√√√√Feedback on Conversion Quality and Customer Satisfaction from the FCSD Hotline (800/34-FLEET)Customer Satisfaction Mail / Phone Survey Results ( If deemed necessary)Certificate of Completion Reports / Incentive Program ComplianceCompliance to Conversion Restrictions / Guidelines

See Attachment 2 - Flow Chart / New Builder Approvals - for a summary of the qualification process.J.MetzNewQVM03.docPage 4 of 101/13/2009

Vehicle Platform RequirementsQVM approved conversions are to be constructed on the indicated heavy-duty option packages andare required to meet the following GVW guidelines. Contact the QVM Engineering Office for moreinformation or questions concerning vehicle platform capabilities.•All conversions must be completed on the specified heavy duty package:Town Car Limousine - 418 option packageTown Car Hearse - 418 or 419 option package (dependent upon availability)Lincoln Navigator & Ford Expedition – 17 L Limousine Builders PackageNote:AnyotherFord Motor Company vehicles than the ones mentioned above are restrictedfrom conversions and will lead to immediate dismissal from the QVM program. Allfollowing vehicle brands are restricted from conversion:FordLincolnMercuryMazdaVolvoThe QVM SpiritQVM certification is not just a program for vehicle modification. QVM envisions complying with thespirit of the program and is intended to create trust between the customer, coachbuilder, andchassis manufacturer with a goal of producing vehicles that meet approved crash and durabilitystandards. QVM is not intended to simply provide a mask (certification) to hide behind, or solely amethod for receiving conversion incentives to increase QVM profitability. QVM is about doing theright thing with all partners involved in the business, even if QVM is not the most convenient oraggressive path available.Therefore, a QVM builder maynotbe involved in any way (including ownership, partial ownership,or receiving profits) with another manufacturing facility that manufactures vehicles outside of theQVM program guidelines, and isnot,or not intending to be a member of the QVM program. Thisspecifically includes facilities / companies which build non-QVM compliant Ford Motor Companyvehicles including all Ford Motor Company affiliated vehicles such as: Ford trucks, Jaguar, Lincoln,Lincoln trucks, Land Rover, Mazda, Mercury, Volvo, and Aston Martin. Affiliation with such acompany is grounds for immediate dismissal from, and loss of all benefits associated with the QVMprogram.If you need further clarification of this policy, please call the QVM Engineering Office: 313 / 322 -7926Platform Maximum Weights•GVW limits for QVM approved conversions are as follows:√Town Car Limousine = 7500 pounds√Town Car Hearse = 6800 pounds√Lincoln Navigator = 9,900 pounds√Ford Expedition = 9,900 pounds

J.MetzNewQVM03.doc

Page 5 of 10

1/13/2009

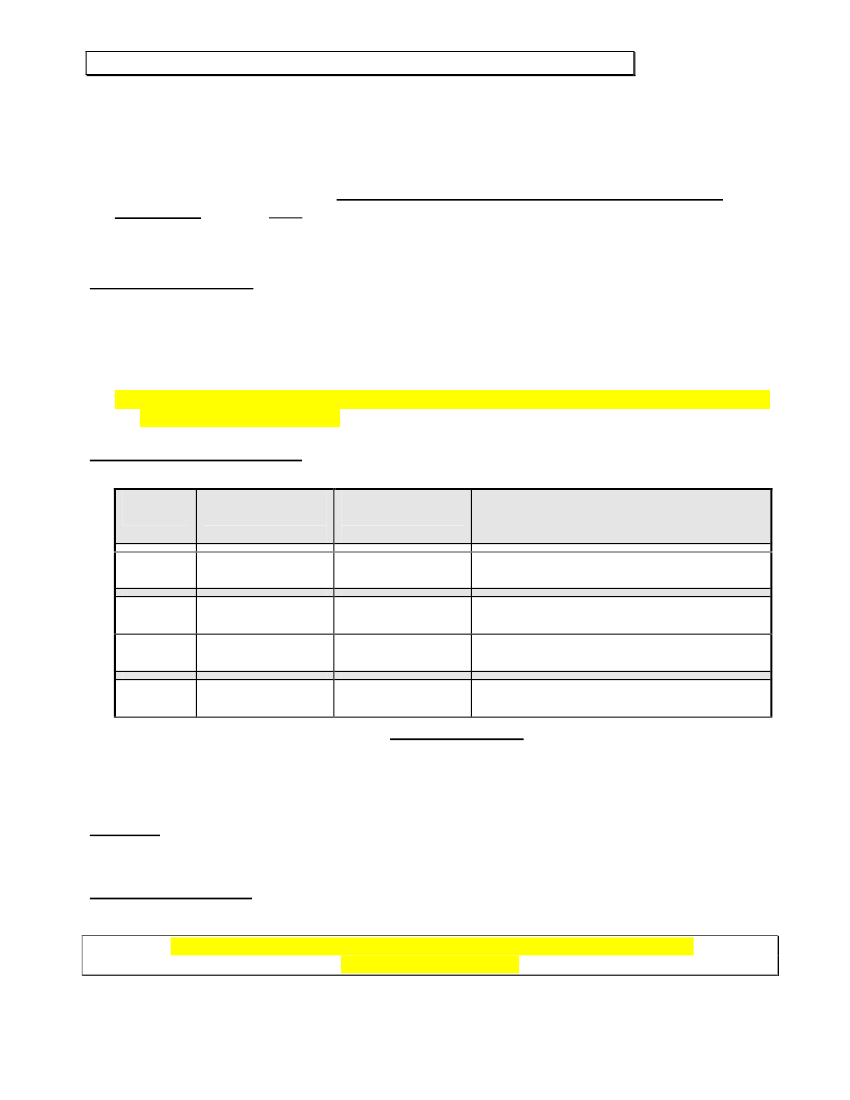

QVM Program - Vehicle Conversion HighlightsThe following information provides a general overview of some of the new or revised conversionrequirements associated with the QVM program. These requirements are applicable to all QVMconversions unless indicated otherwise. The information provided is not meant to be complete, butis intended to provide an overview for product design and development purposes.•B-Pillar Body Reinforcement-Full OEM B-pillars are required at all locations in theconversion.B-pillars must be purchased from the approved OEM source. QVM Engineeringmust approve any modifications to the OEM B-pillar. The chart below provides detail on B-pillarusage, specific requirements for center pillar supports.

B-Pillars / Pillar Spacing⇒Only OEM factory approved B-Pillars may be used at door locations. Contact InfiniteInnovations at (417) 863 - 0300 to purchase OEM approved B-Pillars⇒B-pillars can not be split or modified in any way except as specified in the chart on page (6)⇒Center pillar requirements (conversions over 70 inches - see chart on the following page ( 6)for details)⇒All pillars MUST be welded with a full / continuous seam at the top, bottom, inside andoutside attachment points !B-Pillar Body ReinforcementSpanLength70" orless71" -100""over 100"Acceptable B-PillarTypes (center)- not required -Full (rocker-roof)½ (rocker-beltline)Full (rocker-roof)Acceptable B-PillarDesign (center)---OEM ApprovedOEM (modified)OEM Approved•••Action Required for QVM Approval *

---provide attachment, support structure,& design information for reviewprovide attachment, support structure,& design information for reviewprovide attachment, support structure,& design information for review

* Contact the QVM Engineering Officebefore proceedingfor more information•Frame Rail Extension Design- The followingtwo (2)frame rail extension designs areapproved for QVM conversions for Town Car. Excursion frame material is different and specifiedbelow.*** All other designs must be reviewed and approved by the QVM Engineering Office.√

Town Car:Frame rail extensions must be constructed of A500 structural tubingThree-piece lap tube design with a minimum wall thickness of 3mm√One-piece closed cross-section 2"x4" tube with a minimum wall thickness of .1875" or 3/16"Expedition / NavigatorExpedition/Navigator Frame information can be found in the SUV Builders Guide.*** All Builders Guides for all vehicles may be viewed on our website atwww.fleet.ford.com/limo

J.MetzNewQVM03.doc

Page 6 of 10

1/13/2009

QVM Program - Vehicle Conversion Highlights - Cont'd•Frame Cross-Member Support (TownCar Only)-all conversion designs with wheelbaseextensions over 70 inches must incorporate a rigid under body cross-member attached betweenthe sides of the vehicle frame. The cross-member is required for side impact and must meet thefollowing design criteria:√√√The cross-member must be positioned at a location which is 89 (+/- 1.0) inches from thecenterline of the front axle (imaginary line between center of the two front wheel spindles).The cross-member must be constructed of a closed cross-section (i.e.- box, rectangle, tube)and equivalent in strength and performance of a 1"x 3" rectangular tube, 0.065" minimumwall thickness, 1010 steel.The cross-member should span the distance from the frame side rails in a straight line ifpossible. If the cross-member must be cut to clear obstructions, any cut lines and/or seamsmust be reinforced (i.e. - gusset plate).

•

Side Impact Intrusion Beam- The side impact beam for the extended section of the convertedvehicle must meet or exceed the following guidelines:√√√√1010 steelTubular design - standard 2" x 2" x 0.095" square tube or other cross-section of equivalentor greater bending strength. Round 1 inch O.D. tubing sold by Infinite Innovations is alsoacceptable. Contact Infinite Innovations for specifications and pricing.Maximum unsupported span (distance between B-pillars) of 70 inches.Rigidly attached at each B-pillar

••••••

Roof Supports- OEM style (or equivalent) roof supports must be located and positivelyattached at each B-pillar reinforcement.Driveshaft Length- The OEM driveshaft length can not be extended. Multiple section driveshafts are required for all wheelbase extensions.Center Divider Attachment- The center divider (i.e.-partition) must be rigidly attached to thebody structure.Body Cut Line- the body separation cut line must be rearward of the front door B-pillar.Door Configuration- Vehicle designs with wheelbase extensions over 100 inches whichincorporate more than four (4) doorsmust be reviewed and approved by QVM Engineering.Framing Fixture- All QVM manufacturers are required to incorporate a rigid vehicle cuttingfixture during the extension process. This fixture must be constructed to reference the masterlocator holes of the OEM frame. This will insure accuracy during the extension process andprevent excessive front to rear axle thrust angle concerns.This fixture must be in place andfunctioning at the time of the annual QVM audit.Details on the cutting fixture are in theBuilders Guide. You can view the Builders Guide Online atwww.fleet.ford.com/limo

J.MetzNewQVM03.doc

Page 7 of 10

1/13/2009

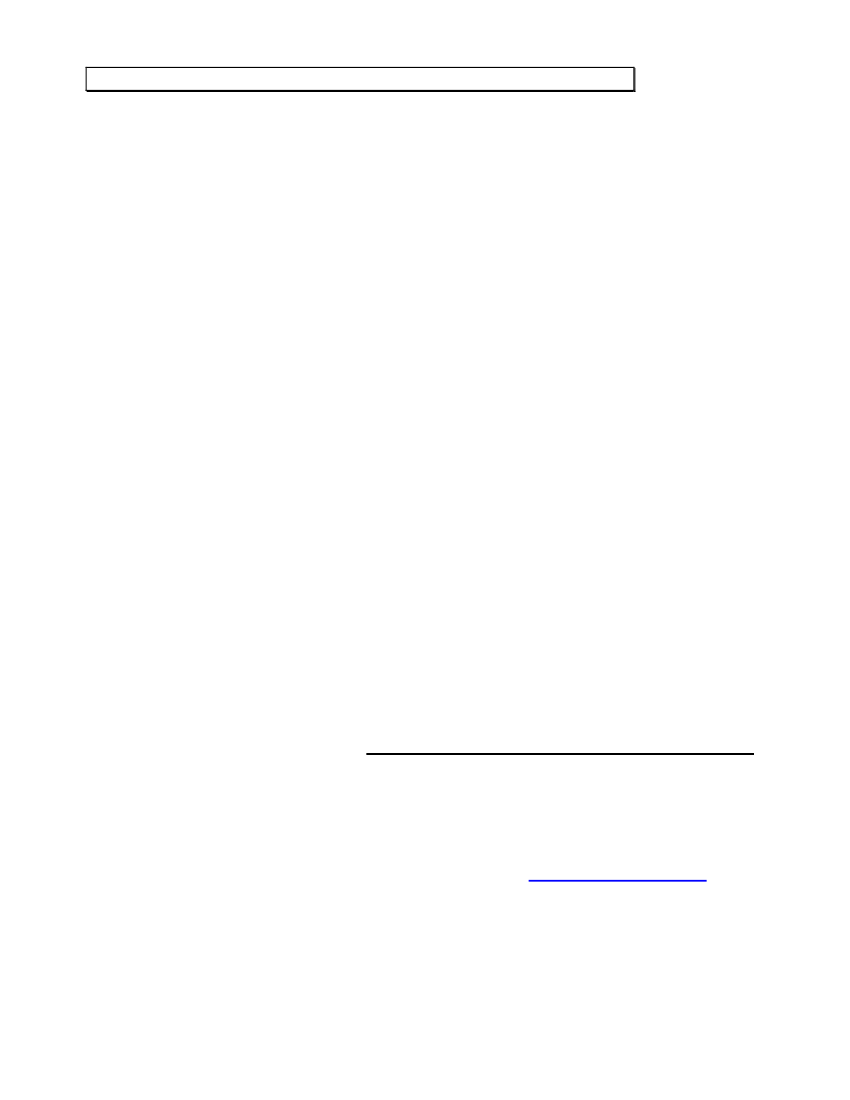

QVM Program - Key Contact ListThe chart below provides the contact names / numbers for several areas that support a prospectivebuilder during the QVM application process.Questions RegardingThe QVM Program, The QVMapplication process, engineering orthe conversion process•Incentive program information•Town Car & SUV order status•Advertising information,(clip art,brochures)QVM incentive process, claim forms,payment schedule.Financing, or setting up a credit linefor purchasing QVM limousines-Acquiring a Fleet IdentificationNumber (FIN) - (required to order andpurchase Town Car 418/419 optionLimousine/Hearse Builders Packagechassis 17 L Navigator & 800AExcursion limo chassis)-Fleet Service AssistancePurchasing OEM approved B-pillarsrequired for QVM approved limousineconversions & alternative round crashbeam bar material.Bud Thomas- Infinite Innovations417-863-0300p417-863-0320xFord Motor Credit CommercialLending ServicesFord Fleet Business Office.Commercial Vehicle Operations800-706-0997p800-343-5338pFor FIN info followthe menu.For Fleet ServiceONLY! use:Menu pick – 3Contact-AreaJeff Metz - QVM EngineeringOffice ([email protected])Kim Johnston- QVM Fleet Office([email protected])Phone (p) / Fax(x)313-322-7926p313-390-3160x313-390-2779p313-390-3488x

Kim Johnston- QVM Fleet Office

Same as above

If you have any questions or need more information, please contact me or the QVM EngineeringOffice.

JeffJeff MetzQVM Engineering Office /Program Coordinator313 / 322 - 7926

JimJim MurrayQVM Engineering Manager313 / 248 - 9819

J.MetzNewQVM03.doc

Page 8 of 10

1/13/2009

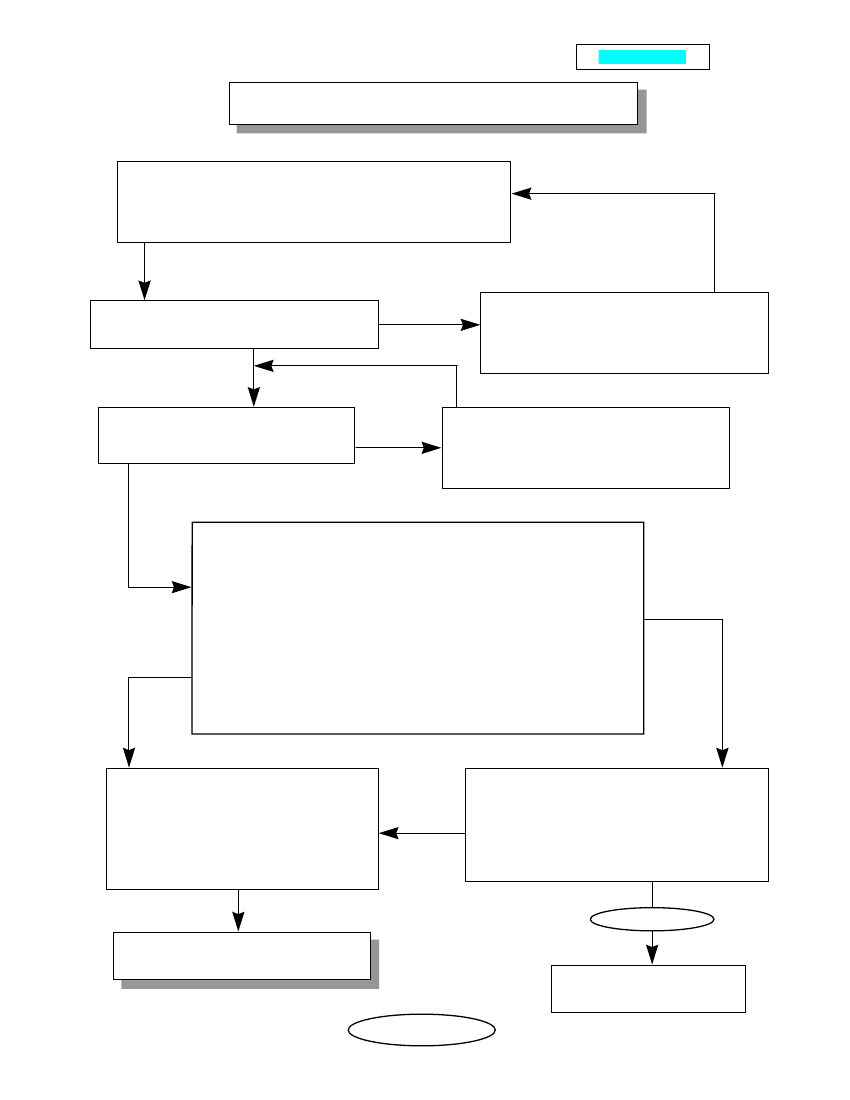

Attachment 2

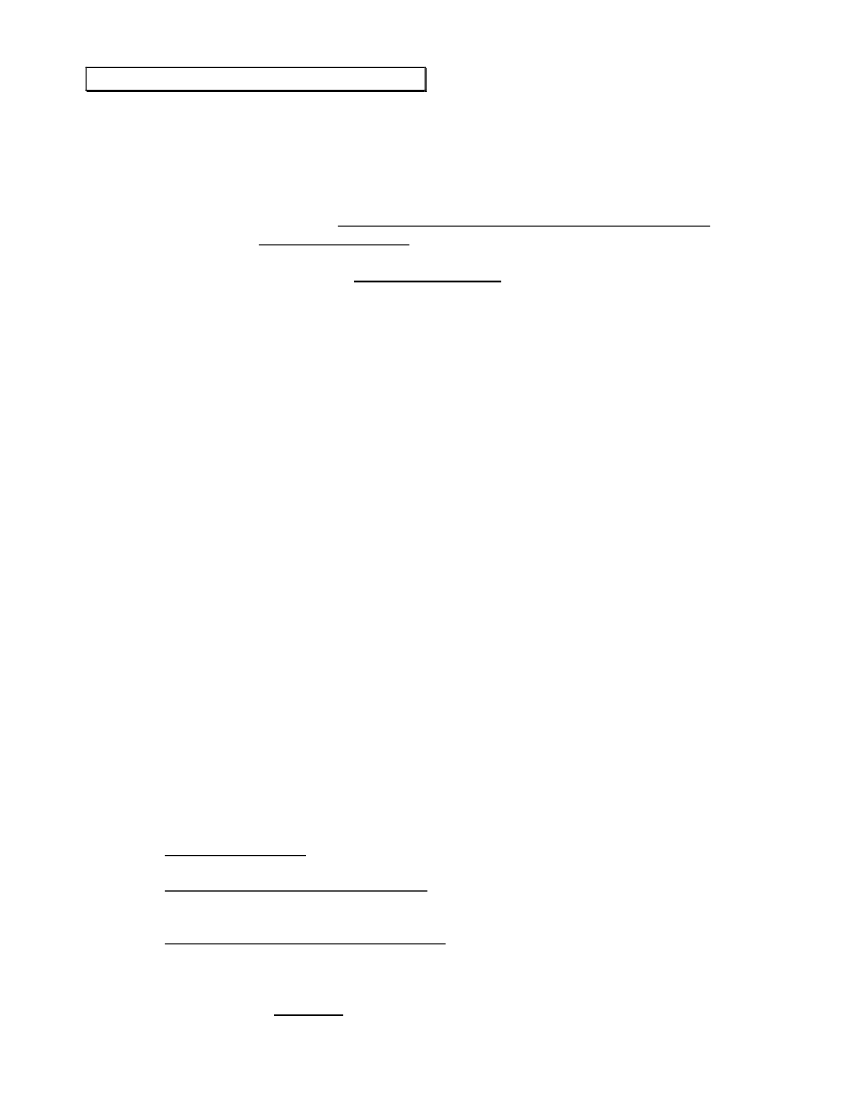

QVM New Builder Approval ProcessQVM New Builder Approval Process

Phase 1 - Analytical Review--> QVM candidate:•Submits written request to QVM Engineering Office for review•Begins the process to develop analytical conversion information•Applicant submits analytical studies for review

RESUBMIT

QVM Engineering Office reviews applicant’sPhase 1 conversion design & FMVSS analysisPASS

FAIL

•QVM Eng. provides feedback & identifiesconcern areas / requirement shortfalls•Applicant develops resolution plan &re-submits to QVM Engineering for approval

RESUBMIT

QVM Engineering conducts a preliminaryphone audit to assess facility andmanufacturing process readinessPASS

FAIL

•QVM Eng. provides feedback & identifiesconcern areas / requirement shortfalls•Applicant develops resolution plan &re-submits to QVM Engineering for approval

PASS

Phase 2- Vehicle Construction / Facility Inspection Stage•Applicant agrees to comply with provisions of the ‘Good Faith’ Agreement•QVM Engineering schedules a tentative facility inspection date to review:- readiness to QVM manufacturing / process requirements- confirmation of analytical analysis provided in Phase 1•QVM applicant is authorized to convert two trial vehicles for inspectionduring the facility audit to review compliance with QVM conversionpractices & guidelines.- one fully completed unit representing the highest content / weightand extension length approved for manufacture- one unit partially completed to allow a structural review of the addedinterior / chassis sections & to assess manufacturing practices

FAIL

Phase 3 - Applicant Approved•QVM agreement signed•Mandatory probation period begins•Conversions limited to approved designs& wheelbase extension limit•New QVM builder begins compiling certifiedconversion weight data

PASS

•QVM Eng. Identifies areas of Non-compliance•QVM Eng. Assesses Impact of concerns &ability to correct areas of non-compliance•Corrective Actions reviewed / discussed•QVM Eng. Assesses coach-builder capabilityto meet program guidelines & correct vehicledefects.

Not Approved

CONGRATULATIONS !!CONGRATULATIONS !!Welcome to the QVM ProgramWelcome to the QVM Program

•Qualification request deferreduntil next program yearAttachment 2

J.MetzNewQVM03.doc

Page 9 of 10

1/13/2009

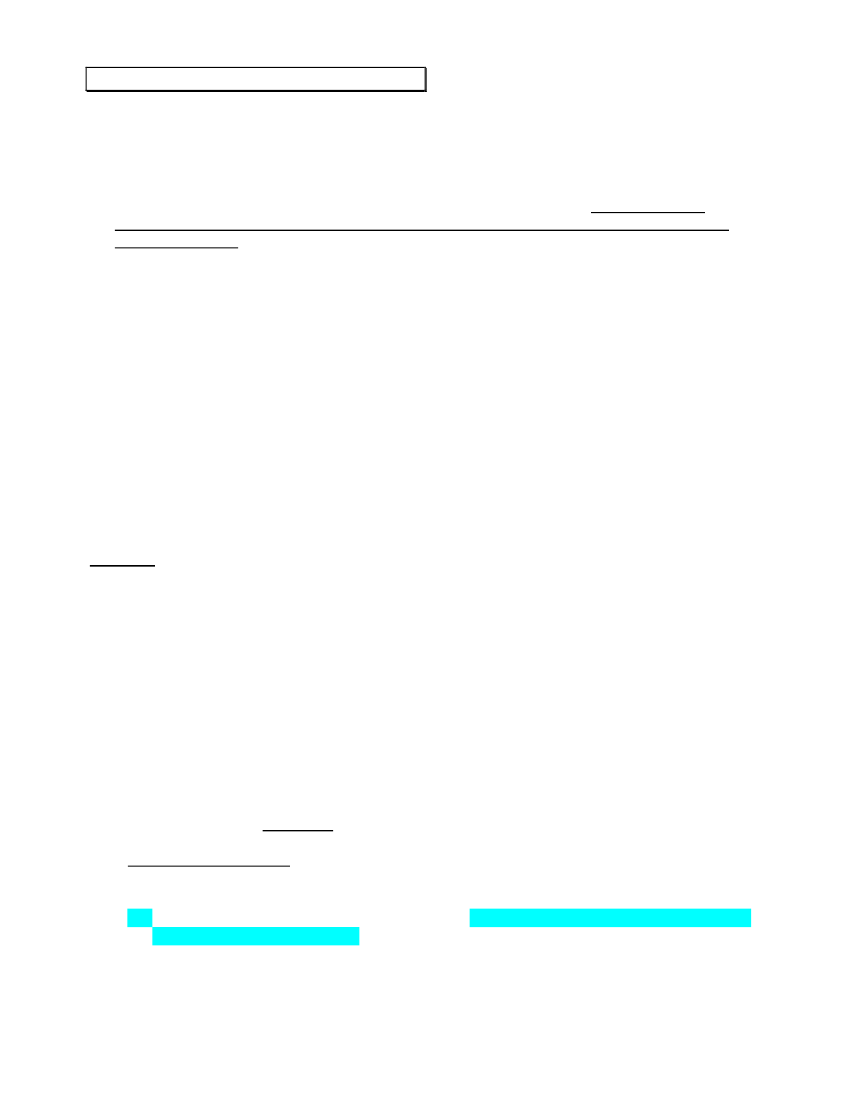

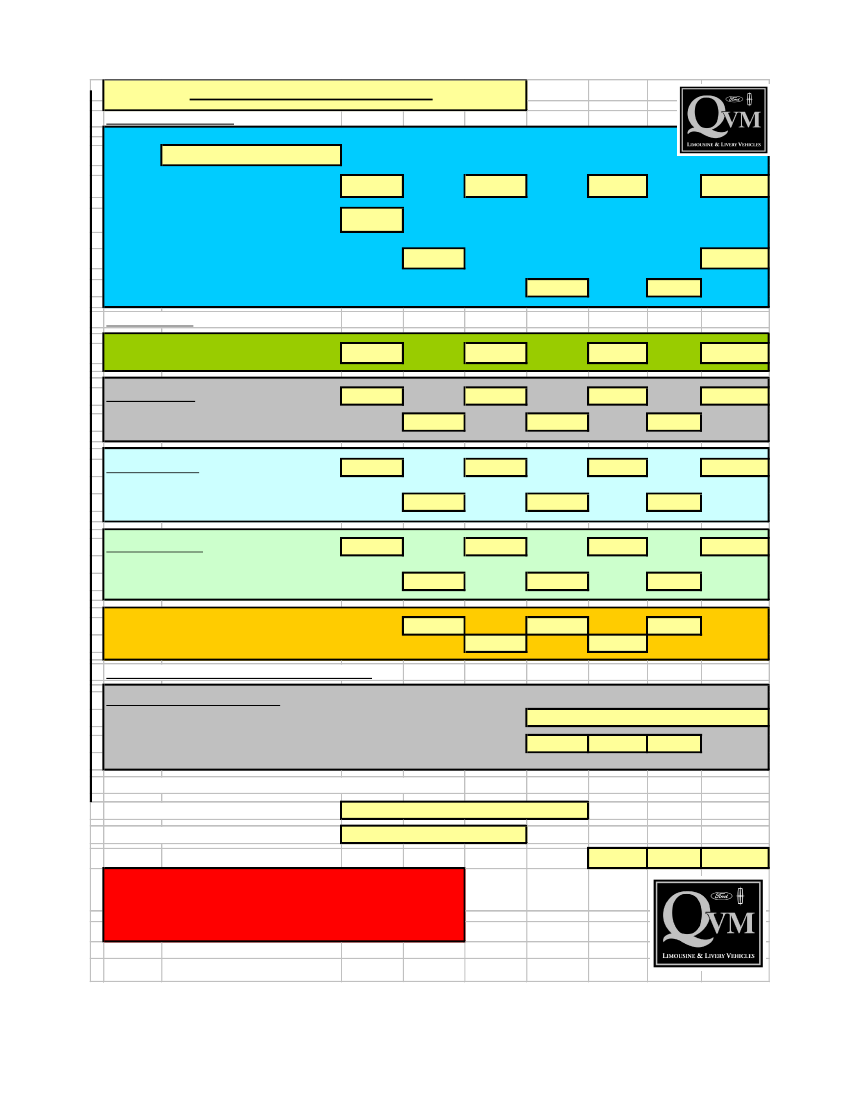

OFFICIAL QVM WEIGHT TICKETGeneral Information:VIN:VEHICLE TYPE:LIMOHEARSEINCHESTOTAL PASSENGERS INCLUDING DRIVER

EXC

NAV

TOTAL WHEELBASE EXTENSIONSEATCONFIGURATION :J, L , BENCH

RIGHT FRONT PASSENGER SEAT INSTALLED?Weight Data:TIRE PRESSURE:LFRFRFFRONT

YES

NO

LRLRREARTOTAL

RRRRLBS

CURB WEIGHT–CORNERS : LFCURBWEIGHT TOTALS:

NORMAL LOAD – CORNERS: LF*Not needed for trucks!

RFFRONTREAR

LRTOTAL

RRLBS

NORMAL LOAD TOTALS:MAXIMUM GVW – CORNERS: LFMAXIMUM GVW TOTALS:

RFFRONTREAR

LRTOTAL

RRLBS

PLEASE INDICATE FUEL LEVEL:

EMPTY3/4

1/4FULL

1/2

Scale Information and Certification of Data:SCALES USED TO MEASURE:MANUFACTURER:DATE LAST CERTIFIED:month*Theinformation above is certified to be accurate:QVM (company name)Authorized Employee:DATEdayyear

J.MetzNewQVM03.doc

Page 10 of 10

1/13/2009